– Cooling time typically accounts for 50% to 70% of the total injection molding cycle, representing the largest opportunity for optimization.

– Conformal cooling channels can reduce cycle times by 20% to 40% compared to traditional baffled or bubbler systems.

– Scientific molding principles rely on data-driven viscosity curves and decoupled pressure settings to maximize consistency and speed.

– Reducing wall thickness and optimizing injection pressure are critical steps to improve plastic manufacturing efficiency without sacrificing part quality.

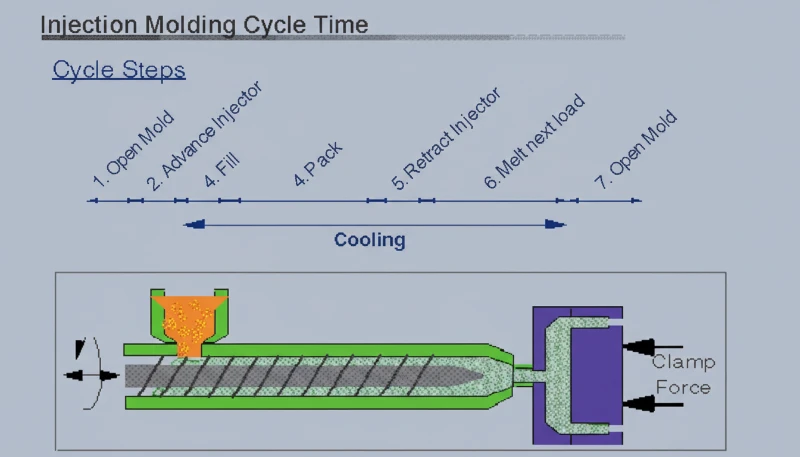

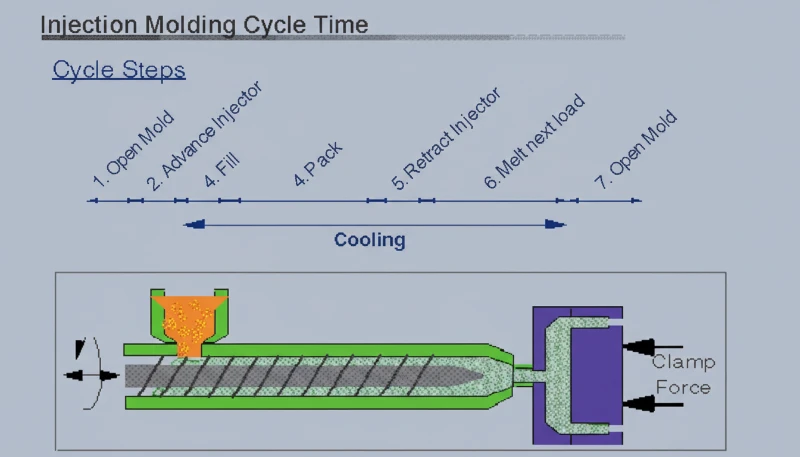

What Is the Definition of Injection Molding Cycle Time?

