Understanding the different types of plastic molding is essential for selecting the right process for your manufacturing needs, impacting product quality and production efficiency.

Common types of plastic molding include injection molding, blow molding, rotational molding, and thermoforming. Each method has unique advantages and applications: injection molding offers precision and high-volume production; blow molding is ideal for hollow objects; rotational molding allows for large, uniform parts; and thermoforming is suitable for thin sheets. Key benefits include flexibility in design, reduced waste, and cost-effectiveness.

While this summary provides an overview of plastic molding techniques, exploring each method’s specific applications and advantages will help you make informed manufacturing decisions.

Injection molding is the most widely used plastic molding method.True

Injection molding accounts for the majority of plastic parts produced due to its versatility and efficiency in high-volume production.

Rotational molding is suitable for producing small, complex shapes.False

Rotational molding is typically used for large, hollow parts, not for small or complex shapes, which are better suited for injection molding.

What is Plastic Molding?

Plastic molding encompasses various techniques, including injection molding, blow molding, and rotational molding. This process allows for the creation of complex shapes and sizes, making it ideal for industries like automotive, consumer goods, and electronics. Key benefits include cost-effectiveness, design flexibility, and rapid production rates.

What is Blow Molding and How Does it Differ from Other Molding Methods?

Blow molding involves inflating heated plastic within a mold to form hollow objects, such as bottles and containers. It differs from injection molding by focusing on creating hollow shapes rather than solid parts. Key advantages include reduced material usage and faster production times, making it ideal for large-volume items.

Meaning

Blow molding is a method for making hollow plastic products. It is a secondary molding technique that uses gas pressure to mold molten plastic into the desired shape.

Process

The plastic resin is heated to a molten state and then injected into the mold cavity. Air blows up the plastic and makes it the shape you want. Then it cools down and you take it out of the mold and look at it.

Application Areas

Blow molding makes things like plastic bottles, water bottles, storage containers, fuel tanks, and plastic barrels. It’s also used in the pharmaceutical and health care products industry, and the health and beauty industry. It can make containers, bottles, small medicine bottles, and single-dose medicine bottles.

It’s best for making hollow things like bottles and containers. It uses less material, so it’s cheaper than other ways of making things. Blow molded things are usually light, strong, and can be used again and again.

Advantages

Low tooling and molding costs, fast production speeds, ability to mold complex parts, and grips can be incorporated into the design. Blow molded products have high resistance to various stresses such as stretching, impact, bending, and environment, and perform well in use.

What is Injection Molding and How Does It Differ from Other Molding Methods?

Injection molding is a versatile and efficient manufacturing technique, ideal for producing large quantities of parts with complex geometries. Unlike other molding methods, it uses high pressure to inject material into molds, ensuring a consistent and high-quality finish. Key advantages include rapid production rates, minimal waste, and the ability to use a wide range of materials, including thermoplastics and thermosets.

Meaning

Injection molding is a way to make parts by injecting material into a mold. It is one of the most common ways to make plastic parts. It involves melting plastic and then forcing it into a mold. The plastic cools and hardens, and you take the part out and make more.

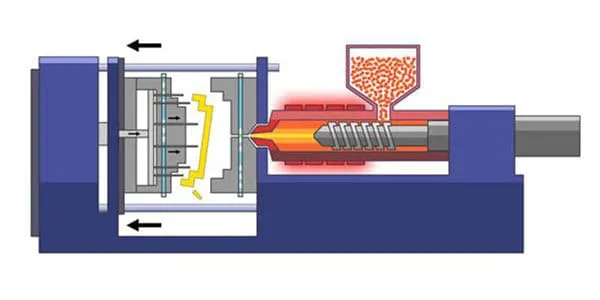

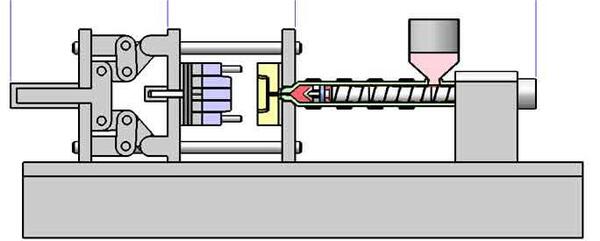

Process

First, you put the plastic in a hopper. Then, you heat the plastic. It goes through a long chamber with a screw that goes back and forth. Then, it gets soft and turns into a liquid. At the end of the chamber, there is a nozzle1. The liquid plastic goes through the nozzle and cools down. That makes the mold close. When the plastic cools down and gets hard, the plastic part comes out of the plastic injection molding machine.

