– A neutral 3D CAD file (STEP or IGES format) is mandatory for calculating part volume, weight, and cycle time accurately.

– 2D technical drawings are essential for specifying critical tolerances (GD&T) and surface finishes (SPI standards) that 3D models cannot convey.

– Clearly defining Estimated Annual Usage (EAU) allows the molder to recommend the correct mold classification (e.g., Class 101 vs. Class 103).

– Providing specific resin grades rather than generic descriptions prevents costly requoting delays and ensures material availability.

What Is a Technical Injection Molding RFQ?

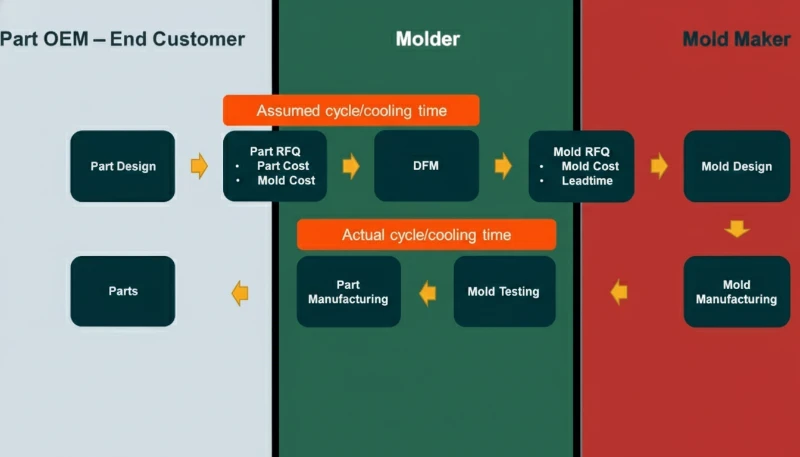

A Request for Quotation (RFQ) in the context of custom plastics is a comprehensive technical package containing all necessary data to calculate the cost of the injection mold (tooling) and the unit price of the manufactured part.

Unlike off-the-shelf procurement, sourcing custom plastics requires calculating physics-based variables—cycle time, cooling rates, and material shrinkage—which can only be derived from precise design files and material specifications. A complete RFQ minimizes risk, ensures the quote is actionable, and drastically reduces the lead time for getting accurate molding quotes1.

A 2D PDF drawing is sufficient for a manufacturer to build a custom injection mold.Ложь

2D drawings miss the complex 3D geometry required for CNC programming and volume calculations. A 3D CAD file (STEP) is mandatory for tooling design.

Providing 3D CAD files in STEP format ensures compatibility across all molding software platforms.Правда

STEP (Standard for the Exchange of Product model data) is the universal ISO standard that eliminates translation errors common with native file formats like SolidWorks or CATIA.

What Are the Essential Data Requirements for an RFQ?

To create a robust injection molding RFQ template2, the following data points must be included. Missing data forces the manufacturer to make assumptions, which leads to "padding" pricing to cover risk or outright "no-quote" decisions.

RFQ Data Checklist

| Category | Data Point | Technical Requirement / Standard | Why It Is Critical |

|---|---|---|---|

| Geometry | 3D CAD File | .STEP (ISO 10303) or .IGES | Used to calculate part weight, projected area (clamping force), and runner system design. |

| Допуски | 2D Drawing | .PDF (ASME Y14.5 / ISO 1101) | Defines critical dimensions, GD&T, and inspection requirements that affect tooling cost. |

| Материал | Resin Spec | Specific Grade (e.g., Sabic Cycolac MG47) | "Black Plastic" is insufficient. Density and flow rate determine shrink factor and cost. |

| Finish | Отделка поверхности | SPI (A-1 to D-3) or VDI 3400 | High polish (SPI A-2) requires harder steel and more labor than a textured finish (SPI C-1). |

| Объем | EAU / Life | Units per year / Total Tool Life | Determines mold cavitation (1-cavity vs 4-cavity) and steel hardness selection. |

What Is the Step-by-Step Process for Submitting an RFQ?

Following this workflow ensures you cover all STEP file requirements and commercial details necessary for a binding offer.

Step 1: Execute a Non-Disclosure Agreement (NDA)3

Before sharing proprietary designs, establish intellectual property protection. Most reputable molders have a standard mutual NDA.

Step 2: Finalize the Проектирование для обеспечения технологичности (DFM)4

Ensure your CAD files are "frozen." If the design is still changing, mark the RFQ as "Budgetary Estimate Only." Changes after the quote usually require a re-quote.

- Action: Export your native CAD (SolidWorks, Creo) to STEP (.stp) format.

