Maintaining high-quality manufacturing standards is critical in today’s competitive industrial environment. Two essential tools in quality assurance are PPAP (Production Part Approval Process) en CPK (Process Capability Index). These tools help manufacturers consistently meet design specifications, reduce defects, and improve overall process reliability.

In this article, we’ll explore how PPAP and CPK work together to ensure high-quality production, their practical applications, and strategies for continuous improvement.

Understanding PPAP

PPAP, or Production Part Approval Process, is a standardized method used to verify that a supplier can produce parts meeting customer requirements consistently.

Objectives of PPAP

- Confirm that production processes are capable of meeting design specifications.

- Minimize the risk of defective parts entering the supply chain.

- Establish a reliable communication framework between suppliers and customers.

PPAP Levels

PPAP submissions are categorized into five levels, based on documentation and sample requirements:

- Level 1: Part Submission Warrant (PSW) only.

- Level 2: PSW + product samples + limited documentation.

- Level 3: PSW + product samples + complete documentation (most common).

- Level 4: PSW + documents as required by the customer.

- Level 5: PSW + complete documentation + on-site approval.

Common PPAP Documents

- Design records (CAD drawings)

- Engineering change documentation

- Process flow diagrams

- PFMEA (Process Failure Mode and Effects Analysis)

- Control plans

- Dimensional results

- Material and performance test reports

- Initial sample inspection reports

- Part Submission Warrant (PSW)

Insight:

Proper PPAP execution reduces production errors and strengthens supplier-customer trust. Neglecting documentation often leads to delays and compliance issues.

Understanding CPK

CPK, or Process Capability Index, measures a process’s ability to produce outputs within specification limits, highlighting the stability and consistency of manufacturing processes.

Key Concepts

- Cp vs. Cpk:

- Cp: Potential capability based on process spread

- Cpk: Actual capability considering mean shift

- Cpk Formula:

Cpk = min{[(USL – u)/3σ]/[(u – LSL)/3σ]}

Waar: - USL = Upper Specification Limit

- LSL = Lower Specification Limit

- μ = Process mean

- σ = Standard deviation

Interpretation

- Cpk ≥ 1.33: Process is capable and acceptable.

- Cpk ≥ 1.67: Excellent process capability.

- Cpk < 1.0: Process requires improvement.

Insight:

Monitoring CPK helps identify process variation early, allowing timely corrective actions and maintaining consistent quality.

How PPAP and CPK Work Together

PPAP and CPK complement each other in quality management:

| Aspect | PPAP | CPK |

|---|---|---|

| Focus | Part approval and supplier readiness | Process capability and stability |

| Objective | Ensure parts meet specifications | Ensure processes are capable and consistent |

| Timing | Pre-production | Ongoing during production |

| Output | Documentation and approved parts | Statistical measure of process performance |

Insight:

Submitting a PPAP demonstrates part compliance, but without high CPK, the process cannot reliably produce defect-free parts. Combining both ensures production reliability and reduces risk.

