Die Entwicklung von Kunststoffformteilen in unserem Werk umfasst einen präzisen Prozess von Technik und Handwerkskunst, der sicherstellt, dass jedes Teil strenge Qualitäts- und Leistungsstandards erfüllt.

Bei der Konstruktion von Kunststoffformteilen liegt der Schwerpunkt auf der Materialauswahl, der Teilegeometrie und dem Werkzeugdesign, um Haltbarkeit, Leistung und Kosteneffizienz zu steigern und gleichzeitig den Materialabfall zu minimieren und die Fertigungsprozesse zu optimieren.

Während diese Einführung die Grundlagen der Konstruktion von Kunststoffteilen umreißt, bietet die Vertiefung der einzelnen Komponenten Einblicke in die Verbesserung der Fertigungsergebnisse. Entdecken Sie, wie die Materialauswahl und fortschrittliche Techniken für den Formenbau die Qualität der Teile und die Produktionseffizienz steigern.

Eine optimierte Formkonstruktion reduziert die Produktionskosten.Wahr

Ein effektiver Formenbau verbessert den Materialeinsatz und minimiert Fehler, was die Gesamtkosten der Fertigung senkt.

Alle Kunststoffformteile werden nach dem gleichen Verfahren hergestellt.Falsch

Das Design von Formteilen ist je nach funktionalen Anforderungen, Materialeigenschaften und anwendungsspezifischen Bedürfnissen sehr unterschiedlich.

Was ist die strukturelle und dimensionale Gestaltung von Kunststoffformteilen?

Das Struktur- und Maßdesign ist beim Gießen von Kunststoffteilen von entscheidender Bedeutung und beeinflusst deren Funktion, Langlebigkeit und Herstellbarkeit in verschiedenen Anwendungen.

Bei der Konstruktion von Kunststoffformteilen müssen Abmessungen, Toleranzen und strukturelle Integrität beachtet werden, um eine effektive Leistung zu gewährleisten. Wichtige Elemente sind eine angemessene Wandstärke, Rippendesign und Entformungswinkel, um die Festigkeit und die Effizienz des Formteils zu verbessern.

Struktur Design

-

Größe der Form:Bei der Auslegung der Formgröße müssen Sie die Größenanforderungen des Produkts und die Schrumpfungsrate des Kunststoffs berücksichtigen. Im Allgemeinen sollte die Größe der Form größer sein als die Größe des endgültigen Formteils. Verschiedene Kunststoffmaterialien haben unterschiedliche Schrumpfungsraten, im Allgemeinen zwischen 0,1% und 2%.

-

Methode der Formspaltung1:Wählen Sie die geeignete Methode der Formteilung je nach Form und Anforderungen des Produkts. Zu den gebräuchlichen Methoden der Formteilung gehören feste obere Form, bewegliche untere Form, bewegliche obere Form, feste untere Form, linke und rechte Formteilung usw. Die Methode der Formteilung sollte die Form des Produkts, die Schwierigkeit der Herstellung, die Struktur der Form, die Kosten und andere Faktoren berücksichtigen und danach streben, die Form reibungslos zu teilen und eine hohe Produktionseffizienz zu erreichen.

-

Das Kühlsystem2:Das Kühlsystem in der Form hat einen großen Einfluss auf die Qualität der Kunststoffprodukte und die Produktionseffizienz. Die Anordnung und Größe des Kühlwassers sollte vernünftig gestaltet sein. Der Kühlwasserkanal sollte so nah wie möglich an der Kontur des Produkts liegen, um die Kühlwirkung zu verbessern. Gleichzeitig sollte darauf geachtet werden, dass Verformungen durch ungleichmäßige Kühlung vermieden, die Kühlzeit verkürzt und die Produktionseffizienz verbessert werden.

-

Auspuffanlage:Bei der Konstruktion einer Form müssen Sie das Gas berücksichtigen, das beim Füllen und Abkühlen des Kunststoffs in der Form entsteht. Es muss ein Weg gefunden werden, das Gas loszuwerden. Bei der Konstruktion des Abgassystems sollte versucht werden, die Bildung von Blasen, kurzen Schüssen und anderen Fehlern zu vermeiden und die Qualität des Produkts zu verbessern.

-

Konstruktion des Trichters:Die Konstruktion des Trichters sollte sinnvoll gestaltet sein, wobei der Trichter und die Düse so positioniert sein sollten, dass das Kunststoffmaterial gleichmäßig in den Trichter fließt und Materialverstopfungen und Düsenblasen vermieden werden. Gleichzeitig sollte die Verbindung zwischen dem Trichter und der Form so gestaltet werden, dass sie leicht zu demontieren und zu reinigen ist.

