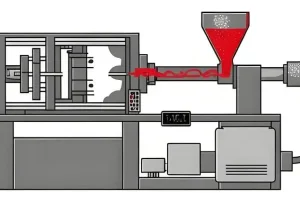

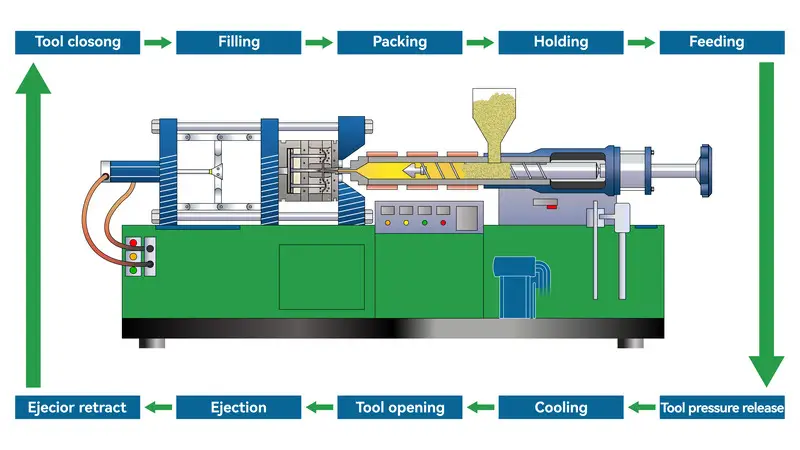

Evaluating injection mold quality is crucial for ensuring precision, durability, and cost-effectiveness in manufacturing processes.

Assess the quality of injection molds by examining material choice, dimensional accuracy, surface finish, and mold design. Focus on durability, maintenance requirements, and production efficiency to ensure optimal performance in manufacturing.

Understanding these quality indicators helps optimize manufacturing operations and product outcomes. Dive deeper into specific criteria and industry best practices to select and maintain high-quality injection molds.

High-quality injection molds always guarantee flawless products.Yanlış

While they enhance consistency and durability, external factors like material and process parameters also affect product quality.

Quality molds require minimal maintenance for optimal performance.Doğru

Well-designed molds with superior materials often require less frequent maintenance, reducing downtime and costs.

What are the Common Problems and Solutions of Injection Molds?

Injection molds face various issues like warping, short shots, and flash, impacting product quality and efficiency.

Common injection mold problems include warping, short shots, and flash, each with specific solutions like proper mold design, venting, and material selection. Addressing these issues enhances the quality and efficiency of the molding process in industries from automotive to consumer goods.

Poor Quality of Molds

-

Sebep:Mold has rough surface, can be easily worn down, and does not last long due to using improper kalıp malzemeleri1 and wrong manufacturing process.

-

Çözüm:Select high quality mold materials, guarantee the manufacturing process to meet the standards, and perform regular inspection and maintenance on the mold to extend mold life.

Mold Dimensional Accuracy is not up to Standard

-

Sebep: Mould processing isn’t high enough precision, assembly precision isn’t enough, resulting in injection molded parts dimension precision isn’t to the criterion, deformation.

-

Çözüm: Improve mold processing precision2, strengthen quality control in the assembly process, and use precision testing equipment to calibrate the mold.

Mold Structure is Unreasonable

-

Sebep: Mold not well designed, draft angle too small, flip mold structure handled incorrectly, resulting in flash and defects on molded parts.

-

Çözüm: Redesign mold, ensure proper draft angle, and redesign flip mold structure to add auxiliary release mechanism, like slides or inclined top.

Mold Maintenance is not Timely

-

Sebep: The mold will be damaged due to long-term use and the life span will be shortened.

-

Çözüm: Establish regular mold maintenance system, clean, lubricate, inspect, and maintain mold regularly to timely detect and repair problems that may occur.

Mold Temperature Control is not Good

-

Sebep: Inaccurate control of mold temperature during injection molding results in heat shrinkage, deformation, and other issues with molded parts.

-

Çözüm: Adopt advanced temperature control system to control the mold temperature accurately to ensure that the mold maintains a stable temperature during the injection process.

Improper Injection Molding Process

-

Sebep: The injection pressure, speed, temperature, and other process parameters are not set properly, causing defects in the injection molded parts.

