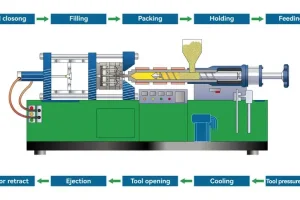

Optimizar un proceso de moldeo por inyección implica tener en cuenta varios factores para garantizar la eficacia, la calidad del producto y la rentabilidad de la fabricación.

Los factores clave en el moldeo por inyección incluyen el diseño del molde, la selección del material, los ajustes de la máquina y los parámetros del proceso, todos ellos cruciales para la calidad del producto, el tiempo de ciclo y la eficiencia de la producción.

Comprender los factores críticos en la configuración del moldeo por inyección es esencial para maximizar la eficiencia y la calidad del producto. Profundice en estos aspectos para mejorar sus resultados de fabricación y lograr unos resultados de producción óptimos.

La selección del material influye en la calidad de las piezas moldeadas por inyección.Verdadero

La elección del material afecta a las propiedades mecánicas, el aspecto y la funcionalidad general de las piezas moldeadas.

Todas las máquinas funcionan de forma idéntica en los procesos de moldeo por inyección.Falso

Las distintas máquinas ofrecen diferentes capacidades, niveles de precisión y compatibilidad con los materiales, lo que repercute en la calidad y la eficacia del producto final.

¿Qué papel desempeña la contracción en el éxito del moldeo por inyección?

Comprender la contracción es vital en el moldeo por inyección, ya que afecta a las dimensiones finales y a la calidad de las piezas moldeadas. Una gestión adecuada garantiza la consistencia del producto y reduce los defectos.

La contracción en el moldeo por inyección es la reducción de tamaño de las piezas de plástico durante el enfriamiento. Un control eficaz es esencial para cumplir las especificaciones, reducir el alabeo y mejorar la calidad.

Factores que afectan a la contracción en el moldeo de termoplásticos

Los plásticos tienen diferentes índices de contracción cuando se moldean. Esto se debe a factores como la cristalización, que cambia la forma del plástico, y la tensión interna. Cuando el plástico se enfría, conserva parte de esa tensión. También tiene mucha tensión por la forma en que se alinean las moléculas. Todo esto hace que los plásticos se encojan más que otros materiales. Pueden encogerse mucho o poco. Pueden encogerse más en una dirección que en otra. Incluso una vez moldeados, pueden encogerse más si se calientan o se mojan.

Cuando el material fundido entra en contacto con la superficie de la cavidad del molde, la pieza de plástico forma una capa sólida de baja densidad que se enfría inmediatamente. Como el plástico tiene una mala conductividad térmica, la capa interior de la pieza moldeada se enfría lentamente y forma una capa sólida de alta densidad que se encoge mucho. Por tanto, cuanto más gruesa es la pared, más lento es el enfriamiento y más gruesa es la capa de alta densidad que se contrae. Además, el hecho de que haya insertos y su disposición afectan directamente a la dirección del flujo de material, la distribución de la densidad y la resistencia a la contracción. Por lo tanto, las características de la pieza moldeada tienen un mayor impacto en el tamaño y la dirección de la contracción.

La dirección del flujo de material, la distribución de la densidad, presión de mantenimiento1 para compensar la contracción y el tiempo de moldeo se ven directamente afectados por la forma de la entrada, el tamaño y la distribución de estos factores. En la entrada directa, cuanto mayor sea la sección transversal de la entrada (especialmente la sección transversal más gruesa), menor será la contracción pero mayor será la direccionalidad; cuanto menor sea la anchura y la longitud de la entrada, menor será la direccionalidad. Cuanto más cerca de la entrada o paralela a la dirección del flujo de material, mayor será la contracción.

Cuando las condiciones de moldeo son tales que la temperatura del molde es alta, el material fundido se enfría lentamente, lo que provoca una alta densidad y una gran contracción. Especialmente en el caso de los materiales cristalinos, la contracción es mayor debido a la alta cristalinidad y al cambio de volumen. El temperatura del molde2 La distribución y la uniformidad del enfriamiento dentro y fuera de la pieza moldeada también están relacionadas con la densidad, afectando directamente al tamaño y la dirección de la contracción de cada pieza.

Además, la duración de la presión de mantenimiento también afecta a la contracción. Si la presión es alta y la duración es larga, la contracción será pequeña pero la direccionalidad será grande. Si la presión de inyección es alta, la diferencia de viscosidad del material fundido será pequeña, la tensión de cizallamiento entre capas será pequeña y la elasticidad después del desmoldeo será grande.

