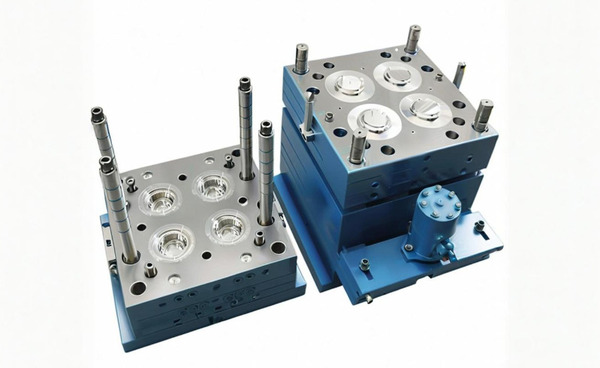

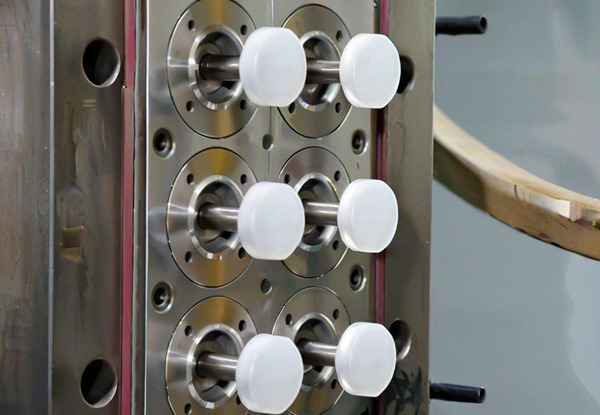

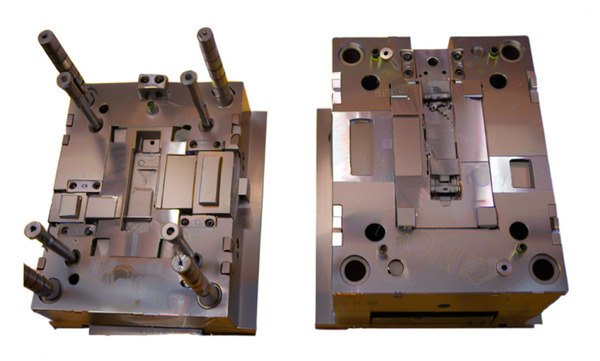

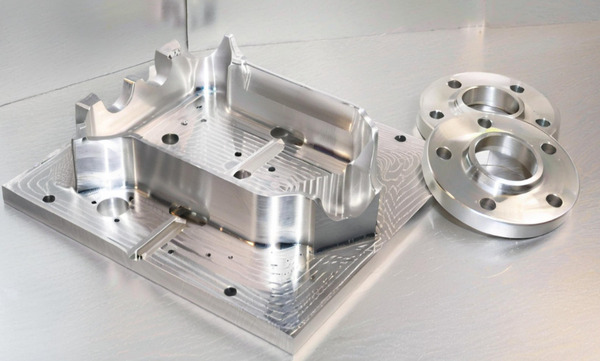

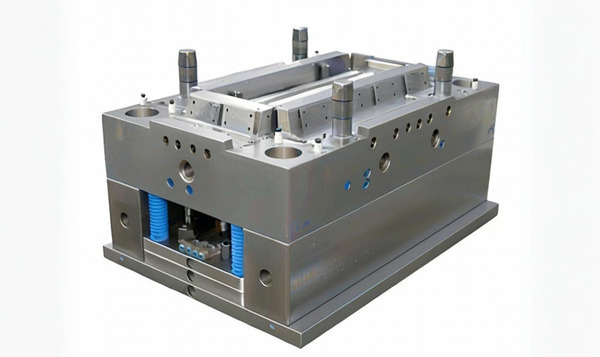

Introduction: Injection molds are these parts that are made to fit the product you want to make. They’re made by doing stuff like CNC machining. You use them to shoot hot plastic into and then it cools down. There are a bunch of different kinds of injection molds. But there are two kinds of mold systems: hot runner and cold runner. That’s based on how hot the runner and mold stay.

Every mold system has a different mechanism and affects plastic manufacturing differently. So, before you choose, you need to understand the comparison between hot runner molds and cold runner molds correctly.

