Hot runners revolutionize the injection molding process, enhancing efficiency and product quality across various industries.

Hot runners minimize waste and improve cycle times by keeping the plastic melt at optimal temperatures during molding. They are commonly used in automotive, consumer goods, and medical device manufacturing. Key benefits include reduced material costs and improved consistency in part quality.

While this overview highlights the advantages of hot runners, understanding their design and application is crucial for optimizing your production processes. Explore further to discover how different hot runner systems can enhance your manufacturing efficiency.

Hot runners reduce cycle times in injection molding.True

Hot runners keep the plastic melted, reducing the cooling time and speeding up the overall production process.

Hot runners are more expensive than cold runners in every case.False

While hot runners generally have a higher initial cost, their efficiency and material savings can lead to lower overall costs in long-term production.

What is the Principle of Hot Runner?

Hot runners maintain the temperature of the molten plastic throughout the molding process, preventing solidification and reducing waste. This technology is widely used in industries such as automotive, consumer products, and medical devices. Key advantages include improved cycle times, lower material costs, and enhanced consistency in finished products.

Hot runner systems are divided into adiabatic runners and micro semi hot runner system1.The hot runner, also known as the non-runner, means that the plastic in the runner does not solidify after each injection, and the water outlet in the runner does not need to be removed when the plastic product is demolded. Since the plastic in the runner is not solidified, the runner is still unobstructed during the next injection. In short, the hot runner is an extension of the injection molding machine nozzle.

The hot runner is a heating component system used in injection molds to inject melted plastic particles into the mold cavity. A hot runner mold is a new structure that heats the runner and channel of a traditional mold or three-plate mold2, so that the runner and runner do not need to be removed during each molding.

What are the Key Technical Factors Affecting Hot Runners?

Key technical factors affecting hot runners include nozzle design, temperature control, and material flow dynamics. Proper temperature management is crucial for maintaining melt viscosity, while nozzle design impacts melt distribution and part consistency. These factors are vital in industries like automotive and consumer goods, where precision is paramount.

To make a hot runner mold3 project successful, you need to make sure you have a few things in place. The two most important technical things you need to have are: control of plastic temperature and control of plastic flow.

Control of Plastic Temperature

Controlling the temperature of plastic is super important when you’re using a hot runner mold. If you don’t control the temperature well, you’ll have a lot of problems with your process and the quality of your parts. For example, if you use a hot tip gate, you’ll have a lot of problems with the quality of your gate. If you use a valve gate, you’ll have a lot of problems with the valve pin closing.

If you have a multi-cavity mold, you’ll have a lot of problems with the fill time and the quality of your parts. If you can, try to get a hot runner system that has a lot of zones so you can control the temperature better and have more flexibility.

Control of Plastic Fflow

Plastics should flow balanced in the hot runner system. The gates should be opened at the same time to allow the plastic to fill each cavity synchronously. For FAMILY MOLD with a large difference in part weight, the runner size design should be balanced. Otherwise, some parts will not be filled with enough pressure, while others will be filled with too much pressure, or the flash will be too large and the quality will be poor. The design of the hot runner runner size should be reasonable.

If the size is too small, the pressure loss will be too large.If the size is too big, the hot runner volume will be too big, and the plastic will stay in the hot runner system for too long, which will damage the material properties and cause the parts to fail to meet the use requirements after molding. There are already CAE software such as MOLDCAE that specifically helps users to design the best runner.

What Types of Hot Runners are There?

There are two main types of hot runners: open and closed systems. Open systems allow direct flow of molten plastic, while closed systems use a manifold to maintain temperature and reduce waste. Hot runners are widely utilized in industries such as automotive, consumer goods, and medical devices, offering benefits like reduced material usage and improved part consistency.

Needle Valve Type

The valve gate system is a mechanical valve needle system that drives the valve needle with air pressure.Needle valve hot runners save materials, have beautiful plastic surface, and have tight internal quality and high strength. There are two major types of needle valve hot runners in the world (based on the injection principle): cylinder type and spring type.

The cylinder type relies on the controller and the timing controller to control the cylinder to push the needle valve to close.The structure is a bit complicated, but the design is simple. The cylinder type is high in mold precision due to its structural characteristics, and the debugging and maintenance are relatively complicated. The biggest feature of the spring type is that it relies on the balance of the spring and the injection pressure to control the needle valve switch.