-

Çözüm: Set the injection process parameters3 properly based on the material and structure characteristics of the injection molded parts to ensure a stable and reliable injection process.

Proper mold venting eliminates flash in injection molding.Doğru

Adequate venting allows trapped air and gases to escape, preventing excess material overflow, known as flash.

Warpage in molds is solely caused by high temperatures.Yanlış

While temperature can influence warpage, factors like uneven cooling, material shrinkage, and improper mold design also contribute to this issue.

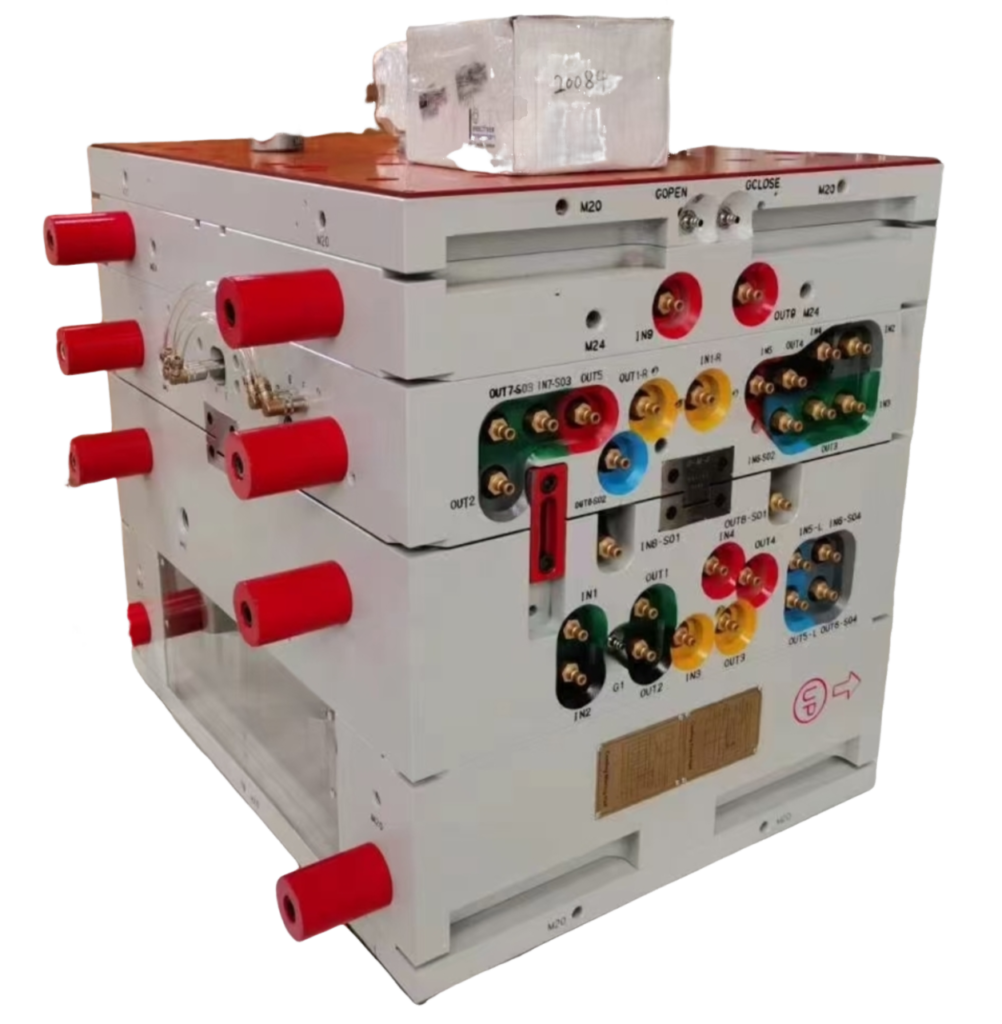

What are the Acceptance Criteria for Injection Mold Quality?

Ensuring high-quality injection molds is essential for product consistency and manufacturing success, requiring strict adherence to specific acceptance criteria.

Injection mold quality criteria include dimensional accuracy, surface finish, uniform thickness, material integrity, and proper functionality. Meeting these standards ensures consistent part quality, longevity, and cost-effectiveness in production.