This article compares hot runner and cold runner литьё под давлением by introducing the two systems, how they work, and their differences. It also shows you how to choose the right mold for your project.

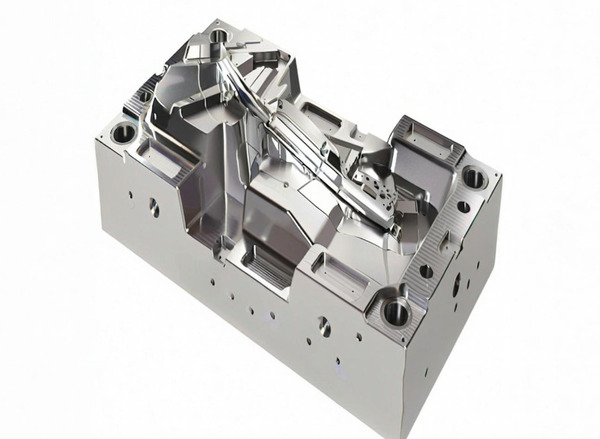

What is a Hot Runner Mold?

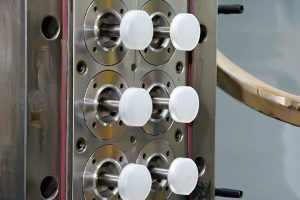

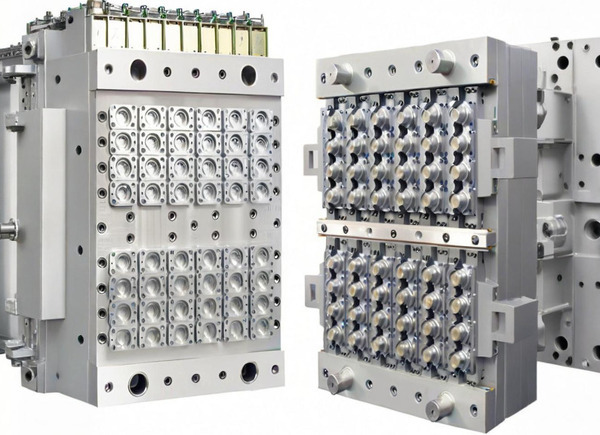

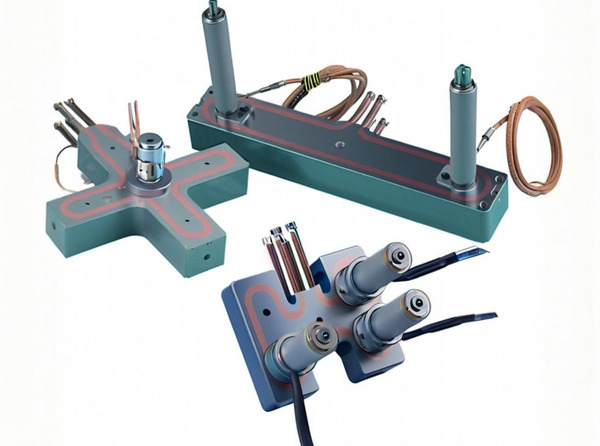

A hot runner mold is an injection mold with a manifold system (i.e., it has heating components, manifolds, and nozzles) that makes sure the molten plastic injected into the mold stays hot.

Hot runner injection molding is good for molding plastic parts that need stable flow and injection pressure. Plus, it can help reduce defects like sink marks from fluctuating injection pressure and unfilled molds.

What are the Types of Hot Runner Molds?

There are two types of hot runner molds for plastic injection molding, based on how they keep the heat:

Insulated Hot Runners

Insulated hot runner molds have really thick runners in the mold plate, which causes the molten plastic to cool down a little and insulates the system. The insulation keeps the heat in and lets the mold system keep the plastic flowing.

Insulated hot runner molds are cheaper than heated molds because they don’t use manifolds and drippers. They have flexible gates, reduced defects, and make it easy to change colors. But they also have some disadvantages. The gate freezes. The mold doesn’t fill evenly. It takes a long time to start up. And you have to run fast cycles to keep the plastic melted because there’s no manifold system.

