Injection molding defects are common challenges in the manufacturing process that affect product quality and production efficiency. Understanding their causes and solutions is essential for improving results.

Common injection molding defects include warping, sink marks, short shots, and air traps. Solutions range from adjusting temperature, pressure, or material to optimizing mold design and process parameters.

Understanding the root causes of these defects and applying the correct solutions can significantly improve your manufacturing process. Dive deeper to explore effective strategies for defect prevention and resolution.

Warping is a common injection molding defect.True

Warping occurs when uneven cooling causes distortion in the part's shape. This can be solved by controlling mold temperature and cooling rates.

Defects in injection molding are always due to poor mold design.False

While mold design can contribute to defects, factors such as material choice, temperature, and pressure also play significant roles in defect formation.

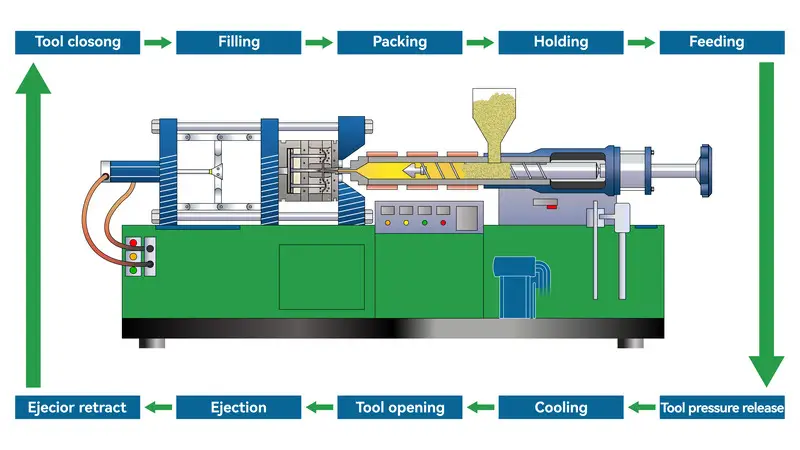

What is Plastic Injection Molding ?

Plastic injection molding is a manufacturing process used to produce a wide range of products, from everyday items to intricate components. It offers speed, precision, and cost-effectiveness.

Plastic injection molding is a process where melted plastic is injected into molds to form parts. It’s used in industries like automotive, electronics, and consumer goods, offering high efficiency, precision, and flexibility.

The injection molding1 process refers to the process of making semi-finished products of a certain shape from molten raw materials through operations such as pressurization, injection, cooling, and separation .

Plastic injection molding allows for high-volume production of parts.True

The process is highly efficient, making it ideal for large-scale manufacturing with consistent quality.

Plastic injection molding is only suitable for simple products.False

Injection molding can produce both simple and complex parts, including intricate designs, making it versatile for various industries.

What are the Causes of Short shots of Injection Molding Products And Their Solutions?

Short shots occur when the molten plastic doesn’t fully fill the mold, leading to incomplete parts. Identifying the causes and solutions is essential for ensuring product quality and manufacturing efficiency.

Short shots in injection molding are caused by factors like insufficient injection pressure, low mold temperature, or inadequate material flow. Solutions include adjusting processing parameters, improving mold design, and ensuring the right material is used.

Definition

Short shot is when the mold cavity doesn’t get filled all the way.

Causes of Short Shot

Mold temperature, material temperature, or injection pressure and speed2 are too low. Raw material plasticization is uneven, exhaust is poor, raw material fluidity is insufficient, the part is too thin or the gate size is too small, and the polymer melt solidifies prematurely due to unreasonable structural design.

Solutions

-

Material: Choose a material that flows better, like toolox44.

-

Mold design: Fill thick walls before filling thin walls to avoid holding, increase the number of gates and runner size, reduce process and flow resistance, and set the position and size of the exhaust port appropriately to avoid poor exhaust.

-

Injection molding machine: Check if the check valve and the inner wall of the barrel are severely worn, and check if there is material or bridge in the feed port.

-

Process conditions: increase injection pressure and injection speed, enhance shear heat, increase injection volume, increase barrel temperature and mold temperature.

Increasing injection pressure can reduce short shots.True

Higher injection pressure helps ensure the mold fills completely, reducing the likelihood of short shots.

Short shots are only caused by equipment malfunctions.False

While equipment malfunctions can cause short shots, other factors like mold design, material viscosity, and processing parameters also play significant roles.

What are the Causes of Brittleness of Injection Molding Products And Their Solutions?

Brittleness in injection molding products can be caused by various factors, such as incorrect material selection, poor processing conditions, or inadequate mold design. Identifying these causes is key to preventing defects.

Brittleness in injection molding is often caused by low processing temperatures, incorrect material grade, or improper cooling rates. Solutions include adjusting the mold temperature, selecting suitable materials, and fine-tuning the injection speed.

Definition

When we talk about brittleness in plastic parts, we’re talking about how easily they crack or break in certain areas.

Causes of Brittleness

The drying conditions are not good, too much recycled material is used, the injection temperature is set wrong, the gate and runner system is not set right, and the strength of the melt mark is not high.

Solutions

Copy Edited Material: Set the right drying conditions before you inject mold, use less recycled stuff, use more new stuff, and use strong plastic.

-

Mold design: Make the main channel, branch channel, and gate bigger .

-

Injection molding machine: Choose a good screw to make the temperature distribution more even during plasticizing.

-

Process conditions: Lower the temperature of the barrel and nozzle, decrease the back pressure, screw speed and injection speed, increase the injection pressure by raising the material temperature, and enhance the strength of the melt mark.