Step 3: Define the Material Strategy

Avoid generic terms like "ABS" or "Polypropylene."

- Primary Choice: Specify the exact manufacturer and grade (e.g., Covestro Makrolon 2407 PC).

- Allowable Substitutes: State if "Generic equivalents allowed" to potentially lower costs using local stock.

Step 4: Specify Quantity and Tooling Class

The mold cost is directly tied to the expected life of the tool. Use SPI Mold Classifications5 as a guide:

- SPI Class 101: >1 Million cycles (Hardened Steel, high cost, long life).

- SPI Class 103: <500k cycles (Pre-hardened Steel, moderate cost).

- Prototype: <5k cycles (Aluminum, low cost).

Step 5: Submit the Package

Include the BOM (Bill of Materials) if the project involves assembly or overmolding.

Designating a 'generic' material allows molders to source cheaper, readily available alternatives.Правда

If specific material properties aren't critical, allowing 'utility grade' or 'generic' resins can significantly reduce unit costs and lead times.

Requesting a 'mirror finish' on all surfaces is a cost-effective way to improve part aesthetics.Ложь

High-gloss finishes require expensive manual hand-polishing of the mold steel and often highlight surface defects like sink marks; they should be used selectively.

How Does RFQ Completeness Impact the Quote?

The quality of the request for quote plastic parts directly correlates to the speed and accuracy of the response.

| Характеристика | Detailed/Complete RFQ | Incomplete/Vague RFQ |

|---|---|---|

| Quote Turnaround | 24 – 48 Hours | 1 – 2 Weeks (due to Q&A loop) |

| Pricing Accuracy | Высокий (Fixed Price) | Низкий (Subject to change) |

| Tooling Design | Optimized for specific material shrink rates. | Risk of dimension errors if material changes later. |

| Supplier Confidence | High; signals a serious buyer. | Low; signals an unprepared buyer or "price fishing." |

When Should You Use This RFQ Structure?

This rigorous approach is applicable in various sourcing scenarios:

- New Product Introduction (NPI): When moving from 3D printed prototypes to the first steel tool.

- Tool Transfer: When moving existing molds to a new supplier (requires additional data on current mold condition).

- Benchmarking: When validating current supplier pricing against the market.

- Cost Reduction Analysis: When asking suppliers to propose design changes to lower unit costs.

Часто задаваемые вопросы (FAQ)

Q: Why do manufacturers insist on STEP files instead of STL files?

A: STL (Stereolithography) files are mesh-based, composed of triangles used for 3D printing. They lack precise geometric surfaces and curves. STEP file requirements are strict because STEP files use vector mathematics (NURBS), allowing for precise CNC machining paths and volume calculations.

Q: What if I don’t know exactly which plastic material to use?

A: In your RFQ, describe the application environment instead. List requirements such as: "Must withstand 100°C," "Must be UV resistant," or "Must be clear." The molder can then recommend a material.

Q: How does the Estimated Annual Usage (EAU)6 affect the mold cost?

A: EAU dictates the "cavitation" of the mold. If you need 100,000 parts/year, a single-cavity mold is too slow; a 4-cavity mold is needed. A 4-cavity mold costs roughly 2-3 times more than a single-cavity mold but produces parts at a much lower unit price.

Q: Can I get a quote with just a physical sample part?

A: Generally, no. While some shops offer reverse engineering, most require a CAD file to quote. Creating CAD from a physical part is a separate service usually charged by the hour.

Q: What is the difference between a "Budgetary Quote" and a "Firm Quote"?

A: A budgetary quote is a rough estimate (+/- 20%) used for feasibility studies. A firm quote is a binding contract offer. A firm quote requires finalized design files and locked material specifications.

Резюме

Preparing a perfect injection molding RFQ is about removing ambiguity. By providing a clean 3D STEP file, a 2D drawing with defined tolerances, specific material grades, and clear volume expectations, you enable manufacturers to calculate costs accurately. This preparation transforms the interaction from a guessing game into a strategic partnership, ensuring you receive optimized pricing and reliable lead times for your custom plastic projects.

-

Discover the key elements that influence quote accuracy to ensure better pricing and timelines. ↩

-

A comprehensive RFQ template can streamline your procurement process and improve quote accuracy. ↩

-

Protecting your designs with an NDA is crucial for maintaining intellectual property security. ↩

-

DFM ensures your designs are optimized for production, reducing costs and lead times. ↩

-

Learn about SPI classifications to choose the right mold for your production needs. ↩

-

Learn how EAU influences mold design and cost, helping you make informed decisions. ↩