Por lo tanto, la contracción puede reducirse moderadamente. Si la temperatura del material es alta, la contracción será grande pero la direccionalidad será pequeña. Por lo tanto, el ajuste de la temperatura del molde, la presión, la velocidad de inyección, el tiempo de enfriamiento y otros factores durante el moldeo también pueden cambiar adecuadamente la contracción de las piezas de plástico.

Diseño de moldes según la experiencia para determinar el índice de contracción de cada parte de las piezas de plástico

Al diseñar un molde, hay que tener en cuenta el rango de contracción del plástico, el grosor de la pared de plástico, la forma de la pieza de plástico, el tamaño de la compuerta y la distribución de la compuerta. Basándose en la experiencia, puede determinar el índice de contracción de cada parte de la pieza de plástico y, a continuación, calcular el tamaño de la cavidad.

Para piezas de plástico de alta precisión o piezas de plástico con una tasa de contracción difícil de controlar, generalmente se pueden utilizar los siguientes métodos para diseñar el molde: tomar una menor índice de contracción3 para el diámetro exterior de la pieza de plástico y tomar una tasa de contracción mayor para el diámetro interior, de modo que haya margen de corrección tras el molde de prueba.

Cuando se diseña un molde, hay que tener en cuenta el rango de contracción del plástico, el grosor de la pared de plástico, la forma de la pieza de plástico, el tamaño de la compuerta y la distribución de la compuerta. Basándose en la experiencia, puede determinar el índice de contracción de cada parte de la pieza de plástico y, a continuación, calcular el tamaño de la cavidad.

Para piezas de plástico de alta precisión o piezas de plástico con una tasa de encogimiento difícil de controlar, generalmente puede utilizar los siguientes métodos para diseñar el molde: tomar una tasa de encogimiento menor para el diámetro exterior de la pieza de plástico y tomar una tasa de encogimiento mayor para el diámetro interior, de modo que haya espacio para la corrección después del molde de prueba.

La contracción en el moldeo por inyección es siempre predecible.Falso

Aunque se comprenden ciertos patrones y comportamientos, factores como la composición del material y las condiciones de procesado pueden provocar variabilidad en los resultados de la contracción.

Un control adecuado de la contracción mejora la precisión dimensional de las piezas moldeadas.Verdadero

La predicción y gestión precisas de la contracción permiten obtener piezas que cumplen las especificaciones de diseño, lo que reduce los defectos y el desperdicio de material.

¿Por qué es importante la fluidez en el moldeo por inyección?

La fluidez en el moldeo por inyección garantiza que el material plástico llene el molde correctamente, lo que da lugar a piezas de alta calidad y reduce los defectos.

La fluidez es esencial para el llenado completo del molde y para minimizar los defectos, lo que repercute en el procesamiento, la selección de materiales y la calidad de las piezas en sectores como la automoción, la electrónica y los bienes de consumo.

Termoplástico Tamaño de flujo

La fluidez de los termoplásticos puede analizarse generalmente a partir de una serie de índices como el peso molecular, el índice de fusión, la longitud de flujo en espiral de Arquímedes, la viscosidad de rendimiento y la relación de fluidez (longitud de flujo/espesor de pared de la pieza de plástico).

Pequeño peso molecular, amplia distribución del peso molecular, pobre regularidad de la estructura molecular, alto índice de fusión, la longitud de flujo del tornillo, la viscosidad de rendimiento es pequeña, la relación de flujo del flujo es buena, el mismo nombre del plástico debe ser examinado en el manual para deducir si su flujo es adecuado para el moldeo por inyección.

Basándose en los requisitos del diseño del molde, los plásticos pueden dividirse en tres categorías según su fluidez: los plásticos con buena fluidez incluyen PA, PE, PS, PP, CA y poli (4) metilpenteno; los plásticos con fluidez moderada incluyen las resinas de la serie del poliestireno (como ABS, AS), PMMA, POM y éter de polifenileno; los plásticos con fluidez deficiente incluyen las resinas de la serie del fluidez4 incluyen el PC, el PVC rígido, el éter de polifenileno, la polisulfona, la polisulfona y los fluoroplásticos.

Los principales factores que afectan a la fluidez de los plásticos

Cuando la temperatura del material es alta, aumenta la fluidez. Sin embargo, los distintos plásticos también tienen sus propias diferencias. PS (especialmente el tipo resistente al impacto y cuanto mayor es el valor MFR), PP, PA, PMMA, poliestireno modificado (como ABS, AS), PC, CA y otros plásticos, la fluidez de los plásticos con el cambio de temperatura es mayor. Para PE, POM, el aumento o disminución de la temperatura tiene menos impacto en su fluidez. Así que el primero en la temperatura de moldeo es apropiado ajustar para dominar el flujo.

