Designing an injection mold involves key steps like material selection and part geometry considerations.

To design an injection mold, first define the product’s shape and material. Then, consider factors like draft angles, venting, and cooling systems. Proper mold design reduces defects, enhances part quality, and ensures cost-effectiveness.

Understanding mold design principles is essential for efficient production. Continue reading to learn how these factors influence mold performance and cost savings.

Proper mold design reduces defects.True

A well-designed mold ensures correct part formation, minimizing defects and reducing the need for rework.

Injection mold design is only about the product shape.False

Mold design also involves factors like material flow, cooling, and part ejection, which affect efficiency and part quality.

What are the Basic Principles of Injection Molds?

Injection molds are essential for producing high-precision parts, using a process where molten material is injected into a mold cavity. This technology underpins many industries, ensuring fast and consistent production.

Injection molds work by injecting molten material into a mold cavity under high pressure. The material cools and solidifies, forming the desired shape. The process is used for producing a wide variety of products, from automotive parts to medical devices. Key benefits include high precision, speed, and repeatability in mass production.

Injection molding process is a process by means of which molten material is injected at a high pressure and into a mold where it solidifies to form the desired product. That is why injection molds are indispensable in realizing this process, injection molds create the shape of plastic products and guarantee the necessary dimensional accuracy. The fundamental working of mold design is to make sure that the product could be easily removed from the mold and could closely resemble the size and the shape that is expected of it.

The materials, structure, and layout of the injection molds have a stringer relationship with the quality of the products and the manufacturing speed. When designing the mold, aspects of material flow, cooling rate and demolding are important. Hence, it is very important to apply not only theoretical knowledge, but also the certain amount of experience while designing the injection molds.

The basic principles of injection mold design include several key stages

-

Preparation of Molten Plastic: The plastic raw material is melted by the shearing action of the screw and the heater.

-

Injection: The molten plastic is forced into the mold cavity through the nozzle with help of pressure exerted by the screw.

-

Holding Pressure and Cooling: The injection molding machine keeps this pressure for some time to ensure that the cavity is filled and then starts cooling process as the plastic starts to set.

-

Mold Opening and Ejection: The mold is opened and the ejection mechanism forces out the final product out of the mold after it has solidified.

Injection molds can produce high-precision parts at low cost.True

Injection molding is a cost-effective way to produce parts with high dimensional accuracy, especially for large-volume production runs.

Injection molds are only suitable for plastic parts.False

Injection molds can be used for a variety of materials, including metals and rubber, depending on the molding process and material requirements.

What are the Mold Materials?

Mold materials are essential in manufacturing processes like injection molding1, ensuring durability, precision, and quality. The choice of material affects production efficiency and the final product’s characteristics.

Mold materials include steel, aluminum, and beryllium copper, chosen based on factors like durability, heat resistance, and cost. Steel is common for high-volume production, while aluminum is preferred for quick-turnaround runs due to its lower cost.

The choice of mold material has a great impact on the service life of the mold and the quality of the finished product. Common mold materials are steel and aluminum.

Steel

-

Advantages: They have higher hardness, better wear resistance, good heat treatment properties, and long working life.

-

Disadvantages: Complex to metabolize, albeit cheaper than WMP, much denser in mass.

Common Steels:

-

P20 Steel: Commonly used for making mold base and large molds, having good mechanical properties and characteristics of easy machining.

-

H13 Steel: H13 steel are used for molds that operate at high temperatures, it has very high high-temperature stability and hardness.

-

S136 Steel: Very chemically inert and quite used in fabrication of clear product moulds.

Aluminum

-

Advantages: They are lightweight, possess good thermal conductivity, are easy to process as well as fairly cheap.

-

Disadvantages: Lower hardness, no resistance to wearing, and it proves to be very sensitive to deformation.

Common Aluminum:

- 7075 Aluminum Alloy: Moderate strength and low hardness, suitable for making small molds and prototype molds.

Steel molds are better for high-volume production.True

Steel molds are more durable and can withstand the pressure of high-volume runs, offering longer lifespan and better performance in mass production.