The assembly, debugging and maintenance are simple, and the mold precision is not high. It is widely used in home appliances, automotive accessories, and precision multi-cavity molds4. The difference between the spring type and the cylinder is that the timing control cannot be performed, and the problem of weld marks cannot be solved well.

What are the Types of Hot Runner Systems?

There are two main types of hot runner systems: open and closed. Open systems expose the melt to the atmosphere, which is simpler but can lead to material degradation. Closed systems, however, keep the melt contained, minimizing waste and maintaining material integrity. Both systems enhance production speed and part consistency, making them essential in industries like automotive and consumer goods.

Hot runner systems can be divided into fully hot runner system and semi-hot runner systems.Hot runner systems can be divided into three types: single nozzle hot runner systems, multi-nozzle hot runner systems, and valve gate hot runner systems.

Single-Head Hot Runner System

The single-head hot runner system is mainly made up of a single nozzle, a nozzle head, a nozzle connecting plate, a temperature control system, and so on.

The structure of the single-head hot runner system is simple. The molten plastic is injected from the injection molding machine into the nozzle connecting plate, and after reaching the nozzle head through the nozzle, it is injected into the cavity.

It is necessary to control the dimensions d, D, L and adjust the thickness of the nozzle connecting plate so that the fixed mold fixing plate presses the end face of the nozzle connecting plate to control the axial displacement of the nozzle, or directly use the injection molding machine nozzle to support the end face of the nozzle connecting plate to achieve the same purpose.

A lead groove is set at a suitable position on the fixed mold fixing plate to allow the power cord to be led out of the mold and connected to the terminal block installed on the mold.

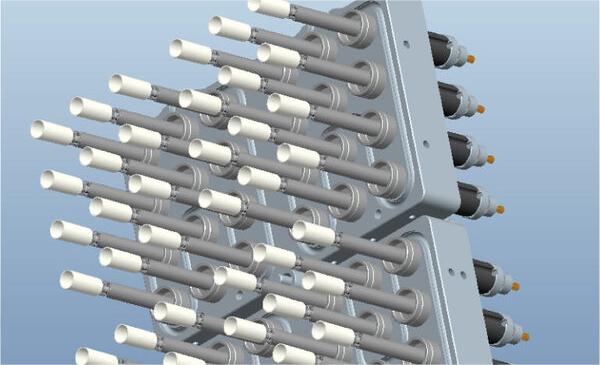

Multi-Head Hot Runner System

The plastic mold of the multi-head hot runner system is pretty complicated. The molten plastic is injected into the nozzle connecting plate by the injection molding machine, flows to the nozzle through the hot runner plate, reaches the nozzle head, and then is injected into the cavity. The nozzle of the hot runner system has to match the radial dimension D1 and the axial dimension limit requirements with the fixed mold plate.

The nozzle head and the fixed mold insert have to match the radial dimension d to make sure the molten plastic doesn’t overflow to the non-cavity part, and the hardness of the fixed mold insert has to be hardened to about 50HRC. The distance L between the parting surface and the axial positioning surface of the hot nozzle has to be strictly controlled.

The dimension should be determined based on the actual distance L\’ of the nozzle at room temperature plus the actual extension ΔL of the nozzle at the normal working temperature of the mold. To ensure that the nozzle fits the hot runner plate reliably and does not deform the hot runner plate, an adjustment pad is provided above the top of the nozzle.

The adjustment pad and the axial positioning surface of the nozzle limit the axial movement of the nozzle and effectively control the possible deformation of the hot runner plate. At room temperature, the gap between the adjustment pad and the hot runner plate and the fixed mold plate is controlled to be 0.025mm so that after the mold is heated, the adjustment pad is just pressed at the working temperature.

The hot runner system’s positioning seat and positioning pin control the hot runner plate’s position in the mold. The positioning seat and the fixed mold plate must have a D2 radial dimension match, and the depth h must be controlled accurately. The positioning seat’s axial direction supports the hot runner plate and directly bears the injection pressure of the injection machine.