La presión de inyección aumenta el material fundido por el efecto de cizallamiento, y el flujo también aumenta. Especialmente para PE y POM, son más sensibles, por lo que es conveniente ajustar la presión de inyección para controlar el flujo de moldeo.

La estructura del molde, la forma del sistema de vertido, el tamaño, la disposición, el diseño del sistema de refrigeración, la resistencia al flujo del material fundido (como la suavidad de la superficie del tipo, el grosor de la sección transversal del canal, la forma de la cavidad, el sistema de escape) y otros factores tienen un impacto directo en el flujo real del material fundido en la cavidad. Dondequiera que el material fundido se promueve la reducción de la temperatura, aumentar la resistencia al flujo, el flujo del material fundido se reducirá.

Al diseñar un molde, debe tener en cuenta el flujo del plástico y elegir una estructura razonable. También puede ajustar las condiciones de llenado, como la temperatura del material, la temperatura del molde, la presión de inyección y la velocidad de inyección, para satisfacer los requisitos del proceso de moldeo.

Una buena fluidez reduce los defectos en el moldeo por inyección.Verdadero

Una fluidez adecuada garantiza que el molde se llene correctamente, minimizando defectos como disparos cortos o marcas de hundimiento.

La fluidez viene determinada únicamente por la temperatura del molde.Falso

Aunque la temperatura del molde afecta a la fluidez, factores como la viscosidad del material y la velocidad de inyección también desempeñan un papel importante.

¿Cómo afecta la cristalinidad al proceso de moldeo por inyección?

La cristalinidad desempeña un papel crucial en el proceso de moldeo por inyección, ya que influye en las propiedades mecánicas y la estabilidad dimensional de las piezas moldeadas.

La cristalinidad influye en el moldeo por inyección al determinar las propiedades térmicas y mecánicas de los plásticos. Una mayor cristalinidad aumenta la resistencia y la rigidez, pero requiere un enfriamiento más prolongado, lo que afecta al procesamiento en sectores como el envasado, la automoción y el aeroespacial.

Plásticos cristalinos y plásticos no cristalinos (también llamados amorfos)

Los termoplásticos pueden dividirse en dos categorías: plásticos cristalinos y no cristalinos (también llamados amorfos). Esto viene determinado por si cristalizan o no al enfriarse.

El llamado fenómeno de cristalización es el plástico del estado fundido a la condensación, las moléculas del movimiento independiente, completamente en un estado desordenado, las moléculas dejan de moverse libremente, de acuerdo con la posición ligeramente fijo, y hay una tendencia a hacer que la disposición molecular de un modelo regular de un fenómeno.

El aspecto de estos dos tipos de estándares de plástico depende de la transparencia de las piezas moldeadas de pared gruesa de plástico. Por lo general, los materiales cristalinos son opacos o translúcidos (como el POM, etc.), mientras que los materiales amorfos son transparentes (como el PMMA, etc.). Sin embargo, hay excepciones. Por ejemplo, la poli (4) metil basura es un plástico cristalino pero muy transparente, y el ABS es un material amorfo pero no transparente.

Requisitos y precauciones para plásticos cristalinos

El calor necesario para elevar la temperatura del material hasta la temperatura de moldeo es elevado, por lo que es necesario utilizar equipos con una gran capacidad de plastificación. El calor liberado durante el enfriamiento es grande, por lo que debe enfriarse lo suficiente. La diferencia de gravedad específica entre el estado fundido y el estado sólido es grande, la contracción de moldeo es grande, y es fácil que se produzca contracción y porosidad. Enfriamiento rápido, baja cristalinidad, pequeña contracción, alta transparencia.

La cristalinidad y el grosor de pared de las piezas de plástico están relacionados. El grosor de pared tarda en enfriarse, la cristalinidad es alta, la contracción es grande y las propiedades físicas son buenas.

Por lo tanto, el material cristalino debe prestar atención al control de la temperatura del molde5. El material cristalino presenta una anisotropía evidente y una tensión interna elevada. Tras el desmoldeo, las moléculas no cristalizadas tienen tendencia a seguir cristalizando, lo que se encuentra en un estado de desequilibrio energético y es propenso a la deformación y el alabeo. El intervalo de temperatura de cristalización es estrecho, y es fácil que el extremo del material no fundido se inyecte en el molde o bloquee el puerto de alimentación.