Aluminum molds are cheaper than steel molds for all applications.False

While aluminum molds are less expensive initially, they may wear out faster than steel molds, making them more suitable for lower-volume or prototype runs.

What Does Mold Structure Design Mainly Include?

Mold structure design is key to creating high-quality injection molds, ensuring efficiency and consistency during the molding process. It involves critical aspects such as mold flow, cooling, and material compatibility.

Mold structure design focuses on optimizing cavity layout, cooling systems, and material flow to enhance molding efficiency. Essential features include gate placement, parting lines, and ejection mechanisms. A well-designed mold reduces production costs and cycle times.

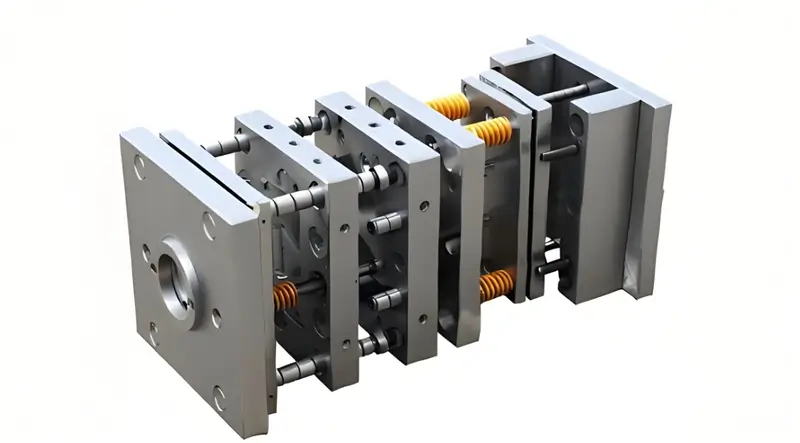

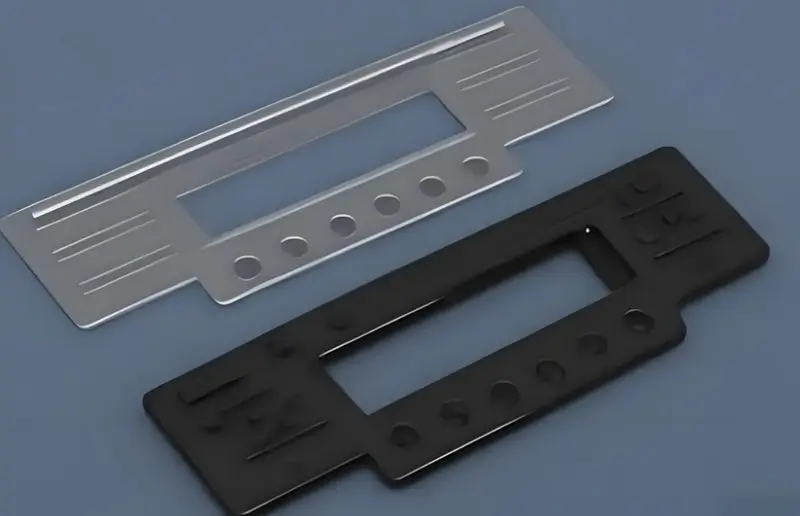

The structure of injection mold design mainly refers to the cavity and the core2, the frame, the gate3, the guide and the withdrawal system. All of them should be well thought in order to achieve proper efficiency, sturdiness, and easy maintenance of the mold.

