Looking around the market, there are fewer and fewer single-color plastic molded products, and every day people wake up and hope to see a colorful world.

Mold companies should always follow in the market’s footsteps and make beautiful and high quality over-molded two-color molds for customers.

This article will introduce all the knowledge about overmold in detail, let’s learn it together.

What is overmolding?

Plastic injection overmolding refers to a product plastic parts manufacturing with two different plastic materials, or two different colors of plastic parts, if this kind of plastic parts, the production of mold injection molding is required to do one piece, then you need to make injection molding overmold.

For example, the most common telephone keys, or calculator keys, keys in the number of two practices, one is screen printing, this time with a long time easy to lose color; there is a practice is achieved through injection overmolding mold, that is, the number with a color of plastic to do, wrapped around the number of keys plastic parts to do another color.

Overmolding Injection molding process

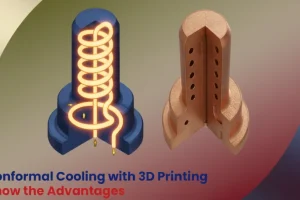

Overmolding is similar to the two-color injection molding process, but there is a relatively big difference with the two color injection molding process. It is to make two sets of molds with a single-color injection molding machine, and to inject the production in two steps.

It is a kind of plastic raw materials in a plastic mold after molding, the molded parts will be removed, put into the second molding plastic mold again injected into the same or another plastic material molding process.

More complex will be multiple molding, so that the plastic product appearance and technology to achieve the desired requirements, called secondary injection molding.

Overmolding involves the combination of two or more materials into one product by molding.

The materials can be of the same type or of different types.

The overmolding process involves softening the overmolded material into a soft plastic material and wrapping it around the other product to be overmolded.

The production method of overmold

After the hard plastic product mold is ready, we will try to get the hard plastic products, then we will put the hard plastic products into the soft plastic material mold and adjust the gap between the soft plastic material mold and the hard plastic product repeatedly to achieve the final product effect.

Therefore, whether the overmold is qualified or not, the mold structure design and the FIT mold process are very important.

All the personnel involved in the design and production process must remember that the best effect of the overmolded products should be exactly the same as the effect of the two-color mold injection.

Therefore, our FIT mold effect should be exactly the same as the production of two-color injection mold, each processing process may affect the final FIT mold, any processing results will be closely related to the mold progress and product quality.

Why do we make overmolded products?

Soft materials such as TPE, TPR, TPU, SEBS and silicone rubber are flexible at room temperature, have relatively high friction, heat insulation and insulating properties.

It is the use of these characteristics of soft plastic material to make overmolded injection products to meet the various functions of the products.

For example, it is usually used as a protective sleeve for some hard objects, such as flashlights, in the metal shell of the flashlight with a silicone rubber protective sleeve, on the one hand, can increase the friction, easy to hold, on the other hand, play the role of insulation and heat insulation, safer to use.

Some power tools are also injection molded by soft plastic material, increasing the anti-slip function, while using the hand grip up more comfortable.

There are also products through the same material of different colors to do the soft plastic material mold to highlight the product brand LOGO, etc.

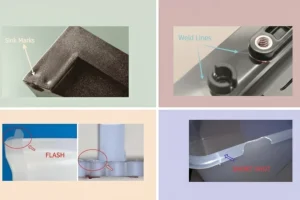

What problems should be noted in overmolding?

Overmolding

It is actually a kind of secondary injection molding, the product generally includes the main body (hard plastic material) and the outer package (soft plastic material) part.

In the mold manufacturing, the main body of the hard plastic first, the main body of the hard plastic mold design according to the normal design procedures, the outer package (soft plastic) mold design to hard plastic finished products as a reference, no need to put shrinkage.

After the mold part, the same as the main body of hard rubber, the front mold is different from the shape of the package rubber, in production, the hard plastic body is made first, and then the hard plastic body is put into the soft plastic material mold for overmolding production.

Characteristics of “Overmolding”

a) The main body of the hard plastic part of the mold design when calculating shrinkage.

To pay attention to the shrinkage of the overmold: the overmold should pay attention to the shrinkage rate, the external parts are not shrinkage.

b) The overmold process usually have two sets of independent mold.

c) The male cavity for soft plastic material mold same as the hard plastic product, there are a small number of avoid empty space, and plastic parts to use the main body of hard plastic can not have empty space..

The empty place as far as possible to open up the hollow to facilitate the external parts into and mold costs, in principle, does not affect the sealing melting plastic material.

d) To pay attention to the positioning of the soft plastic material mold: to achieve reliable sealing and anti-slope holes in the soft plastic parts to prevent deformation of the pulling.

In the soft plastic material sealing bit to leave more 0.07 ~ 0.13 as pre-pressure; hard palstic part to have steel material as support, especially with soft glue back, avoid space gap can not be greater than 0.3.

The bottom finished product and the plastic part manufacturing of the reasonable ratio of material thickness is 5:4; the last point, the runner should not play light, leaving the grain can help out of the mold, the front mold to sun grain, otherwise it will stick to the front mold.

e) If the product takes the front of the situation, you can deal with this:

(1) before the mold burned.

(2) The bottom part of the front mold to add material.

(3) Add material to the back mold of the bottom part.

(4) The back mold of the clad mold is burned.

The choice of cladding material

The softening temperature of the base piece and the covering material should differ by at least 20, otherwise the base piece will be melted.

In general, if you want to strengthen the adhesion covering material resin melting temperature should be the same as the base material.

If the melting temperature of the covering material is too low, it will not be able to melt the surface of the base material. The bond between the two will not be strong enough.

If the melting temperature is too high, the substrate will be softened and deformed. In severe cases, the covering material can penetrate the substrate and cause the part to fail.

Therefore, a good bond can only be ensured by selecting a matching material.

In general, matching materials should have similar chemical properties or contain matching compound components.

When the base material does not match the overlay material, the bonding can usually only be enhanced by making the product structural, rather than chemically bonded.

Precautions for overmolding process

1. The surface should not be uneven to avoid holes caused by air inclusion;

2. The speed of the hopper can not be higher than 40 rpm to avoid hanging points;

3. Plasticizing temperature under the corresponding volume is generally 160℃-210℃ for one minute for complete plasticization (shiny, smooth to the touch is plastic mature) gross surface to no white spot color uniform for complete plasticization, the use of temperature than the light surface correspondingly low 5-15℃.

Conclusion

Through the study of this article, we have learned about the overmolding process, which involves the selection of materials for overmolded products, considerations for injection mold making, and some problems that may be encountered in the injection molding manufacturing process.

The overmolding process involves two sets of molds, which requires more experience of injection mold makers than conventional injection molding, so when the actual project is made.

It is recommended to examine the experience of overmold suppliers and overmolding production suppliers, so as to avoid various problems in the actual production process of the project, which will affect the progress of the project.