Improper cooling rates cause brittleness in injection molding.True

Cooling rates that are too fast or too slow can lead to internal stresses, causing the molded part to become brittle.

Increasing mold temperature always solves brittleness issues.False

While higher mold temperatures can help, the root cause of brittleness often lies in the material and processing conditions, which should also be optimized.

What are the Causes of Burning of Injection Molding Products And Their Solutions?

Burning in injection molding can result from excessive heat, improper material selection, or poor machine settings. Identifying and addressing these factors is crucial to ensure high-quality products and efficient processes.

Common causes of burning in injection molding include high temperatures, incorrect injection speed, and inadequate cooling. Solutions involve adjusting machine parameters, using the right material, and improving mold design to prevent overheating and product defects.

Definition

Scorch marks happen when the gas in the cavity can’t get out fast enough and burns at the end of the flow.

Causes of Scorching

The air in the cavity cannot be discharged in time. Material degradation: the melt temperature is too high; the screw speed is too fast; the runner system design is improper.

Solutions

-

Mold Design: Add an exhaust system and increase the size of the runner system3in areas where poor exhaust is likely to occur.

-

Process conditions: decrease injection pressure and speed, decrease barrel temperature, inspect heater and thermocouple to determine if they are functioning correctly

High temperatures cause burning in injection molding.True

Excessive heat can degrade the material and lead to discoloration, resulting in burned parts.

Lower injection speeds can prevent burning.False

While lower injection speeds may reduce heat, they can also affect part quality. Balancing speed and temperature is key.

What are the Causes of Flash of Injection Molding Products And Their Solutions?

Flash in injection molding refers to excess material that leaks out of the mold cavity, creating unwanted projections. It can affect part quality and increase costs.

Flash is caused by factors such as high injection pressure, worn-out molds, or improper mold design. Solutions include adjusting pressure, optimizing cooling, and maintaining molds to ensure precision and quality.

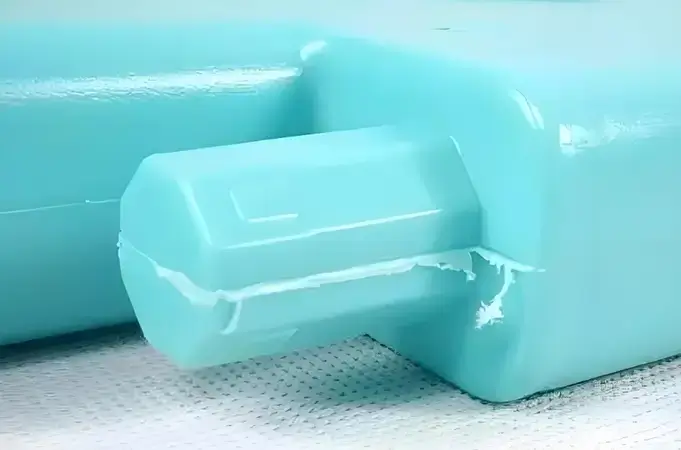

Definition

Flash is the extra plastic on the mold parting surface or ejector pin.

Causes ofFlash

not enough clamping force, mold problems, bad molding conditions, exhaust system design is wrong .

Solutions

-

Mold design: Design the mold so it can close tightly when clamped. Check the size of the exhaust port and clean the mold surface.

-

Injection molding machine: set an injection molding machine4 with the right tonnage.

-

Molding process: increase injection time, reduce injection speed5, reduce barrel temperature6and nozzle temperature, reduce injection pressure and holding pressure7.

High injection pressure causes flash.True

Excessive pressure pushes molten plastic past the mold cavity, leading to flash formation.

Worn-out molds can cause flash.True

Damaged or worn molds create gaps, allowing material to escape, which results in flash. Regular maintenance is key to avoiding this issue.

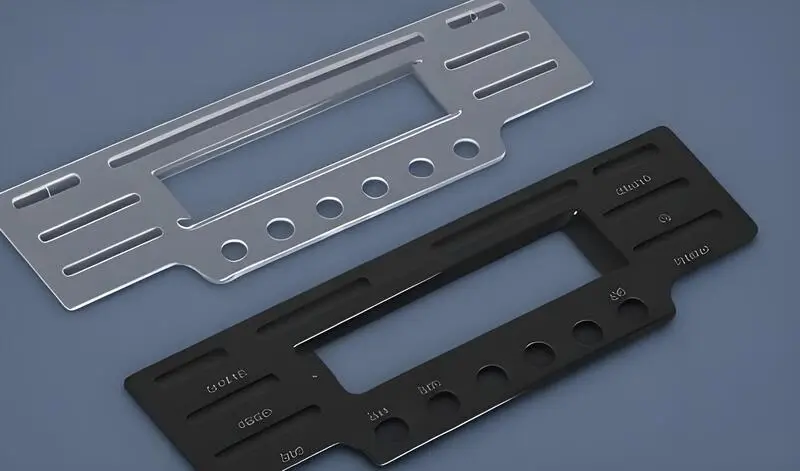

What are the Causes of Delamination of Injection Molding Products And Their Solutions?

Delamination in injection molding occurs when layers of the material separate, often causing product defects. Understanding its causes and solutions is key to improving product quality.

Delamination in injection molding can be caused by factors like poor material compatibility, incorrect mold temperature, or moisture in materials. Solutions include optimizing processing conditions, ensuring proper material handling, and improving mold design.

Definition

Delamination is when the surface of the part peels off, layer by layer.

Causes of Delamination

Mixed with other polymers that don’t mix well, too much release agent when you’re molding, the resin isn’t the same temperature all the way through, too much water, sharp corners in the gates and runners.

Solutions

-

Content: Don\’t mix impurities or dirty recycled materials with raw materials.

