– Bonding Criticality: Chemical compatibility between materials is essential for “bonding rubber to plastic” without delamination; otherwise, mechanical interlocks are required.

– Volume vs. Cost: Insert molding has lower tooling costs but higher cycle times (labor-intensive); Multi-shot (2K) overmolding has high initial tooling costs but is optimized for high-volume automated production.

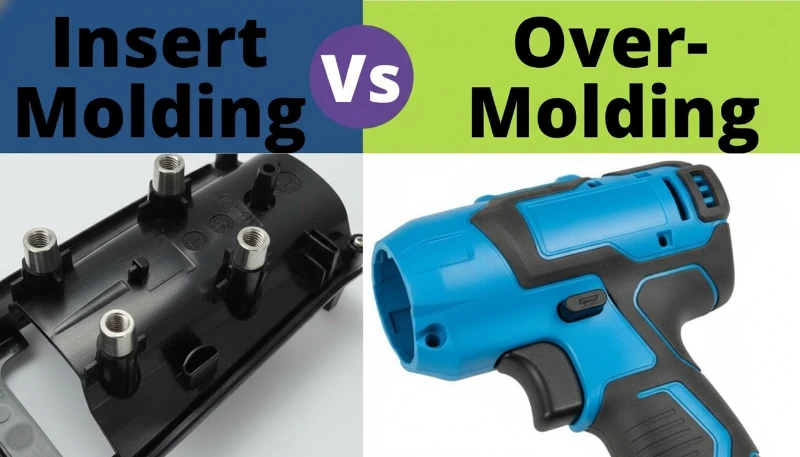

– Functional Goals: Use insert molding for structural reinforcement (threaded inserts); use overmolding for ergonomics (soft-touch handles) and vibration dampening.

What Are Overmolding and Insert Molding?

While both processes fall under the umbrella of "multi-material molding," they serve different engineering functions and utilize distinct manufacturing workflows.

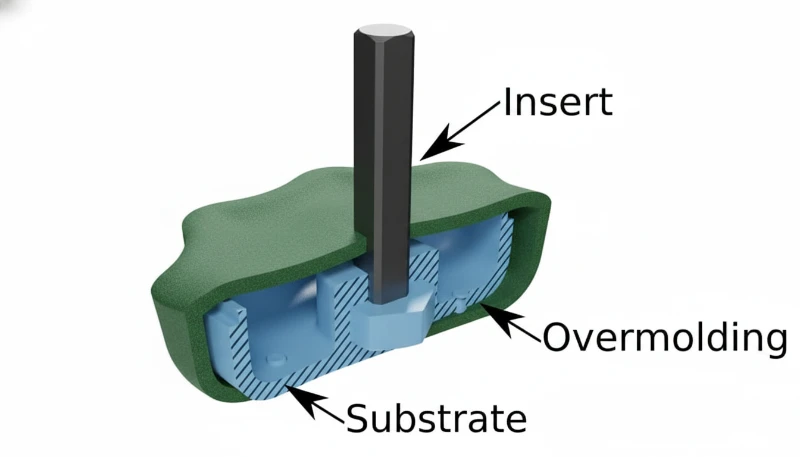

Umspritzen is a process where a second material is molded over a pre-molded substrate (the first shot). This is most commonly used to add soft-touch grips, seals, or multiple colors to a part. It can be performed via Multi-Shot Injection Molding (2K)1 (done in one machine with a rotary platen) or Pick-and-Place (moving a cold part to a second cavity).