Dimension Design

-

Ausführung der Wandstärke:Die Dicke der Wand des Produkts wirkt sich direkt auf die Qualität und Leistung des geformten Produkts aus. Eine zu dicke Wand verursacht Schrumpfung und Verformung des Formteils, und eine zu dünne Wand führt zu mangelnder Festigkeit des Produkts. Bei der Konstruktion sollte die Wanddicke entsprechend der Verwendung und den Anforderungen des Produkts vernünftig kontrolliert werden, um die Qualität des Produkts zu verbessern.

-

Auslegung der Spannkraft3:Die Schließkraft ist die Kraft, die zum Trennen der Form erforderlich ist. Sie sollte auf der Grundlage der Größe des Produkts, der Struktur des Produkts und der Art des Materials bestimmt werden. Ist die Schließkraft zu hoch, erhöht sich die Belastung für die Ausrüstung. Ist die Schließkraft zu gering, kann die Form nicht vollständig getrennt werden.

-

Konstruktion der verschiebbaren Teile4:Wenn Sie Teile mit einer gleitenden Struktur formen, müssen Sie die Position und Form des Schiebers richtig gestalten. Dadurch wird sichergestellt, dass sich der Schieber reibungslos bewegt und bei der Verwendung nicht stecken bleibt oder beschädigt wird. Außerdem müssen Sie bei der Konstruktion der Form die Abmessungen der Schieberteile und der Form beachten. So wird sichergestellt, dass sich die Form reibungslos öffnen und schließen lässt.

-

Zugfestes Design5:Um sicherzustellen, dass der Zugstab nicht verbogen oder gebrochen wird, wenn man etwas mit einer hohen Zugfestigkeit dehnt, muss man ihn an der richtigen Stelle anbringen und darauf achten, dass er die richtige Form hat. Sie müssen auch sicherstellen, dass der Zugstab und die Form die richtige Größe haben, damit Sie die Dinge richtig dehnen können.

Eine angemessene Wandstärke verringert die Wahrscheinlichkeit, dass sich Formteile verziehen.Wahr

Die gleichmäßige Wandstärke gewährleistet eine gleichmäßige Abkühlung und Erstarrung und minimiert Spannungen und Verformungen.

Alle Kunststoffformteile erfordern komplexe Rippendesigns, um funktional zu sein.Falsch

Je nach Anwendung und Belastungsanforderungen können einfache Konstruktionen oft auch ohne komplexe Verrippung funktionieren.

Wie sieht der Design- und Entwicklungsprozess von Kunststoffformteilen aus?

Der Entwurf und die Entwicklung von Kunststoffformteilen erfordert einen systematischen Ansatz, um Effizienz, Funktionalität und Qualität in der Produktion in verschiedenen Branchen zu gewährleisten.

Der Entwurfsprozess für Kunststoffformteile umfasst die Konzepterstellung, die Materialauswahl, den Formenbau, die Prototypenerstellung und die Prüfung, wobei der Schwerpunkt auf der Herstellbarkeit, der Kosteneffizienz und dem Erreichen bestimmter mechanischer Eigenschaften liegt.

Ermitteln Sie die Nachfrage

Zunächst müssen Sie wissen, wofür dieses Kunststoffteil gedacht ist. Ist es ein Spielzeugteil oder ein Teil für ein Auto? Wenn Sie wissen, wofür es bestimmt ist, wissen Sie auch, welche Leistungsanforderungen Sie erfüllen müssen. Muss es stark sein? Muss es verschleißfest sein? Muss es chemisch beständig sein? Und so weiter. Gleichzeitig müssen wir auch an die besonderen Anforderungen denken, die der Kunde oder der Markt an dieses Kunststoffteil stellt. Muss es gut aussehen? Muss es eine bestimmte Farbe haben? Muss es billig sein? Und so weiter.

Skizzieren beginnen

Auf der Grundlage dessen, was der Designer mir gesagt hat, würde ich ein einfaches Kunststoffteil auf Papier oder mit einer Computersoftware skizzieren. Ich würde die Form und die ungefähre Größe des Teils darstellen. Ich würde mir zu diesem Zeitpunkt keine Sorgen machen, zu genau zu sein. Ich möchte nur die allgemeine Idee vermitteln. Ich möchte sehen, ob es so aussieht, als ob es funktionieren würde. Zum Beispiel, ob es einige Stellen gibt, an denen die Form wirklich seltsam ist und sie nicht gemacht werden kann, oder ob die Größe nicht so aussieht, als würde sie für das, wofür sie verwendet werden soll, funktionieren.