The positioning pin must match the hot runner plate’s fixed plate. There must be enough space between the hot runner plate and the mold plate to wrap the insulation material. The hot runner plate and the fixed plate must have enough wiring grooves to allow the power cord to exit the mold and connect to the wiring seat installed on the mold.

There is a radial dimension D1 matching requirement between the nozzle connecting plate and the fixed mold fixing plate so that the injection head of the injection molding machine can cooperate well with the nozzle connecting plate on the mold. Near the hot runner plate, the fixed mold plate, the hot runner plate fixing plate, and the fixed mold fixing plate are connected with screws to enhance the rigidity of the hot runner plate.

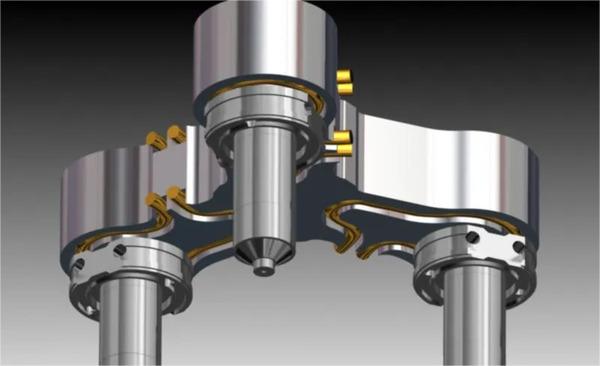

Valve Gate Hot Runner System

The valve gate hot runner system plastic mold is the most complex. It has the same structure as the ordinary multi-head hot runner system plastic mold, and there is an additional set of valve needle transmission device to control the opening and closing movement of the valve needle.

The transmission device is equivalent to a hydraulic cylinder, which uses the hydraulic device of the injection machine to connect with the mold to form a hydraulic circuit to realize the opening and closing movement of the valve needle and control the injection of molten plastic into the cavity.

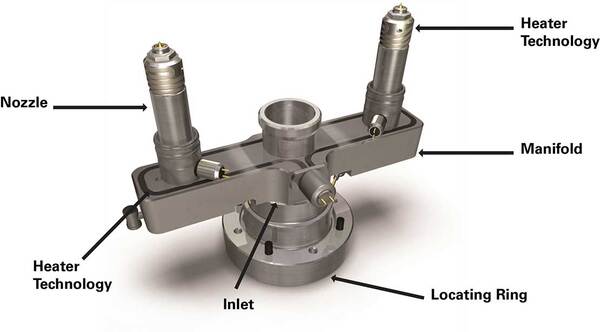

What are the Hot Runner Assembly?

Hot runner assemblies streamline the injection molding process by maintaining plastic at optimal temperatures, reducing cycle times, and minimizing material waste. They are widely used in industries such as automotive, consumer products, and medical devices, offering benefits like lower production costs and improved part consistency.

Positioning Ring

The positioning ring positions the injection mold in the injection molding machine to make sure the mold is lined up right with the machine.

Main Nozzle

When the resin is shot into the mold, this is the gate where the resin comes in from the injection molding machine nozzle. Depending on the type of resin and the design of the hot runner, the gate component can be heated to optimize the molding process.

Manifold

Manifolds are used when you have multiple cavities in a mold or when you have multiple feed points or when you have a single feed point but the material level is offset. The material is usually P20 or H13. Manifolds are generally divided into two categories: standard and non-standard. Their structural form is mainly determined by the distribution of cavities on the mold, the arrangement of nozzles and the location of gates.

Manifolds allow resin to flow into different nozzles and injection points (gates). Manifolds are usually used when you have multiple cavities or when you need more than one nozzle/gate for each part. Manifolds can be used for a variety of materials, designs and shapes, and are usually optimized through CAE analysis to improve the molding process.

Nozzle

There are two types of hot nozzles: open hot nozzles and needle valve hot nozzles5. The type of hot nozzle you use determines the type of hot runner system you need and the type of mold you need to make. So, hot runner systems are divided into open hot runner systems and needle valve hot runner systems.

Heater Technology

Heater technology is the foundation of all hot runner systems and has a big impact on the molding process and part quality. There are several heating methods, each with its own pros and cons. Choose the right hot runner based on different molding processes, part performance, reliability and cost requirements. The most common hot runner technologies include heaters with heating belts/plates, adhesive/flexible heaters or brazed heaters.