Heated Hot Runners

Heated hot runners are the main type of hot runner mold systems that achieves heating using a heating component on one half of the mold. However, they come in two designs: externally heated and internally heated.

Hot runners that are heated externally: The heating element is outside the mold. This means there are no obstructions in the melt flow of the plastic (better flow control) and there is no drop in injection pressure. Also, the plastic doesn’t freeze, which is great for color change. Externally heated hot runner molds are good for heat-sensitive materials.

Hot runner with internal heating: Here, the heating element is in the mold, which causes a drop in injection pressure, which is incompatible with color change, and the material hangs up and degrades in the mold. However, the flow is better due to heated runners and gate tip control.

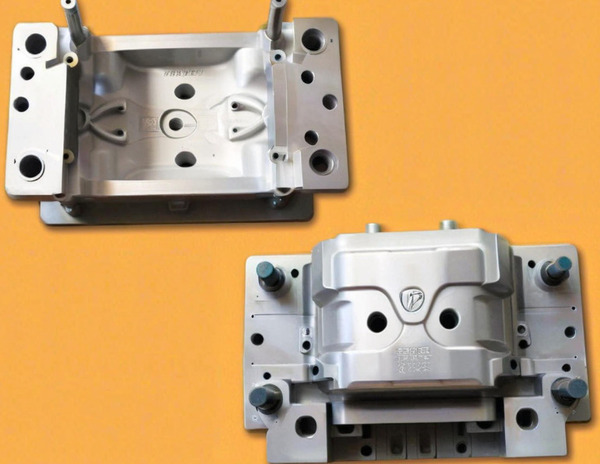

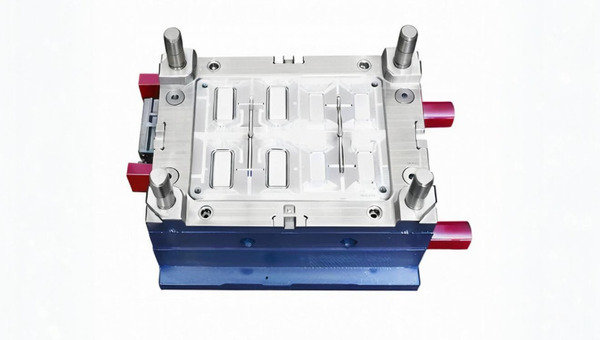

What is a Cold Runner Mold?

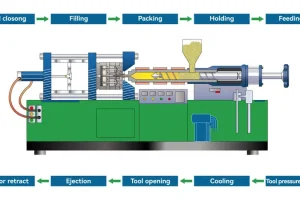

A cold runner mold is a basic injection mold where the runner is at the same temperature as the mold cavity. You inject the molten plastic into a locating ring. Then, the molten plastic goes through the cooled gate and runners before it enters the mold cavity. As the plastic cools, it takes the shape of the mold cavity with the solidified plastic in the runner attached.

Cold runner molds have large runners (larger than the part) which eliminates the tendency of underfilling the mold. Apart from this, it is suitable for any plastic polymer regardless of heat sensitivity, is cheaper than hot runners, and is easy to maintain. However, they generate waste.

What are the Types of Cold Runner Systems?

There are two types of cold runner mold systems, depending on the number of plates:

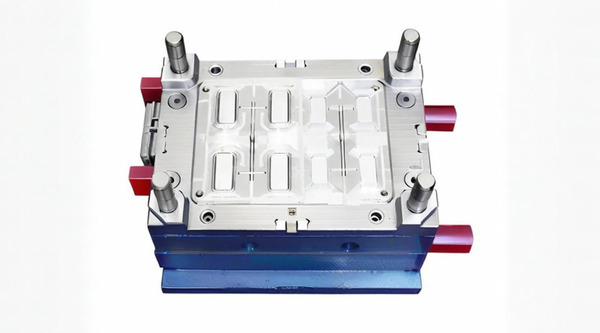

Two-Plate Cold Runner System

The two-plate cold runner system is made up of two plates. The fixed mold has the gate, runner, gate, and cavity. It is the fastest, simplest, and cheapest cold runner system. However, the runner is attached to the final product and must be cut off.

