– Preventative maintenance protocols are essential for sustaining Class A tooling beyond 1 million cycles.

– Cleaning mold vents regularly prevents diesel effect burns and short shots.

– Preventing mold corrosion requires strict moisture control and appropriate neutralizing agents.

– Strategic tool life management reduces unplanned downtime and amortizes tooling costs effectively.

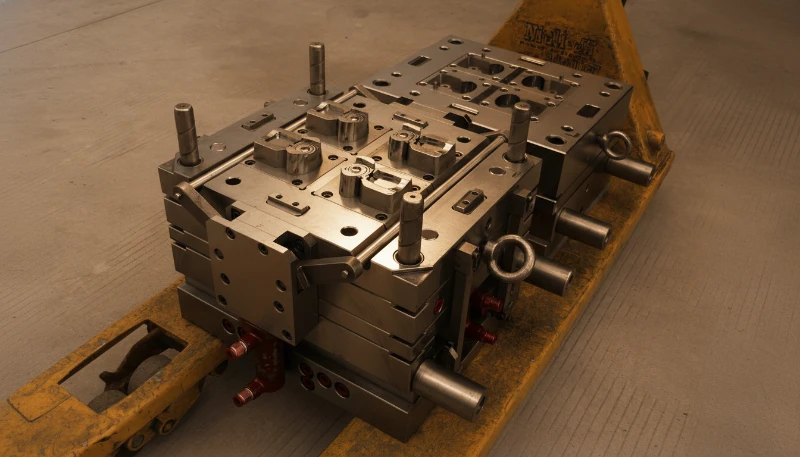

What is Class A Tooling and Why is Maintenance Critical?

In the context of injection molding, Class A Tooling1 (often referring to SPI Class 101 molds as defined by the Society of the Plastics Industry) represents the highest standard of mold construction. These molds are built with hardened tool steels—such as H13 or S7—and are designed for extremely high production volumes, typically exceeding one million cycles.

Maintenance is not merely about cleaning; it is a holistic strategy to preserve tight tolerances (often within ±0.005 mm) and surface finishes. Neglecting maintenance leads to flash, part rejection, and catastrophic tool failure. Effective tool life management ensures that the high initial capital investment yields the expected Return on Investment (ROI) by maximizing machine uptime and part consistency.

What Parameters Define an Effective Maintenance Schedule?

To implement a robust injection mold maintenance checklist2, operators and maintenance teams must adhere to a schedule based on cycle counts rather than calendar dates. The following table outlines standard parameters for high-volume production.

| Maintenance Level | Cycle Count / Trigger | Key Actions | Responsibility |

|---|---|---|---|

| Level 1 (Running) | Every Shift / Daily | Visually inspect for flash; clear vents; check water flow; apply spray rust inhibitor if stopping. | Machine Operator |

| Level 2 (Preventative) | 20,000 – 50,000 cycles | Clean parting lines; lubricate ejector pins; inspect gates for wear; check low-pressure close protection3. | Mold Technician |

| Level 3 (Inspection) | 100,000 cycles | Disassemble minor components; replace seals/O-rings; ultrasonic clean inserts; check hot runner electricals. | Toolroom Engineer |

| Level 4 (Major) | 250,000 – 500,000 cycles | Full disassembly; verify dimensional accuracy of cores/cavities; replace worn bushings/pins; polish surfaces. | Senior Toolmaker |

Regular cleaning of mold vents is required before visible defects like burns appear to maintain gas escape efficiency.Правда

Vents can become partially clogged with resin residue and volatiles long before visible burn marks occur, altering cavity pressure.

You should wait until parts show flash or defects before performing any mold maintenance.Ложь

Reactive maintenance leads to accelerated tool wear and unscheduled downtime; preventative maintenance is required to stop defects from happening.