What are the Advantages of Hot Runner?

Hot runners reduce material waste and enhance cycle times by maintaining optimal temperatures for the plastic melt during the molding process. Commonly utilized in industries like automotive, consumer goods, and medical devices, their key advantages include lower material costs and improved consistency in part quality.

Shortened Cycle

The molding cycle of parts is shortened. Because there is no cooling time limit for the runner system, the parts can be ejected in time after molding and curing. The molding cycle of many thin-walled parts produced with hot runner molds can be less than 5 seconds.

Expand the Scope of Application

Hot runner technology has been the basis for many advanced plastic molding processes. These include PET preform molding, multi-color injection molding, multi-material injection molding, stack molding, and more.

Improve Pproduct Quality

When you’re making plastic parts with a hot runner mold, you can control the temperature of the plastic melt in the runner system. This means the plastic can flow into each mold cavity in a more even way, so you get parts that are the same quality every time. The parts you make with a hot runner mold have good gates, low stress after you take them out of the mold, and they don’t get messed up.

That’s why you see a lot of high-quality products made with hot runner molds. A lot of the plastic parts in MOTOROLA phones, HP printers, and DELL laptops are made with hot runner molds.

Save Plastic

In pure hot runner molds, there is no cold runner, so there is no production cost. This is particularly important for applications where plastics are expensive. In fact, major international hot runner manufacturers have developed rapidly in the era when oil and plastic raw materials are expensive in the world. Because hot runner technology is an effective way to reduce material costs.

Reduce Waste

Cut waste and make better stuff. When you’re molding with a hot runner mold, you can control the temperature of the plastic melt in the runner system. That means the plastic can flow into each mold cavity in a more even way, so you get parts that are the same quality every time. The parts you make with a hot runner mold have good gates, low stress after you take them out of the mold, and they don’t get messed up.

Production Automation

Eliminating subsequent processes is good for automation. The parts are finished after being molded by the hot runner mold, and there is no need to trim the gate and recycle the cold runner. It is good for automation. Many foreign product manufacturers combine hot runners with automation to greatly improve production efficiency.

Many advanced plastic molding processes are developed on the basis of hot runner technology. Such as PET pre-molding, multi-color co-injection in the mold, multi-material co-injection process, STACK MOLD, etc.

What are the Disadvantages of Hot Runner?

Common disadvantages of hot runners include higher initial costs, potential for thermal degradation of materials, and increased maintenance requirements. They may also complicate the molding process and require precise temperature control, which can lead to production delays if not managed properly.

Rising Costs

Hot runner components are expensive, and the cost of hot runner molds can go up a lot. If you’re making a small number of parts, the mold tool cost ratio is high, which isn’t cost-effective. Mold expert WeChat editor For mold users in many developing countries, the high price of hot runner systems is one of the main problems that keeps hot runner molds from being used more.

High Equipment Requirements

The production process equipment requirements are high, and hot runner molds require precision processing machinery to ensure. The integration and matching requirements of the hot runner system and the mold are extremely strict, otherwise the mold will have many serious problems during the production process.

For example, poor plastic sealing leads to plastic overflow and damage to hot runner components6, interrupting production, and poor relative position of nozzle inserts and gates leads to serious decline in product quality.

Complex Operation and Maintenance

Hot runner molds are more complicated to operate and maintain than cold runner molds. If you don\’t operate them properly, it\’s very easy to damage the hot runner parts, which will make production impossible and cause huge economic losses. For new users of hot runner molds, it takes a long time to accumulate experience.

What are the Application Areas of Hot Runners?

With the fast development of science and technology and the continuous innovation of technology, hot runner system, as an efficient and precise plastic molding technology, has been widely used in many fields. The following will introduce the main application fields of hot runner system in detail.The following will introduce the main application fields of hot runner system in detail.

Automotive Industry

Hot runner systems are a big deal in the automotive industry. They’re used to make everything from headlights and doors to entire car bodies. They’re great because they can control how plastic melts, which means parts come out the same every time. That makes cars better. Hot runner systems can also make other parts for cars, like dashboards, door panels, and seats. That’s good for the car business.