Detaillierter Entwurf

Die Skizzen werden weiter verfeinert und das 3D-Modell des Kunststoffteils wird mit Hilfe von spezialisierte Konstruktionssoftware6 (z.B. CAD, ProE, usw.). In diesem Prozess müssen die spezifischen Abmessungen des Kunststoffteils, die Details der Form jedes Teils, die geeignete Wandstärke usw. festgelegt werden. Außerdem muss berücksichtigt werden, wie das Kunststoffteil mit anderen Teilen zusammenpasst, z. B. ob es mit Schraubenlöchern versehen oder mit anderen Teilen verbunden werden soll.

Gleichzeitig sollten Sie das richtige Kunststoffmaterial wählen. Verschiedene Kunststoffmaterialien haben unterschiedliche Eigenschaften. Manche sind sehr hart, manche sehr weich. Einige sind transparent, andere undurchsichtig. Wählen Sie entsprechend der Verwendung der Kunststoffteile und den Leistungsanforderungen.

Analysieren und Prüfen

Führen Sie eine Reihe von Tests mit den von Ihnen entworfenen Kunststoffteilen durch, um zu sehen, ob sie tatsächlich funktionieren. Verwenden Sie zum Beispiel eine ausgeklügelte Software, um festzustellen, ob sich das Kunststoffteil verbiegt oder bricht, wenn Sie darauf drücken, wie heiß es wird, wie gut der Kunststoff in die Form fließt usw. Wenn du Probleme feststellst, musst du zurückgehen und deinen Entwurf ändern, bis alle Tests gut ausfallen.

Herstellung der Form

Nachdem Sie ein Kunststoffteil entworfen haben, müssen Sie eine Form für die Massenproduktion herstellen. Der Werkzeugkonstrukteur entwirft die Struktur des Werkzeugs auf der Grundlage der Konstruktionszeichnung des Kunststoffteils, einschließlich des Formhohlraums (in dem das Kunststoffteil geformt wird), des Anschnitts (in den die Kunststoffschmelze eintritt), des Kühlsystems (damit der Kunststoff für die Formgebung schnell abkühlen kann) und so weiter. Dann suchen Sie eine Fabrik, die die Form auf der Grundlage der folgenden Kriterien bearbeitet und herstellt Formgestaltungszeichnung[^7]. Dieses Verfahren erfordert hohe Präzision, da sich die Qualität der Form direkt auf die Qualität des Kunststoffteils auswirkt.

Versuchsform

Wenn die Form fertig ist, wird sie zunächst auf der Spritzgießmaschine getestet. Man erhitzt das Kunststoffmaterial, schmilzt es, spritzt es mit der Spritzgießmaschine in den Formhohlraum und öffnet die Form, nachdem der Kunststoff abgekühlt und erstarrt ist, und entnimmt die Kunststoffteile.

Man prüft, ob die Kunststoffteile mit dem Entwurf übereinstimmen, ob es keine Fehler gibt, wie z. B. eine nicht glatte Oberfläche, Blasen, eine ungenaue Größe usw. Wenn es ein Problem gibt, müssen Sie die Form oder die Parameter des Einspritzverfahrens (wie Temperatur, Druck, Einspritzgeschwindigkeit usw.) anpassen, und dann versuchen Sie die Form erneut, bis Sie ein zufriedenstellendes Kunststoffteil herstellen.

Massenproduktion

Sobald Sie Ihre Form erfolgreich getestet haben, können Sie mit der Massenproduktion von Kunststoffteilen beginnen. Während der Produktion müssen Sie die Qualität der Produktion streng kontrollieren und regelmäßig die Größe, das Aussehen und die Leistung der Kunststoffteile überprüfen, um sicherzustellen, dass jedes Produkt den Anforderungen entspricht.

Qualitätskontrolle und -verbesserung

Qualitätsprüfungen sind für Kunststoffteile erforderlich. Verwenden Sie verschiedene Methoden (z. B. Messung der Abmessungen, Prüfung der Festigkeit, Prüfung des Aussehens usw.), um herauszufinden, welche Produkte nicht den Normen entsprechen. Achten Sie auch auf Rückmeldungen von Kunden und Probleme, die während der Produktion auftreten. Verbessern Sie das Design oder den Produktionsprozess für Kunststoffteile, damit die Qualität immer besser wird.

