The manufacturing industry is undergoing a paradigm shift from a linear "take-make-dispose" model to a circular economy. For plant managers and engineers, the challenge lies in adopting sustainable manufacturing practices1 without compromising the mechanical integrity or dimensional stability of the final part. This trend report explores the technical realities of integrating Post-Consumer Recycled (PCR) materials and biodegradable resins into standard injection molding workflows.

– PCR materials often require re-stabilization additives to match the impact strength of virgin resins.

– Biodegradable resins like PLA and PHA are shear-sensitive and require lower melt temperatures to prevent degradation.

– Sustainable molding is a system-level approach involving all-electric machinery, cold runner systems, and material science.

– Regulatory standards like the Global Recycled Standard (GRS) are becoming prerequisites for market entry in the EU and North America.

What Defines Eco-Friendly Injection Molding?

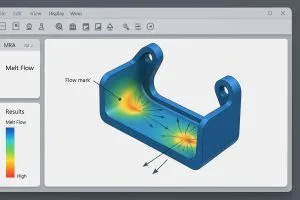

Eco-friendly injection molding2 is an engineered approach to manufacturing that minimizes environmental impact through three pillars: Material Selection (biopolymers vs. fossil-fuel-based), Process Efficiency (energy consumption per kg), and Waste Reduction (regrind usage and scrap minimization).

Unlike traditional molding, which prioritizes cycle time and cost above all, sustainable molding introduces Life Cycle Assessment (LCA) into the engineering phase, evaluating the carbon footprint from raw material extraction to end-of-life disposal.

How Does PCR Plastic Material Compare to Virgin Resin?

One of the most immediate ways to reduce carbon footprint is substituting virgin polymer with PCR plastic material3. However, technical buyers often fear a drop in performance.

Post-Consumer Recycled (PCR) plastics are derived from end-user products (bottles, packaging) that have been diverted from landfills, cleaned, and re-pelletized.

PCR vs. Virgin: Technical Comparison Matrix (Polypropylene Example)

| Parameter | Virgin Polypropylene (PP) | PCR Polypropylene (High Grade) | Deviation Impact |

|---|---|---|---|

| Schmelzflussindex (MFI) | Consistent (e.g., 12 g/10min) | Variable (10–15 g/10min) | Requires adaptive process control to prevent short shots. |

| Zugfestigkeit | 32 MPa | 28 – 30 MPa | Minimal reduction; acceptable for non-load bearing structural parts. |

| Impact Strength (Notched) | 4.5 kJ/m² | 3.5 – 4.0 kJ/m² | Can be brittle; impact modifiers may be needed. |

| Color Consistency | Ausgezeichnet | Variable (Greys/Blacks common) | Limits aesthetic options; Lab* values fluctuate batch-to-batch. |

| Contamination Risk | 0% | <0.1% | Requires finer filtration mesh in the nozzle. |

High-quality PCR resins can achieve near-parity performance with virgin resins when properly compounded with additives.Wahr

Modern compounding adds stabilizers and impact modifiers to PCR, restoring mechanical properties close to virgin levels.

PCR plastic is always cheaper than virgin resin due to being 'waste' material.Falsch

High-quality, sorted, and cleaned PCR often carries a premium due to the intensive processing required to make it mold-ready.

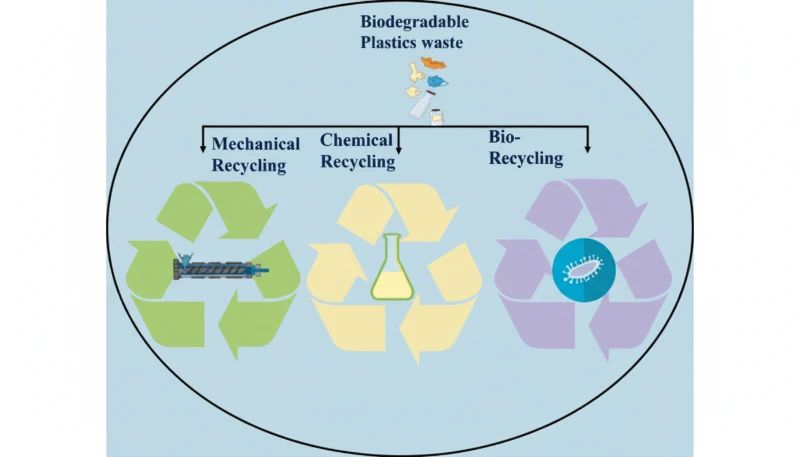

What Are the Processing Challenges of Biodegradable Resins?