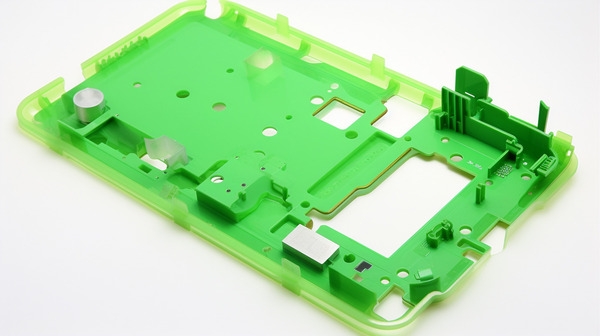

Electronic Industry

In the electronics industry, hot runner systems are also widely used. Whether it’s the shell, keyboard, mouse, chassis, or other parts of electronic equipment like TVs, stereos, or computers, they can be made using hot runner systems.

Hot runner systems can ensure that the plastic material reaches the ideal melting state during the injection molding process, which improves the precision and surface finish of the parts. Additionally, hot runner systems can improve production efficiency, reduce production costs, and provide strong support for the development of the electronics industry.

Medical Device Field

In the field of medical devices, the application of hot runner systems cannot be ignored. It can be used to manufacture accessories for medical devices, such as needles, syringes, infusion sets, and perfusion sets.

The manufacturing precision of these medical devices is extremely high, and the hot runner system can accurately control the injection process to ensure the consistency and precision of the products. In addition, the hot runner system can also improve production efficiency and reduce production costs, providing strong support for the development of the medical device industry.

Daily Necessities Manufacturing Field

In the field of daily necessities manufacturing, the hot runner system also plays a very important role. It can be used to manufacture daily necessities such as furniture, tableware, beverage bottles, shampoo bottles, and cosmetic bottles.

These products require plastic injection molding, and the hot runner system can improve the surface finish and precision of the product, improve the injection molding production efficiency, and reduce the production cycle and cost of the product. Therefore, the application of hot runner systems in the field of daily necessities manufacturing is becoming more and more extensive.

Toy Manufacturing Field

Toy manufacturing is another important application area for hot runner systems. Toys are usually diverse in style and large in quantity, so hot runner systems can greatly improve production efficiency. By precisely controlling the melting process of plastic materials, hot runner systems can ensure the consistency and precision of toy parts, thereby improving the overall quality and performance of toys.

Aerospace Field

Hot runner systems are also super useful in the aerospace industry. They can be used to make all sorts of parts, like seats, accessories, dashboards, controllers, pilot supplies, and more. These parts have to be made really precisely. Hot runner systems can control the injection process really well, so the product is always the same and always perfect. Plus, hot runner systems make production faster and cheaper, which is great for the aerospace industry.

Conclusion

Hot runner (Hot Runner Systems) is a heating component system used in injection molds to inject melted plastic particles into the mold cavity. Hot runner molds are a new structure that heats the runners and runners of traditional molds or three-plate molds, so that the runners and runners do not need to be removed at each forming.

Hot runner technology was introduced to the plastics industry more than 50 years ago, and it has completely changed the injection molding process capabilities by improving the quality of injection molded parts, improving operating efficiency, reducing scrap, and saving money.

-

Learn about Semi Hot Runner System vs Cold Runner: Which Is Better : The hot runner system is used in injection molding, and it comes in both fully hot and semi-hot runner types. ↩

-

Learn about How to Design Three-Plate Molds, Part 1: Three-plate molds have significantly more design considerations that affect their cost, functionality and longevity. ↩

-

Learn about WHAT IS A HOT RUNNER: A hot runner system is a molten plastic conveying unit used within an injection mold. ↩

-

Learn about Optimizing Multi-Cavity Molds for Enhanced Injection Molding Production: Multi-cavity injection molding is crucial for mass production of goods. ↩

-

Learn about Sequential injection-molding needle-valve type hot nozzle: injection-molding needle-valve type hot nozzle, which comprises a hot-runner plate, a hot nozzle and a valve needle in the hot nozzle. ↩

-

Learn about Hot Runner Systems : A hot runner system is an assembly of heated components that directly inject molten resin into the mold cavities. ↩