Practical Applications

Automotive Example

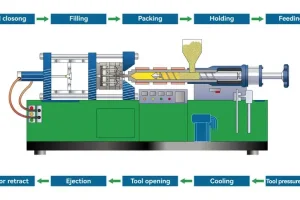

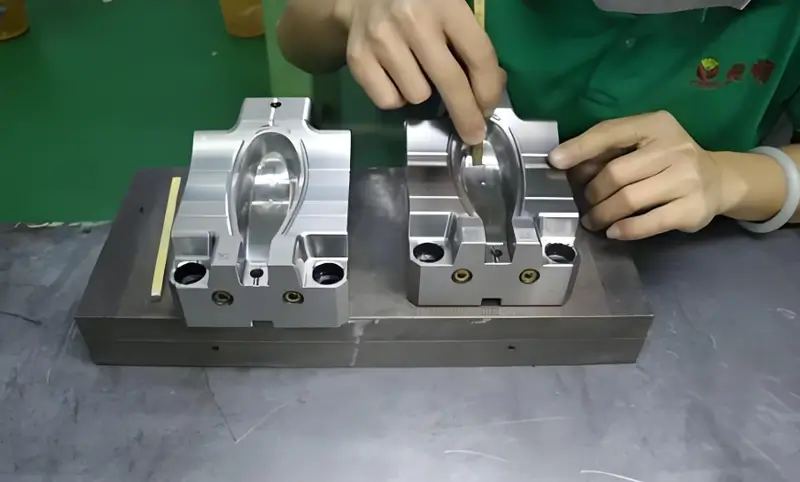

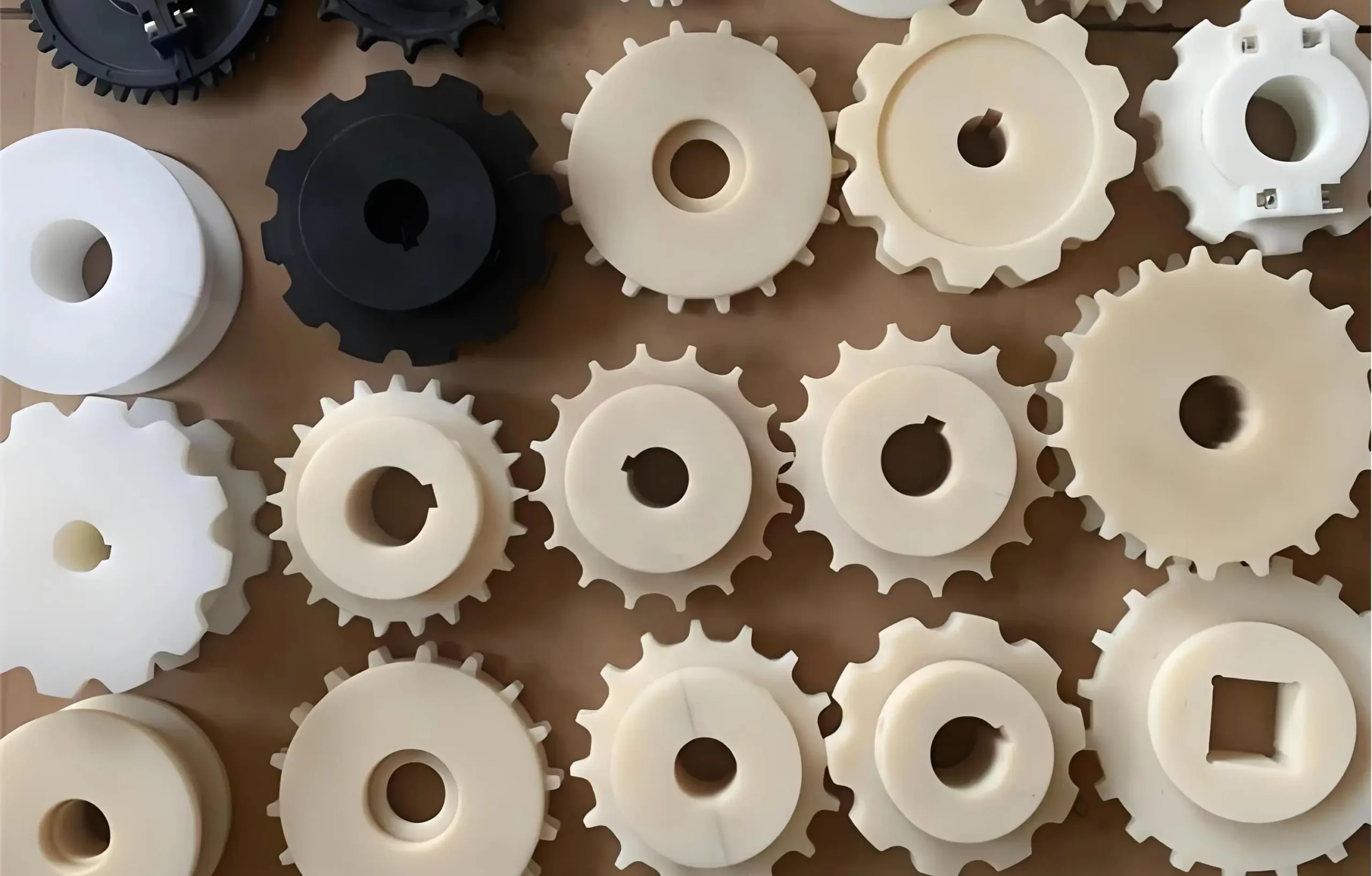

An automotive supplier submits a PPAP Level 3 package for injection-molded components, including CPK analysis for critical dimensions. Achieving Cpk ≥ 1.67 confirms process capability, reducing risk for OEM customers.

Lessons Learned

- Early CPK monitoring prevents costly rework.

- Combining SPC (Statistical Process Control) with PPAP strengthens quality assurance.

- Supplier training on PPAP requirements ensures smooth approvals.

Best Practices

- Maintain Complete Documentation: Keep PPAP files updated.

- Implement SPC: Monitor process trends to detect deviations early.

- Set Realistic Tolerances: Align design specifications with process capabilities.

- Continuous Improvement: Regularly review and improve process capability.

- Collaboration: Ensure communication between suppliers, quality teams, and manufacturers.

Insight:

Integrating PPAP rigor with CPK monitoring achieves higher quality, lower defect rates, and stronger supplier relationships.

Conclusie

PPAP and CPK are vital for maintaining high-quality manufacturing. PPAP ensures supplier readiness, while CPK ensures process stability. Using them together allows manufacturers to reduce risk, improve reliability, and meet customer expectations consistently.

Actionable Tip:

Track CPK as part of your PPAP submissions to show both part compliance and process capability, setting your operations apart in competitive industries.

References

- AIAG, Production Part Approval Process (PPAP) Manual, 4th Edition

- Montgomery, D.C., Introduction to Statistical Quality Control, 8th Edition

- ISO 9001:2015 Quality Management Systems Standard