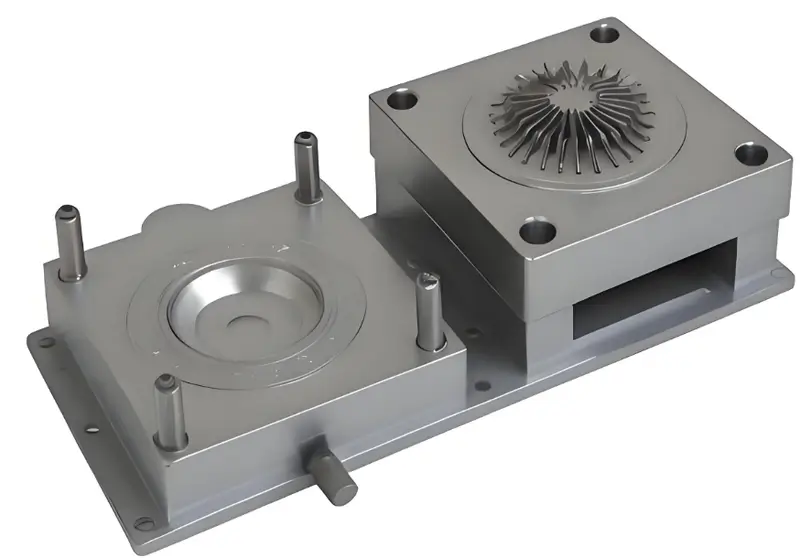

Cavity and Core

The cavity creates the outer dimensions of the product while the core gives the inner dimensions bonded together to provide the final and desired product shape and size.

-

Material Selection: Often employ high-hardness, wear-resistant steel, such as P20 or H13 steel4.

-

Design Points: The finished surfaces of cavity & core should be smooth so that high dimensional accuracy should be maintained for the surface finish of the product.

Mold Base

The mold base is also the tool’s skeletal framework and has the task of fastening and linking all the components. It usually has a standard form to allow assembly of molds and their replacement when necessary.

-

Material Selection: Usually, 45 steel or Q235 steel is adopted for the mold base to guarantee the stability of the mold base.

-

Design Points: The mold base should possess enough robustness and sturdiness to be able to cope with injection pressure, injection temperature and the general to and fro pressure during injection.

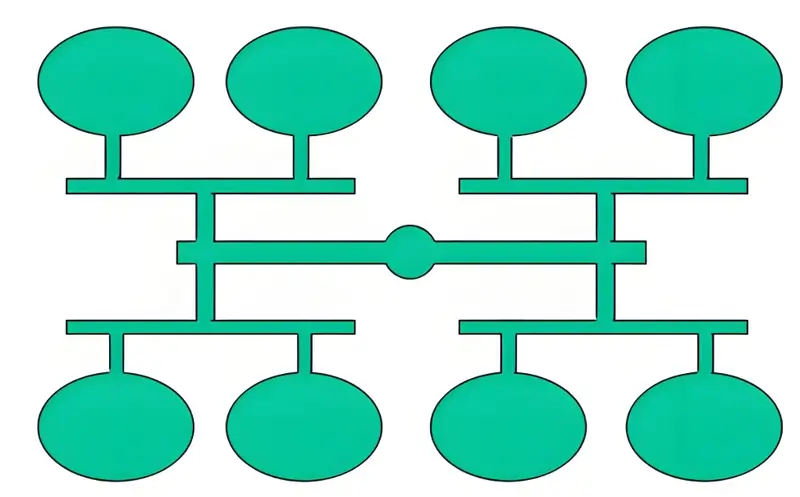

Gating System

The gating system comprises the primary runner, the sub-runners and the gates by which the molten plastic is led into the cavity. An effective gating system is helpful for increasing the quality of molding and decreasing the amount of material used.

-

Design Points:The main runner should be as short and as straight as can be in order to minimize the pressure loss as well as cuts as much as is possible.

-

Design Points:Sub-runners should be properly arranged so that it would apply equal mass to the cavity.

-

Design Points: The nature of the gate should not in any way influence the look of the product or compromise on its strength The size of the gate used should be good.

Guiding Mechanism

The guiding mechanism includes guide pins and bushings, which helps in the alignment between the moving and the fixed molds.

-

Material Selection: Typically uses high-hardness steel, such as GCr15.

-

Design Points: The guiding mechanism should be very accurate in term of the alignment to prevent misalignment over a long period of time besides being very resistant to wear.

Ejection Mechanism

The ejection part is applied to take out the molded product from the mold and normally the ejection pins, plates and sleeves are used.

- Design Points: Another requirement of this force is that it should be constant or smooth since a sudden force may affect the product in a negative way. The movement of the ejection mechanism should also be smooth to avoid sticking.

