Warpage in injection molded products is influenced by various factors, which affect the final quality and functional performance of the products.

Warpage is primarily influenced by mold design, material selection, cooling rates, and process conditions in injection molding. Controlling these factors can reduce defects and improve the geometric precision of molded parts.

Understanding the key factors affecting warpage is essential for producing high-quality injection molded products. Dive deeper into each aspect to enhance your product consistency and performance.

Material choice is the most critical factor in preventing warpage.Falsch

While material choice is important, factors like mold design and cooling rates significantly contribute to warpage as well.

Optimizing cooling rates can reduce warpage.Wahr

Proper cooling ensures even solidification, minimizing stress and preventing deformation in the final product.

What is the Effect of Mold Structure on Warpage Deformation of Injection Molded Products?

Mold structure significantly influences warpage deformation in injection molded products, affecting dimensions and quality.

Mold structure impacts warpage in injection molding by influencing cooling rates and material flow. Key factors are mold design, gate location, and cooling channel placement. Proper design minimizes warpage, enhancing dimensional stability crucial for automotive and electronics industries.

Large Shrinkage Rate

Different plastic materials have different shrinkage rates1. Some materials have large shrinkage rates, which will produce large volume changes during the cooling process after injection molding and easily cause warpage deformation. For example, crystalline plastics undergo significant volume contraction during the crystallization process and are more prone to warpage problems than non-crystalline plastics.

Gating-System

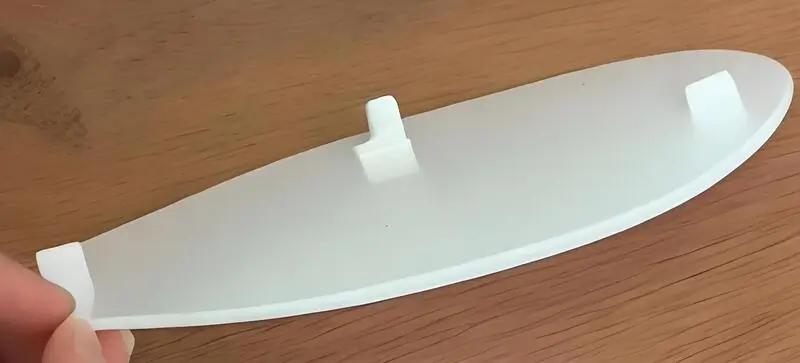

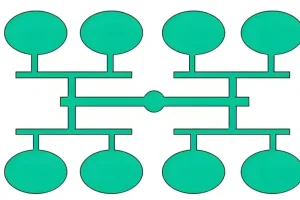

The position, shape, and number of gates in the injection mold will affect the filling state of the plastic in the mold cavity, which will cause the plastic part to warp.

The longer the flow distance, the greater the internal stress caused by the flow and shrinkage between the frozen layer and the central flow layer; conversely, the shorter the flow distance, the shorter the flow time from the gate to the end of the part flow, the thinner the frozen layer is during the mold filling process, the lower the internal stress, and the resulting warping deformation will be greatly reduced.

The number, shape, and location of gates in the mold will affect how the plastic fills the mold cavity, which can cause the plastic part to warp. The longer the flow length, the more internal stress there will be from flow and shrinkage between the frozen layer and the center of the flow; conversely, the shorter the flow length, the shorter the time it takes for the plastic to flow from the gate to the end of the part, the thinner the frozen layer is during the filling process, the lower the internal stress, and the resulting warping will be greatly reduced.

Also, using more gates can make the plastic flow ratio (L/t) shorter, which makes the melt density in the mold cavity more even and the shrinkage more even. It can also fill the whole part at a lower injection pressure.