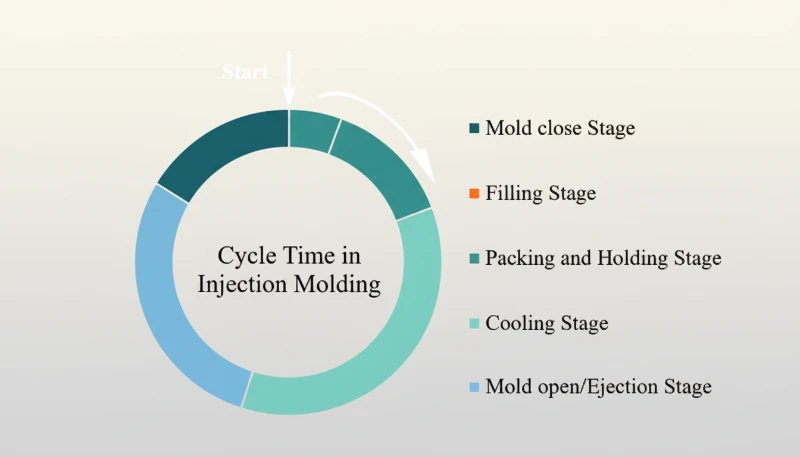

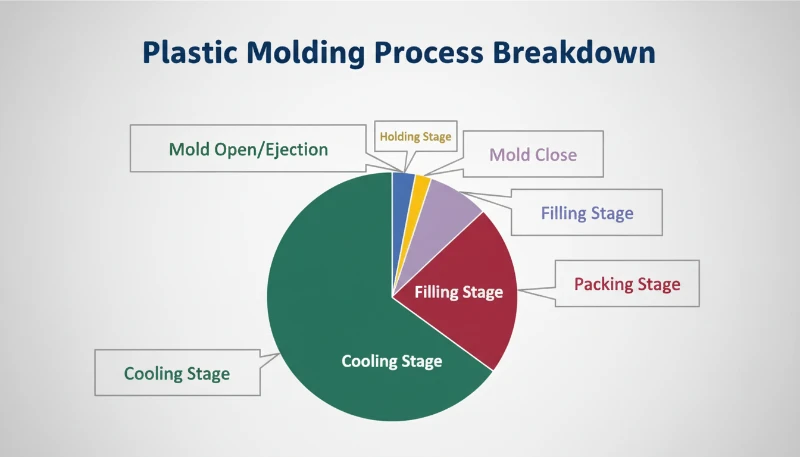

На сайте Scientific Molding Principles, the cycle time is defined as the total duration required to complete one full sequence of the injection molding process, resulting in the production of a finished part. It is the summation of four distinct phases:

- Время введения: The time required to fill the mold cavity with molten plastic.

- Packing/Holding Time: The duration pressure is applied to compress the melt and compensate for material shrinkage.

- Время охлаждения: The period allowed for the plastic to solidify to a temperature where it can be ejected without deformation.

- Mold Open/Eject/Close Time: The mechanical time required to open the tool, eject the part, and close the clamp for the next shot.

Optimizing this metric is the primary lever for reducing unit costs and increasing plastic manufacturing efficiency1.

Decoupled molding separates the filling phase from the packing phase to improve process consistency.Правда

By separating the fast fill phase from the pressure-controlled packing phase, manufacturers gain tighter control over dimensions and cycle repeatability.

Increasing injection speed indefinitely is the best way to reduce overall cycle time.Ложь

Excessive speed can cause shear burning, flash, and gas traps, often necessitating slower cycles to correct defects; optimization requires balancing speed with material limits.

What Factors Influence the Cycle Time Breakdown?

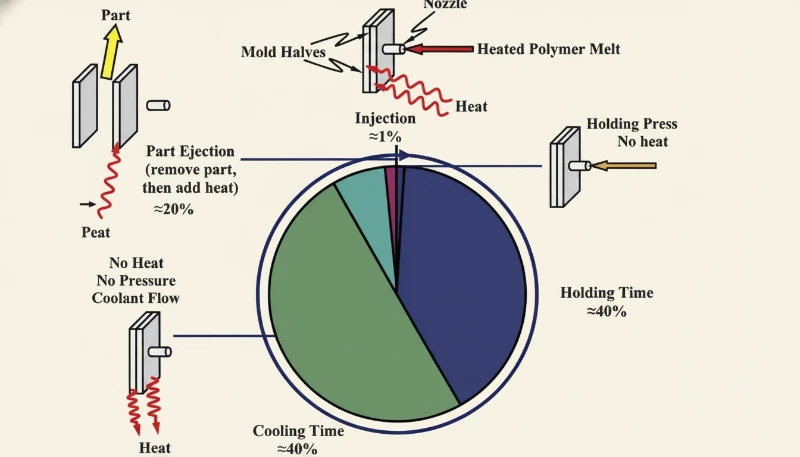

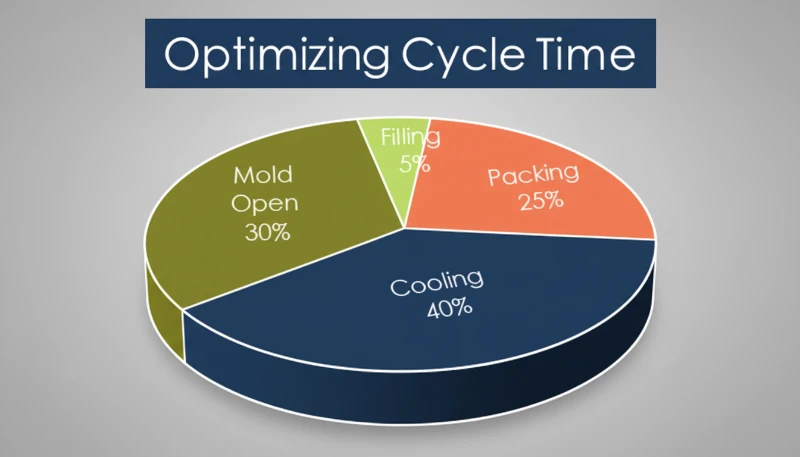

На сокращение времени цикла литья под давлением, one must first understand the proportional weight of each phase. Cooling is almost always the dominant factor, governed by the thermal conductivity of the resin and the mold material (e.g., tool steel vs. beryllium copper).