Mold structure design ensures part quality and production efficiency.True

A well-designed mold structure enables smooth plastic flow, consistent part formation, and faster production cycles.

All mold structures are the same for different industries.False

Mold structure design varies across industries, with each requiring specialized features for optimal performance, such as specific cooling or ejection mechanisms.

What is Flow Channel Design?

Flow channel design is crucial in injection molding, ensuring efficient plastic flow and optimal part quality by controlling the material path and temperature.

Flow channel design optimizes plastic flow during injection molding, enhancing part consistency and minimizing defects. It involves controlling the material’s path, temperature, and pressure to ensure an even fill and reduce cycle times.

Runner design holds a lot of influence on the quality of the product and how efficient its production process is. It is composed of the main runner, sub-runners, and the gate , all of which require thoughtful specification for the purposes of getting the plastic melt to equally and without hindrance fill the cavity.

Main Runner

The main runner links the injection machine nozzle to the sub-runners and should be the shortest and a straight as possible to reduce pressure loss and material waste.

- Design Points: The main runner diameter should be right to promote adequate flow all the same reduce wasteful use of the materials.

Sub-Runners

The sub-runners distribute the plastic melt to each cavity of the mold and balance should be a major consideration here.

- Design Points: Sub-runner cross-sectional shapes should be best circular or semicircular to lower the resistance offered by flows. The length should ideally be as equal as possible, so that the cavity filling time is almost equal for all the lengths.

Gates

Gates are the means by which molten plastic introduced to the cavity impact product quality.

- Design Points: The gates should be placed in areas which do not alter the look and strength of the product, and their sizes should adequately provide for the rates of filling while being easy to remove and finish. Depending on the kind of product that is being created, different gates may be used including point gates, edge gates, hot tip gates and ring gates.

Additionally, runner design should consider:

-

Runner Balance: For multiple cavities make sure that the runners lengths and their cross sectional area as they are the primary determinet of the time taken to fill the molds.

-

Runner Cooling: Sufficient również être for cooling channels for the runner section so that high temperature does not influence the melt flow.

-

Runner Precision: Machining precision is high and the surface smooth to lower the restriction to melt flow and pressure drop.

Flow channel design enhances molding efficiency.True

Well-designed flow channels ensure uniform distribution of molten plastic, improving cycle time and part consistency.

Flow channel design is the same for all types of molds.False

Different molds require customized flow channel designs based on geometry, size, and material type to optimize performance.

What is Cooling System Design?

Cooling system design is crucial in optimizing manufacturing processes, ensuring consistent product quality and efficiency in production cycles.

Cooling system design involves the strategic placement of cooling channels to regulate temperature, reduce cycle time, and improve product quality. It is vital for injection molding, die casting, and other industrial processes. Effective design minimizes energy consumption and maximizes throughput.

The cooling system plays a very important role in the injection mould design since it reduces injection molding cycle time and mould quality. The cooling system majorly involves the cooling channels and the stages of cooling time.

Cooling Channels

Cooling channels guide cooling water through various mold parts to remove excess heat.

-

Design Points:Because the channels’ purpose is to remove heat, they should be as close to the cavity surface as possible to enhance the heat dissipation.

-

Design Points: Promotion should be spread out equally to avert local trends of heating up.

-

Design Points: Diameter should guarantee good coolant circulation without being blocked.

Cooling Time

Cooling time also depends with the wall thicknesses5 of the product, the type of material used, and the temperatures of the mold.

- Design Points: Sufficient cooling time is necessary to avoid warping and shrinking of the plastic products also adds to the dimensional stability of the plastic parts. Excessively long cooling times reduce efficiency, while too short times may lead to quality issues.

Other considerations for cooling systems include:

-

Coolant Flow Speed: Error control of the flow speed as low speed can damage the cooling and high speed might lead to blockage and wearing of the mold.

-

Coolant Temperature: Optimal temperature, as high temperature decrease the cooling rate while low temperature will cause condensation on the mould surface and may affect the quality of the product.

-

Coolant Quality: Keep coolant clean to avoid blockages and mold damage.