Kühlsystem

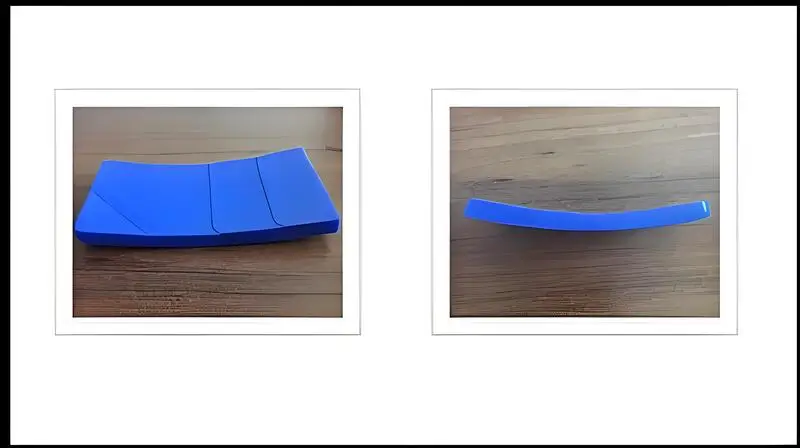

When you inject the plastic, the part cools unevenly, which causes the part to shrink unevenly.

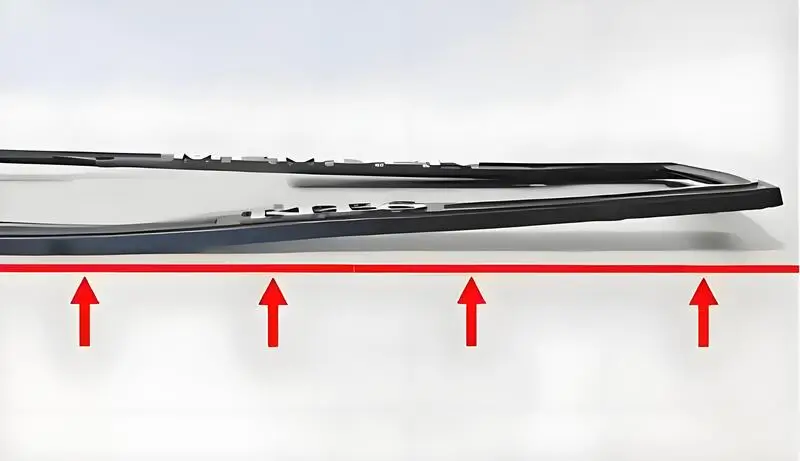

If the temperature difference between the mold cavities and cores used in injection molding of flat shaped parts (such as cell phone battery shells) is too large, the melt close to the cold mold cavity surface cools down quickly, while close to the hot cavity surface of the material layer will continue to contract, the uneven contraction will cause the part to warp.

So, when the injection mold is cooled, it is necessary to pay attention to the temperature balance2 between the cavity and the core, and the temperature difference between the two cannot be too large (at this time, you can consider using a two-mold thermostat).

In addition to considering the temperature balance between the inner and outer surfaces of the plastic parts, it is also necessary to consider that the temperature of the plastic parts on all sides is the same, that is, the mold cooling3 should try to maintain the temperature balance of the cavity and the core everywhere, so that the cooling speed of the plastic parts is balanced everywhere, so that the shrinkage of each place is more uniform, and the generation of deformation can be effectively prevented.

Unreasonable Location and Number of Gates

The gate is where the plastic melt goes into the mold, and where and how many gates you have affects how the melt flows and fills. If you put the gate in the wrong place, the melt might not flow evenly in the mold, and that can make different parts of the injection molded part have different density and shrinkage, and then the part warps. If you don’t have enough gates, the melt might not fill the whole cavity evenly, and that can also make the part warp.