Die richtige Formgestaltung ist für die Qualität von Kunststoffteilen entscheidend.Wahr

Eine gut konzipierte Form gewährleistet Präzision, reduziert Fehler und verbessert die Wiederholbarkeit des Produktionsprozesses.

Alle Kunststoffformteile erfordern komplexe Formen.Falsch

Die Komplexität einer Form hängt von der Konstruktion und den Anforderungen an das Teil ab; für einfache Teile sind möglicherweise weniger komplizierte Formen erforderlich.

Was sind die wichtigsten Punkte bei der Gestaltung von Kunststoff-Formteilen?

Bei der Konstruktion von Kunststoffformteilen müssen Funktionalität, Herstellbarkeit, Materialauswahl und Kosteneffizienz in einem ausgewogenen Verhältnis zueinander stehen, um eine hochwertige Produktion und Leistung zu gewährleisten.

Die Konstruktion von Kunststoffformteilen erfordert ein Verständnis der Materialeigenschaften, die Sicherstellung der richtigen Wandstärke, die Berücksichtigung von Entformungswinkeln und die Planung der Herstellbarkeit zur Verbesserung der Produktleistung, Haltbarkeit und Kosteneffizienz.

Loch

Die Löcher sollten so einfach wie möglich sein, im Allgemeinen rund. Das Loch sollte in der gleichen Richtung wie die Formöffnungsrichtung liegen, um ein Ziehen des Kerns zu vermeiden. Wenn das Verhältnis von Länge zu Durchmesser des Lochs größer als 2 ist, sollte die Entformungsschräge eingestellt werden.

Zu diesem Zeitpunkt sollte der Durchmesser des Lochs anhand des kleinen Durchmessers (der größten Festkörpergröße) berechnet werden. Das L/D-Verhältnis von Sacklöchern beträgt im Allgemeinen nicht mehr als 4. Der Abstand zwischen dem Loch und dem Rand des Produkts ist im Allgemeinen größer als die Lochgröße.

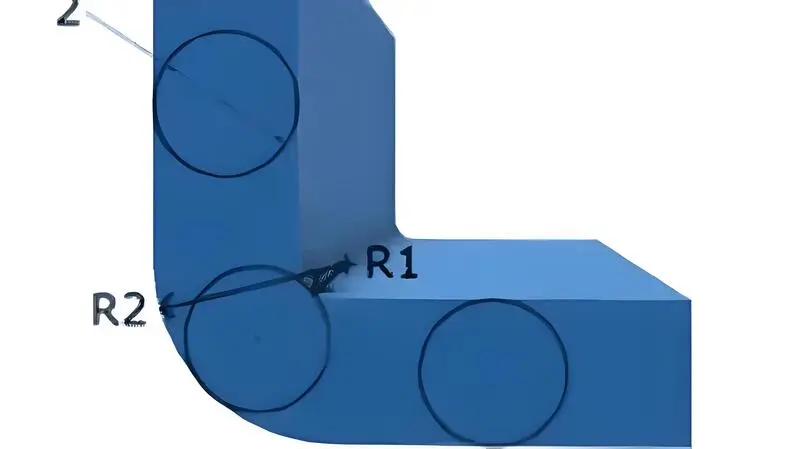

Abgerundete Ecken

Wenn die abgerundeten Ecken zu klein sind, kann das Produkt aufgrund von Spannungskonzentration reißen. Wenn die abgerundeten Ecken zu klein sind, kann der Formhohlraum aufgrund der Spannungskonzentration reißen. Die Einstellung einer angemessenen abgerundeten Ecke kann auch die

Verschiedene abgerundete Ecken können zu einer Verschiebung der Trennlinien führen, so dass verschiedene abgerundete oder gereinigte Ecken in Abhängigkeit von der tatsächlichen Situation ausgewählt werden sollten. Kennzeichnung

Produktkennzeichnung ist in der Regel auf der inneren Oberfläche des Produkts ist relativ flach, und die erhabene Form, wählen Sie die normale Richtung und die Formung Richtung Lineal kann im Einklang mit dem Gesicht der Kennzeichnung, können Sie vermeiden, Strapazen.