Cooling system design reduces defects in injection molding.True

Effective cooling systems prevent over-heating and under-cooling, ensuring parts solidify correctly, which reduces defects.

Cooling system design is the same for all manufacturing processes.False

Cooling system designs vary based on the specific material, machine type, and product being manufactured, with each requiring tailored cooling solutions.

What is Exhaust System Design?

Exhaust system design is crucial for automotive and industrial applications, focusing on efficiently directing and managing exhaust gases while minimizing emissions and noise.

Exhaust system design ensures proper gas flow, noise reduction, and compliance with environmental standards. Key components include the exhaust manifold, catalytic converter, and muffler, all contributing to performance and emission control.

The venting system expels gas from the mold cavity to prevent defects such as bubbles and burns, directly affecting product quality and mold longevity.

Venting Grooves

Relief groove is a channel for the escape of gas and it is mostly in the parting line.

-

Design Points: Put location grooves where/when gas can freely build up.

-

Design Points: Width and depth should optimise cross-sectional area for the required venting so that there will not be any issues on the side of plastic ejection.

-

Design Points: Even distribution to prevent localized venting issues.

Venting Holes

The venting holes are among the components of the venting system which are normally located in thin regions of a product.

-

Design Points: Appropriate diameter in order not to hinder the release of gas build up while at the same time guaranteeing proper exhaust.

-

Design Points: Positioning should not in any way influence the look of the product and neither its strength.

-

Design Points: Quantity and location should be reasonable with the structure of mould and the shape of product.

Venting system design should also consider:

-

System Maintenance: They should be cleaned now and then to ensure unrestricted and unhindered flow but be checked at times to avoid tools to avoid blockages that may cause quality issues.

-

System Cooling: In the case of using high-temperature molds, make use of cooling means to avoid condensation of the gases during the time of venting.

-

Processing Precision: High precision with smooth surfaces to reduce gas flow resistance and pressure loss.

Exhaust systems reduce harmful emissions in vehicles.True

Exhaust systems filter harmful gases, reducing pollutants like carbon monoxide, nitrogen oxides, and hydrocarbons before they are released into the atmosphere.

All exhaust systems are identical across different vehicle types.False

Exhaust systems are tailored to specific vehicle types and engine sizes, with design variations to optimize performance, noise reduction, and emissions control.

What are the Mold Processing?

Mold processing refers to the steps involved in creating products using molds, from material selection to final shaping and cooling, optimizing efficiency and precision in manufacturing.

Mold processing is the procedure of shaping material, often plastic, into specific designs using molds. This includes injection molding, compression molding, and blow molding, which are widely used in industries like automotive, electronics, and consumer products.

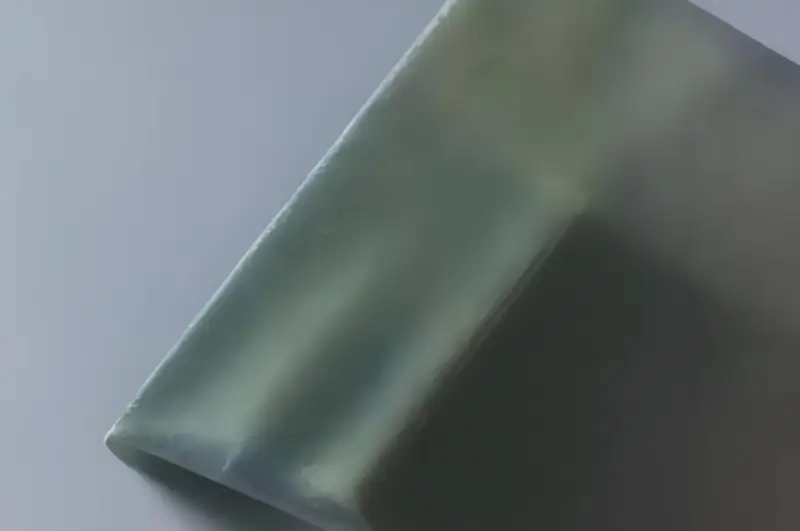

Mold processing is the process of converting the design drawing into the actual mold through rough processing, fine processing, surface treatment, etc. Through analysis, it can be seen that the processing accuracy and quality directly affect the function and durability of the mold.