Biodegradable resins for molding4, such as Polylactic Acid (PLA), Polyhydroxyalkanoates (PHA), and PBAT, behave differently than traditional olefins. They are chemically designed to break down, which makes them thermally unstable during processing.

Key Processing Parameters for Bioplastics

- Moisture Sensitivity: Most bioplastics are highly hygroscopic. PLA must be dried to <250 ppm (0.025%) moisture. Failure to dry results in hydrolysis, causing severe molecular weight loss and brittle parts.

- Temperaturkontrolle: Bioplastics have a narrow processing window.

- Beispiel: PLA degrades rapidly above 200°C.

- Tipp: Use low-shear screws and minimize residence time in the barrel to prevent thermal degradation.

- Temperatur der Form:

- Amorphous PLA requires cool molds (20–40°C) for clarity.

- Semi-crystalline PLA (high heat) requires hot molds (80–100°C) to induce crystallization for heat resistance.

What Are the Best Green Molding Solutions for Machinery?

Implementing green molding solutions5 extends beyond materials to the machinery itself.

Hydraulic vs. All-Electric Efficiency

| Merkmal | Hydraulic Machine | All-Electric Machine | Sustainability Impact |

|---|---|---|---|

| Energie-Effizienz | 40–50% | >80% | Electric machines reduce energy consumption by 30–70%. |

| Idle Power | Pumps run continuously | Near zero | Significant reduction in baseline energy waste. |

| Cooling Load | High (Hydraulic oil cooling) | Low (No oil) | Reduces water usage and chiller load. |

| Präzision | Mäßig | Hoch | Less scrap production due to higher repeatability. |

All-electric injection molding machines consume 30% to 70% less energy than hydraulic counterparts.Wahr

Electric servo motors only draw power during movement, whereas hydraulic pumps often idle at load, wasting significant energy.

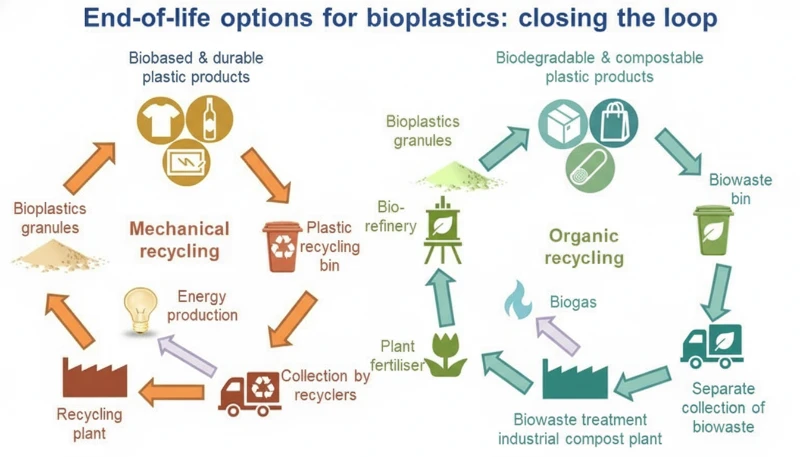

Biodegradable plastics will degrade quickly in any environment, including a backyard pile.Falsch

Most 'biodegradable' industrial resins (like PLA) require specific industrial composting conditions (high heat/humidity) to break down effectively.