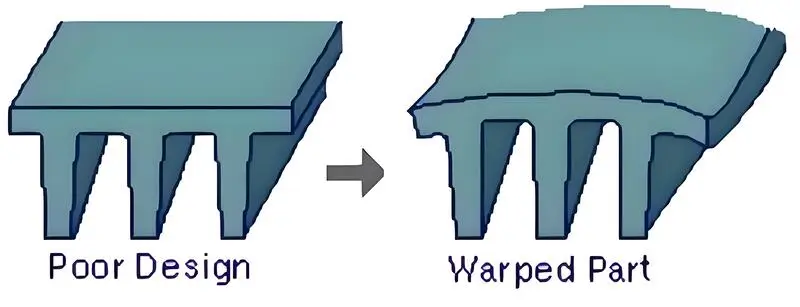

Irrational Mold Structure

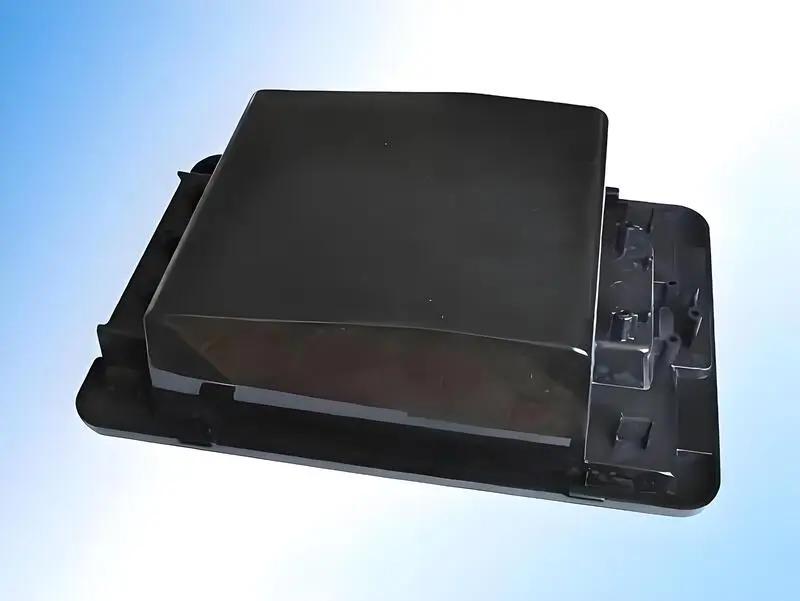

The mold’s structure also affects how much injection molded parts warp and deform. For example, if a mold’s release mechanism is poorly designed, it might put uneven pressure on the injection molded part when it’s released from the mold, causing warping.

Also, if the mold isn’t rigid enough, the high-pressure melted plastic can deform it during the injection process, which can indirectly cause the injection molded parts to warp. Material Characteristics

Unreasonable Design of the Ejector System of the Mold

The design of the Auswerfersystem4 also directly affects the deformation of the molded part. If the arrangement of the ejector system is not balanced, it will cause an imbalance of the ejector force and deformation of the molded parts. Therefore, in the design of the ejector system, you should strive to balance it with the demolding resistance.

Also, the cross-sectional area of the ejector rod should not be too small, because that would cause too much pressure per unit area on the plastic part (especially if the demolding temperature is too high) and deform the plastic part. The ejector rod should be placed as close as possible to the part that is hard to demold.

If it doesn’t affect the quality of the plastic part (including its use, size, and appearance), you should add a top rod to reduce the overall deformation of the plastic part (that’s why the top rod is on top of the mold).

Proper mold structure reduces warpage in injection molded products.Wahr

By optimizing mold design and cooling channels, warpage deformation is minimized, leading to better dimensional accuracy and stability.

Mold structure has no impact on the cooling rate of injection molded products.Falsch

The mold structure directly affects cooling rates by determining how heat is dissipated, influencing the final product's warpage and quality.

What are the Effects of Filling and Crystalline Plastics on the Warpage and Deformation of Products?

Understanding the effects of filling and crystalline plastics is crucial to optimizing product integrity, minimizing warpage and deformation during the manufacturing process.

Filling materials and crystalline plastics impact warpage by altering thermal expansion and shrinkage rates during cooling. Proper material selection and design adjustments are essential to maintaining product dimensional stability.