Präzision von Spritzgussteilen; aufgrund der ungleichmäßigen und unsicheren Schrumpfung während des Spritzgießens ist die Präzision von Spritzgussteilen natürlich geringer als die von Metallteilen, und die entsprechenden Toleranzanforderungen sollten in Übereinstimmung mit der Norm (OSJ1372-1978) gewählt werden.

Einsätze

Man kann Einsätze in Spritzgussteile einbauen, um sie stärker, härter und genauer zu machen und um kleine Gewindelöcher (Vorsprünge) in sie einzubringen, aus welchem Grund auch immer. Dadurch wird das Teil auch teurer. Einsätze bestehen in der Regel aus Messing, können aber auch aus anderen Metallen oder Kunststoff hergestellt werden. Einsätze, die in das Kunststoffteil eingegossen werden, sollten so gestaltet sein, dass sie sich nicht drehen oder herausziehen lassen.

Zum Beispiel: Rändelungen, Löcher, Hinterschneidungen, Abflachungen, Schultern, usw. Einsätze, die um den Kunststoff herum liegen, sollten dicker sein, damit der Kunststoff nicht bricht. Wenn Sie einen Einsatz entwerfen, müssen Sie überlegen, wie er in der Form gehalten wird (Löcher, Stifte, Magnete usw.).

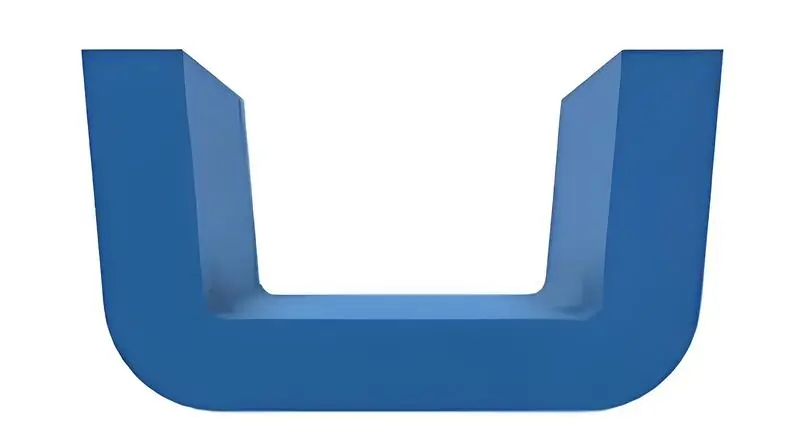

Formtrennung Neigung

Eine gute Entformungsneigung kann das Ziehen der Produkthaare verhindern. Die Neigung der Form sollte mehr als 0,5 Grad für glatte Oberflächen, mehr als 1 Grad für fein strukturierte Oberflächen und mehr als 1,5 Grad für grob strukturierte Oberflächen betragen. Eine gute Entformungsneigung kann die Verletzung der Produktoberseite vermeiden.

Beim Entwurf von Produkten mit tiefer Hohlraumstruktur sollte die Neigung der Außenfläche geringer sein als die Neigung der Innenfläche, um sicherzustellen, dass der Kern der Form beim Spritzgießen nicht abweicht, um eine gleichmäßige Wandstärke des Produkts zu erhalten und um die Festigkeit der Materialdichte des offenen Teils des Produkts zu gewährleisten.

Wanddicke

Verschiedene Kunststoffe haben eine bestimmte Wandstärke, im Allgemeinen 0,5 bis 4 mm. Wenn die Wandstärke mehr als 4 mm beträgt, kommt es zu einer übermäßigen Abkühlungszeit, was zu Schrumpfung und anderen Problemen führt. Sie sollten eine Änderung der Produktstruktur in Betracht ziehen. Ungleiche Wandstärken führen zu Oberflächeneindrücken. Ungleiche Wandstärken führen zu Luftlöchern und Schmelzspuren.

Verstärkung

Die richtige Verwendung von Verstärkungen kann das Produkt steifer machen und Verformungen verringern. Die Dicke der Bewehrung sollte weniger als 1/3 der Wanddicke des Produkts betragen, da es sonst zu Oberflächeneindrücken kommt. Die Neigung einer Seite des Bewehrungsstabs sollte mehr als 1,5° betragen, um Verletzungen von oben zu vermeiden.

Einteiliges Scharnier

Durch die Nutzung der Zähigkeit des PP-Materials kann das Scharnier so gestaltet werden, dass es in das Produkt integriert werden kann. Die Größe der als Scharnier verwendeten Folie sollte weniger als 0,5 mm betragen und gleichmäßig gehalten werden. Beim Spritzgießen eines einteiligen Scharniers kann der Anschnitt nur auf einer Seite des Scharniers gestaltet werden.

