Molds for injection molding are tools used to shape things. They are made up of different parts, and different molds have different parts. The injection molding process mainly includes raw material preparation, feeding, heating and melting, injection, cooling and solidification, mold opening and extraction, flash removal, trimming, and processing, inspection, and packaging.

Ⅰ. Heating System

1. Mold Heating Methods

1.1 Steel Heating

Steel heating is a heating method that is almost mandatory in the design of all plastic molding molds. It can be designed in various forms such as single-phase wiring, two-phase wiring, etc. Materials such as seamed pipes, seamless pipes, stainless steel pipes can be used, characterized by low heat loss, high thermal efficiency, simple wiring, and flexible wiring configurations according to needs, designed for either 220V or 380V. However, due to limitations in materials and processing techniques, attention should be paid to its unique characteristics in mold design.

1.2 Soldering Iron Core Heating

The soldering iron core is often used as a type of mold heating tube. It has high power per unit length (usually a diameter of 10mm, a length of 8cm soldering iron core can achieve an output power of 150 watts), durability, good safety, resistance to short circuits, can be embedded through blind holes, but difficult to customize design, prone to fragility and breakage during replacement.

2. Factors Affecting Injection Mold Heating Rate

There are many factors that affect how fast an injection mold heats up. Some of these factors include:

2.1 Mold Material and Structure

The material and structure of the mold directly affect the heating rate. Different materials have different thermal conductivity and heat capacity, while the thickness and design of the mold also affect the speed of heat conduction.

2.2 Heating Method and Equipment

Injection molds are heated using electric heating or hot runner systems. Different heating methods have different heating rates and control capabilities. For example, electric heating can heat up quickly and control temperature precisely, while hot runner systems can transfer heat directly to specific parts of the mold, making heating more efficient.

2.3 Heating Temperature and Time

The heating temperature and heating time are the two main factors that affect the heating rate. Increasing the heating temperature and extending the heating time can speed up the heating rate of the mold, but you have to be careful not to damage the mold or cause thermal stress.

2.4 Environmental Conditions

The heating rate of the mold is also affected by environmental conditions like the temperature and humidity of the room. If it’s really cold or really humid, the heating rate might be affected a little bit.

2.5 Mold Condition and Maintenance

The heating rate is affected by the condition and maintenance of the mold. If there is ash accumulation, oxidation, or damage on the surface of the mold, it will reduce heating efficiency and prolong heating time.

2.6 Heating Medium

Different heating mediums, like electric heating wires, thermal oil, etc., have different heat transfer characteristics, which will affect the heating rate. Choosing the right heating medium can improve heating efficiency.

Ⅱ. Cooling Stage

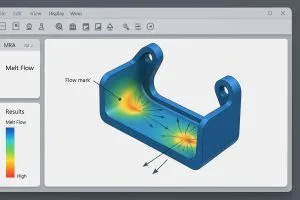

In injection molding molds, the design of the cooling system is very important. This is because molded plastic products need to cool and solidify to a certain rigidity before demolding to prevent deformation due to external forces. Since cooling time accounts for about 70% to 80% of the entire molding cycle, a well-designed cooling system can greatly shorten the molding time, increase injection molding productivity, and reduce costs. Improperly designed cooling systems can prolong molding time, increase costs, and uneven cooling can further cause warpage and deformation of plastic products.

Based on experiments, the heat from the melt entering the mold generally goes away in two ways: 5% is transferred to the atmosphere through radiation and convection, and the other 95% is conducted from the melt to the mold. Because of the cooling water pipes in the mold, the heat is transferred from the plastic in the mold cavity to the cooling water pipe through heat conduction via the mold base, and then carried away by the cooling liquid through heat convection. A small amount of heat not taken away by the cooling water continues to conduct in the mold and dissipates into the air upon contact with the outside.

The injection molding process has five stages: mold closing, filling, holding pressure, cooling, and demolding. Cooling takes the longest, about 70% to 80% of the total time. So, cooling time affects the cycle time and how many parts you can make. When you take the part out of the mold, it needs to be cooled below the heat distortion temperature. This stops the part from relaxing and getting warped or deformed.

1. Mold Cooling Methods

1.1 Water Cooling

Water cooling is the most commonly used cooling method for most molds, but it also has its drawbacks; it requires good pipeline sealing and unobstructed upper and lower water pipelines, resulting in significant water waste. When the cooling temperature exceeds 100°C, steam explosions are likely to occur. The advantage is that it has a large heat capacity and can achieve rapid cooling.

1.2 Air Cooling

Air cooling is a relatively ideal cooling method. Unlike water cooling, it does not require tight pipeline sealing, there is no waste of resources, it can cool molds with temperatures higher than 100°C, and the cooling speed can be determined by the flow rate of gas. Moreover, it is simple and convenient to obtain gas sources in production workshops of a certain scale.

2. Factors Affecting Product Cooling Rate

2.1 Plastic Product Design

The main thing is the wall thickness of the plastic part. The thicker the part, the longer it takes to cool. As a rule of thumb, cooling time is roughly proportional to the square of the part thickness or the 1.6th power of the largest gate diameter. In other words, doubling the part thickness increases cooling time by four times.

2.2 Mold Material and Cooling Method

The mold material, including the core and cavity materials of the mold and the mold frame material, has a big effect on the cooling rate. The higher the thermal conductivity of the mold material, the better the effect of transferring heat from the plastic in a unit of time, and the shorter the cooling time.

2.3 Cooling Water Pipe Configuration

The closer the cooling water pipe is to the mold cavity, the larger the diameter, and the greater the number, the better the cooling effect and the shorter the cooling time.