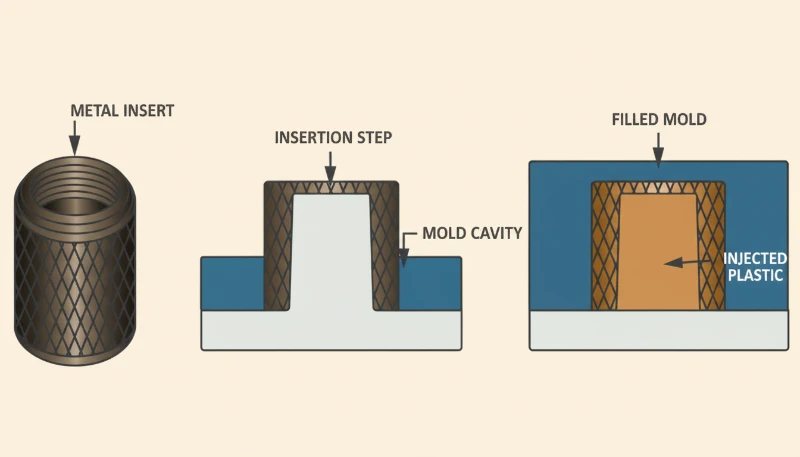

Einsatzformteil involves placing a pre-formed component (the insert) into the mold cavity before the plastic is injected. The molten plastic flows around the insert, encapsulating it. The insert is typically a non-plastic material, such as brass threaded nuts, stainless steel pins, or printed circuit boards (PCBs).

What Are the Technical Parameters and Process Differences?

The choice between these processes dictates tooling strategy, cycle time, and bonding requirements.

| Merkmal | Einsatzformteil | Overmolding (2-Shot / 2K) | Overmolding (Pick-and-Place) |

|---|---|---|---|

| Primary Objective | Structural strength, conductivity, or assembly simplification. | Ergonomics, aesthetics, sealing, or vibration dampening. | Low-volume overmolding or complex substrate geometry. |

| Typical Insert/Substrate | Metal (Brass, Steel, Copper), Ceramic, or PCB. | Rigid Plastic (e.g., Polycarbonate, Nylon). | Rigid Plastic (Cold substrate). |

| Encapsulation Material | Rigid Thermoplastics (PA, PBT, ABS). | Thermoplastic Elastomers (TPE, TPU). | TPE, TPU, or Silicone (LSR). |

| Bonding Mechanism | Mechanical Lock (knurling, undercuts). | Chemical Bond (molecular adhesion) + Mechanical. | Chemical Bond (requires pre-heating) + Mechanical. |

| Zykluszeit | Slower (15–60s) due to manual/robotic loading. | Fastest (15–30s) due to simultaneous molding. | Slowest (30s–2 mins) due to part transfer/heating. |

| Werkzeugkosten | Moderate (Standard machine, complex mold). | High (Rotary platen, dual injection units). | Moderate (Two separate molds). |

You can rely solely on chemical bonding when overmolding TPE onto any rigid plastic substrate.Falsch

Chemical bonding only occurs between chemically compatible materials (e.g., TPE and PP). For incompatible pairs (like TPE and Nylon), mechanical interlocks (holes, grooves) are mandatory to prevent peeling.

Insert molding metal components significantly increases the pull-out strength compared to installing inserts post-molding via heat staking.Wahr

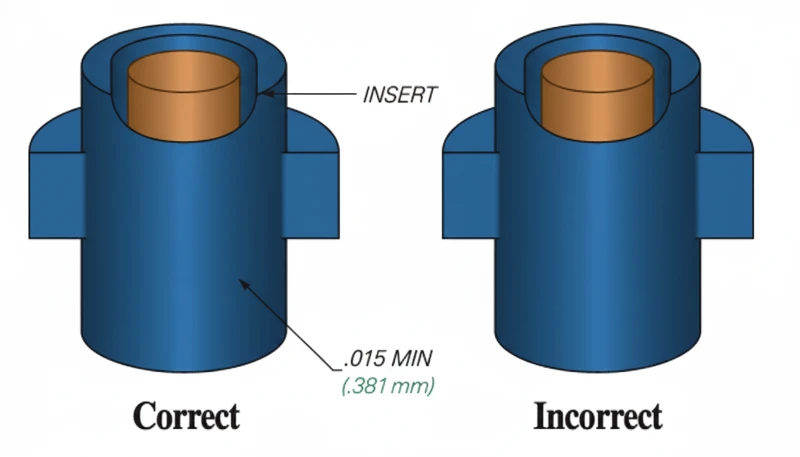

Because the plastic shrinks around the knurled metal insert during cooling, it creates a robust, stress-relieved encapsulation that offers superior torque and pull-out resistance compared to heat staking.