Spritzgießen mit Gasdruckunterstützung

Durch gasunterstütztes Spritzgießen können Produkte steifer werden und sich weniger verformen. Durch das gasunterstützte Spritzgießen kann die Schwindung verhindert werden. Die Verwendung von gasunterstütztes Spritzgießen7 können Rohstoffe eingespart und die Kühlzeit verkürzt werden.

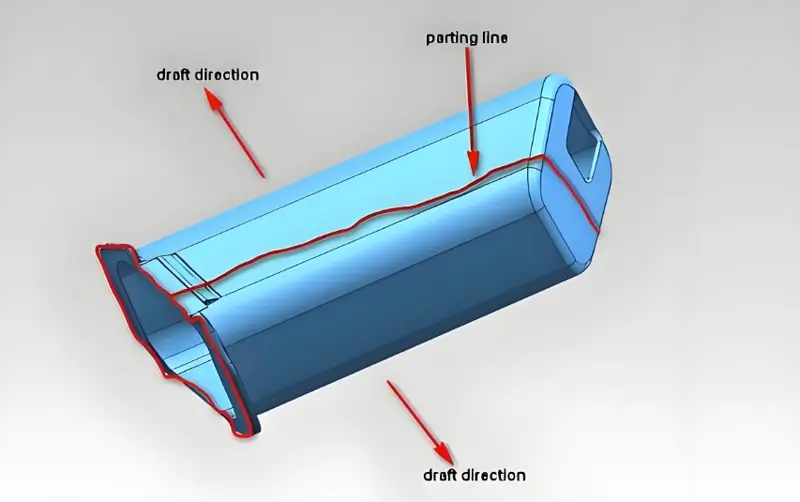

Richtung der Formöffnung und Trennebene

Bei der Konstruktion eines Spritzgussprodukts sollten die Öffnungsrichtung der Form und die Trennebene bereits zu Beginn des Konstruktionsprozesses festgelegt werden. Dies trägt dazu bei, den Bedarf an komplexen Kernzugmechanismen zu minimieren und negative Auswirkungen der Trennlinie auf das Aussehen des Produkts zu vermeiden.

Sobald Sie wissen, in welche Richtung sich die Form öffnet, können Sie die Verstärkungen, Klammern, Rippen und anderen Merkmale so gestalten, dass sie so weit wie möglich mit der Öffnungsrichtung der Form übereinstimmen. So können Sie Hinterschneidungen vermeiden, Stricklinien reduzieren und die Lebensdauer der Form verlängern. Wenn sich die Form für das Teil beispielsweise in X-Richtung öffnet und Sie ein Merkmal konstruieren, das sich in Y-Richtung öffnet, müssen Sie dies in der Zeichnung vermerken. Sobald Sie wissen, in welche Richtung sich die Form öffnet, können Sie die beste Trennlinie wählen, damit das Teil optimal aussieht und funktioniert.

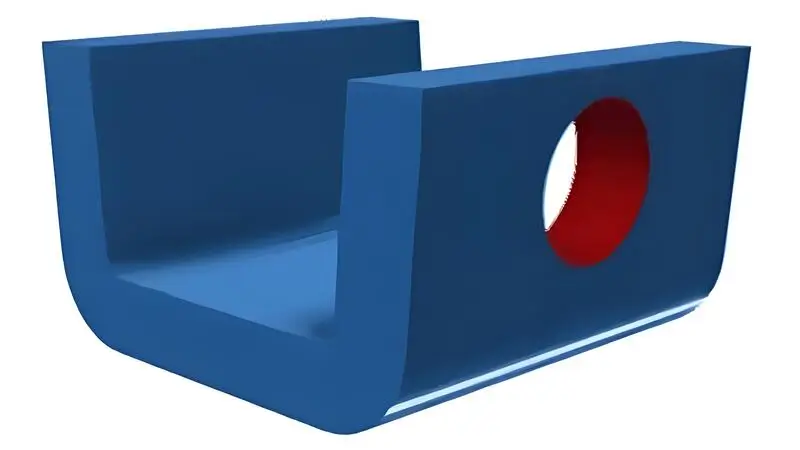

Mechanismus der Kernentnahme aus der Spritzgussform und deren Vermeidung

Wenn das Formteil nicht reibungslos entsprechend der Formrichtung entformt werden kann, muss die Kernziehverfahren8 sollte entworfen werden. Der Kern Ziehen Mechanismus kann Form komplexe Produkt-Struktur, aber es ist leicht zu verursachen Produkt Naht, Schrumpfung und andere Mängel, und erhöhen die Kosten für die Form, um die Lebensdauer der Form zu verkürzen.