-

Mold design: Round all runners or gates with sharp angles.

-

Process conditions: Increase barrel and mold temperature, dry the material before molding, and don\’t use too much release agent.

What are the Causes of Spray Marks of Injection Molding Products And Their Solutions?

Spray marks are common defects in injection molding, caused by various factors such as mold temperature, injection speed, and material quality. Addressing these issues can improve product quality significantly.

Spray marks occur due to improper mold temperature, excessive injection speed, or low-quality material. Solutions include optimizing molding conditions, adjusting speed, and ensuring material consistency for better results.

Definition

A type of jetting mark caused by melt flow that is too fast, usually in the shape of a snake.

Causes of Jetting Marks

The gate is too small, facing the product surface with a large cross-sectional area, and the filling speed is too fast.

Solution

- Mold Design: Make the gate bigger, change the side gate to a lap gate, and put a material stopper pin in front of the gate.Process Conditions: Slow down the filling speed right after the gate.

Spray marks are caused by improper mold temperature.True

If the mold temperature is too high or low, it can cause the plastic to cool unevenly, leading to spray marks on the product surface.

Increasing injection speed always eliminates spray marks.False

While adjusting injection speed can reduce spray marks, excessively high speeds can worsen defects. A balanced approach is necessary for optimal results.

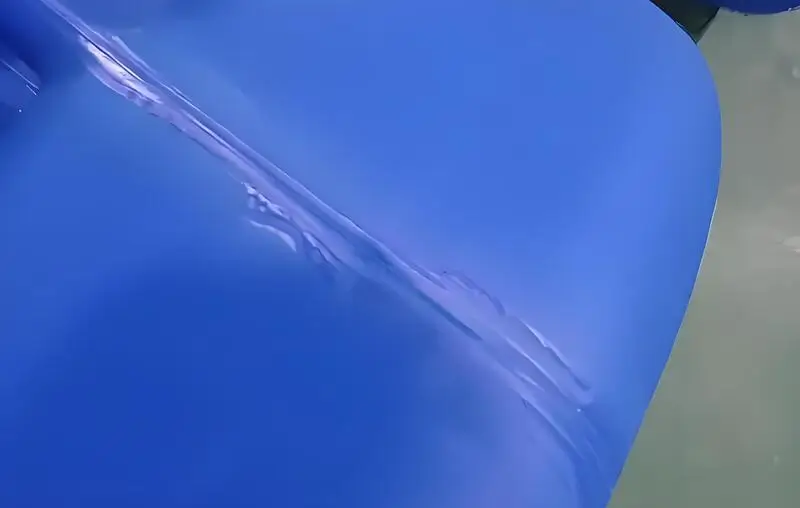

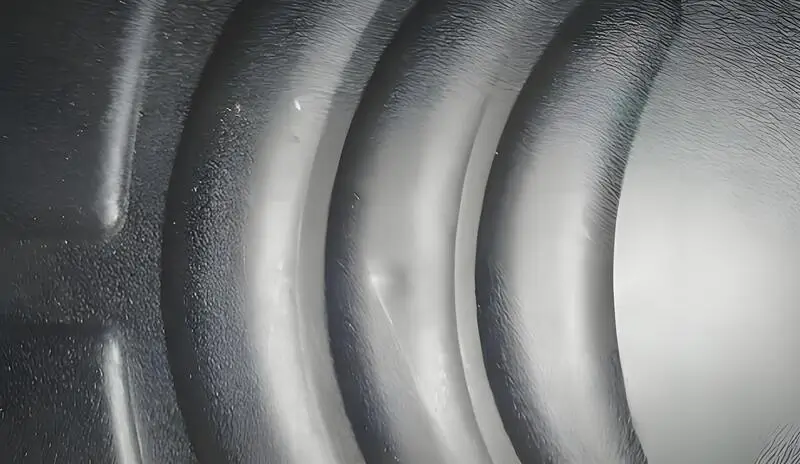

What are the Causes of Flow Marks of Injection Molding Products And Their Solutions?

Flow marks in injection molding can compromise the surface finish of products, making them less visually appealing and functional. Identifying the causes and solutions is key to improving product quality.

Flow marks occur due to uneven cooling, improper injection speeds, or inadequate venting. Solutions include adjusting mold temperature, optimizing injection speed, and improving venting to ensure uniform filling and cooling.

Definition

Flow marks are a molding defect that looks like waves on the surface of the part. It’s caused by the plastic flowing too slowly into the mold, which makes the plastic look like it jumped like a frog.

Causes of Flow Marks

Mold temp and material temp are too low, injection speed and pressure are too low, runner and gate size are too small, and due to product structure, the acceleration is too large when filling and flowing.

Solutions

-

Mold design: Make the cold well in the runner bigger, make the runner and gate bigger, make the main runner shorter or use a hot runner instead.

-

Process conditions: Make the injection speed faster, make the injection pressure and holding pressure higher, make the holding time longer, make the mold temperature and material temperature higher.

Improper cooling is a primary cause of flow marks.True

Flow marks often appear when the cooling rate is uneven, causing surface defects. Proper cooling techniques help eliminate this issue.

Using faster injection speeds always prevents flow marks.False

Faster injection speeds can sometimes cause flow marks due to turbulence or uneven filling. Optimizing injection speed for specific part designs is crucial.