How Is the Process Executed Step-by-Step?

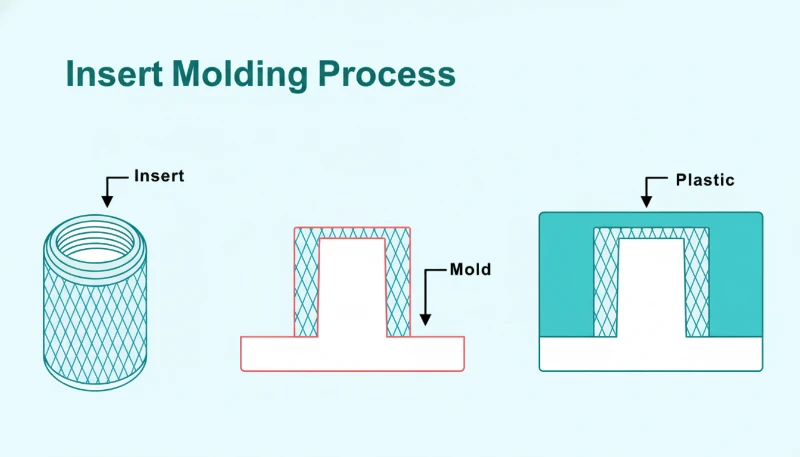

The Insert Molding Process

- Loading: The mold opens. A robotic arm or operator places the insert (e.g., a brass threaded nut) onto locating pins in the mold cavity.

- Injektion: The mold closes. Molten plastic is injected, flowing around the insert. The pressure ensures the plastic fills the knurls (grooves) of the metal.

- Cooling & Ejection: The plastic solidifies, locking the insert in place. The part is ejected as a single integrated unit.

The Multi-Shot (2K) Overmolding Process

- First Shot (Substrate): The rigid material (e.g., Polypropylene – PP) is injected into the first cavity to form the structural skeleton.

- Rotation/Transfer: The mold opens, and the platen rotates 180 degrees (or a robotic arm transfers the part) to the second cavity. The substrate remains hot.

- Second Shot (Overmold): The soft material (e.g., Thermoplastic Elastomer – TPE) is injected onto the specific areas of the substrate. The heat facilitates a chemical bond (melt fusion).

- Rauswurf: The finished multi-material part is ejected.

What Are the Advantages and Disadvantages?

| Prozess | Vorteile | Benachteiligungen |

|---|---|---|

| Einsatzformteil | • Eliminates post-molding assembly (e.g., screwing in inserts). • Increases part strength and reliability. • Allows for electronic integration (sensors inside plastic). | • High risk of "mold smash" if inserts are misaligned. • Metal inserts must be pre-heated to prevent stress cracking in plastic. • Difficult to recycle due to mixed materials. |

| Umspritzen2 | • Superior aesthetics and "soft touch" feel. • Excellent water/dust sealing (IP ratings) without gaskets. • Reduces vibration and noise. • High-volume efficiency (2K process). | • Very high tooling costs (complex runners and gating). • strict material compatibility requirements. • Longer development cycles to perfect the bond. |

Overmolding Design Guide: Practical Tips for Success

To ensure robust results in soft touch handles manufacturing oder bonding rubber to plastic, engineers must adhere to specific design guidelines.

- Wall Thickness Ratios: The overmold layer should generally be thinner than the substrate to prevent warpage. A common ratio is 1:2 (TPE thickness vs. Substrate thickness).

- Shut-offs and Feather Edges: Never design the overmold to taper to a zero thickness (feather edge). This will peel. Instead, design a "shut-off" groove (0.5mm – 1.0mm deep) in the substrate where the TPE ends. This creates a clean flush finish and protects the edge.