Una mayor cristalinidad aumenta la resistencia mecánica de las piezas moldeadas.Verdadero

Los materiales con mayor cristalinidad presentan un mayor orden molecular, lo que aumenta su resistencia y rigidez.

En el moldeo por inyección siempre se prefieren los plásticos amorfos a los cristalinos.Falso

Mientras que los plásticos amorfos son más fáciles de procesar, los cristalinos ofrecen propiedades mecánicas superiores para aplicaciones específicas.

¿Cómo afectan los plásticos sensibles al calor y los plásticos hidrolizables al proceso de moldeo por inyección?

Los plásticos sensibles al calor e hidrolizables desempeñan un papel crucial en el proceso de moldeo por inyección, ya que influyen en factores como las temperaturas de moldeo y la degradación del material.

El control adecuado de la temperatura es crucial para los plásticos sensibles al calor en el moldeo por inyección para evitar su degradación, mientras que la gestión de la humedad es esencial para los plásticos hidrolizables para preservar la integridad del material, garantizando productos consistentes y de alta calidad.

Los plásticos termosensibles son los más sensibles al calor. Cuando se exponen a altas temperaturas durante un periodo de tiempo prolongado o cuando la sección transversal del puerto de alimentación es demasiado pequeña y el efecto de cizallamiento es significativo, estos plásticos tienden a cambiar de color, degradarse y descomponerse. Esta característica es lo que los convierte en plásticos sensibles al calor.

Como PVC duro, cloruro de polivinilo, copolímero de acetato de vinilo, POM, politrifluoroetileno, etc. Cuando plásticos termosensibles6 Al descomponerse, producen monómeros, gases, sólidos y otros subproductos. Los gases producidos durante la descomposición pueden ser irritantes, corrosivos o tóxicos para las personas, los equipos y los mohos.

Por lo tanto, debe prestar atención al diseño del molde, la elección de la máquina de moldeo por inyección y el proceso de moldeo. Debe elegir una máquina de moldeo por inyección de tornillo, la sección transversal del canal debe ser grande, el molde y el barril deben estar cromados, y no debe haber esquinas muertas para el material. Es necesario controlar estrictamente la temperatura de moldeo, y añadir estabilizadores al plástico para debilitar su sensibilidad al calor.

Algunos plásticos, como el PC, pueden descomponerse a altas temperaturas y presiones, aunque sólo contengan un poco de agua. Esto se llama ser hidrolizables, y hay que calentarlos y secarlos antes de utilizarlos.

Los plásticos sensibles al calor requieren temperaturas de inyección más bajas.Verdadero

El control preciso de la temperatura es esencial para evitar la degradación, que puede comprometer la calidad de la pieza moldeada.

Todos los plásticos hidrolizables se degradan en presencia de cualquier humedad.Falso

Aunque los plásticos hidrolizables pueden ser sensibles a la humedad, el grado de degradación depende de la estructura química específica del plástico y de las condiciones ambientales.

¿Cómo afectan el agrietamiento por tensión y el agrietamiento por fusión al proceso de moldeo por inyección?

El agrietamiento por tensión y el agrietamiento por fusión son problemas críticos en el moldeo por inyección, que afectan a la durabilidad del producto y a la eficacia de la fabricación en todos los sectores.

La tensión y el agrietamiento por fusión en las piezas moldeadas causan debilidad y defectos. Ambos pueden mitigarse optimizando la temperatura de procesamiento y la selección de materiales para mejorar la integridad y el rendimiento del producto.

Algunos plásticos son sensibles a la tensión, lo que significa que pueden desarrollar fácilmente tensiones internas durante el proceso de moldeo. Como resultado, estos plásticos pueden volverse quebradizos y propensos a agrietarse. Cuando se exponen a fuerzas externas o disolventes, las piezas de plástico fabricadas con estos materiales pueden agrietarse.

Por lo tanto, además de añadir aditivos a la materia prima para mejorar la resistencia a las grietas, debe prestar atención al secado de la materia prima, elegir una condición de moldeo razonable, reducir la tensión interna y mejorar la resistencia a las grietas. Y usted debe elegir una forma razonable para las piezas de plástico, no establecer insertos y otras medidas para minimizar la concentración de tensiones.