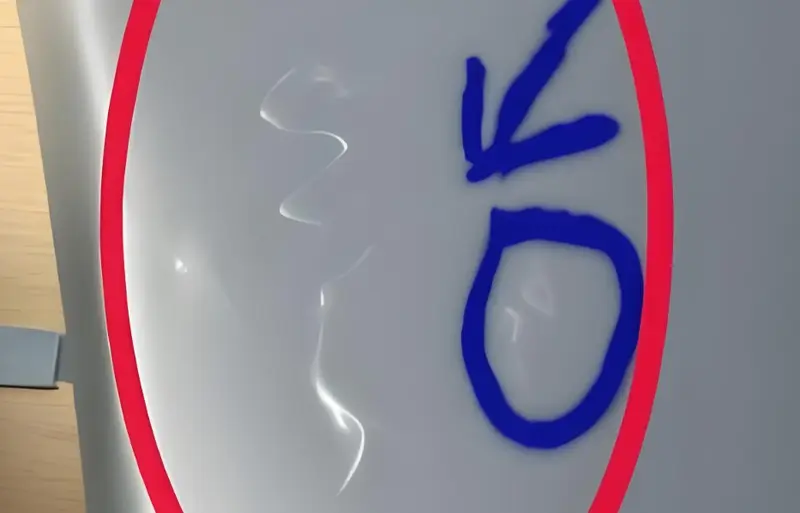

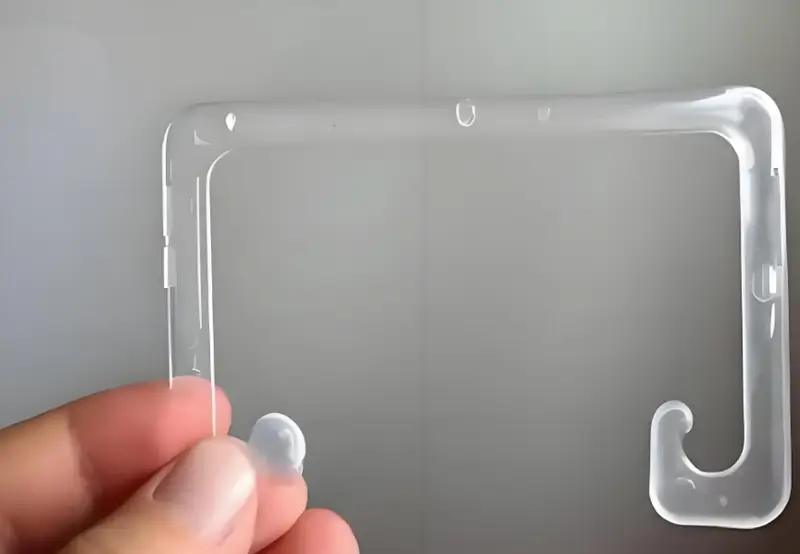

What are the Causes of Silver Streaks of Injection Molding Products And Their Solutions?

Silver streaks in injection molding are caused by issues like moisture, temperature fluctuations, or improper material handling, affecting the aesthetic and performance of the products.

Silver streaks are often caused by moisture in the resin, inconsistent melt temperatures, or contamination. Solutions include proper drying of materials, stable processing conditions, and using high-quality resins to ensure smoother products.

Definition

Silver streaks are when water, air, or carbonized material is distributed on the surface of the part in the direction of flow.

Causes of Silver Streaks

The moisture content in the raw material is too high, air is trapped in the raw material, polymer degradation: the material is contaminated; the barrel temperature is too high; the injection volume is insufficient.

Solutions

-

Content: Dry the raw material based on the data provided by the raw material supplier before injection molding.

-

Mold design: Make sure there are enough vents.

-

Molding process: Choose the right injection molding machine and mold, clean the old material completely from the barrel when changing materials, improve the exhaust system, and lower the melt temperature, injection pressure or injection speed.

Silver streaks are caused by moisture in the resin.True

Moisture in the resin leads to steam bubbles during molding, which create silver streaks on the surface. Proper drying before molding resolves this issue.

Silver streaks are always due to poor material quality.False

While material quality can contribute, silver streaks are more commonly caused by moisture or improper processing conditions.

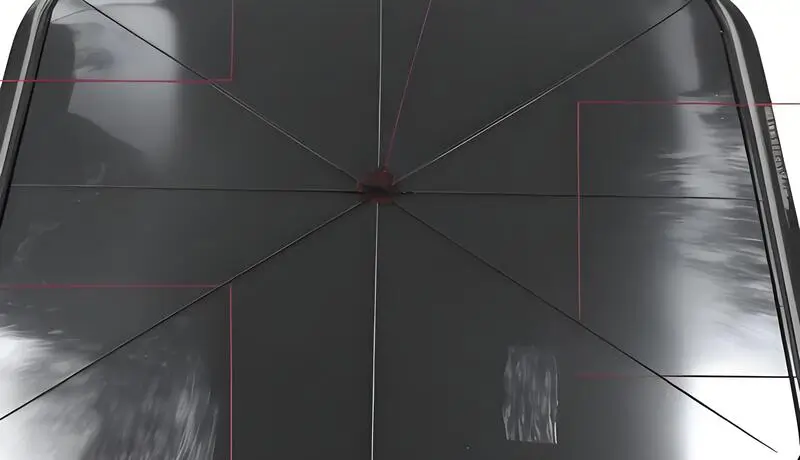

What are the Causes of Dents of Injection Molding Products And Their Solutions?

Dents in injection molding products are common issues caused by improper settings, material defects, or cooling problems. Addressing them ensures product quality and reduces waste.

Dents in injection molding products often result from inconsistent cooling, poor material flow, or incorrect mold design. Solutions include optimizing cooling rates, adjusting injection pressures, and ensuring proper mold design.