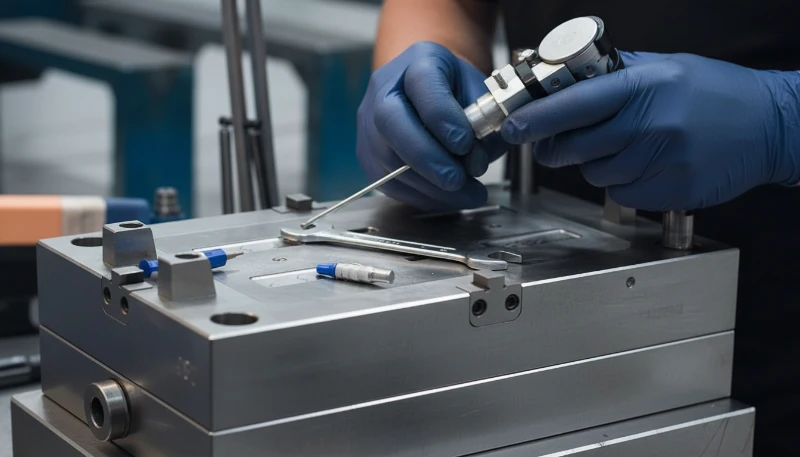

How Should the Injection Mold Maintenance Checklist Be Executed?

A systematic approach to maintenance ensures no critical component is overlooked. The following process guide details the execution of a standard Level 2 or 3 maintenance routine.

1. Initial Inspection and Last-Shot Analysis

Before disassembly, examine the "last shot" (the final part produced before the mold was pulled). Look for flash, drag marks, or texture inconsistencies. This guides the technician on where to focus.

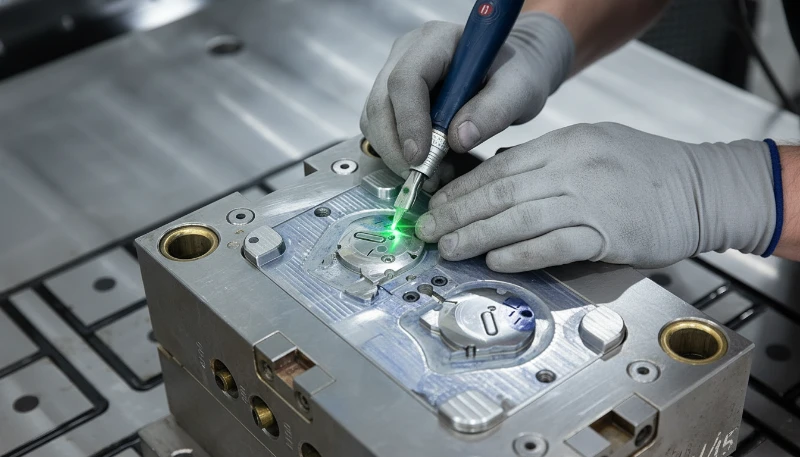

2. Cleaning Mold Vents

Cleaning mold vents is arguably the most critical step for part quality. Clogged vents trap air, leading to the "diesel effect" (gas traps burning the material) and short shots.

- Method: Use a mild solvent (e.g., isopropyl alcohol) and non-abrasive brass tools or ultrasonic cleaning.

- Caution: Never use steel tools on vent depths, which are typically 0.01–0.03 mm deep. Scratches here will cause flash.

3. Lubrication of Moving Components

Apply high-temperature lithium-based grease or dry lubricants (like PTFE) to leader pins, bushings, and ejector pins.

- Примечание: Avoid over-greasing. Excess grease can migrate into the cavity, contaminating parts, especially in medical or optical applications.

4. Water Line Maintenance

Inspect cooling channels for scale buildup or blockages. Scale reduces heat transfer efficiency, increasing cycle times.

- Action: Flow test circuits. If flow is restricted, use an acid flush or descaling agent compatible with the mold base material.

5. Preventing Mold Corrosion

Corrosion is the enemy of Class A surfaces. It occurs due to condensation, water leaks, or volatile gases released by materials like Polyvinyl Chloride (PVC) or Flame Retardant (FR) additives.