2.4 Cooling Liquid Flow Rate

The more water you can get moving through the system (turbulent flow is better), the better the water will be at taking heat away from the engine by convection.

2.5 Properties of Cooling Liquid

The viscosity and thermal conductivity of the cooling liquid also affect the heat transfer effect of the mold. The lower the viscosity of the cooling liquid, the higher the thermal conductivity, the lower the temperature, and the better the cooling effect.

2.6 Selection of Plastic Material

Plastic’s thermal conductivity is how fast it moves heat from a hot spot to a cold spot. The higher the thermal conductivity, the better it moves heat, or the lower the specific heat, the easier it is to change temperature, so it cools off faster and moves heat better, so it takes less time to cool.

3. Cooling System Design Rules

3.1 The cooling channels should be designed to cool the mold uniformly and quickly.

3.2 The purpose of designing the cooling system is to keep the mold cool and do it efficiently. The cooling holes should be standard sizes so they can be machined and assembled easily.

3.3 When designing the cooling system, the mold designer must decide on the following design parameters based on the wall thickness and volume of the plastic part: where and how big the cooling holes should be, how long the holes should be, what kind of holes to use, how to arrange and connect the holes, and how much cooling liquid to use and how well it transfers heat.

Ⅲ. The Importance of Mold Temperature Control in Injection Molding

Temperature control is super important in injection molding because it directly affects the quality, consistency, and cycle time of molded parts. Cooling and heating are both big parts of this control mechanism, making sure that the molten material flows good, solidifies right, and is demolded without defects from the mold.

1. Influence of Mold Temperature on Product Appearance

When the temperature is higher, the resin flows better. This usually makes the surface of the parts smooth and shiny, especially for glass fiber reinforced resin parts. It also makes the weld lines stronger and look better.

For textured surfaces, if the mold temperature is low, the melt can’t fill the roots of the texture, so the surface of the product is shiny and can’t show the true texture of the mold surface. If you increase the mold temperature and the material temperature, you can get the texture you want on the surface of the product.

2. Influence on Internal Stress of Products

When you mold something, it gets hot and then cools down. When it cools down, it shrinks. The outside of the thing shrinks first and gets hard. Then the inside shrinks and gets hard. The inside and the outside shrink at different rates, and that makes the inside and the outside fight each other. When the inside and the outside fight each other too much, the thing cracks.

When the inside of the thing fights the outside of the thing too much, the thing cracks. This happens when the inside of the thing fights the outside of the thing too much, and the inside of the thing is too weak or the outside of the thing is too strong. This also happens when the inside of the thing fights the outside of the thing too much, and the inside of the thing is too weak or the outside of the thing is too strong, and the thing gets wet or gets chemicals on it. When the inside of the thing fights the outside of the thing too much, the thing cracks.

The surface compressive stress depends on the surface cooling conditions. Cold molds cause the molten resin to cool rapidly, resulting in higher residual internal stress in the molded product. Mold temperature is the most basic condition for controlling internal stress, and slight changes in mold temperature can greatly change its residual internal stress. Generally, each product and resin have their lowest mold temperature limit for acceptable internal stress. When molding thin-walled or long-flow parts, the mold temperature should be higher than the minimum limit during general molding.

3. Improving Product Warpage

If the cooling system of the mold is designed improperly or the mold temperature control is improper, insufficient cooling of the plastic parts can cause warpage and deformation of the parts.

For mold temperature control, the temperature difference between the male and female molds, the core and cavity, the mold core and wall, and the wall and inserts should be determined based on the structural characteristics of the product. By utilizing the different cooling shrinkage rates of different parts of the mold to compensate for the orientation shrinkage difference after demolding, the product tends to bend towards the side with higher temperature after demolding, thus offsetting the warpage deformation of the product according to the orientation law.

For plastic parts with completely symmetrical body structures, you should keep the mold temperature consistent to make sure all parts of the product cool down evenly.

4. Impact on Product Shrinkage Rate

Lower mold temperatures make the molecules freeze faster, make the frozen layer of the melt in the cavity thicker, and make it harder for crystals to grow, so the product shrinks less. Higher mold temperatures make the melt cool slower, make the relaxation time longer, make the orientation level lower, make it easier for crystals to form, so the product shrinks more.

5. Influence on Product Heat Deflection Temperature

For crystalline plastics, if you mold the product at a low mold temperature, the molecular orientation and crystallization freeze right away. When you put it in a higher temperature environment or secondary processing conditions, the molecular chains will partially rearrange and crystallize, causing the product to deform even at temperatures way below the material’s heat deflection temperature (HDT).

Ⅳ. Optimizing Temperature Control

1. Temperature Control System Upgrade

Electric heating rods are a big part of the temperature control system of injection molding machines. If you upgrade your electric heating rods, you can make your temperature control more stable and accurate. That means you can make your injection molding more accurate and better quality.

2. Improvement of Temperature Control Strategy

When it comes to injection molding, temperature control is a big deal. It affects the quality and cost of your parts. If you do it right, you can reduce cycle time and energy consumption, improve production efficiency, and cut costs.

3. Adjustment of Temperature Control Parameters

To get the best injection molding effect, you need to adjust the temperature control parameters. You can do this by adjusting the proportion of the rear, middle, and front zone temperatures.

Ⅴ. Conclusion

To get good parts fast, you need to master mold cooling and heating. You need to understand temperature control, use the latest cooling and heating technologies, and have the best monitoring and control systems. That’s how you get the most out of your injection molding process.