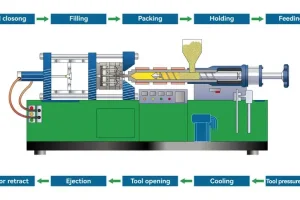

Befüllungsphase

The melted plastic is injected into the mold under pressure and cooled in the mold to solidify. This process is the most important step in Spritzgießen5. During this process, temperature, pressure, and speed are all interrelated and have a significant impact on the quality and productivity of the molded part.

Increasing the pressure and flow rate will increase the shear rate, which causes the difference between the molecular orientation parallel to the flow direction and perpendicular to the flow direction, at the same time, the “freezing effect”. The “freezing effect” produces freezing stresses, which form internal stresses in the molded part.

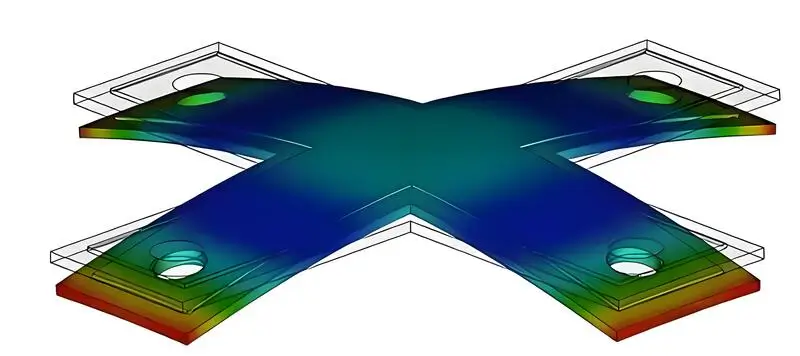

The influence of temperature on warpage deformation is: the temperature difference between the upper and lower surfaces of the plastic part will cause thermal stress6 and thermal deformation; the temperature difference between different areas of the plastic part will cause non-uniform contraction between different areas; different temperature states will affect the shrinkage of the plastic part.

Crystalline Plastics

Crystalline resins (like paraformaldehyde, nylon, polypropylene, polyethylene, and PET resins) generally deform more than non-crystalline resins (like PMMA resins, polyethylene, polystyrene, ABS resins, and AS resins, etc.) with large shrinkage. They also deform more because of the fiber directionality of the glass fiber reinforced resins.

Most of the deformations happen because the melting point temperature range is narrow, and it’s hard to fix them. The crystallinity of crystalline plastics7 changes depending on how fast they cool. If they cool fast, the crystallinity goes down and the molding shrinkage goes down. If they cool slow, the crystallinity goes up and the molding shrinkage goes up. We use this property to fix deformations in crystalline plastics.

In practice, the correction method used is to make the moving and static molds have a certain temperature difference. It is to take the temperature that makes the other side of the warpage to produce strain, and then it can correct the deformation. Sometimes this temperature difference is as high as 20°C or more, but it must be very evenly distributed.

It must be pointed out that in the design of crystalline plastic molding parts and molds, such as not in advance to take special means of preventing deformation, the parts will be deformed and can not be used, only to make the molding conditions to meet the requirements of the above, the majority of cases still can not correct the deformation.

Crystalline plastics reduce warpage in products.Falsch

Crystalline plastics can cause non-uniform shrinkage, potentially increasing risk of warpage.

Filling materials can modify the shrinkage rate of plastics, reducing warpage.Wahr

Fillers can alter a plastic’s shrinkage behavior, minimizing variations that lead to warpage.

What are the Effects of the Demolding Stage and Shrinkage of the Molded Part on Warpage Deformation?

The demolding stage and shrinkage significantly affect warpage deformation in molded parts, impacting their dimensional stability and performance.

Warpage deformation results from uneven shrinkage during cooling and demolding. Managing mold temperature and cooling rates can minimize warpage, ensuring better part quality and precision.

Entformungsphase

When you take the part out of the mold and let it cool down to room temperature, it’s mostly a glassy polymer. If you don’t get the part out of the mold right, or if you don’t get it out of the mold right and you don’t get it out of the mold right, you can warp the part.