- Material Compatibility Matrix:

- Excellent Chemical Bond: TPE + Polypropylene (PP); TPU + ABS; TPE + PC/ABS.

- Poor Chemical Bond (Requires Mechanical Interlock): TPE + Acetal (POM); TPE + PBT; Standard TPE + Nylon (PA) (Requires specialized modified TPEs).

- Entlüftung: Overmolds often trap air because they fill "blind" pockets. Ensure adequate venting at the end of fill to prevent burning (diesel effect).

Multi-shot (2K) overmolding is always more expensive than pick-and-place overmolding.Falsch

While the initial tooling for 2K is higher, the piece-part cost is significantly lower for high volumes (100k+ units) because it eliminates the manual labor and handling time associated with pick-and-place or insert molding.

Insert molding is strictly limited to encapsulating metal parts.Falsch

Insert molding frequently utilizes other plastics (e.g., high-temperature PEEK sensors), filters (mesh), or even glass elements, provided they can withstand the injection pressure and temperature of the encapsulating resin.

Anwendungsszenarien

When to Choose Insert Molding

- Threaded Fasteners: Adding brass nuts to a plastic housing for repeated assembly/disassembly (e.g., electronics enclosures).

- Electrical Conductivity: Encapsulating copper pins or lead frames for connectors.

- Chirurgische Instrumente: Embedding stainless steel shafts into plastic handles for rigidity and sterilization resistance.

When to Choose Overmolding

- Power Tools: Adding a TPE grip to a glass-filled Nylon drill body for shock absorption and ergonomics.

- Unterhaltungselektronik: Creating water-tight seals (gaskets) directly onto a smartphone case frame.

- Körperpflege: Toothbrush handles with multiple colors and grip textures.

Häufig gestellte Fragen (FAQ)

Q: What is the primary cause of delamination in overmolding?

A: Delamination (peeling) is usually caused by material incompatibility (low surface energy mismatch) or a substrate that is too cold during the second shot. If the substrate has cooled completely (in pick-and-place), the surface must often be pre-heated or plasma-treated to reactivate the surface molecules for bonding.

Q: Can I overmold TPE onto metal directly?

A: Yes, this is technically "Insert Molding" with TPE. However, TPE does not chemically bond to metal. You must use an adhesive primer on the metal or rely entirely on aggressive mechanical interlocks (holes which the TPE flows through to lock itself).

Q: How does the "shrinkage" rate affect insert molding?

A: Different materials shrink at different rates. If a plastic with high shrinkage (like Polyethylene) is molded over a large metal insert (zero shrinkage), the plastic creates immense internal stress as it cools, leading to "hoop stress" cracking. Low-shrinkage or glass-filled resins are preferred for insert molding.

Q: Is Flüssigsilikonkautschuk (LSR)3 overmolding different from TPE overmolding?

A: Yes. LSR requires a hot mold (vulcanization) while the plastic substrate usually requires a cold mold. Overmolding LSR onto plastic requires high-temperature plastics (like PEEK or specialized Nylon) that won’t melt during the silicone curing process.

Q: What is the "crush rib" concept in insert molding?

A: When loading a metal insert into a mold, it must fit tightly so plastic doesn’t flash over the threads. "Crush ribs" are small deformable plastic features inside the mold or on the insert locator that yield when the mold closes, ensuring a seal without damaging the expensive steel tool.

Zusammenfassung

Choosing between Overmolding and Insert Molding depends on whether you are trying to combine materials for ergonomic/aesthetic layers (Overmolding) or encapsulating a discrete component for structural/functional reasons (Insert Molding).

Für soft touch handles manufacturing, multi-shot overmolding offers the most streamlined, high-quality finish, provided the bonding rubber to plastic chemistry is validated. Conversely, for robust assemblies requiring threaded interfaces or electronic integration, the insert molding process provides unmatched pull-out strength and reliability. Engineers must balance the high tooling investment of 2K molding against the higher labor costs of insert molding based on projected production volumes.