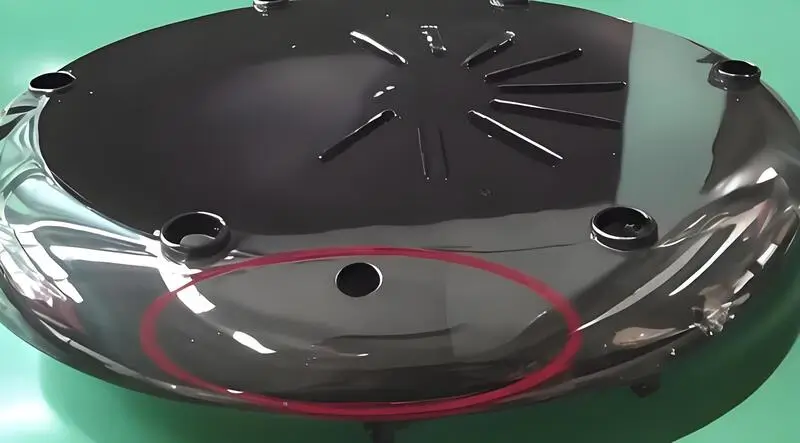

Definition

Dent is when the surface of the part is concave at the wall thickness.

Causes of Dent Formation

The injection pressure or holding pressure is too low, the holding time or cooling time is too short, the melt temperature or mold temperature is too high, and the part structure design is improper.

Solutions

-

Design structure: Corrugate the surface that is easy to dent, reduce the thick wall size of the part, minimize the thickness-to-diameter ratio, the adjacent wall thickness ratio should be controlled at 1.5~2, and try to make a smooth transition, redesign the thickness of the reinforcement ribs, countersunk holes and corner ribs, and their thickness is generally recommended to be 40-80% of the basic wall thickness.

-

Molding process: Increase injection pressure and holding pressure, increase gate size or change gate position.

Inconsistent cooling causes dents in injection molded parts.True

Uneven cooling rates lead to stress and warping, causing visible dents in molded products.

All dent issues in injection molding can be fixed by adjusting cooling settings.False

While cooling adjustments help, material flow, injection pressure, and mold design also play a critical role in preventing dents.

What are the Causes of Welding Marks of Injection Molding Products And Their Solutions?

Welding marks in injection molding occur when two plastic flows meet and fail to bond properly, leaving visible scars on the final product.

Welding marks are caused by improper mold design, inadequate injection speed, or insufficient temperature control. Solutions include optimizing the mold design, adjusting injection speed, and controlling the mold temperature for better flow consistency.

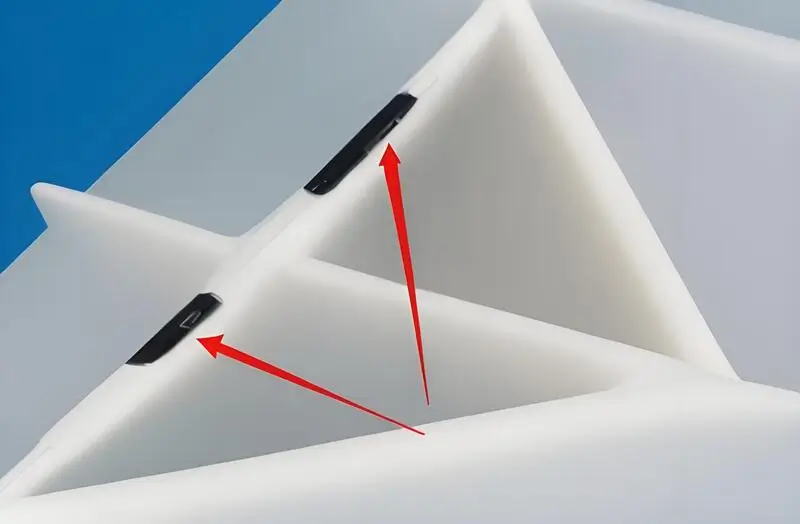

Definition

Weld mark is when two streams of material meet and weld together, and it causes a defect on the surface.

Causes of Weld Mark

If there are holes, inserts, or multi-gate injection molding mode in the part, or if the wall thickness of the part is uneven, weld marks may occur.

Solutions

-

Material: Make the plastic melt flow better.

-

Product design: Change the way the product is made and how thick the walls are.

-

Mold design: Move where the plastic goes into the mold and add places for the air to get out.

-

Process conditions: Make the plastic hotter and use less stuff to keep it from sticking to the mold.Scorch marks are when the air in the mold can’t get out fast enough and the plastic burns at the end of the flow.

Welding marks are caused by improper injection molding settings.True

Welding marks can result from poorly adjusted temperature, speed, or mold design, leading to ineffective bonding of the plastic flow.

Welding marks can be completely eliminated by increasing injection speed.False

Simply increasing the injection speed may not eliminate welding marks if other factors like mold design or temperature control aren't properly adjusted.

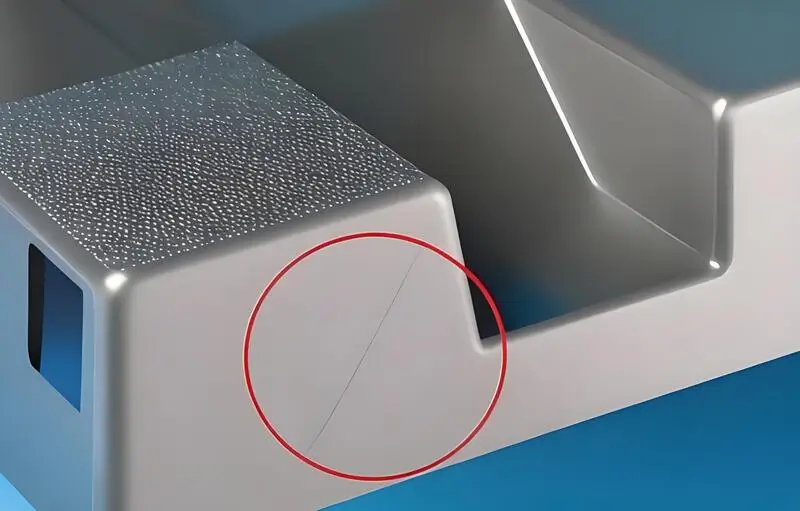

What are the Causes of Warping and Deformation of Injection Molding Products And Their Solutions?