Mold Appearance Acceptance Criteria

The injection mold should look smooth and flat, without any obvious scratches, sand holes, cracks, or other problems. The plating or coating on the surface should be even and strong, without any peeling or skinning. The mold should have clear and accurate markings, including the mold number, specifications, production date, and other information.

The content on the mold nameplate should be complete, with clear characters that are neatly arranged. The nameplate should be fixed on the mold foot near the template and the reference corner. The nameplate should be fixed securely and not easily come off.

Bu cooling water nozzle4 should use a plastic block insert water nozzle, and if the customer has other requirements, they should be followed. The cooling water nozzle should not extend beyond the surface of the mold frame. The cooling water nozzles need to have countersunk holes, with three specifications for the countersunk hole diameter: 25mm, 30mm, and 35mm.

The holes should have chamfers, and the chamfers should be consistent. The cooling water nozzle should have an in and out mark. The marking for the English characters and numbers should be larger than 5/6, with the location of the water nozzle directly below by 10mm. The handwriting should be clear, beautiful, neat, and evenly spaced.

Mold accessories should not affect the lifting and storage of the mold. When installing the following exposed cylinders, nozzles, pre-reset mechanisms, etc, there should be support legs to protect them. The support legs should be fixed on the mold frame by screws through the support legs. If the support legs are too long, they can be fixed to the mold frame by turning the outer thread column.

The size of the mold ejection hole should meet the requirements of the specified injection molding machine. Except for small molds, only one center ejection cannot be used. The positioning ring should be fixed reliably. There are two types of ring diameters: 100mm and 250mm. The positioning ring is 10-20mm above the base plate, unless otherwise specified by the customer.

The external dimensions of the mold should meet the requirements of the specified injection molding machine. Molds that require directional installation should be marked with an arrow on the front or rear template to indicate the direction of installation. There should be the word “UP” next to the arrow.

The arrow and the text are yellow, and the height of the text is 50mm. The surface of the mold frame should be free of pits, rust stains, redundant hanging rings, steam inlets and outlets, oil holes, and other defects that affect the appearance.

The mold should be easy to lift and transport. The mold parts should not be disassembled during lifting. The lifting ring should not interfere with the water nozzle, oil cylinder, pre-reset lever, etc.

Size Acceptance Standard

Bu mold dimensions5 should match the design drawings, and the key dimensions should be within the specified tolerance. Different molds and products have different requirements for dimensional tolerances. Precision injection molds usually have stricter dimensional tolerances.

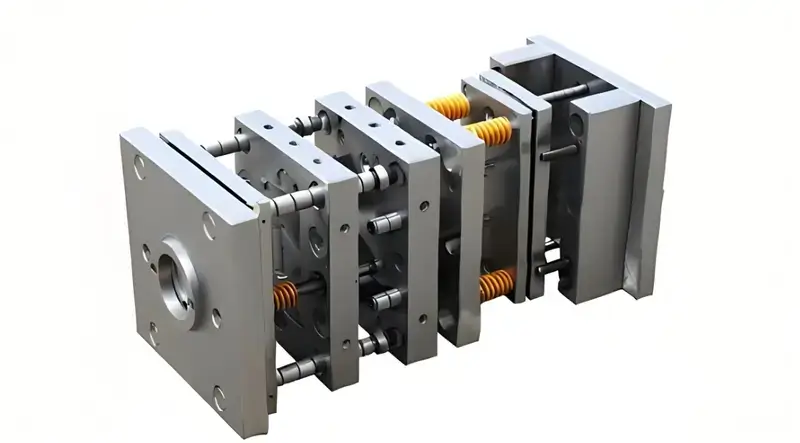

Acceptance Standard of Mold Structure

Bu kalıp yapısı6 should be reasonable and firm, and the parts should be closely and reliably connected. The mold opening and closing action should be smooth, without jamming and abnormal noise. The mold guiding mechanism and positioning mechanism should be accurate to ensure the accuracy of the mold when it is closed.

Acceptance Standard of Injection Molding Performance

When you’re testing a mold, it should be able to shoot good parts. The parts should look good, with no flash, short shots, or bubbles, and they should be the right size. The mold should run fast enough to make the parts you need.

Mold Material and Hardness Heat Treatment Acceptance Criteria

Choose the mold base according to the standard mold base. The materials of the mold forming parts and the casting system (core, movable and fixed inserts, movable inserts, runner cone, push rod, sprue) should have a performance higher than 40Cr.

