– Undercuts prevent direct part ejection and require auxiliary mechanisms like side-actions, lifters, or collapsible cores.

– Side-actions are best for external features, while lifters and collapsible cores handle internal geometries.

– Utilizing “bump-offs” with flexible materials can eliminate the need for expensive mechanical actions.

– Proper maintenance of moving mold components is critical to prevent flash and seizing.

What Is the Definition of an Undercut in Injection Molding?

In de context van Spuitgieten (IM)1, an undercut is a specific feature in the part geometry that prevents the mold from opening or the part from being ejected along the primary "line of draw" (the direction in which the mold halves separate).

Without a specialized mechanism to release the feature, the steel of the mold cavity would physically trap the solidified plastic, causing damage to the part or the tool upon ejection. Solving this challenge is the core of complex mold design.

Common mechanisms used to resolve undercuts include:

- Side-Actions (Slides)2: Cam-driven blocks that move perpendicular to the mold opening.

- Lifters3: Internal cores that move on an angle during ejection to release internal features.

- Collapsible Cores4: Segmented cores that shrink inward to release threads or deep internal undercuts.

All undercuts in part design require expensive mechanical side-actions or lifters to be molded successfully.Vals

This is a misconception. Many minor undercuts can be resolved using 'bump-offs' (stripping) if the material is flexible, or by redesigning the part with slot-throughs or shut-offs to eliminate the undercut entirely.

Incorporating slight draft angles on undercut features significantly reduces the force required for side-actions and lifters to disengage.Echt

Adding draft to the undercut feature reduces friction and drag during the retraction of the metal component, extending tool life and reducing the risk of part deformation.

What Are the Key Parameters for Side-Action Cam Definition?

A side-action (often called a slide or cam action) is the most robust method for handling external injection molding undercuts. It typically consists of a cam pin (angle pin), a sliding body, and a locking block.

When the mold opens, the angle pin forces the slide to retract away from the part. When the mold closes, the locking block (heel block) holds the slide firmly in place against injection pressure.

Table 1: Critical Design Parameters for Side-Actions

| Parameter | Typische waarde / bereik | Opmerkingen |

|---|---|---|

| Angle Pin Angle | 10° – 25° | The angle of the pin determines the travel distance. Steeper angles provide more travel but less mechanical advantage. |

| Heel Block Angle | Pin Angle + (2° to 5°) | The locking angle must be steeper than the pin angle to prevent the slide from backing up during injection. |

| Slide Material | H13, P20, or S7 Tool Steel | Moving components require hardened steel (48–52 HRC) to resist wear and galling. |

| Wear Plates | Aluminum Bronze / Graphitic Steel | Used under the slide to prevent steel-on-steel seizing; typically self-lubricating. |

| Clearance | 0.012 – 0.025 mm (0.0005" – 0.001") | Tight tolerances are required to prevent "flash" (excess plastic leakage) at the parting line. |