Application Areas

In the car industry, you can find injection molded parts like dashboards, bumpers, and small parts like mirror housings, cup holders, and many other parts you see in cars. In the medical industry, injection molding is used to make accurate and sustainable parts. Dentures, surgical equipment, operating room preparation equipment, and fracture brackets are all made using plastic injection molding.

In the consumer products industry, you can find window frames, cutlery holders, handles, shelves, and more made using injection molding. In the aerospace industry, plastic injection molding is used to make aerodynamic components for most of today\’s aircraft. Turbine blades and casings, panels, chassis components, panels, housings, and more are all made using plastic injection molding.

Advantages

This is a fast and efficient way to make a lot of parts. It’s pretty easy to automate, which means you don’t have to pay people to do it. Injection molded parts are always the same and they’re always the right size. The surface of injection molded parts is usually really smooth. You can make parts out of all kinds of different stuff with injection molding, like metal, plastic, and ceramic. You don’t make any trash when you do injection molding.

What is Compression Molding and How does it Differ from Other Molding Methods?

Compression molding involves placing material into a heated mold, where it is then compressed and cured, leading to efficient production of complex parts. This method is distinct from injection molding, which injects molten plastic into molds, offering advantages like lower tooling costs and the ability to produce larger parts. Key benefits include reduced waste and high dimensional accuracy.

Meaning

Compression molding is when you put plastic material into a heated mold and then squish it into a shape. The heat makes the plastic strong. Then you cool it down and cut off the extra before you take it out of the mold.

Process

Plastic molding Powders and other stuff are added to the mix to make special qualities. When the mold is closed and heated, the stuff hardens to make the shape you want. The temperature, pressure, and time you use depend on what you want. It’s a cheap way to make shapes that need to be just right.

Applications

Companies that need strong, long-lasting products use compression molding. It’s great for making car parts. It’s also good for making tough plastic parts for things like appliances, bulletproof vests, and buttons.

Advantages

The product has low internal stress, low warpage, and stable mechanical properties. The mold cavity wears slowly and the mold maintenance cost is low. Large flat products can be formed. The size of the product that can be molded is determined by the clamping force of the molding machine2 and the size of the template. A mold with many cavities can be placed on a given template, which can improve productivity.

Automatic production can be achieved through automatic feeding and automatic removal of products. Uniform parts are formed without any traces. The surface is smooth and no secondary modification is required. The product has high dimensional accuracy and low shrinkage. It can be produced in large quantities and has a relatively low price.

What is Extrusion Molding and How does it Differ from Other Molding Methods?

Extrusion molding creates continuous shapes by pushing heated material through a die, making it ideal for products like tubing and sheets. It differs from injection molding, which produces discrete parts, and blow molding, which is used for hollow objects. Key benefits of extrusion molding include lower production costs, consistent material properties, and high efficiency for long runs.

Meaning

Plastic extrusion is a big-time production process where melted plastic to make continuous profiles. Extrusion molding can make long strips and cylindrical plastic products. This plastic molding process is also different from other molding processes because it uses molds instead of dies to shape the product. The process is to push the hot raw plastic through a custom-shaped mold to get the shape you want.

Process

It’s like injection molding. You put the dry plastic in a hopper and it goes into a long heating chamber. At the end of the chamber, the material is squeezed out of a little hole or mold to make the shape you want for the final product. After the plastic comes out of the mold, it goes on a conveyor to cool. Sometimes they use blowers to help cool it.

Application Areas

Products made using extrusion molding technology typically require consistent shape along the length of the product. This is why it is mainly used to make long hollow products such as straws, hoses, plastic decorative panels, PVC pipes, and plastic gutters. Some manufacturers can even make different continuous shapes such as U-shaped, L-shaped, T-shaped, and circular sections. It is best used to make long and straight parts with consistent wall thickness throughout the length.

Advantages

Equipment is simple, investment is low, production is continuous, efficiency is high, equipment automation is high, labor intensity is low, production operation is simple, process control is easy, extrusion product is uniform, chamber is tight, quality is high, raw material adaptability is strong, most thermoplastic materials3, a small amount of thermosetting materials, application range is wide, one machine is multi-purpose, production line covers a small area, and production environment is clean.

What is Rotational Molding and How Does it Differ from Other Molding Methods?

