The surface treatment of plastic products mainly includes coating treatment and plating coating treatment.

Generally, the crystallinity of plastics is validitye polarity is small or non-polar, and the surface energy is low, which affects the adhesion of coating.

Since plastic is a non-conductive insulator, it cannot be that directly on the plastic surface according to a plating process specification.

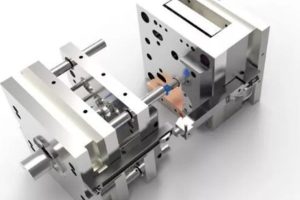

Therefore, before the plastic surface treatment process, necessary pre-treatment should be carried out to improve the adhesion of the coating and provide a conductive base layer with good adhesion for plating.The composite injection molding process achieves a seamless effect.

Pre-treatment for coating

The pre-treatment includes degreasing treatment of the wear resistance plastic surface, i.e. cleaning the surface oil and release agent, and activation treatment of the plastic surface, to improve the adhesion of the discontinuous coating technology coating is coated.

Degreasing of plastic products

Similar to the surface degreasing of metal and insulating compounds, plastic mold making products can be cleaned with organic solvents or degreased with an alkaline aqueous solution containing surfactants.

Organic solvent degreasing is suitable for cleaning paraffin, beeswax, fat, and other organic dirt from the surface of plastics, the organic solvent used should not dissolve, swell and crack the plastic, its low boiling point, is easy to evaporate, non-toxic, and non-flammable.

The alkaline aqueous solution is suitable for heat resistant adhesive paper, degreasing alkali-resistant plastics. The solution contains caustic soda, alkaline salts, and various surface-active substances.

The most commonly used surface-active substance is OP series, i.e. alkylphenol polyoxyethylene ether, which does not form foam and does not remain on the plastic surface.

Activation of the surface of plastic products

The surface treatment of plastics is to form a surface layer with some or more special properties on the surface of the material through physical or chemical methods.

This activation is to improve the surface energy of the plastic, that is, to generate some polar groups on the surface of the plastic or to roughen it, to make the coating easier to wet and adsorb on the surface of the parts.

There are many methods of surface activation, such as chemical oxidation, flame oxidation, solvent vapor etching, and corona discharge oxidation.

The most widely used is the chemical crystal oxidation treatment method, this method is commonly used in chromic acid treatment solutions, its typical formula is 4.5% potassium dichromate, 8.0% water, concentrated sulfuric acid (more than 96%) 87.5%.

It is very suitable for the surface treatment of plastic injection molded products such as PC plastic materials and ABS plastic materials. Some plastic products, such as polystyrene and ABS plastics, can also be coated directly without chemical oxidation treatment.

To obtain a high-quality coating, chemical oxidation treatment is also used, such as ABS plastic after degreasing, which can be used more dilute chromic acid treatment solution etching, the typical treatment formula is chromic acid 420g / L, sulfuric acid (specific gravity 1.83) 200ml / L.

The typical treatment process is 65 ℃ 70 ℃ / 5min10min, water washing, drying.

The advantage of etching with chromic acid treatment solution is that the plastic products can be treated evenly no matter how complex the shape of the product, and the disadvantage is that the operation is dangerous and has pollution problems.

Pretreatment of plating coating

The purpose of pretreatment is to improve the adhesion of the plating to the plastic surface and to form a conductive metal base layer on the plastic surface.

The pre-treatment processes include mechanical roughening, chemical degreasing, chemical roughening, sensitization, activation, reduction, and chemical plating.

The first three of them are to improve the adhesion of the plating layer, and the last four are to form a conductive metal base layer.

1. Mechanical Roughening and Chemical Roughening

Mechanical roughening and chemical roughening treatments are used to coarsen the plastic surface by mechanical and chemical methods respectively to increase the contact area between the plating and the substrate.

It is generally believed that the bonding power achieved by mechanical roughening is only about 10% of that of chemical roughening.

2. Chemical Degreasing

The method of removing oil before coating the plastic surface is the same as the method of removing oil before coating.

3. Sensitization

Sensitization is to make certain adsorption capacity of the plastic injection molding surface adsorption of some easy to oxidize substances, such as tin dichloride, titanium trichloride, etc.

These adsorbed easy-to-oxidize substances are oxidized during the activation treatment, and the activator is reduced to catalytic nuclei, which remain on the surface of the plastic product.

The role of sensitization is to lay the foundation for the subsequent chemical coating of the metal layer.

4. Activation

Activation is the treatment of the sensitized surface with the aid of a solution of a catalytically active metal compound.

In essence, the product adsorbed with a reducing agent is immersed in an aqueous solution of oxidizer containing precious metal salts, whereupon the precious metal ions are reduced by S2+n as an oxidizer, and the reduced precious metal is deposited as colloidal particles on the surface of the product, which has strong catalytic activity.

When such a plastic molding mold surface is immersed in the chemical plating solution, these particles become the catalytic center and speed up the reaction of chemical plating.

5. Reduction of treatment

After activation and washing with water, before chemical plating, the product is impregnated with a certain concentration of the reducing agent solution used in chemical plating to reduce and remove the unwashed activator, which is called reduction achieve surface treatment processes.

For pad printing, copper chemical plating, formaldehyde solution is used for reduction treatment, and nickel chemical plating, sodium hypophosphite solution is used for reduction plasma treatment.

6. Chemical plating

The purpose of chemical plating is to create a conductive metal film on the surface of plastic injection molded products to create the conditions for plating metal surface layers on plastic products, so chemical plating is the key step of plastic plating.