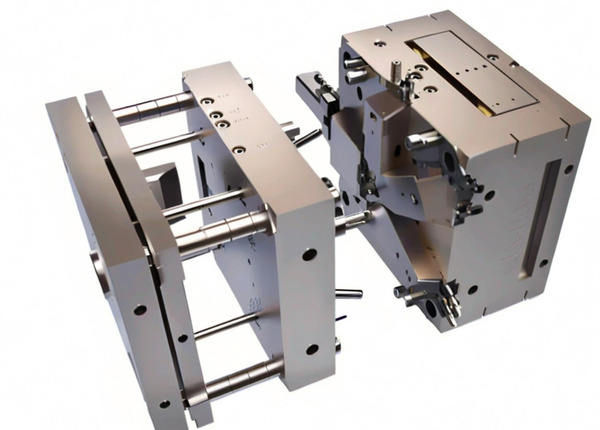

Three-Plate Cold Runner System

The three-plate cold runner system is similar to the two-plate system. However, the three-plate injection mold has the flexibility of attaching the runner plate. In addition, you don’t have to cut the runner from the injection molded part, and you don’t need an ejection system for part removal.

Three-plate injection molds are friendlier and more flexible. They are best suited to handle products with complex designs and are a low-cost alternative to hot runner systems. The disadvantages of this type of injection mold include long cycle times, complex tool design, and high material waste.

What are the Advantages of Hot Runner Systems?

Hot runner systems are used a lot in making plastic products because they have a lot of advantages.

Faster cycle time: One of the main differences between hot runner and cold runner injection molding is the cycle time. Since the plastic is kept at the optimal temperature, which increases fluidity, hot runner injection molds have faster cycle times. Hot runner systems can improve the efficiency of injection molding production.

Since the temperature control of the hot runner is more precise, the cooling time of the plastic can be shortened, thereby shortening the литьё под давлением cycle and increasing production. In addition, the hot runner system can further improve production efficiency through simultaneous injection molding of multiple runners. Thus shortening the cycle time.

Less waste: It’s more cost-effective because the mold system produces almost no waste. The hot runner system can save plastic. Traditional cold runner systems require extra plastic to fill the runners and nozzles, while hot runner systems can inject plastic directly into the mold, reducing waste and cost.

Plus, the hot runner system can save even more plastic by controlling the temperature of the plastic precisely and reducing overheating and overcooling.

Quality is better: The parts made with hot runner molds have better final quality because the filling curve and injection pressure are excellent. Hot runner technology can reduce scrap during plastic injection molding.

Compared with traditional cold runner systems, hot runners can better control the flow and solidification process of plastics, reduce defects such as bubbles, shrinkage, and cracks, and thus improve the molding rate and quality of products.

Molding automation: You can automate because you don’t have to do any post-processing like trimming, reclaiming waste, or removing runners.

Design Flexibility: Injection mold design has flexibility. The gates are placed using hot tip gates, valve gates, or edge gates. This improves the part’s aesthetics and the mold cavity’s optimal filling effect during the injection molding process.

Make product look better; hot runner systems can make injection molded products look better. Because hot runners can control how plastic flows and hardens, they can make the product have fewer mistakes and marks on the outside and make the product look shinier and feel better.

Also, hot runner systems can make products that have more than one color or more than one layer, which makes the product look even better.

What are the Advantages of Cold Runner Systems?

Cold runner systems have the following advantages:

Reduced mold costs: Cold runner molds cost less to make. You’ll save money on molds.

Less inspection and maintenance costs: Cold runner molds aren’t complicated. So, you don’t have to inspect and maintain them as much. That means you’ll spend less on maintenance and have less downtime.

Thermosensitive plastics: Another difference between hot runner and cold runner molds is their application in molding thermosensitive plastics. Cold runner systems are best suited for thermosensitive polymers. In addition, they are suitable for any plastic.

What are the Disadvantages of Hot Runner Systems?

Hot runner systems have the following disadvantages:

High investment costs: The first investment and maintenance costs of hot runner systems are expensive because of the complexity of the molds and the benefits like reduced cycle time, part quality, and flexibility.

High requirements for equipment precision: This system requires high-end equipment because it needs to be precise. If the equipment isn’t precise, the machine can break and cause defects. For example, if the plastic seal breaks, the hot runner parts can get damaged because the melted plastic will overflow.