Rotational molding uses a two-part mold that is heated and rotated on multiple axes, allowing the plastic to coat the mold evenly. Unlike injection molding, which injects molten plastic into a mold, rotational molding requires lower temperatures and produces less waste. It is ideal for items like tanks, toys, and large containers, offering advantages such as cost-effectiveness and design flexibility.

Meaning

Rotational molding is a process that makes plastic parts by rotating the mold in an oven while pouring molten plastic into it. This ensures that the plastic covers all surfaces evenly, resulting in a strong product with uniform wall thickness.

Process

The rotomolding process starts by adding plastic raw materials to the mold. The mold is then rotated and heated along two vertical axes, so that the plastic raw materials in the mold are gradually and evenly coated, melted, and attached to the entire surface of the mold cavity under the action of gravity and heat energy, forming the desired shape, and then cooled and molded, and finally the product is obtained.

Application Areas

Water and chemical storage tanks – up to 50,000 liters, material handling products like bins, crates, pallets, insulated fish and cool boxes. Environmentally friendly products include bins, cones, bollards, barriers and signs. Floats, buoys and pontoons. Automotive products like truck mudguards, pipes, diesel tanks, tool boxes and tractor dashboards. Kayaks, canoes and boats. Outdoor products like garden pots, water features and furniture. Toys and play equipment.

Advantages

There’s no pressure in the molding process, so the mold is relatively cheap, and the relatively short production cycle also makes the production process more economical. The remaining plastic can be reused to reduce waste. The roto-molded parts have no internal stress, are not easy to deform, have no seams, and have high strength.

Suitable for manufacturing large and super-large products. There is almost no upper limit to the size of the parts formed by the roto-molding process4. The molds used in roto-molding are not affected by external forces, so the manufacturing is simple, cheap and convenient. In addition, roto-molding equipment also has greater flexibility.

What is Thermoforming and How Does it Differ from Other Molding Methods?

Thermoforming involves heating a thermoplastic sheet until pliable, then forming it over a mold using pressure or vacuum. It differs from other molding methods like injection molding by requiring less tooling and offering faster prototyping, making it ideal for low to medium volume production. Key advantages include cost-effectiveness and flexibility in design.

Meaning

Thermoforming is a process where you heat up a plastic sheet until it’s soft, and then you press it into a mold. It’s a molding process where you heat up a thin sheet of plastic until it’s soft and then you use a mold to shape it. Then, you cut it to the shape you want. You don’t use a lot of pressure in this process, and you can make three-dimensional products with aluminum molds.

Process

It is a special plastic process for processing thermoplastic sheets into various products. The sheet is clamped on a frame and heated to a softened state. Under the action of external force, it is made to fit closely to the mold surface to obtain a shape similar to the mold surface After cooling and shaping, trimming is the finished product. This process is also used in rubber processing.

Application Fields

Thermoformed plastic products are used in many areas, such as food packaging, medical devices, car parts, building materials, and more. In the future, as new industries grow and people’s needs change, thermoformed plastic products will be used in even more areas. For example, in the new energy industry,

Thermoformed plastic products can be used to make things like solar panels and wind turbines. In the smart home industry, thermoformed plastic products can be used to make the cases and parts of smart home appliances.

Advantages

Thermoforming can save you money because it can use thinner plastics, which means you’ll spend less on materials. It also has higher precision and faster production speeds than other plastic molding processes. Plus, thermoformed products are stronger and lighter than injection molded parts. The process is also very flexible in the types of materials that can be used. This means your product can have different characteristics and properties, like heat resistance or enhanced durability.

What is Vacuum Forming and How Does it Differ from Other Molding Methods?

Vacuum forming is a widely used manufacturing technique that shapes plastic sheets into desired forms by applying heat and vacuum pressure5, making it ideal for creating packaging, prototypes, and more.

Meaning

Vacuum forming is a process for making plastic stuff. You heat up a flat sheet of plastic, then suck it down onto a mold with a vacuum, and then let it cool off and harden into the shape of the mold.

Process

You put the plastic sheet in a frame and clamp it down. You heat the plastic sheet up until it gets soft and you can bend it. You put the frame with the hot, bendable plastic sheet over the mold and use a vacuum on the other side of the mold to hold it down. The mold that you put the plastic sheet on top of has to have tiny holes drilled in it so the vacuum can suck the plastic sheet down.