Design von Spritzguss-Produkten, wie keine besonderen Anforderungen, versuchen, den Kern Struktur zu vermeiden. Wie die Richtung des Lochs axiale und Sehne, um die Richtung der Form, die Verwendung von Hohlraum Kern berühren durch und andere Methoden.

Schweißen (Heizelementschweißen, Ultraschallschweißen, Vibrationsschweißen)

Schweißen macht Verbindungen stärker. Schweißen kann das Produktdesign erleichtern.

Angemessene Berücksichtigung des Widerspruchs zwischen Prozess- und Produktleistung

Bei der Entwicklung spritzgegossener Produkte muss man sich Gedanken darüber machen, wie das Produkt aussieht, wie es funktioniert und wie es hergestellt wird. Manchmal muss man ein wenig von der Herstellung aufgeben, um ein wirklich gutes Aussehen oder eine wirklich gute Leistung zu erhalten.

Die richtige Wandstärke verhindert Verzug und Einfallstellen in Formteilen.Wahr

Eine gleichmäßige Wandstärke sorgt für eine gleichmäßige Abkühlung und reduziert Defekte wie Verzug und Einfallstellen.

Alle aus Kunststoff geformten Teile erfordern komplexe Konstruktionen, um effektiv zu sein.Falsch

Auch einfache Entwürfe können sehr effektiv sein; die Komplexität hängt von den spezifischen Produktanforderungen und der beabsichtigten Funktionalität ab.

Was sind die häufigsten Fehler bei der Konstruktion von Kunststoff-Formteilen?

Bei der Konstruktion von Kunststoffformteilen muss man auf Details achten, um Fehler zu vermeiden, die sich auf die Funktionalität und Herstellbarkeit auswirken können.

Zu den häufigen Konstruktionsfehlern beim Kunststoffspritzgießen gehören unzureichende Wandstärken, schlechte Entformungswinkel und das Ignorieren des Materialflusses, was zu Defekten, höheren Kosten und geringerer Leistung führt.

Die Wahl des falschen Materials

Ein weiterer Fehler, den viele machen, ist die Wahl des richtigen Materials. Man sollte das Material danach auswählen, wo das Teil eingesetzt werden soll. Wenn es im Freien verwendet wird, muss es mit UV-Stabilisatoren versehen werden, damit es nicht bricht. Wenn es sich um ein tragendes Teil handelt, muss es mit Füllstoffen wie Glasfasern gefüllt werden, damit es stabiler wird. Wenn es sich um ein Teil handelt, das auf etwas gleiten soll, müssen Sie ihm Zusatzstoffe wie Schmiermittel zufügen.

Ungleiche Wanddicke

Unterschiedliche Wandquerschnitte sind bei der Konstruktion von Teilen üblich und können beim Gießen zu unerwarteten Teileigenschaften führen. Für Kunststoffe ist es schwierig, zwischen ungleichen Wandstärken zu fließen und überzugehen.

Dicke Wandquerschnitte führen zu unterschiedlicher Schrumpfung, was zu einem Verzug des Teils führen kann. Versuchen Sie, die Wandstärken zumindest im Anschnittbereich dicker und am Ende der Füllung dünner zu machen. Streben Sie eine Wandstärke von 0,080-0,120 Zoll an und verwenden Sie Rippen- und Winkelverstrebungsplatten bei der Teilekonstruktion.

Keine Hinzufügung der Formzugneigung

Sie benötigen einen Auszugskonus in Ihrer Form, um das Kunststoffteil aus der Form zu bekommen. Der Kunststoff schrumpft normalerweise zur Mitte des Teils hin. Wenn Sie keinen Auszugskonus haben, bleibt das Teil in der Form hängen und kommt nicht richtig heraus. Wenn möglich, setzen Sie auf jeder Seite einen Entnahmekegel von 1° ein. Jede Entformungsschräge hilft, das Teil herauszubekommen.