Al diseñar un molde, debe aumentar la pendiente del mismo, elegir un buen mecanismo de entrada y expulsión, y ajustar adecuadamente la temperatura del material, la temperatura del molde, la presión de inyección y el tiempo de enfriamiento durante el moldeo. Intente evitar que las piezas de plástico estén demasiado frías y quebradizas al desmoldarlas. También es bueno realizar algún tratamiento posterior en las piezas de plástico moldeadas para mejorar su resistencia al agrietamiento, reducir la tensión interna y evitar el contacto con disolventes.

Cuando el caudal de fusión7 de un determinado polímero alcanza un determinado valor, si la velocidad de flujo supera un determinado valor, aparecerán grietas transversales evidentes en la superficie de la masa fundida, lo que se denomina agrietamiento de la masa fundida. Es perjudicial para el aspecto y las propiedades físicas de las piezas de plástico.

Por lo tanto, al seleccionar un polímero con un alto índice de flujo de fusión, etc., debe aumentarse el área de la sección transversal de la boquilla, el canal y la compuerta, debe reducirse la velocidad de inyección y debe aumentarse la temperatura del material.

El agrietamiento por tensión reduce la vida útil de las piezas moldeadas.Verdadero

Las piezas afectadas por el agrietamiento por tensión tienen más probabilidades de fallar bajo tensión mecánica o ambiental, lo que reduce su vida útil funcional.

El agrietamiento por fusión puede evitarse por completo utilizando cualquier tipo de plástico.Falso

Aunque la elección del material puede influir en la aparición del agrietamiento por fusión, es necesario seleccionar los parámetros de proceso y las combinaciones de materiales adecuados para minimizar este defecto.

¿Cómo afectan las propiedades térmicas y la velocidad de enfriamiento al proceso de moldeo por inyección?

Las propiedades térmicas de los materiales y la velocidad de enfriamiento influyen significativamente en el proceso de moldeo por inyección, afectando a la calidad del producto final y a la eficiencia de la producción.

En el moldeo por inyección, las propiedades térmicas influyen en el comportamiento del material bajo el calor, lo que afecta al flujo y al enfriamiento. El control de la velocidad de enfriamiento es crucial para la integridad estructural y la estabilidad, optimizando la calidad de la pieza y reduciendo el alabeo y los tiempos de ciclo.

Los distintos plásticos tienen propiedades térmicas diferentes, como el calor específico, la conductividad térmica y la temperatura de distorsión térmica. Los plásticos con un calor específico elevado necesitan mucho calor para fundirse, por lo que es necesario utilizar una máquina de moldeo por inyección con una gran capacidad de fusión. Los plásticos con una temperatura de distorsión térmica elevada pueden enfriarse rápidamente y desmoldearse con rapidez, pero después del desmoldeo hay que evitar que se enfríen y se deformen.

Los plásticos con baja conductividad térmica tienen una velocidad de enfriamiento lenta (por ejemplo, los polímeros iónicos, etc. tienen una velocidad de enfriamiento muy lenta), por lo que deben enfriarse lo suficiente y debe reforzarse el efecto de enfriamiento del molde.

Los moldes de canal caliente son adecuados para plásticos con bajo calor específico y alta conductividad térmica. El calor específico es grande, baja conductividad térmica, baja temperatura de distorsión de calor, velocidad de enfriamiento lenta del plástico no es propicio para el moldeo de alta velocidad, la necesidad de elegir la máquina de moldeo por inyección adecuada y fortalecer la refrigeración del molde.

Los distintos tipos de plásticos, en función de sus propiedades y de la forma de la pieza moldeada, requieren una velocidad de enfriamiento específica. Por lo tanto, el molde debe diseñarse con un sistema de calentamiento y enfriamiento para mantener una determinada temperatura del molde, de acuerdo con los requisitos de moldeo. Cuando la temperatura del material es superior a la del molde, éste debe enfriarse para evitar que la pieza de plástico se deforme después de ser expulsada, acortar el ciclo de moldeo y reducir el grado de cristalinidad.

Cuando el calor de los residuos plásticos no es suficiente para mantener el molde a una cierta temperatura, el molde debe tener un sistema de calefacción para mantener el molde a una cierta temperatura, para que pueda controlar la velocidad de enfriamiento, asegurarse de que el flujo es bueno, mejorar las condiciones de llenado o utilizarlo para controlar la pieza de plástico para que se enfríe lentamente, para que no tenga piezas de paredes gruesas que se enfríen de forma desigual en el interior y el exterior y mejorar la cristalinidad, etcétera.