Rough Machining

Rough machining is done on the mold from the raw material and common equipment used is CNC milling and lathe.

-

Key Points: Leave sufficient allowance for finishing.

-

Key Points: The optimum speed and feed rates that help in avoiding deformation of the material and gradual wearing of the tools and machinery.

-

Key Points: Rough machining to decrease the burr and bringing the smoother surface.

Finishing

Finishing achieves the mold\’s are done to reach the size and specifications of the mold and uses the grinding process, EDM, and polishing.

-

Key Points: Accuracy ensure that the shape and size is correct for the mold.

-

Key Points: Avoid over-polishing to prevent dimensional deviations.

-

Key Points:Finishing the surface with the best and most appropriate equipment in order to obtain a smooth and proper finish.

Surface Treatment

Mold surface treatment enhances the mold hardness and wear resistance in which the processes of quenching, nitriding, and the use of a surface coating are employed.

-

Key Points: Select appropriate treatment methods based on mold material and application.

-

Key Points: To reduce mold deformation and cracks the amount of time for treatment and temperature should be controlled.

-

Key Points: Clean thoroughly before treatment for better adhesion and performance.

Mold processing improves manufacturing efficiency.True

By utilizing optimized molding techniques, production times are shortened, and material usage is minimized, leading to cost savings and higher output.

Mold processing is only suitable for mass production.False

Mold processing can be used for both mass production and small batch manufacturing, depending on the specific needs and mold design.

How to Maintain the Mold?

Proper mold maintenance is crucial for ensuring consistent quality and longevity in injection molding. Regular care can prevent downtime and costly repairs.

Mold maintenance involves cleaning, lubrication, and timely inspections to prevent wear and tear. Key practices include regular cleaning after each use, ensuring proper cooling, and inspecting for damage.

The normal use and extension of the service life of the mold require maintenance work including daily and periodical maintenance. If proper maintenance is done then use of mould can be made efficient and thus lowers down the cost of production.

Routine Maintenance

Routine maintenance refers to the cleaning, lubrication, and inspection of molds during the production process.

-

Key Points: Ensure the mold surface is as clean to avert temperatures and dust from penetrating the mold.

-

Key Points:Lubricate the guide pillar and guide bushing regularly to ensure the flexibility of the guide mechanism.

-

Key Points:It may be necessary to often inspect the other components of the mold, and repair or replace them in time.

-

Key Points:It is necessary to confirm whether the cooling channel and exhaust system are normally opened and whether they are blocked, if they are blocked, they should be cleared up in time.

Regular Maintenance

Maintenance implies the general check-up and repair of the mold after it has been used for some time.

-

Key Points: Inspect the mold cavity and core and look for the part of the cavity which has severely worn and repair or replace them.

-

Key Points: Check whether the guiding mechanism, demoulding mechanism and other parts of the mold are normal, and make necessary adjustments or replacements.

-

Key Points: Check whether the cooling system of the mold and the exhaust system of the mold are normal and perform the need for cleaning and clearing.

-

Key Points: Thoroughly clean and lubricate the mold to ensure that the mold is in good working condition.

Regular cleaning extends mold lifespan.True

Regular cleaning removes debris and prevents contamination, which can reduce wear and tear on the mold, extending its usability.

Mold maintenance is the same for all types of molds.False

Different types of molds, such as hot and cold runner systems, require specific maintenance practices tailored to their design and application.

What are the Common Problems in Mold Design and Their Solutions?

Mold design issues, such as poor cooling, uneven material flow, and improper gate placement, can affect the quality and efficiency of injection molding processes.

Common mold design problems include inconsistent cooling, improper gate placement, and poor material flow. These issues can result in defects like warping, short shots, and long cycle times. Solutions involve optimizing cooling channels, gate design, and material selection.

During the design of injection mold , there are several issues that maybe affect the quality and production rate of the final product in the event they are not well addressed. Below are some of the common problems that their solutions need to be found.