Unnötige Depressionen

Aufgrund der Komplexität der heutigen Teilekonstruktionen werden Vertiefungen zwar vorgesehen, aber oft übersehen. Vertiefungen in der Form müssen behoben werden, bevor das Teil freigegeben wird, da es sonst beschädigt wird. Es gibt viele Möglichkeiten, Vertiefungen bei der Handhabung von Formen durch Kerndesign, Schieber, Kerne oder Heber zu behandeln. Eine einfache Regel für die Konstruktion: Dellen + komplexe Formen = höhere Kosten.

Ausgenommen Filetierradien

Bei der Konstruktion von Teilen werden Verrundungsradien oft vergessen. Aber sie sind wichtig, denn sie machen das Teil stabiler. Ein Radius reduziert Spannungskonzentrationen und Brüche in Kunststoffteilen. Außerdem sieht das Teil dadurch besser aus und verringert die Verletzungsgefahr bei der Handhabung.

Richtige Entformungswinkel verbessern die Entformung von Formteilen aus der Form.Wahr

Die Entformungsschrägen ermöglichen ein beschädigungsfreies Auswerfen der Formteile und gewährleisten eine reibungslose und effiziente Produktion.

Dickere Wände sind bei Kunststoffformteilen immer besser.Falsch

Dicke Wände können zwar die Festigkeit erhöhen, aber auch zu Komplikationen wie Verformung und erhöhtem Materialverbrauch führen, daher ist Ausgewogenheit wichtig.

Schlussfolgerung

Bei der Gestaltung von Kunststoffformteilen müssen sowohl die Struktur als auch die Abmessungen berücksichtigt werden. Bei der Struktur muss man sich Gedanken über die Größe der Form machen, wie man die Teile trennt, wie man die Form kühlt, wie man die Luft aus der Form herausbekommt und wie man den Kunststoff in die Form bringt. All diese Dinge sind wichtig, um sicherzustellen, dass das Teil effizient geformt werden kann und dass es gut ist.

Wenn es um die Abmessungen geht, müssen Sie sich Gedanken über die Wandstärke9wie viel Kraft Sie aufwenden werden, um die Form zusammenzuspannen, wie Sie die Teile zum Gleiten bringen und wie Sie sicherstellen, dass das Teil nicht zerbricht. All diese Dinge sind wichtig, um sicherzustellen, dass das Teil nicht verformt wird und dass es gut ist.

Der Entwurfsprozess umfasst die Bedarfsanalyse, die Skizze, den detaillierten Entwurf, den Formenbau, die Formprüfung und die Massenproduktion, wobei der Schwerpunkt auf der Qualitätsprüfung und -verbesserung liegt. Zu den häufigen Konstruktionsfehlern gehören unangemessene Materialauswahl, ungleiche Wandstärken, fehlende Ziehschrägen usw., die vermieden werden sollten, um die Kosten zu senken und die Qualität der fertigen Produkte zu verbessern.

-

Wenn Sie die verschiedenen Methoden der Formteilung kennen, können Sie Ihre Konstruktionseffizienz und Produktqualität verbessern. ↩

-

Die Untersuchung der Auswirkungen von Kühlsystemen kann Ihnen helfen, die Produktionseffizienz und Produktqualität zu optimieren. ↩

-

Das Wissen über die Auslegung der Schließkraft ist entscheidend für eine effektive Formtrennung und die Langlebigkeit der Geräte. ↩

-

Die Kenntnis bewährter Verfahren bei der Konstruktion von Gleitteilen kann die Funktionalität und Haltbarkeit Ihrer Kunststoffteile verbessern. ↩

-

Die Erforschung wirksamer Strategien für die Zugfestigkeit kann Ausfälle verhindern und die Leistung Ihrer Kunststoffteile unter Belastung verbessern. ↩

-

Mit der besten Konstruktionssoftware können Sie Ihren Konstruktionsprozess optimieren und die Genauigkeit bei der Erstellung von Kunststoffteilen verbessern. ↩

-

Gasunterstütztes Spritzgießen kann die Produktqualität verbessern und die Kosten senken. Entdecken Sie die Vorteile, um Ihren Herstellungsprozess zu optimieren. ↩

-

Lernen Sie die Mechanismen der Kernentnahme kennen, um häufige Fallstricke bei der Werkzeugkonstruktion zu vermeiden und die Produktionseffizienz zu verbessern. Dieses Wissen ist entscheidend für den Erfolg. ↩

-

Erfahren Sie alles, was Sie über das Dünnwandspritzgießverfahren wissen müssen: Dünnwandspritzgießen ist ein Verfahren zur Herstellung dünner Kunststoffteile. ↩