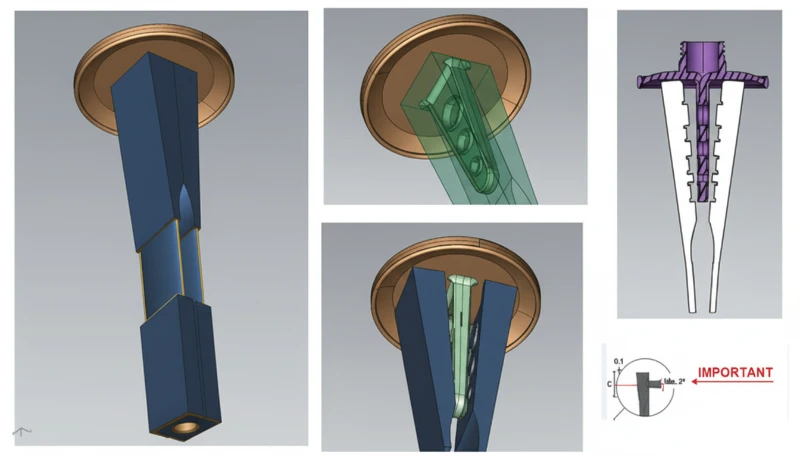

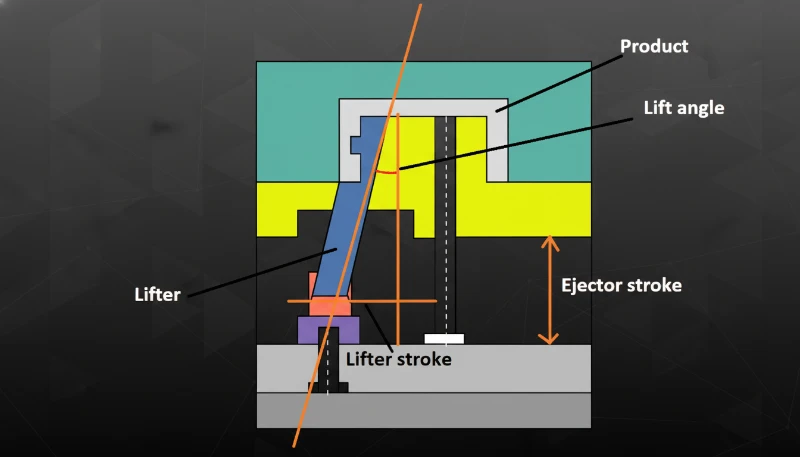

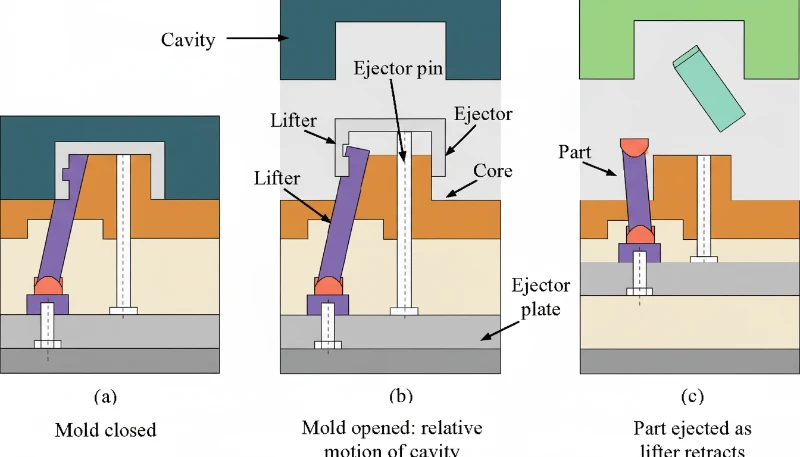

How Do You Design Lifters for Molds?

Designing lifters for molds is necessary when the undercut is located on the interior of the part, where a side-action cannot reach. A lifter is part of the ejection system. As the ejector plates push forward, the lifter moves upward and inward (laterally) on an angle, releasing the undercut feature.

Step-by-Step Lifter Function:

- Injectie: The lifter forms a portion of the internal wall or clip detail.

- Mold Opening: The A-side (cavity) separates from the B-side (core). The part stays on the core.

- Ejection Start: The ejector plate pushes the lifter rod.

- Lateral Movement: Because the lifter rod is angled, the vertical ejection force translates into lateral movement, pulling the steel detail out of the plastic undercut.

- Release: Once the lifter clears the undercut, the part falls or is picked by a robot.

Engineering Constraint: Cooling lifters is notoriously difficult because they are thin, moving rods. This can lead to longer cycle times compared to side-actions, which can be water-cooled easily.

Lifters are generally less expensive and easier to maintain than external side-action slides.Vals

Lifters are often more prone to mechanical failure and galling due to the complex stresses during ejection. They are also much harder to cool, which can extend cycle times and increase part cost compared to externally cooled slides.

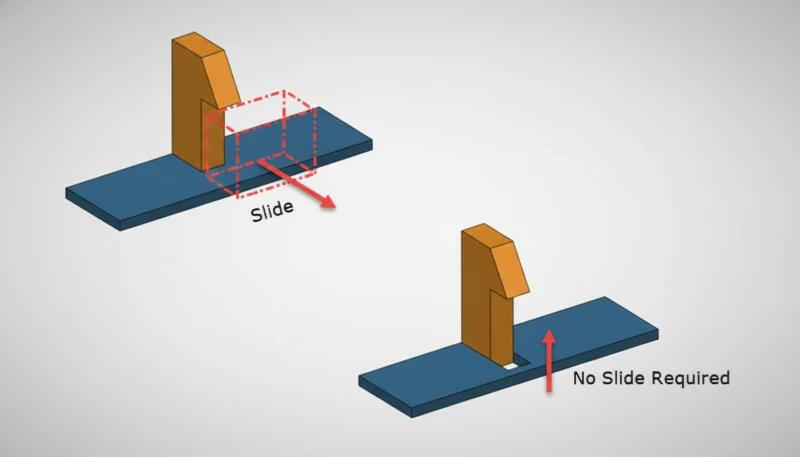

Using 'shut-offs' or 'pass-throughs' allows engineers to mold features that look like undercuts without using any moving mechanisms.Echt

By designing a hole in the part floor directly below a clip or snap-fit, the core and cavity steel can 'kiss' (shut off) to form the feature, eliminating the need for side-actions.

What Are the Advantages and Disadvantages of Undercut Solutions?

Choosing the right mechanism is essential for avoiding undercut5 costs and ensuring tool longevity.

Table 2: Comparison of Undercut Mechanisms

| Mechanism | Beste voor | Pros | Cons |

|---|---|---|---|

| Side-Action (Slide) | External undercuts, ports, holes on side walls. | Robust; easy to cool; high pressure resistance; reliable. | Increases mold footprint (requires wider mold base); expensive to machine. |

| Lifter | Internal snap-fits, internal threads, internal barbs. | Solves internal trapped geometry; activates automatically with ejection. | Difficult to cool (hot spots); prone to breaking/galling; complex maintenance. |

| Collapsible Core | Full circumference internal threads (e.g., bottle caps). | Allows ejection of 360° internal undercuts; fast cycle times. | Extremely expensive; high maintenance; size limitations. |

| Bump-off (Stripping) | Shallow undercuts in flexible materials (PP, PE, TPE). | Zero mechanism cost; simplest mold design. | Limited to specific geometry constraints; requires material elasticity; part distortion risk. |

What Are Practical Tips for Reducing Complexity and Cost?