What Are the Pros and Cons of Sustainable Materials?

| Material Typ | Vorteile | Benachteiligungen |

|---|---|---|

| PCR (Recycled) | Reduces landfill waste, lower carbon footprint than virgin, circular economy compliant. | Inconsistent melt flow, color limitations (mostly black/grey), potential for contamination. |

| Bio-based (PLA/PHA) | Derived from renewable resources (corn, sugarcane), compostable (under conditions), high stiffness. | Low heat deflection temperature (standard PLA), brittle, shear sensitive, higher material cost. |

| Bio-composites | Natural fibers (hemp, flax) reduce polymer usage and density. | High moisture absorption, lower impact strength, potential odor during processing. |

How Do You Implement a Sustainable Molding Strategy? (Step-by-Step)

- Material Audit: Analyze current BOMs. Can internal non-visible structural parts (brackets, ribs) be switched to reprocessed or PCR Black material?

- Design for Recycling (DfR): Avoid over-molding incompatible materials (e.g., melting TPE onto PP makes recycling difficult). Stick to mono-material designs where possible.

- Tooling Optimization: Utilize hot runner systems to eliminate runners and sprues, which account for 15–50% of plastic waste in cold runner systems.

- Partner Verification: Require suppliers to provide LCA reports and certifications like ISCC PLUS oder Blue Angel to verify sustainability claims.

Applications of Sustainable Molding

- Automobilindustrie: Fender liners and under-body shields made from 100% PCR Polypropylene.

- Packaging: Thin-wall food containers using rPET (Recycled PET) or compostable PLA variants.

- Unterhaltungselektronik: Device housings utilizing PC/ABS blends with 30-50% PCR content.

- Agriculture: Biodegradable mulch clips and pots that decompose in the soil after use (PHA based).

FAQ: Sustainable Injection Molding

1. Does using PCR material require changing mold tooling?

Generally, no. However, because PCR flow rates can vary, you may need to adjust gate sizes or runner systems slightly. If the PCR has a different shrinkage rate than the virgin material originally specified, dimensional adjustments might be necessary.

2. Can biodegradable plastics like PLA be molded on standard machines?

Yes, but with caution. The barrel must be thoroughly purged of standard resins (like PE or PP) because residual material can cause contamination. Screw designs with high shear ratios should be avoided to prevent degrading the sensitive biopolymer.

3. What is the difference between PCR and PIR?

PCR (Post-Consumer Recycled) comes from waste generated by households or commercial facilities (e.g., milk jugs). PIR (Post-Industrial Recycled), also known as regrind, is scrap generated during the manufacturing process (e.g., sprues, runners) that is immediately reused. PCR is considered more "sustainable" as it diverts waste from the environment.

4. Are bioplastics weaker than traditional plastics?

Standard PLA is brittle and has low heat resistance compared to ABS or PP. However, advanced grades and blends (impact-modified PLA) can rival the performance of engineering thermoplastics, though often at a higher cost.

5. How does mold cooling affect sustainability?

Efficient cooling reduces cycle time. Shorter cycles mean the machine runs for less time per part, consuming less total energy. Conformal cooling channels (3D printed into the mold) can drastically reduce cooling time and energy usage.

Zusammenfassung

Navigating sustainable injection molding requires a balanced approach between material science and process engineering. By leveraging PCR plastics for structural components and biodegradable resins for short-lifecycle products, manufacturers can significantly lower their carbon footprint. Success depends on rigorous material testing, adopting energy-efficient green molding solutions, and understanding the specific processing nuances of non-virgin resins to maintain the quality customers expect.

-

Sustainable manufacturing practices involve integrating circular economy principles, reducing energy use, and selecting low-impact materials to minimize industrial carbon footprints. ↩

-

Eco-friendly injection molding encompasses the holistic reduction of waste through regrind usage, energy-efficient machinery, and responsible resin sourcing. ↩

-

PCR plastic materials are reclaimed from consumer waste streams; their use supports recycling infrastructure but requires careful processing due to variability. ↩

-

Biodegradable resins for molding, such as PLA and PHA, offer end-of-life compostability but demand strict moisture control and temperature limits during processing. ↩

-

Green molding solutions refer to technologies like all-electric machines and hot runner systems that directly reduce energy consumption and material scrap rates. ↩