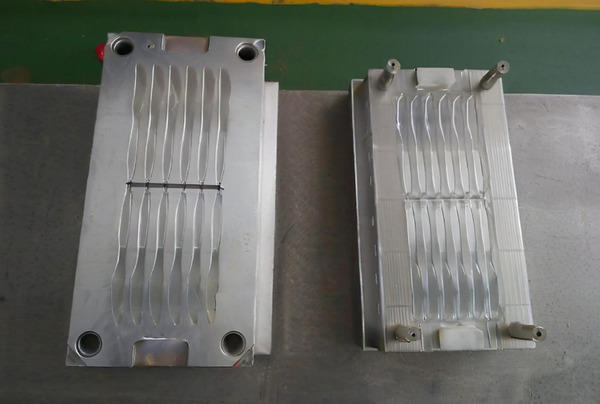

What are the Disadvantages of Cold Runner System?

Cold runner injection molding has the following disadvantages:

Material waste:Waste material is another difference in hot runner vs cold runner molding comparison. Molten plastic solidifies in cold runner system. Hence, these result in scrap material that needs trimming.

Injection pressure drop: When plastic flows, it loses heat to the mold, which makes it shrink. This shrinkage causes the pressure to drop, which makes sink marks and unfilled parts.

Long cycle time: Cold литьё под давлением has a longer cycle time because the plastic doesn’t flow as well. Plus, you have to take extra time to remove runners and gates (especially in two mold systems).

What are the Considerations When Choosing a Hot Runner Mold?

When you’re picking a hot runner mold, you gotta think about price, delivery time, and quantity. But the most important thing is the technical stuff about the runner system. Here are some things you should think about.

Давление впрыска

Because the temperature of the molten plastic is constant, the injection pressure drop is low when it goes through the manifold system. So, when you design the injection mold, it is very important to make sure you simulate the correct mold flow of the materials you are going to use for injection molding, especially if you are using materials that have poor melt flow properties.

Heating

The heating element can be internal or external. External heating systems are good for heat-sensitive materials. On the other hand, internal heating systems are good for other plastic polymers.

Тип ворот

Every material and product design needs a different gate design. So, when making the gate, we consider things like gate mark, gate location, type of material being injected, and so on.

Standard or Customized System

Deciding between standard or custom systems depends on what you need. Standard systems have standard parts and sizes. So, they’re the best choice for cost, delivery time, and maintenance. Custom systems are great for making products with unique designs.

Plastic Processing Type

The plastic you’re working with also plays a big role in your choice. For example, FRP requires a mold with a gate insert that has good wear resistance or an external heating system runner.

Runner Size

The size of the runners is important for how the system performs. If you get it wrong, you can mess up the final part or not fill it all the way. Some things that can help you figure out the size of the runners are how much pressure you lose, how long the plastic is in there, how hot it is, how fast it’s moving, and how often it happens.

Multi-Zone Temperature Control

When you’re working with big, complicated systems or heat-sensitive plastics, make sure you use a multi-zone temperature control system to account for heater mass and heat loss.

What are Some Considerations When Selecting a Cold Runner Mold?

When you’re choosing a cold runner mold, there are a few things you need to think about.

Насадка

Choose a nozzle that isn’t welded to keep particles from getting into the water jacket.

Nozzle Tip

The type of nozzle tip depends on the manufacturer. For example, some mount the nozzle tip rigidly to the end of the nozzle, while others use a spring-loaded nozzle tip because it allows for thermal expansion of the mold during heating.

Runner Manifold

The runner manifold should be a split-plate design so you can take it off and clean it. Other designs, like gun-drilled runners, can make “dead spots” that make the mold harder to clean.

Piston assembly

Using gun-drilled air passages eliminates the need for air hoses and barb fittings in the nozzle to prevent air tube damage and eliminate connection errors.

Pneumatic Connections

Better cold runner molds should have an external air line or an air junction box with quick-disconnect connectors.

Заключение

Once you understand the runner system, you can choose between hot runner or cold runner. So, in this article, I will compare cold runner vs. hot runner литьё под давлением, explain the differences, and tell you how to choose the right one.

Do you need high-quality injection molded parts using hot runner systems or cold runners systems? Contact Zetar Mold.