In my experience on the factory floor, the best way to handle an undercut is to eliminate it during the Design for Manufacturing (DfM) phase. If that is not possible, follow these practical insights:

- Use Sliding Shut-Offs: Instead of a side-action for a hole in a vertical wall, see if you can draft the wall and use a "telescoping" shut-off where the cavity and core slide past each other to form the hole.

- Limit Side-Action Travel: Keep the undercut depth shallow. A deeper undercut requires a longer side-action travel, which forces a larger mold base, significantly increasing tooling costs.

- Material Selection for Bump-Offs: If avoiding undercut costs is the priority, use materials like Polypropylene (PP) or Polyethylene (PE). Design the undercut with a lead-out angle (30° to 45°) so the plastic can stretch over the steel bump during ejection without shearing.

- Prioritize Cooling in Slides: Always plumb cooling lines into side-action bodies if they are large enough. Uncooled slides are a primary source of cycle time variation and dimensional instability.

What Are the Common Application Scenarios?

- Automotive Interior Trim: Uses lifters extensively for internal snap-fits that mount door panels to the chassis.

- Consumer Electronics (Housings): Uses side-actions for USB ports, power buttons, and HDMI slots located on the sidewalls of the device casing.

- Plumbing Fittings: Uses collapsible cores or unscrewing racks for internal threads that cannot be stripped.

- Medical Vials: Often utilizes bump-offs for cap retention rings, relying on the medical-grade Polypropylene’s flexibility.

Collapsible cores are the standard industry solution for molding all types of internal threads.Vals

Collapsible cores are complex and costly. For many standard internal threads, automatic unscrewing molds (using rotational gears) are preferred, or simple bump-offs if the thread profile is rounded and the material is flexible.

Standardizing the angle of side-action pins to 15° or 20° simplifies mold design and replacement part procurement.Echt

Adhering to standard angles allows mold makers to use off-the-shelf components from suppliers like DME or Hasco, reducing design time and maintenance costs.

What Steps Are Recommended for Selecting the Right Mechanism?

- Analyze Geometry: Is the undercut internal or external? (External → Side-Action; Internal → Lifter/Core).

- Check Material Properties: Is the material flexible (TPU, PP) or rigid (PC, Glass-Filled Nylon)? Flexible materials may allow bump-offs.

- Calculate Stroke Required: How far must the steel move to clear the plastic? Ensure the mold base can accommodate this travel.

- Evaluate Volume: For low volume (1,000 units), consider hand-loaded inserts. For high volume (100,000+ units), invest in hardened, automatic slides with wear plates.

- Simulate: Use Moldflow analysis to ensure the moving components do not impede cooling or create air traps (gas burns).

Veelgestelde vragen (FAQ)

Q1: Can I mold undercuts without any moving parts?

Yes, through a method called "bump-off" or stripping. This works only if the plastic is flexible (e.g., Polypropylene (PP) or Thermoplastic Elastomer (TPE)), the undercut is shallow, and the feature has a radiused edge to slide over the steel.

Q2: What is the difference between a slider and a lifter?

A slider (side-action) typically handles external undercuts and is actuated by an angle pin when the mold opens. A lifter handles internal undercuts and is actuated by the ejector plate system pushing the part out.

Q3: How much does adding a side-action increase mold cost?

Adding a simple side-action can increase tooling cost by $1,500 to $5,000 USD depending on complexity, size, and cooling requirements. It adds design time, machining time, and component costs.

Q4: What is the maximum angle for an angle pin in a side-action?

While 25° is generally the recommended maximum to prevent locking or bending the pin, some designs push to 30° in extreme cases. However, exceeding 20-25° significantly increases wear and friction.

Q5: Why are lifters prone to breaking?

Lifters are long, slender steel rods subjected to bending moments and friction during every cycle. They also heat up significantly because they are hard to cool. The combination of thermal expansion and mechanical stress often leads to seizing or fatigue failure.

Samenvatting

Dealing with injection molding undercuts requires a balance between part functionality and tool complexity. While side-actions are the standard for external features and lifters for internal ones, they add significant capital cost and maintenance requirements. Strategies like complex mold design simplification—using shut-offs or material flexibility for bump-offs—are essential for avoiding undercut costs. By understanding the mechanical constraints of slides, lifters, and collapsible cores, engineers can design robust parts that are manufacturable at scale.

-

Understanding the basics of Injection Molding is crucial for grasping how undercuts and their solutions fit into the manufacturing process. ↩

-

Side-Actions are essential for handling external undercuts, making them a key component in mold design. ↩

-

Lifters are crucial for releasing internal undercuts, and understanding their function is vital for mold design. ↩

-

Collapsible Cores are used for complex internal geometries, making them an advanced solution in mold design. ↩

-

Learning about undercuts helps in understanding the challenges they pose in mold design and the need for specialized mechanisms. ↩