- Action: Neutralize surface acids immediately after the run. Apply a heavy-duty mold saver (rust inhibitor) for storage. For running production, ensure mold temperature is above the dew point to prevent "mold sweating."

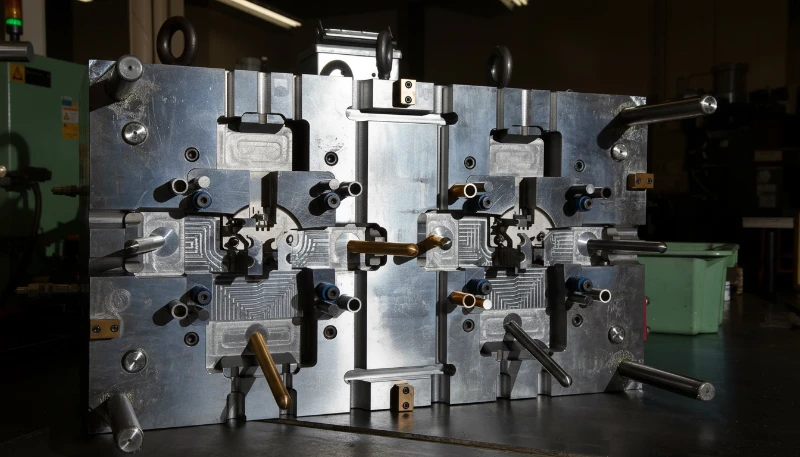

What Are the Advantages and Disadvantages of In-House vs. Outsourced Maintenance?

Deciding whether to handle maintenance internally or utilize external mold repair services depends on the complexity of the repair and available resources.

| Характеристика | In-House Maintenance | Outsourced Mold Repair Services |

|---|---|---|

| Время выполнения заказа | Fast (Hours to Days). Minimal logistics delay. | Slower (Days to Weeks). Includes shipping time. |

| Стоимость | Lower operational cost (labor overhead). | Higher per-incident cost, but eliminates machinery CapEx. |

| Expertise Required | Requires skilled technicians and basic equipment (polishing, spotting). | Access to specialized equipment (Laser welding, 5-axis CNC). |

| Scope | Best for cleaning, minor polishing, seal replacement. | Best for major dimensional restoration, texturing, or fractures. |

| Risk | Risk of improper repair if staff is untrained. | Vendor quality risk; requires vetting reliable partners. |

What Practical Tips Optimize Tool Life Management?

To extend the life of the mold beyond the standard warranty, consider these expert insights:

- Monitor Tonnage: Do not use maximum clamp force unless necessary. Running a 200-ton mold in a 400-ton press at full pressure compresses vents and fatigues the parting line. Use the minimum tonnage required to seal the mold (calculated as Projected Area × Injection Pressure).

- Soft Start/Stop: When shutting down, purge the barrel to remove corrosive resins (like Acetal/POM). When starting up, allow the mold to reach thermal equilibrium before cycling at high speeds.

- Low-Pressure Close Protection: Set the machine’s low-pressure close strictly. It should be just enough to overcome friction. This prevents the mold from smashing properly if a part is stuck in the cavity.

Applying a specific acid-neutralizer is necessary when molding PVC or POM to prevent gas-induced pitting.Правда

These materials release hydrochloric or formaldehyde gases that chemically attack steel surfaces, requiring neutralization before rust inhibitors are applied.

Stainless steel molds are completely immune to corrosion and require no rust preventative measures.Ложь

While resistant, stainless steel (like 420SS) can still corrode under harsh conditions or due to galvanic corrosion; protective coatings are still recommended for long-term storage.

Where is Rigorous Mold Maintenance Most Critical?

While all molds require care, specific applications demand stricter adherence to tool life maintenance protocols due to the cost of failure.