The plastic that is easy to corrode on the mold should be made of corrosion-resistant materials[^7], or the molding surface should take anti-corrosion measures. The hardness of the mold forming parts should not be less than 50HRC, or the surface hardening treatment hardness should be higher than 600HV. The heat treatment of the mold7 should meet the process requirements to ensure the hardness, strength and other performance indicators of the material.

Ejector, Reset, Insertion and Removal Standards

Ejection should be smooth, no jamming, no abnormal sound. The slanting top surface should be polished, and the slanting top surface should be lower than the core surface. The sliding parts should be equipped with oil groove, and the surface should be nitrided, and the hardness of the treated surface should be HV700 or above.

All top rods should have stop-rotation positioning, and each top rod should be numbered. The ejection distance8 should be limited by the limit block to limit the reset spring should be selected from the standard parts, the spring ends should not be polished, cut.

Slider, core should have a travel limit, small slider with spring limit, spring inconvenience can be installed when the wave screws; cylinder core must have a travel switch. Slider core generally use oblique guide column, oblique guide column angle should be smaller than the slider locking surface angle of 2 ° ~ 3 °. Slider stroke is too long should be used cylinder extraction.

When the end face of the molding part of the cylinder core extraction is wrapped, the cylinder should be added with self-locking mechanism9.

Slider width of more than 150 mm large slider should be below the wear plate, wear plate material10 should be selected T8A, heat-treated hardness of HRC50 ~ 55, wear plate than the large surface higher than 0.05 ~ 0.1 mm, and open the oil groove. The top bar should not be strung up and down.

Add barbs on the top bar, the direction of the barbs should be consistent, and the barbs are easy to remove from the products.

The clearance between the hole of the top bar and the top bar, the length of the sealing section, and the surface roughness of the hole of the top bar should be according to the requirements of the relevant enterprise standards. The product should be favorable for the operator to take down. When the product is ejected, it is easy to follow the slanting top, and the groove or etching should be added on the top bar.

The top block fixed on the top bar should be firm and reliable, and the non-molding part around should be processed with a slope of 3°~5°, and the lower periphery should be chamfered. The oil holes on the mold frame should be free of iron debris. The end surface of the return rod is flat, without spot welding. No gasket and spot welding at the bottom of the sprue.

Three-plate mold gate plate guide sliding smoothly, the gate plate is easy to pull apart. The limit lever of three-platen mold should be arranged on both sides of the mold installation direction, or add a pull plate outside the mold frame to prevent the limit lever from interfering with the operator.

The oil and air channels should be smooth, and the hydraulic ejection reset should be in place. The bottom of the guide sleeve should be opened to make the exhaust port. There should be no gap in the positioning pin installation.

Acceptance Criteria for Cooling and Heating System

The cooling or heating system should be smooth enough. The sealing should be reliable, and the system should not have leakage under 0.5MPa pressure and be easy to repair.

The size and shape of the sealing groove opened on the mold frame shall meet the requirements of relevant standards. The sealing ring should be greased when it is placed, and it should be higher than the surface of the mold frame after it is placed. The water and oil runner spacer should be made of non-corrosive material.

The front and rear molds should adopt centralized water feeding and method. The heating system should be able to accurately control the temperature of the mold to ensure the stability of the injection molding process. Cooling and heating pipes should be free of leakage.

Standard of Pouring System

The gate location should not affect the appearance of the product and should meet the requirements of product assembly. The cross-sectional shape and length of the runner should be reasonably designed to shorten the process as much as possible under the premise of ensuring the quality of the molded part, and reduce the cross-sectional area to shorten the filling and cooling time, and at the same time, minimize the loss of plastic in the pouring system.

The cross section of the sprue of the three-plate mold at the back of the front template should be trapezoidal or semi-circular. The three-plate mold should have a break handle on the sprue plate, a sprue inlet diameter of less than 3 mm, and a 3 mm deep step in the ball end recessed into the sprue plate. The ball puller should be fixed reliably and can be pressed under the locating ring, fixed with headless screws, or pressed with a pressure plate.

Gates and runners should be sized according to the drawing requirements and machined, not hand ground. The point gate sprue should be sized according to the specification requirements. The front end of the runner should have an extended section as a cold slug well. The Z-bend on the ejector pin should have a smooth transition. The runner on the parting line should be round and the front and back halves should not be misaligned.