Para garantizar una producción sin problemas y la calidad de las piezas moldeadas, a veces es necesario ajustar la temperatura del molde durante el proceso de moldeo de plástico. Esto puede hacerse calentando o enfriando todo el molde o calentando o enfriando zonas específicas del molde. Por lo tanto, el molde debe estar equipado con el correspondiente sistema de refrigeración o calefacción.

Una gestión térmica adecuada reduce los defectos en el moldeo por inyección.Verdadero

Un control térmico eficaz ayuda a mantener un flujo y una refrigeración constantes, reduciendo el alabeo y otros defectos en las piezas moldeadas.

La velocidad de enfriamiento no influye en la duración del ciclo.Falso

La velocidad de enfriamiento influye directamente en los tiempos de ciclo; un enfriamiento más rápido puede reducir los tiempos de ciclo, aumentando la eficiencia global de la producción.

¿Cómo afecta la higroscopicidad al proceso de moldeo por inyección?

Comprender la higroscopicidad es vital para mantener la calidad y la eficacia del proceso de moldeo por inyección, ya que afecta directamente a las propiedades del material y a la integridad del producto final.

La higroscopicidad de los plásticos influye en la absorción de humedad, afectando a la viscosidad y a los procesos de moldeo. Un secado y una manipulación adecuados son cruciales para evitar defectos como alabeos, burbujas y reducción de la resistencia.

Los plásticos tienen diferentes niveles de absorción de agua8 debido a diversos aditivos. Por ello, los plásticos pueden dividirse en tres categorías: higroscópicos, absorbentes de agua y no higroscópicos. El contenido de agua del material debe controlarse dentro de un rango determinado. De lo contrario, cuando la temperatura y la presión sean elevadas, el agua se convertirá en gas o sufrirá hidrólisis.

Por lo tanto, si la resina está ampollada, la fluidez se reduce y el aspecto y las propiedades mecánicas son deficientes. Por lo tanto, cuando se utilizan plásticos higroscópicos, es necesario precalentarlos de acuerdo con los requisitos del método de calentamiento adecuado y las especificaciones para evitar la absorción de humedad.

Los materiales higroscópicos requieren un secado especial antes del moldeo por inyección.Verdadero

La humedad en los plásticos higroscópicos puede provocar defectos, por lo que deben secarse a fondo para garantizar un procesamiento y una calidad del producto óptimos.

Todos los plásticos utilizados en el moldeo por inyección son higroscópicos.Falso

No todos los plásticos son higroscópicos; por ejemplo, el polietileno tiene una baja absorción de humedad en comparación con materiales como el nailon.

Conclusión

Moldeo por inyección9 es un proceso complejo que requiere una cuidadosa consideración de muchos factores para garantizar una producción sin problemas y una calidad constante del producto. Estos factores incluyen la contracción, la fluidez, la cristalinidad, la sensibilidad al calor y la hidrólisis del plástico, así como su resistencia al agrietamiento por tensión y al agrietamiento por fusión, y sus propiedades térmicas, velocidad de enfriamiento y absorción de humedad.

Los distintos tipos de plásticos tienen diferentes comportamientos de flujo y características de contracción durante el proceso de moldeo por inyección, y estas características se ven influidas por la temperatura, la presión y el diseño del molde.

-

Conocer los efectos de la presión de mantenimiento puede mejorar la calidad y la precisión de los componentes de plástico moldeados. ↩

-

Explorar la relación entre la temperatura del molde y la contracción puede conducir a un mejor control de las dimensiones finales de las piezas moldeadas. ↩

-

Comprender los factores que influyen en los índices de contracción puede ayudar a optimizar el diseño de las piezas de plástico y los procesos de fabricación. ↩

-

Comprender la fluidez es crucial para optimizar los procesos de moldeo por inyección y la selección de materiales. ↩

-

Explorar el impacto de la temperatura del molde puede mejorar su conocimiento del comportamiento termoplástico durante el moldeo. ↩

-

Comprender los plásticos sensibles al calor es crucial para un moldeo eficaz y la selección de materiales, garantizando la calidad y la seguridad en la producción. ↩

-

Explorar la velocidad de flujo de la masa fundida ayuda a optimizar los procesos de moldeo por inyección, mejorando la calidad del producto y reduciendo los defectos. ↩

-

Conocer la absorción de agua en los plásticos es esencial para evitar defectos y garantizar la durabilidad de los productos moldeados. ↩

-

Guía para principiantes sobre el moldeo por inyección: El moldeo por inyección permite producir grandes volúmenes de piezas precisas, utilizando materiales como plásticos, metales y cerámica. ↩