Warping and deformation in injection molding occur due to factors like uneven cooling, improper material choice, and incorrect mold design. Addressing these causes ensures better product quality and reduced waste.

Warping and deformation are caused by uneven cooling, poor mold design, and improper material selection. Solutions include optimizing cooling rates, using appropriate materials, and refining mold design for better part accuracy and strength.

Definition

Warping deformation is when the shape of the injection molded thing gets all messed up and it warps all unevenly, which is not what you want. It’s one of the things that can go wrong when you’re making stuff with injection molds.

Causes of Warping

-

Material properties that are not good: The hardness, strength, toughness, stability and other properties of the material have a great influence on the warping of the product. If the properties of the material are not good or do not meet the requirements, then warping will occur after being subjected to stress.

-

Improper manufacturing process: If you don’t control the temperature and speed of heating, cooling, cutting, welding, and other processes during production, your product will warp.

-

Improper design: If you don’t design your product right, it will warp. For example, if your product is too big or too complicated, it will warp and deform.

Solutions

-

Material selection: Choose good materials to make sure they have the right stuff, especially when you’re making important parts, you gotta use strong materials.

-

Processing technology: You gotta heat, cool, cut, and weld things right, and you gotta do it the way the rules say so you don’t get any warping.

-

Design optimization: When designing a product, you should consider the physical properties of the material and choose a product solution with a simple structure and a reasonable size to avoid warping.

-

Control stress during processing: Control the stress during processing by reducing the cooling speed, heating time, and other methods, which can effectively avoid warping and deformation of the product.

-

Use a fixed mold: Use a fixed mold to fix the product and avoid warping and deformation.

Uneven cooling causes warping in injection molding.True

Uneven cooling leads to uneven shrinkage, causing warping and deformation in molded parts.

Using any material can solve warping issues.False

Selecting the right material for the specific application is crucial to prevent warping, as different materials have varying shrinkage rates.

What are the Causes of Bubbles of Injection Molding Products And Their Solutions?

Bubbles in injection molding products can lead to defects, impacting product quality and production efficiency. Identifying their causes is key to solving this issue.

Bubbles in injection molding are often caused by trapped air, moisture, or improper injection speed. Solutions include optimizing venting, drying materials, and adjusting injection parameters to reduce defects and improve part quality.

Definition

The gas in the bubbles (vacuum bubbles) is very thin and belongs to vacuum bubbles. Generally speaking, if bubbles are found at the moment of mold opening, it is a gas interference problem. The formation of vacuum bubbles is due to insufficient plastic filling or low pressure. Under the rapid cooling of the mold, the fuel at the corner of the cavity is pulled, resulting in volume loss.

Causes of Bubble

-

Problems with the injection molding machine: If you don’t control the temperature, pressure, speed, and other parameters of the injection molding machine properly, you’ll get bubbles in your injection molded parts.If the temperature is too high or the pressure is too low, the raw material won’t flow smoothly and you’ll get bubbles. If the speed is too fast or too slow, the gas in the injection molded parts won’t be able to get out in time and you’ll get bubbles. Also, if you use old injection molding machines or don’t maintain them properly, you’ll have similar problems.

-

Raw material issues: The quality, moisture content, and mixing conditions of raw materials will also affect the quality of injection molded parts. If the raw material has too much water, it will evaporate quickly and produce bubbles during the injection molding process .if the raw material quality is poor or different types of raw materials are mixed, bubbles will also be produced. Therefore, before the production of injection molded parts, the raw materials need to be fully tested and screened.

-

Mold problems: There are many problems in the design, manufacturing, and use of injection molds that can also cause bubbles. For example, poor mold exhaust, improper exhaust port position, scratches on the mold surface, etc., will affect the quality of injection molded parts. Therefore, when using the mold for injection molding production, it is necessary to fully inspect and maintain it.

Solutions

When the wall thickness of the product is large, the outer surface cools faster than the center. As the cooling proceeds, the resin in the center shrinks and expands toward the surface, causing insufficient filling in the center. This is called vacuum bubbles. The main solutions are: determine the reasonable gate and runner size according to the wall thickness.

Generally, the gate height should be 50% to 60% of the product wall thickness until the gate is sealed, leaving a certain amount of supplementary injection material, the injection time should be slightly longer than the gate sealing time, the injection speed should be reduced, the injection pressure should be increased, and materials with high melt viscosity grades should be used.

-

The solutions to bubbles caused by the generation of volatile gases are: fully pre-drying, reducing the resin temperature, and avoiding the generation of decomposition gases.

-

The bubbles caused by poor fluidity can increase the injection energy: pressure, speed, time and material amount, and increase the back pressure to make the mold full.Raise the melt temperature to improve flow. Lower the melt temperature to reduce shrinkage, and raise the mold temperature, especially locally where the vacuum bubbles form.Put the gate in the thickest part of the part, improve the flow conditions of the nozzle, runner, and gate, and reduce the pressure drop. Improve the venting of the mold.