Typical Cycle Time Composition

| Phase | Percentage of Total Cycle | Key Influencing Factors |

|---|---|---|

| Охлаждение | 50% – 70% | Wall thickness, материал пресс-формы2, coolant temperature, channel design. |

| Packing/Holding | 15% – 20% | Gate size, material shrinkage rates (e.g., Polypropylene (PP) vs. Polycarbonate (PC)). |

| Injection (Fill) | 5% – 10% | Injection speed, machine response, melt viscosity. |

| Mold Reset (Dry Cycle) | 10% – 15% | Clamp speed, ejection stroke length, automation/robot speed. |

How Do Cooling Channels Impact Cycle Speed?

The efficiency of heat exchange determines the minimum safe cycle time. Traditional straight-line cooling often fails to reach "hot spots" in complex geometries, leading to longer required cooling times to prevent warpage.

Conformal Cooling Channels vs. Traditional Cooling

Конформные каналы охлаждения are complex cooling pathways printed directly into the mold insert using Direct Metal Laser Sintering (DMLS). Unlike drilled straight lines, these channels follow the contours of the part geometry, maintaining a consistent distance from the cavity wall.

- Traditional Baffled/Bubbler Systems: Limited by drilling angles; creates uneven cooling gradients.

- Conformal Systems: Can reduce cooling time by 20% to 40%. Although the initial tooling cost is higher, the ROI is realized through significantly higher throughput.

Cooling Optimization Parameters

| Параметр | Traditional Cooling | Конформное охлаждение | Impact on Cycle |

|---|---|---|---|

| Distance to Cavity | Variable (limited by drilling) | Uniform (Follows 3D contour) | Conformal ensures faster, uniform heat removal. |

| Coolant Flow | Laminar or Turbulent | Highly Turbulent (Reynolds > 4000) | Turbulent flow increases heat transfer efficiency. |

| Cycle Reduction | Baseline | -20% to -40% | Significant increase in parts per hour. |

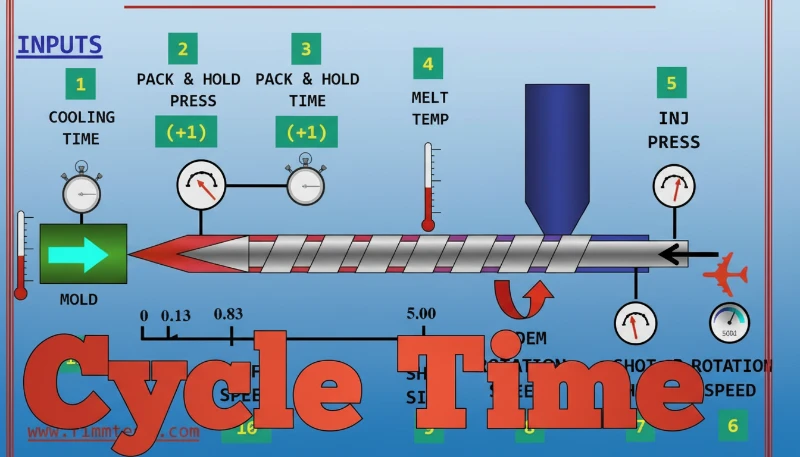

How Can Injection Pressure Optimization Improve Efficiency?

Injection pressure optimization is a core component of scientific molding. The goal is to fill the mold as fast as possible without degrading the material, then switch to packing pressure immediately.

The Viscosity Curve Study

To find the optimal fill speed:

- Perform an in-mold rheology study.

- Plot injection speed (shear rate) against viscosity.

- Identify the point where viscosity stabilizes (the Newtonian plateau).

- Set injection speed in this stable region to ensure small variations in the machine do not affect part quality.

Recommended Processing Parameter Ranges

Note: These are general ranges; refer to specific Technical Data Sheets (TDS) and ISO 294 standards.

| Материал | Melt Temp Range (°C) | Mold Temp Range (°C) | Max Injection Pressure (Bar) | Cooling Factor |

|---|---|---|---|---|

| Полипропилен (PP) | 200 – 280 | 20 – 80 | 1,000 – 1,500 | Быстрый |

| Polyamide 66 (PA66) | 275 – 300 | 60 – 100 | 1,000 – 1,800 | Средний |

| Поликарбонат (PC) | 280 – 320 | 80 - 120 | 1,200 – 2,000 | Slow |

| ABS (акрилонитрил-бутадиен-стирол) | 220 – 260 | 40 – 80 | 1,000 – 1,500 | Средний |

Conformal cooling channels follow the 3D geometry of the part to provide uniform heat dissipation.Правда

By maintaining a consistent distance from the mold wall, conformal channels eliminate hot spots and significantly shorten cooling time.

