– P20 steel is pre-hardened and requires no post-machining heat treatment, making it ideal for rapid lead times and medium-volume production.

– H13 steel offers superior hardness (48–52 HRC) and abrasion resistance, essential for glass-filled resins and high-volume runs (>500k cycles).

– MUD inserts made from H13 require extra processing time for heat treatment and grinding compared to the “cut-and-shoot” nature of P20.

– Material selection for MUD inserts should be driven by resin abrasiveness, surface finish requirements (SPI standards), and total projected production volume.

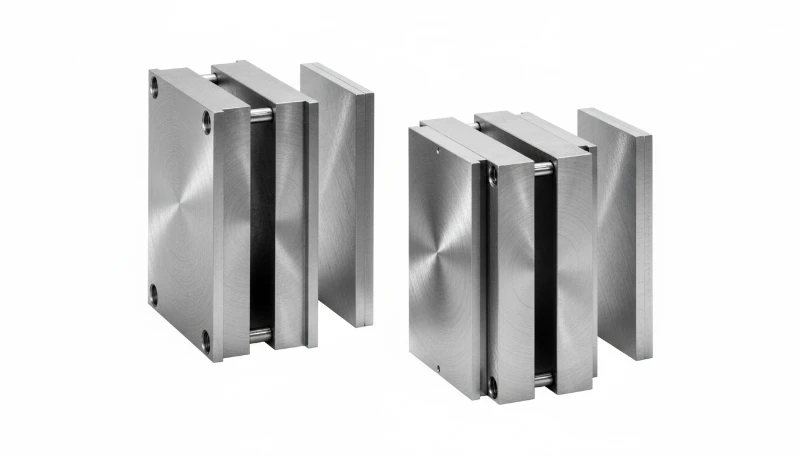

What Defines P20 and H13 in the Context of MUD Inserts?

In the realm of rapid tooling materials, the choice often narrows down to two industry workhorses: P20 and H13. Understanding their fundamental states is critical for mold material selection1.

- P20 Tool Steel2 (AISI P20 / DIN 1.2311):

A low-alloy mold steel typically supplied in a pre-hardened condition (28–32 HRC). It balances toughness and hardness, allowing it to be machined directly into the final mold geometry without subsequent heat treatment. This makes it the standard for "bridge tooling" and general-purpose P20 steel molds. - H13 Tool Steel3 (AISI H13 / DIN 1.2344):

A hot-work tool steel supplied in an annealed (soft) state for machining. Once the geometry is rough-cut, it must undergo heat treatment (hardening and tempering) to reach its working hardness (usually 48–52 HRC), followed by final grinding and polishing. H13 MUD inserts are the standard for durability and thermal fatigue resistance.

How Do P20 and H13 Compare Technically?

To assist in material selection for MUD inserts, the following table contrasts the physical and operational properties of both steels.

P20 vs. H13 Technical Comparison Table

| Недвижимость | P20 (Pre-Hardened) | H13 (Hardened) |

|---|---|---|

| Typical Hardness | 28–32 HRC | 48–52 HRC |

| Обрабатываемость | Good; machined "as is". | Poor in hardened state; requires EDM or hard milling. |

| Износостойкость | Moderate; suitable for non-abrasive resins. | Excellent; suitable for glass/mineral fillers. |

| Теплопроводность | ~29 W/m·K (Better cooling). | ~24 W/m·K (Slightly lower). |

| Polishability | Good (SPI A-3 / B-1). | Excellent (SPI A-2 / A-1). |

| Weldability | Fair; requires careful pre/post heating. | Good; but requires annealing/re-hardening for large repairs. |

| Relative Cost | Lower (Material + Processing). | Higher (Due to heat treat & grinding steps). |

MUD inserts made of P20 are only suitable for prototyping and cannot be used for production.Ложь

P20 inserts frequently run hundreds of thousands of cycles in production environments, provided the resin is non-abrasive (e.g., Polypropylene or ABS).

H13 steel is mandatory for any injection molding application involving glass-filled nylon.Правда

Glass fibers are highly abrasive and will scour soft steels like P20, ruining the gate and cavity details within a few thousand cycles; hardened H13 is required to resist this wear.