Once the plastic is on the mold, you cool it off. Sometimes, for big parts, you use fans and cold air humidifiers to make it cool off faster. Once the plastic is cool, you take it off the mold and the frame. You have to cut off the extra plastic and trim, sand, or polish the edges.

Applications

Vacuum forming is used by manufacturers to make a wide range of parts for cars, buses, boats, and airplanes. In cars, everything from bumpers to carpets and even the interior of the cabin is made using vacuum forming. Manufacturers also use vacuum forming to make industrial crates and shipping containers that fit the shape of the machine. Vacuum forming is used to make a wide variety of consumer goods.

Manufacturers make products, including children\’s toys, travel goods, and home decorations, by vacuum forming. Medical parts and components that are antibacterial or anti-pollution are usually made by vacuum forming. The packaging for razors, toothbrushes, electronic products, cosmetics, and cleaning products is usually vacuum formed.

Advantages

Save raw and auxiliary materials, light weight, convenient transportation, good sealing performance, in line with the requirements of environmentally friendly green packaging; can package any special-shaped products, no additional cushioning materials are required for packaging.

the packaged products are transparent and visible, beautiful in appearance, easy to sell, and suitable for mechanized and automated packaging, convenient for modern management, saving manpower and improving efficiency. The molding process can save materials; the product is light in weight, convenient for transportation, good sealing performance, and meets environmental protection and green requirements.

What is Pultrusion and How Does it Differ from Other Molding Methods?

Pultrusion involves pulling raw materials through a heated die to create uniform composite shapes. It differs from other molding methods, such as injection molding, by focusing on continuous production and the use of reinforcing fibers. Key benefits include high strength-to-weight ratios, minimal waste, and the ability to create complex shapes with high precision.

Meaning

Pultrusion is a process for making continuous lengths of plastic-based composite materials. It’s like extrusion, but instead of pushing the reinforcement material through the mold, you pull it into the mold.

Process

Pultrusion is a three-step process: wetting, molding, and curing/cooling. It starts with reinforcing fibers (like glass or carbon) soaked in thermosetting resin. The wet fibers are pulled through a die to shape the material. After it’s formed, it’s cured at high temperatures to make a long piece of reinforced plastic composite material.

Application Areas

You can use pultruded products for all sorts of things, like structural supports, utility poles, and handrails. It’s great for making strong, lightweight stuff with a smooth finish. You can make FRP sheets, FRP square tubes, FRP round tubes, FRP profiles, and more. Plus, you can cut the long pieces into any size or shape you want. So, it’s perfect for making custom shapes.

Advantages

Pultrusion has many advantages, such as high utilization of raw materials, high production efficiency, and stable quality. Extrusion molding technology6 is an automatic or semi-automatic assembly line production, which can achieve continuous production and extrusion speeds of up to 10m/s.

Conclusion

Plastic molding is awesome because it’s fast, strong, and can make complex parts. That’s why so many businesses use it.Do you want to know more about the different types of plastic molding? This will help you choose the right method for your product. Do you need more help understanding how to do plastic molding and which molding process is best for you?

Zetar Mold Group’s experts are excited to hear about your unique situation and figure out the best fit for your goals. Zetar Mold Group is a leading injection molding and blister molding manufacturing company in China, and we also offer many other value-added services.

Our process includes understanding your project, figuring out the best way to meet your functional and cost requirements, creating a manufacturable concept using cutting-edge software and other innovative tools, and making a final working model.Find out about our plastic manufacturing capabilities today. To learn how we can meet your plastic product and packaging needs, please contact our experts.

-

Learn about Injection Molding Nozzle – Types, Defects, And Characteristics Of A Quality Nozzle : An injection molding nozzle is a key part of the ejector system at the bottom of the molding machine. ↩

-

Learn about Understanding And Calculating Clamping Force In Injection Molding : Clamping force refers to the power provided by the hydraulic system (or the oil pump) in an injection molding machine. ↩

-

Learn aboutAll You Should Know About Thermoplastic Materials : Thermoplastic materials are one of the many types of plastics known for their recyclability and application versatility. ↩

-

Learn about Rotational molding : Rotational molding (BrE: moulding) involves a heated mold which is filled with a charge or shot weight of the material. ↩

-

Learn about Vacuum Pressure Basics : Vacuum Pressure describes any pressure less than normal atmospheric pressure. ↩

-

Learn about How does extrusion moulding work : Extrusion moulding is used to form plastic or metal materials into a pre-defined shape. ↩