Lowering the mold temperature to near-freezing always results in a better, faster cycle.Ложь

Excessively low temperatures can cause condensation on the mold (mold sweating), leading to surface defects and actually complicating part ejection.

What Is the Step-by-Step Process to Reduce Cycle Time?

To systematically сокращение времени цикла литья под давлением, engineers should follow this audit process:

- Minimize Wall Thickness:

- Review part design (DFM). Cycle time is proportional to the square of the wall thickness. Reducing thickness by 10% can reduce cooling time by roughly 20%.

- Optimize the Switchover Point:

- Set the switchover from injection to packing at 95-98% full. Switching too late causes flash (requiring trimming); switching too early causes short shots.

- Reduce Mold Open/Close Strokes:

- Limit the clamp opening stroke to the minimum required for the robot or part to drop. Saving 0.5 seconds on opening and 0.5 seconds on closing saves 1 second per cycle.

- Parallel Operations:

- Ensure screw recovery (plasticizing) happens during the cooling phase. If screw recovery takes longer than the cooling time, increase back pressure or screw RPM slightly (within shear limits) so it doesn’t delay the cycle.

- Implement Robot Optimization:

- Use high-speed side-entry robots rather than top-entry robots for faster takeout times in high-volume applications.

What Are the Advantages and Disadvantages of Aggressive Optimization?

While speed is profit, pushing a process to the limit carries risks.

| Характеристика | Преимущества | Недостатки |

|---|---|---|

| Aggressive Cooling | Higher throughput; lower unit cost. | Risk of thermal shock to mold steel; potential for vacuum voids in thick sections. |

| High-Speed Injection | Better flow in thin walls; reduced cycle time. | Higher shear stress on material; increased wear on gates and runners; potential for "diesel effect" (burns). |

| Automated Takeout | Consistent cycle time; no operator variance. | High initial capital investment; complex setup for short runs. |

In Which Applications Is Cycle Time Optimization Critical?

Plastic manufacturing efficiency is paramount in sectors where profit margins are driven by volume:

- Thin-Wall Packaging: Food containers and cups (Cycles often < 4 seconds).

- Medical Consumables: Syringe barrels and pipettes (High cavitation, fast cycles).

- Automotive Connectors: High volume PBT or PA66 parts where reducing cycle by 1 second yields millions of additional parts per year.

- Caps and Closures: High-density polyethylene (HDPE) screw caps requiring rapid cooling and ejection.

Часто задаваемые вопросы (FAQ)

Q: How does "Scientific Molding" help reduce injection molding cycle time?

A: Scientific Molding decouples the process into fill, pack, and hold phases. By using data to find the process window rather than trial and error, engineers can set the fastest possible parameters that still guarantee quality, eliminating "safety buffers" that artificially inflate cycle times.

Q: What is the main benefit of conformal cooling channels?

A: The primary benefit is the ability to cool complex geometries evenly and quickly. This reduces the cooling phase (the longest part of the cycle) and minimizes differential shrinkage, which causes warpage.

Q: Can increasing injection pressure optimization3 reduce cycle time?

A: Indirectly, yes. Optimizing injection pressure ensures the mold fills as fast as the material allows. However, the goal is usually to fill fast to stabilize viscosity, not just to save time. The time savings come mostly from the subsequent reduction in packing and cooling requirements due to a better-formed part.

Q: How does wall thickness affect cycle time?

A: Время охлаждения4 is governed by the equation k∝h², where h is wall thickness. Doubling the толщина стенки5 quadruples the required cooling time. Keeping walls uniform and thin is the most effective design change for speed.

Q: Is it safe to reduce mold open/close speeds?

A: You should optimize the distance first. Reducing the opening stroke saves more time safely. Increasing the speed of the clamp protects the cycle time but increases wear on the toggle mechanism and platen. It should be balanced against machine maintenance costs.

Резюме

Optimizing cycle times requires a holistic approach combining scientific molding principles, advanced tooling engineering (such as conformal cooling channels), and precise machine setting adjustments. By focusing on the cooling phase—which dominates the cycle—and optimizing давление впрыска and mechanical movements, manufacturers can significantly boost throughput. However, all reductions must be validated against quality standards (e.g., ISO 2859) to ensure that speed does not compromise the structural integrity or dimensional accuracy of the final product.

-

Discover effective methods to improve efficiency and reduce costs in plastic manufacturing. ↩

-

Explore how different mold materials can affect cooling efficiency and cycle times. ↩

-

Find out how optimizing injection pressure can enhance the speed and quality of your molded parts. ↩

-

Understanding cooling time’s role can help manufacturers identify key areas for efficiency improvements. ↩

-

Understanding the relationship between wall thickness and cycle time can lead to better design choices. ↩