The latent gate on the top bar should have no surface sink. The diameter and depth of the cold slug well for clear parts should be per the design standard. The sprue is easy to remove, the part has no sprue marks, and there is no sprue left on the part when assembled. For latent sprue with a curved hook, both halves of the insert should be nitrided and have a surface hardness of HV700.

Hot Runner System Standard

The hot runner wiring layout should be reasonable and easy to access. The wiring numbers should correspond one-to-one. The hot runner should be tested for safety, and the insulation resistance to ground should be greater than 2 MW.

The temperature control cabinet, hot nozzle, and hot runner should be standardized. The mainstream nozzle is set with a threaded hot runner connection, and the bottom plane is in contact with the sealing surface. The hot runner is in good contact with the heating plate or heating rod, and the heating plate is fixed with screws or studs with good surface fit.

J-type thermocouples should be used and matched with the temperature control meter. Each group of heating elements should have thermocouple control, and the thermocouple position should be reasonably arranged.

The nozzle should meet the design requirements. The hot runner should be reliably positioned, at least two locating pins, or add screws fixed. There should be a heat insulation pad between the hot runner and the template.

The error between the set temperature of the temperature control meter and the actual display temperature should be less than ±5°C, and the temperature control is sensitive. Cavity and nozzle mounting holes should be penetrated.

Hot runner wiring should be bundled and covered with a pressure plate. There are two sockets of the same size, should be clearly marked. The control wire should be sheathed and not damaged. The temperature control cabinet is of reliable construction with no loose screws. The socket is installed on the bakelite board and cannot exceed the maximum size of the moldboard. Wires are not allowed to be exposed outside the mold.

All places of hot runner or template in contact with wires should have rounded transition. All wiring is free of breaks and shorts before the template is assembled. All wiring should be properly connected and well insulated. After the template is mounted and clamped, all wiring should be checked again with a multimeter.

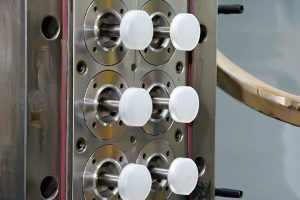

Molding Part, Parting Surface, Exhaust Groove Standard

The front and back molds should not have uneven surfaces, pits, rust, or other defects that affect the appearance. The gap between the insert and the mold frame should be less than 1mm. The parting surface should be clean and tidy, without any portable grinding wheels to avoid gaps, and no depressions in the sealing area. The depth of the exhaust groove should be less than the overflow edge of the plastic.

Inserts should be in place, smooth placement, reliable positioning. Inserts, cores, etc. should be reliably positioned and fixed, round pieces have a stop rotation, the inserts are not padded with copper or iron underneath. The end face of the top bar is consistent with the core. The molding part of the front and rear molds should be free of defects such as buckling and chamfering. The ejection of the bar should be smooth.

If you have a multi-cavity mold, you should indicate the left and right parts as L or R. If the customer has requirements for the position and size, it should be in accordance with the customer’s requirements, and generally added in a place that does not affect the appearance and assembly, with a font size of 1/8. The locking surface of the mold frame should be in place, and more than 75% of the area should be touched.

The top bars should be arranged closer to the side walls and next to the bars and bosses, and larger top bars should be used. For the same part, it should be marked as 1, 2, 3, etc. Each touching through surface, inserting through surface, parting surface should be researched and matched in place.

The sealing part of the parting surface should meet the design standard. For medium-sized molds below 10 ~ 20 mm, large molds 30 ~ 50 mm, the rest of the machining should be avoided. The skin pattern and sandblasting should be uniform to meet the customer’s requirements. Appearance requirements of the products, products on the screw should be anti-shrinkage measures. The depth of more than 20 mm screw column should be selected to use the top tube.

The wall thickness of the products should be uniform, and the deviation should be controlled below ±0.15 mm. The width of the rib should be below sixty percent of the wall thickness of the appearance of the slanting top, slider on the core should be a reliable way of fixing. The front mold is inserted into the rear mold or the rear mold is inserted into the front mold, there should be beveled locking around and machined to avoid air.