Sink Marks

-

Problem Description: The surface of the product is dented, which affects the appearance.

-

Solution: It is advised to the position as well as the size of the gate to be such that it can accommodate melt and fill up the cavity uniformly.

-

Solution: Maximize the cooling circuit design and layout in order to allow equal distribution of the cooling to the products.

-

Solution:Adjust the holding time and pressure to reduce melt shrinkage.

Flash

-

Problem Description: Scrap forms on the peripheral region of the product giving it a poor appearance and may not be of accurate dimension.

-

Solution: About the parting surface design of the mold, try to make the mold closed to the minimum.

-

Solution: Enhance the clamping force of the mold to prevent the mold from separating during the injection molding manufacturing process.

-

Solution: To check the mold, first it is required to check the guiding mechanism of the mold and the clamping mechanism of the mold.

Bubble

-

Problem Description: There are visible pores on the body of the product or in the product itself in the form of bubbles which influences the looks and the durability.

-

Solution: Minimize the design of the exhaust system so as to allow the gas in the mold cavity to be released effectively.

-

Solution: Adjust the parameters used in injection like the speed of injection, injection force and temperature of injection molding materials in a bid to minimize generation of gases.

-

Solution: Check the drying of raw materials to ensure that the moisture content of raw materials is at an appropriate level.

Deformation and Warping

-

Problem Description: The injection molded part becomes partly shrunken or distorted after cooling and the dimensional stability and surface finish of the product are compromised.

-

Solution: Improve on the cooling system so as to give as equal temperatures to all the injection molded parts.

-

Solution: Adjust the holding time and holding pressure6set in the injection parameters to reduce internal stress.

-

Solution: Strengthen the changes in mold structure design, such as adding reinforcing ribs to make the product have uniform wall thickness and consistent wall thickness.

Dimensional Instability

-

Problem Description: The geometry is out of the required sizes and standards to affect the assembly and usage of the product.

-

Solution: Examine the correctness of machining on the mold and assembly realization of products to verify whether or not the sizes of the mold conform with the injection molding design specifications.

-

Solution: Control the process parameters as injection pressure, holding pressure time and cooling time should be controlled in order to have stable size of the product.

-

Solution: Confirm the manufacture stability of the injection molding machines in order to have ability to determine the variation of the injection molding.

Improper cooling is a common mold design problem.True

Improper cooling can lead to warping and uneven shrinkage. Optimizing cooling channels ensures uniform temperature distribution throughout the mold.

All mold design problems can be solved by adjusting the geometry.False

While geometry optimization is important, other factors like venting, cooling, and material choice also play key roles in solving mold design problems.

Conclusion

Injection mold design is very delicate and meticulous, and it requires high requirements for designers. Designers need to have rich experience and solid theoretical foundation. Reasonable material selection, fine structural design, scientific flow channel design, perfect cooling system and exhaust system, as well as good mold processing and maintenance can ensure the high quality and long life of the mold, thereby improving the efficiency and quality of injection molding.

I hope this article can provide some references and methods for injection mold designers. If you encounter any problems in designing molds, please feel free to contact us, we are always ready to help you.

-

Learn about Injection Molding: A Comprehensive Guide: Injection molding is a manufacturing process where molten plastic is injected into a mold to create parts with high accuracy and repeatability. ↩

-

Learn about What is core and cavity in injection molding? The cavity and core in a typical plastic injection molding machine of an injection mold are the molding parts of the mold . ↩

-

Learn about Types Of Gates for Injection Molding: A Complete Design Guide : An injection molding gate is a designed opening, usually small, that controls molten plastics flow into the mold cavity. ↩

-

Learn about H13 Tool Steel : H13 is a hot work tool steel that has good resistance to thermal fatigue, erosion and wear, and is widely used for making molds and dies. ↩

-

Learn about Four Important Principles Should Be Considered In The Design Of Wall Thickness : Plastic Product wall thickness is a critical structural feature frequently discussed and considered in the design of plastic product structures. ↩

-

Learn about How to Determine Holding Pressure and Holding Time In Injection Molding? injection pressure includes both pressure and speed . ↩