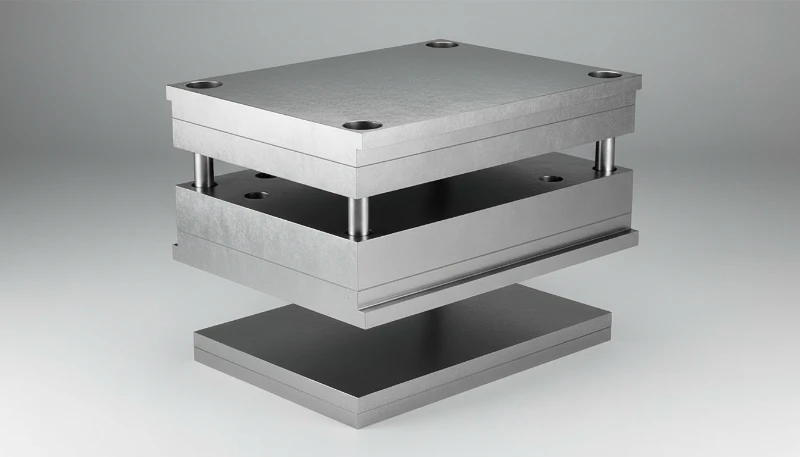

When Should You Choose P20 for MUD Inserts?

P20 is the backbone of rapid tooling materials4 because it prioritizes speed and cost-efficiency.

Преимущества

- Скорость выхода на рынок: Since no heat treatment is required, a shop can machine a P20 insert and have it in the press in days.

- Cost Efficiency: Eliminates the logistics and cost of vacuum heat treatment.

- Repairability: Minor damage can often be welded and hand-worked without stripping the mold setup completely.

Недостатки

- Lower Wear Resistance: Not suitable for abrasive materials (Glass Fiber > 10%).

- Surface Finish Limits: While it can be polished, it may reveal "orange peel" or pitting if polished to a high mirror finish (SPI A-1).

Best Application Scenarios

- Medium Production Runs: 50,000 to 300,000 cycles.

- Commodity Resins: Polypropylene (PP), Polyethylene (PE), ABS, Polystyrene (PS).

- Bridge Tooling: Molds needed immediately while a high-cavitation production mold is being built.

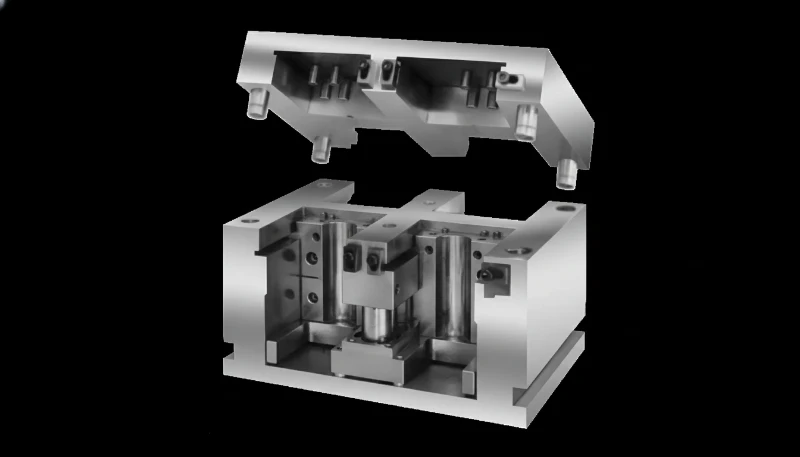

When Should You Choose H13 for MUD Inserts?

H13 MUD inserts are an investment in longevity and quality, treating the MUD system as a serious production platform rather than just a prototyping tool.

Преимущества

- High Cycle Life: Capable of exceeding 1 million cycles with proper maintenance.

- Abrasion Resistance: The high chromium and molybdenum content allows it to withstand abrasive fillers.

- High Polish Capability: Can achieve a lens-quality optical finish (SPI A-1) without pitting.

- Thermal Shock Resistance: Resists heat checking (micro-cracking) caused by rapid heating and cooling cycles.

Недостатки

- Longer Lead Time: Requires rough machining -> heat treat (outsourced 3-5 days) -> finish grinding/hard milling.

- Хрупкость: Hardened steel is more prone to cracking if the MUD insert has sharp corners or thin walls under high clamp tonnage.

Best Application Scenarios

- Крупносерийное производство: 500,000 to 1,000,000+ cycles.

- Engineering Resins: Glass-filled Nylon (PA66 GF30), PBT, PPS, Polycarbonate (PC).

- Optical Parts: Lenses or cosmetic covers requiring mirror finishes.

Heat treating H13 MUD inserts changes their dimensions, requiring post-process grinding.Правда

The hardening process causes slight dimensional distortion; inserts must be left 'steel safe' and precision ground to fit the MUD frame after heat treatment.

You can simply plate P20 with chrome to make it perform exactly like solid H13.Ложь

While chrome plating adds surface hardness, the substrate (P20) is still soft. Under high injection pressure or impact, the soft 'skin' can collapse, cracking the plating.

How to Select Based on Cycle Count and Resin?

Use this decision matrix to determine the insert life cycle capability versus material choice.