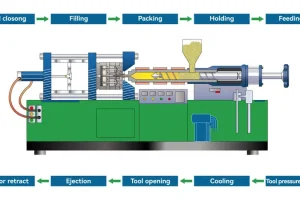

Injection Molding Production Process Standards

In the normal injection molding process, the mold should have the stability of injection molding production and the adjustability and repeatability of process parameters. The injection pressure of the mold during injection production should generally be less than 85% of the rated maximum injection pressure of the injection molding machine.

The injection speed of the mold during injection production should be three-quarters of the stroke of the injection speed, not less than 10% of the rated maximum injection speed or more than 90% of the rated maximum injection speed. The holding pressure of the mold during injection production should generally be less than 85% of the actual maximum injection pressure.

The clamping force of the mold during injection production should be less than 90% of the rated clamping force of the applicable model. During the injection molding process, the products and sprues should be taken out easily and safely (the time is generally no more than 2 seconds each). The mold with inserts should be easy to install and fix reliably during production.

Packaging, Transportation Standards

Clean the mold cavity and spray it with anti-rust oil. Apply lubricant to the sliding parts. Seal the sprue bushing inlet with grease. Install the mold with the clamping piece and make sure it meets the design requirements. Make sure the spare parts are complete, with a detailed list and the name of the supplier.

Seal the mold water, liquid, gas, and electrical inlets and outlets to prevent foreign objects from entering. Spray the outer surface of the mold with paint, as required by the customer.

Pack the mold in moisture-proof, waterproof, and shockproof packaging, as required by the customer. Make sure the mold product drawings, structure drawings, cooling and heating system drawings, hot runner drawings, spare parts and mold material supplier information, operating instructions, mold test reports, factory inspection certificates, and electronic documents are complete.

Injection molds must always achieve dimensional accuracy.Doğru

Dimensional accuracy is crucial to ensure that parts fit and function as intended, minimizing production errors and rejects.

Surface finish of injection molds can be ignored if functional criteria are met.Yanlış

Surface finish impacts the aesthetic and functional properties of molded parts, making it an integral aspect of mold quality.

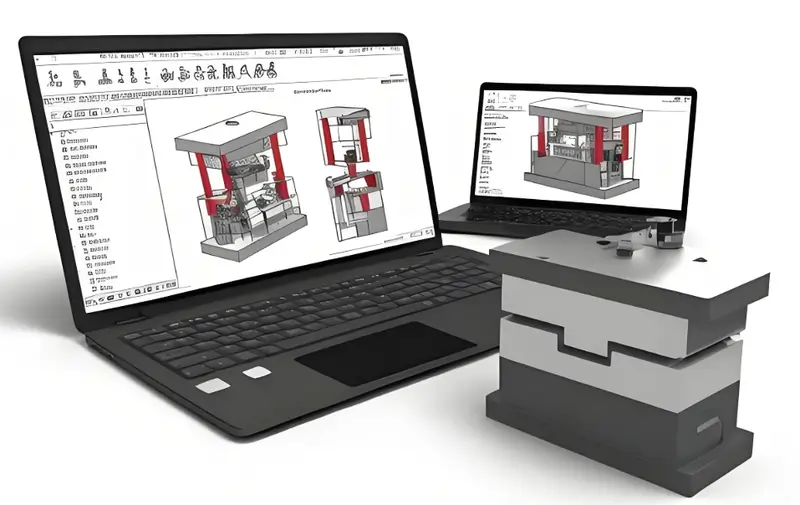

What are the Injection Mold Quality Inspection Methods?

Ensuring the quality of injection molds is vital for producing high-quality parts consistently. Various inspection methods verify mold precision, durability, and function before production begins.

Injection mold quality inspection methods include visual inspections, dimensional measurements, and tool wear assessments. These methods ensure alignment, proper cavity dimensions, and mold functionality, critical for maintaining high-quality production standards.

Appearance Inspection Method

Looks is one of the important signs of good or bad injection molds, good injection molds should have a neat looks, no defects, smooth surface. When you buy injection molds, you can judge whether the injection molds are good or bad by looking at whether there are cracks, bubbles, scratches and other defects on the surface of the molds.

Dimension Checking Method

The dimensional accuracy of injection molds is very important for the quality of injection molded products. Good injection molds should have high dimensional accuracy and dimensional stability. We can use measuring tools, such as calipers, vernier calipers and other tools, to measure the dimensions of injection molds accurately and judge whether the injection molds are good or bad.