At the same time, when the part is filling the mold and cooling down, the stress that’s “frozen” into the part is released as “deformation” because it’s not being held in place anymore, and that’s what causes the warping and the deformation.

Schrumpfung von spritzgegossenen Produkten

The main reason for the warpage deformation8 of injection molded products is the uneven shrinkage9 of the molded parts. If the shrinkage effect during the filling process is not considered in the mold design stage, the shape of the product will be very different from the design requirements, and serious deformation will lead to product scrap (that is, shrinkage problem).

In addition to the filling stage, the temperature difference between the upper and lower walls of the mold will also cause differences in the shrinkage of the upper and lower surfaces of the molded part, resulting in warpage deformation.

When analyzing warpage, it’s not the shrinkage itself that matters, but rather the difference in shrinkage. During the injection molding process, the molten plastic in the mold fills up and the polymer molecules align themselves in the direction of flow. This causes the plastic to shrink more in the flow direction than in the vertical direction, resulting in warped parts (also known as anisotropy).

Normally, uniform shrinkage only affects the volume of plastic parts, only uneven shrinkage will cause warpage deformation. Crystalline plastic has a larger shrinkage rate than non-crystalline plastic10 in the flow direction and the vertical direction, and its shrinkage rate is also larger than non-crystalline plastic.

The shrinkage of crystalline plastic and its anisotropy are superimposed. After adding the effect of crystalline plastic, the warping deformation tendency of the parts is much larger than that of non-crystalline plastic.

Demolding always increases warpage deformation.Falsch

Demolding can be controlled to minimize deformation through precise temperature and timing adjustments.

Shrinkage does not affect warpage.Falsch

Shrinkage can cause uneven stress distribution, leading to warpage if not properly managed.

What are the Effects of Residual Thermal Stress and Molding Strain on Warpage of Products?

Residual thermal stress and molding strain significantly affect the warpage of molded products, impacting their dimensional accuracy and performance.

Residual thermal stress and molding strain lead to warpage in molded products, impacting shape stability. Proper management is crucial for accurate geometrical conformity in automotive and electronics industries.

Thermische Eigenspannung

When the plastic melt is molded, the uneven orientation and shrinkage of the plastic melt cause uneven internal stress, so after the product comes out of the mold, it will warp and deform under the action of uneven internal stress.

Therefore, the internal stress and warpage of the product are analyzed and calculated from the mechanical point of view. In some foreign literature, warpage is considered to be caused by residual stress11 generated by uneven shrinkage.

During the cooling stage of injection molding, when the temperature is higher than the glass transition temperature, the plastic is a viscoelastic fluid, and it will experience stress relaxation. When the temperature is lower than the glass transition temperature, the plastic becomes solid.

The plasticity of the liquid-solid phase transition and stress relaxation during cooling has a significant effect on the accurate prediction of the residual stress and deformation of the product. The plasticity of the liquid-solid phase transition and stress relaxation during cooling.

In the uncured region, the plastic acts like a thick liquid, which we describe with the thick liquid model. In the cured region, the plastic acts like a thick liquid and a spring, which we describe with the spring and thick liquid model. We use the spring and thick liquid model and a computer program to predict the thermal stresses and the warping.

Molding Strain

The deformation caused by molding strain is mainly due to the difference in molding shrinkage12 in the direction and the change in wall thickness.

Therefore, increasing the mold temperature, increasing the melt temperature, reducing the injection pressure, and improving the flow conditions of the pouring system can reduce the difference in the direction of shrinkage. However, it is mostly difficult to correct the problem by changing only the molding conditions, and then it is necessary to change the location and number of gates, such as injecting from one end when molding a long rod.

Sometimes you have to change the cooling waterway configuration; longer sheet parts are more prone to deformation, and sometimes you have to change the local design of the part to set up reinforcement bars on the back of the upturned side. The use of cooling aids to correct this deformation is mostly effective. If it can’t be corrected, you have to amend the mold design.