Selection Decision Matrix

| Project Requirement | Recommended Steel | Причина |

|---|---|---|

| < 10,000 Cycles (Prototype) | Aluminum (QC-10) or P20 | Speed and lowest cost. |

| 50k – 250k Cycles (Commodity Resin) | P20 | Balance of cost and durability. |

| 250k – 500k Cycles (Abrasive Resin) | NAK80 | P20 will wash out at gates/vents quickly. |

| > 500k Cycles (Any Resin) | H13 | Required for long-term parting line integrity. |

| High Gloss / Lens Finish | S136 or 420 SS | P20 cannot sustain SPI A-1 polish. |

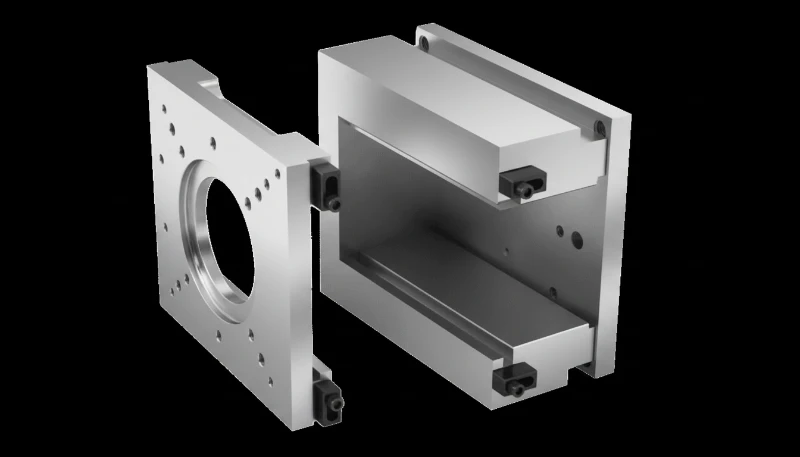

What are the Practical Tips for MUD Material Management?

- Standardize Your Inserts: If you run many MUD inserts, keep pre-squared P20 blocks in stock. For H13, stock annealed blocks but establish a reliable relationship with a vacuum heat treater to minimize the standard 1-week delay.

- Gate Wear Watch: If you choose P20 for a borderline abrasive material (e.g., 10% glass fill) to save money, design the gate as a replaceable sub-insert. You can replace just the small gate insert made of H13 while keeping the rest of the cavity P20.

- Cooling Channel Corrosion: P20 and H13 are not stainless. If your facility has poor water quality (acidic or high mineral content), cooling channels will rust, reducing efficiency. Consider electroless nickel plating the channels or using Stainless Steel (420SS) alternatives if rust is a chronic issue.

FAQ: Material Selection for MUD Inserts

Q: Can I weld H13 MUD inserts if they get damaged?

A: Yes, but it is difficult. Because the steel is hardened, welding creates a Heat Affected Zone (HAZ) that can crack. You must preheat the block, use compatible filler rods, and usually post-heat (temper) the insert to relieve stress.

Q: Is S7 steel a good alternative to H13 for MUD inserts?

A: S7 is an excellent shock-resisting steel. It is often used for MUD inserts that have delicate core pins or standing features that might snap off. However, H13 generally handles high heat better than S7.

Q: Does P20 cool faster than H13?

A: Marginally, yes. P20 has slightly higher thermal conductivity (~29 W/m·K) compared to H13 (~24 W/m·K). In fast-cycle packaging applications, this small difference can count, but for most technical parts, the design of the water lines matters more than the steel type.

Q: Why is my P20 insert showing "orange peel" after polishing?

A: P20 is a mixed-alloy steel. If polished aggressively for a high-gloss finish, the soft and hard spots in the microstructure wear unevenly, creating a wavy "orange peel" texture. H13 is more uniform and holds a better polish.

Q: Can I use Aluminum MUD inserts for production?

A: Only for low-volume or non-critical cosmetic parts. Aluminum (like 7075 or QC-10) is soft. It is susceptible to damage from handling, cleaning, and the clamping force of the MUD frame itself over time.

Заключение

Choosing between P20 steel vs. H13 for MUD inserts is a tradeoff between agility and endurance. P20 is the superior choice for rapid tooling materials where lead time is tight, budgets are constrained, and resins are non-abrasive. Conversely, H13 is the mandatory choice for high-volume production or abrasive applications where the insert life cycle must extend into the millions. By analyzing the resin’s filler content and the target volume, manufacturers can select the material that maximizes ROI without risking mold failure.

-

Get insights on selecting the best mold materials based on specific production needs. ↩

-

Understand the properties and applications of P20 Tool Steel in manufacturing. ↩

-

Find out the unique characteristics of H13 Tool Steel that enhance mold performance. ↩

-

Discover the top materials for rapid tooling and how they impact production efficiency. ↩