Moisture in materials can cause bubbles in injection molding.True

Moisture trapped in the raw materials turns into vapor during injection, creating air bubbles inside the mold. Drying materials before molding can prevent this issue.

Bubbles in injection molding are always caused by equipment failure.False

While equipment issues can contribute, most bubble defects are due to improper material handling, injection speed, or venting.

What are the Causes of Black Spots of Injection Molding Products And Their Solutions?

Black spots in injection molding products are common defects caused by material degradation, insufficient venting, or contamination during the molding process. Identifying the root cause is crucial for effective solutions.

Black spots occur when plastic degrades due to excessive heat or contamination. Solutions include adjusting temperatures, improving venting, and using cleaner raw materials. Proper material handling is essential to avoid this issue.

Definition

Black spots on injection molded parts are caused by impurities, foreign matter, or degradation products that get mixed into the plastic during the injection molding process. This results in black particles or spots on the surface or inside of the plastic part. The size, distribution, and density of black spots are all related to the nature and quantity of impurities or foreign matter.

Causes of Black Spots

When making injection molding machines, there are many reasons why there are black spots on the products. Here are some common situations:

-

Overheating: If the temperature set on the injection molding machine is too high, the molten material will decompose and oxidize due to heat, and black things will be produced.

-

Thermal cracking: Polymer materials can crack due to factors such as changes in alloy composition, rapid cooling, and air in the head. After thermal cracking, black fragments will be left in the material.

-

Extrusion failure: When the material flows too fast during extrusion, it can easily cause the colloid near the head to fail to extrude properly, leaving black spots.

Solution

-

Change the temperature: Change the set temperature of the injection molding machine to avoid overheating.

-

Check the mold: Check the cooling effect of the mold to see if the temperature can be lowered to avoid overheating.

-

Add anti-decomposition agent: Adding anti-decomposition agent can effectively reduce the decomposition and thermal oxidation of the material.

-

Swap out materials: Swap out fancy polymer materials, swap out materials that work for molds, etc., which can lower the chance of thermal cracking and bad extrusion.

Black spots are caused by plastic degradation during injection molding.True

Excessive heat or prolonged exposure to heat can break down the plastic, leading to black spots.

Using higher-quality raw materials guarantees no black spots.False

Even high-quality materials can form black spots if not properly processed or handled in the molding process.

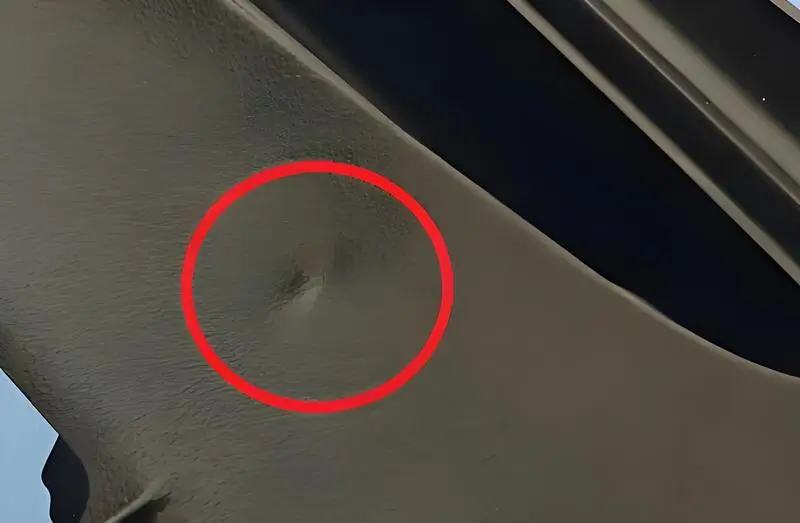

What are the Causes of Depression of Injection Molding Products And Their Solutions?

Depression in injection molding products can result from various factors such as improper cooling, material issues, or mold design flaws. Identifying the root causes helps improve product quality and production efficiency.

Depression in injection molding occurs due to inconsistent cooling, improper material selection, or inadequate mold venting. Solutions include optimizing cooling rates, using suitable materials, and improving mold design.

Definition

Shrink marks are localized collapses on the surface of a product, also known as dents, shrink pits, and sedimentation spots.

When the thickness of a plastic part is uneven, some parts will shrink too much during the cooling process, resulting in shrink marks.

However, if the surface is hard enough during the cooling process, shrinkage inside the plastic part will cause structural defects in the plastic part.

Reasons for Depression

-

Mold design that doesn’t make sense: One of the main reasons why injection molded parts sink is because the mold design is bad. If the mold design is bad, the pressure distribution inside the injection molded part will be uneven, which will cause the part to sink.For example, during the injection molding process, the wall thickness of the mold cavity is inconsistent, and some parts are prone to sink or defects. In addition, during the long production process, mold wear and deformation can also cause sink marks.

-

Unreasonable injection molding process parameters: The setting of injection molding process parameters is also a possible reason for the depression of injection molded parts.If the injection molding temperature is too high or too low, the pressure is unstable, the injection molding speed is too fast or too slow, etc., it may cause the pressure inside the injection molded part to be unbalanced, resulting in depression problems.

- Wrong choice of materials: The choice of plastic materials is also a reason for the depression of injection molded parts. If the selected plastic material is not heat-resistant or pressure-resistant, it is easy to produce dents and defects during the injection molding process.In addition, during the injection molding production process, the moisture content of the plastic material also needs to be paid attention to. If it contains too much water, it may also cause dents and defects.

Solutions

-

Make the mold better: One of the main reasons for dents in injection molded parts is bad mold design. So, making the mold better is a good way to fix the problem. Making the mold better means changing the thickness difference of the mold cavity and the design of other local structures to make the internal pressure distribution of the injection molded parts even, and finally stop the dents.