Residual thermal stress contributes to product warpage.Wahr

Thermal stress arises from temperature differentials during cooling, leading to deformation in the final product.

All warpage issues are solely due to molding strain.Falsch

While molding strain is a factor, warpage is often caused by a combination of thermal stresses and material properties.

What is the Effect of Injection Molding Process Factors on Product Warpage Deformation?

Injection molding process factors significantly influence warpage deformation, affecting the final product’s appearance and performance across various applications.

Key factors affecting product warpage in injection molding include mold temperature, injection speed, and cooling time. Adjusting these parameters optimizes material flow and minimizes deformation in automotive, electronics, and packaging products, improving both quality and functionality.

Improper Injection Pressure and Holding Time

If the injection pressure is too high, the molded part will have large residual stress, and the release of this stress after demolding will cause warpage and deformation13.

If the holding time is too long or too short, it will also affect the quality of the product. If the holding time is too long, the injection part will be over-compacted, and it will be easy to rebound and warp after demolding; if the holding time is too short, the product will not have enough shrinkage, and it will warp due to uneven shrinkage.

Too Fast Injection Speed

If the injection speed is too fast, the flow of melted plastic in the mold will be unstable, causing uneven filling, and then different degrees of shrinkage will occur after cooling, resulting in warpage and deformation.

Mold temperature is the only factor affecting warpage in injection molding.Falsch

While mold temperature is crucial, injection speed and cooling time also play significant roles in managing warpage.

Adjusting cooling time can reduce warpage in injection molded products.Wahr

Optimizing cooling time ensures uniform solidification, which helps in reducing product warpage.

Schlussfolgerung

The warpage of injection molded products is mainly affected by the mold structure, material properties, Kühlsystem14, ejector system, filling process, and shrinkage. The unreasonable mold design, such as the inappropriate location and number of gates, will cause the uneven flow of the melt, resulting in the difference in density and warpage.

High shrinkage materials (such as crystalline plastics) are prone to warpage due to uneven cooling shrinkage. Uneven cooling and mold temperature differences can cause stress concentration and increase the risk of warpage. The unreasonable ejector system may cause uneven force, which will further affect the shape stability.

In addition, the temperature, pressure, and flow rate during the filling stage will affect the molecular orientation, resulting in internal stress and warpage.

-

Understanding shrinkage rates is crucial for optimizing injection molding processes and minimizing warpage issues. ↩

-

Maintaining temperature balance is essential for preventing warpage and ensuring uniform cooling in injection molded parts. ↩

-

Understanding mold cooling is crucial for achieving uniform temperature and preventing deformation in molded parts. ↩

-

Exploring the ejector system’s design can help you minimize deformation and improve the quality of molded parts. ↩

-

Understanding the factors affecting injection molding can help improve product quality and efficiency in manufacturing. ↩

-

Exploring the impact of thermal stress can provide insights into preventing deformation in molded plastic parts. ↩

-

Learning about crystalline plastics can enhance your knowledge of material behavior and improve molding processes. ↩

-

Understanding the causes of warpage deformation can help in designing better molds and improving product quality. ↩

-

Exploring the impact of uneven shrinkage can provide insights into preventing defects in molded products. ↩

-

Learning about crystalline plastic properties can enhance your knowledge of material selection and processing techniques. ↩

-

Understanding residual stress is crucial for improving product quality in injection molding. Explore this link for in-depth insights. ↩

-

Molding shrinkage significantly impacts product quality. Discover the key factors that influence it for better manufacturing outcomes. ↩

-

Minimizing warpage and deformation is essential for product integrity. This resource provides effective strategies and solutions. ↩

-

Learn about How many types of cooling systems are there for injection molds?The cooling system of injection molds can be divided into air cooling, water cooling and oil cooling depending on the medium, but the most common is the water cooling system. ↩