Material and Heat Treatment Inspection Methods

Check if the material used in the mold meets the requirements by looking at the quality certification documents of the material. Use a hardness tester to measure the hardness of key parts of the mold to see if the heat treatment meets the process requirements. For some important mold parts, you can do a metallographic analysis to check the material’s organizational structure and the quality of the heat treatment.

The material of the injection mold directly affects the service life of the mold and the quality of the injected products. Qualified injection molds should use high-quality materials, such as imported steel, special alloys and so on. You can judge the quality of injection molds by checking the material certificate of injection molds11 and conducting physical property tests on the materials.

Processing Accuracy Inspection Method

The accuracy of injection molds directly affects the dimensional accuracy and surface quality of injection molded products. Good injection molds should have high processing accuracy and smooth surface. The processing accuracy of injection molds[^13] can be tested by using tools such as coordinate measuring machine to judge the quality of injection molds.

Service Life Inspection Method

The service life of injection molds directly affects the production efficiency and cost. Qualified injection molds should have a long service life and be easy to maintain. You can judge the quality of injection molds by knowing the service life of injection molds, maintenance methods, and other information.

Mold Structure Inspection Methods

Manually open and close the mold to see if it moves smoothly, if there are any weird noises, or if it gets stuck. Check the mold’s guiding and positioning mechanisms, like guide pins, guide bushings, and alignment pins, to see if they fit tightly and if they’re worn. Use a feeler gauge to check the clearances between different parts of the mold to make sure they’re what they’re supposed to be.

Injection Molding Performance Testing Methods

Run a test mold using the specified plastic materials and injection molding process parameters for production molding. Check the appearance of the molded parts to see if there are any appearance defects.

Use gauges to measure the dimensions of the parts to see if they meet the requirements. Record the injection cycle of the mold and see if it can meet the production efficiency requirements. Based on the results of the test mold, adjust and optimize the mold until you can make good parts.

Cooling and Heating System Testing Method

Fill the cooling system with water or coolant at a certain pressure and check if there is any leakage in the pipeline. Use a temperature sensor to measure the temperature around the cooling pipes to see if the cooling effect of the cooling system is uniform. For the heating system, check the working condition of the heating element and measure the temperature of the mold surface to see if the heating system can accurately control the temperature.

Visual inspections detect surface defects in injection molds.Doğru

Visual inspections help identify any obvious surface imperfections that might affect part quality before mold use.

Dimensional measurements are unnecessary for quality inspection.Yanlış

Dimensional measurements ensure the mold meets design specifications, preventing defects in the final product.

Özetleyin

To judge the quality of the enjeksiyon kalıbı11, first, we should check whether its design meets the product requirements and make sure that the mold structure is reasonable and can effectively support the production of the product.

Second, the mold material should have high strength and wear resistance to improve the service life. At the same time, the processing precision of the injection mold should be high to ensure that the size of the products produced is accurate.

Finally, the maintenance and upkeep of the mold is also crucial, affecting its long-term stability and production efficiency.

[7]: Exploring the best corrosion-resistant materials can enhance the longevity and performance of molds in various applications.

-

Exploring this resource will help you understand the importance of selecting high-quality mold materials for better durability and performance. ↩

-

This link will provide insights into enhancing mold processing precision, crucial for achieving high-quality injection molded parts. ↩

-

Understanding the correct injection process parameters is vital for ensuring a stable and reliable injection process, leading to defect-free products. ↩

-

Understanding the specifications for cooling water nozzles can enhance your mold design and efficiency. ↩

-

Knowing standard mold dimensions ensures compatibility with injection molding machines, improving production efficiency. ↩

-

Understanding the key components of a mold structure can help ensure quality and efficiency in manufacturing processes. ↩

-

Learning about heat treatment can provide insights into improving mold durability and performance, crucial for successful production. ↩

-

Understanding ejection distance is crucial for optimizing molding efficiency and product quality. Explore this link for detailed insights. ↩

-

Learn about self-locking mechanisms and their role in enhancing safety and reliability in molding processes. ↩

-

Discover the best materials for wear plates to improve durability and performance in your projects. ↩

-

Learn aboutHow to Design An Injection Mold?To design an injection mold, first define the product’s shape and material. Then, consider factors like draft angles, venting, and cooling systems. ↩ ↩