-

Tweak the injection molding process parameters: To dodge the dents on the injection molded parts, you need to tweak the injection molding process parameters. For example, you can up the injection temperature a bit or slow down the injection speed, extend the cooling time, and so on. Meanwhile, you also need to make sure the injection molding machine is stable and keep the pressure and temperature stable during the injection molding process.

-

Pick the right stuff: Picking the right plastic stuff can help you avoid dents in your injection molded parts. You need to pick the plastic stuff based on what your part is made of, or you can add special stuff to make your plastic stronger and able to handle more pressure. Also, make sure your stuff isn’t too wet or you’ll get dents.

Improper cooling leads to depression in injection molded parts.True

Uneven cooling causes warping and sinking, leading to depression on molded products. Optimizing cooling rates can minimize these issues.

Depression in molded parts always indicates mold design flaws.False

While mold design flaws can cause depression, material issues and cooling problems also contribute to the defect, requiring a comprehensive approach to resolve it.

What are the Causes of Deformation of Injection Molding Products And Their Solutions?

Deformation in injection molding products is a common issue caused by improper processing, material choices, or mold design. Addressing these causes ensures higher quality and reduced defects.

Deformation of injection molding products can result from factors like uneven cooling, high injection pressure, or mold design flaws. Solutions include optimizing temperature control, adjusting pressure, and refining mold design to ensure uniform part quality.

Definition

Shell deformation in injection molding refers to the deformation or defects in the shape, size, appearance, etc. of the plastic product that don’t meet the design requirements during the injection molding process. It usually shows up as the product being too big, too small, twisted, warped, uneven shell, short shot, etc.

Cause of Deformation

-

Temperature Issue: The deformation of injection molded parts is often related to temperature. When we do injection molding, the molten flow is injected into the mold through a closed cavity, and solidifies into the shape of the product after cooling.Therefore, the temperature has a great influence on the flow and solidification of the plastic melt. When the temperature is too high or too low, changes in the plastic material flow rate and solidification rate will cause deformation of the injection molded parts.

-

Material issue: The quality difference of injection molding materials will cause deformation of injection molded parts. For example, raw materials containing micropowder or aging materials will cause uneven shrinkage of the product, thereby causing deformation.

-

Mold problem: Mold is one of the factors that affect the molding process of injection molding. Improper settings of parameters such as mold temperature, injection pressure, injection speed, or defects or deficiencies in the mold itself can also cause deformation of injection molded parts.

- Process issues: Injection molding is a key part of production. If the process flow isn’t set right, the injection molding machine isn’t set right, or the operation isn’t done right, it’ll lead to poor uniformity or product deformation.

Solutions

-

Tweak the process: You can change the flow state, control the deformation and shrinkage of the material, and reduce the deformation of the injection molded parts by adjusting the injection molding process parameters, such as injection temperature, injection speed, holding time, etc.

-

Pick the right stuff: Choose the right injection molding material based on the product’s characteristics and how it’s going to be used. For example, if you need something that can keep its shape when it gets hot, you’ll want a material with high-temperature toughness.

-

Make the mold better: Make the mold better by making the mold better. Make the mold better by making the mold better. Make the mold better by making the mold better.

-

Fix the injection molding machine performance: By fixing the injection molding machine’s accuracy and stability, controlling the physical parameters during the injection process, you can get rid of the problem of deformation of the injection molded parts.

-

Strengthen inspection and flexibility: Increase quality inspection points, detect injection molded parts deformation problems in a timely manner, and reduce product batch differences.

Uneven cooling causes deformation in injection molded parts.True

Uneven cooling leads to shrinkage variations, causing warping or distortion of parts. Controlling temperature distribution minimizes this issue.

Mold design flaws always lead to deformation.False

While mold design flaws can contribute to deformation, issues such as temperature control and pressure also play a significant role in product quality.

Conclusion

In summary, injection molding defects mainly include short shot, air entrapment, brittleness, burning, flash, delamination, spray marks, flow marks, silver streaks, dents, weld marks, warping, deformation, bubbles, black spots, flow lines, and weld lines.

So, the process requires a big upfront tooling investment. And it’s really important to always design your molds right. That’s where Zetar Mold comes in! At Zetar Mold, we specialize in giving you the best injection molding services.

We know all the different injection molding defect and what causes them.

Our top-notch technical expertise lets us avoid these defects in a bunch of different ways. We can do our cost-effective injection molding services for both mass production and rapid prototyping. You’ll get all that and more when you upload your design files for a quote.injection molding defect.

-

Learn about Injection Molding: A Comprehensive Guide : Injection molding is a manufacturing process where molten plastic is injected into a mold to create parts with high accuracy and repeatability. ↩

-

Learn about Understanding Injection Speed and Injection Pressure : Injection pressure is provided by the hydraulic system of the injection molding machine. Typically, the set injection speed refers to the screw’s forward speed. ↩

-

Learn about Runner System : The Runner System is the filling system through which material travels from the injection unit into the part cavity. ↩

-

Learn about Injection molding machine: An injection molding machine is a machine for manufacturing plastic products by the injection molding process. ↩

-

Learn about Injection Speed : The injection speed has a great impact on the degree of molecular orientation in the component ↩

-

Learn about Barrel Temperature: Barrel temperatures vary with different grades of TPUs (different hardness), with part design, ratio of shot volume to barrel volume, and cycle time. ↩

-

Learn about How to Determine Holding Pressure and Holding Time In Injection Molding? Generally speaking, injection pressure includes both pressure and speed, while holding pressure only involves pressure, not speed. ↩