- Medical Device Manufacturing: Molds often run in cleanrooms. Grease contamination or particulate matter from wear is unacceptable. Dry lubricants and coating technologies (like DLC – Diamond-Like Carbon) are frequently monitored.

- Automotive Lighting (Lens Molding): Any scratch or haze on the cavity surface transfers to the lens, affecting light transmission. Cleaning mold vents must be done without touching the optical surfaces.

- Thin-Wall Packaging: High injection speeds and pressures create immense stress. Fatigue failure is common, necessitating frequent Magnaflux (magnetic particle inspection) to detect micro-cracks.

How Do We Troubleshoot Common Wear Issues?

When defects arise, use this stepwise recommendation guide to address the root cause via maintenance.

- Выпуск: Flash appearing on the parting line.

- Maintenance Step: Check parting line integrity. Look for hobbing (indentations) caused by closing on debris. If minor, stone the high spots. If major, send for mold repair services to weld and re-grind.

- Выпуск: Ejector Pin Marks or "Push Through."

- Maintenance Step: Inspect pins for galling. Measure pin length; they may have stretched or the return springs may be fatigued, preventing full retraction.

- Выпуск: Water Leaks.

- Maintenance Step: Replace all O-rings during Level 3 maintenance. Check O-ring grooves for corrosion or burrs that might cut the new seal.

Laser welding is an effective method for repairing minor parting line damage without distorting the surrounding steel.Правда

Laser welding introduces minimal heat into the tool steel (small Heat Affected Zone), preserving the hardness and dimensions of the surrounding area.

Grinding down the entire parting line is the first solution for eliminating flash.Ложь

Grinding the parting line changes the mold's stack height and cavity depth; it is a drastic measure that requires comprehensive dimensional adjustments.

Часто задаваемые вопросы (FAQ)

Q1: How often should I perform "cleaning mold vents4"?

A: It depends on the material. For clean materials like Polypropylene (PP), every 20,000 cycles may suffice. For waxy or additive-heavy materials (like ABS with flame retardants), vents may need cleaning every shift (approx. 2,000–5,000 cycles).

Q2: What is the best way to remove rust without damaging the surface finish?

A: Use chemical rust removers specifically designed for tool steel, applied with a soft cloth. For textured surfaces, electrolytic cleaning or dry ice blasting are non-abrasive methods that preserve the texture depth.

Q3: When should I utilize third-party mold repair services?

A: Outsourcing is recommended when the repair involves welding critical shut-off surfaces, restoring complex textures, or when the dimensional restoration requires equipment not available in-house (e.g., large surface grinders or EDM machines).

Q4: How does "preventing mold corrosion" impact cycle time?

A: Indirectly, it improves it. Corrosion in cooling channels creates an insulating layer of rust/scale (fouling), which reduces heat transfer. This requires longer cooling times to solidify the part. Keeping channels clean maintains optimal cycle speeds.

Q5: What is the difference between reactive and predictive maintenance?

A: Reactive maintenance fixes the mold after it breaks (high cost, high downtime). Predictive maintenance uses sensors (e.g., monitoring cycle time drift or ejection force) to perform maintenance before a failure occurs, which is the core of modern tool life management5.

Резюме

Extending the lifespan of Class A tooling requires a shift from reactive repairs to proactive tool life management. By adhering to a strict injection mold maintenance checklist, rigorously cleaning mold vents, и preventing mold corrosion, manufacturers can ensure part quality remains consistent over millions of cycles. Whether performed in-house or via specialized mold repair services, maintenance is the safeguard of your production efficiency and profitability.

-

Understanding Class A Tooling is crucial for anyone involved in high-quality mold production. ↩

-

A comprehensive checklist can help ensure no critical maintenance steps are overlooked. ↩

-

Understanding this feature can help prevent mold damage and improve production reliability. ↩

-

Learn the best practices for cleaning mold vents to prevent defects and ensure quality. ↩

-

Gain insights into tool life management strategies that maximize efficiency and reduce costs. ↩