– Weight Reduction: Converting metal to plastic typically reduces part weight by 30% to 50% due to the lower specific gravity of polymers.

– Cost Efficiency: While polymer materials (like PEEK) can be more expensive per pound than steel, injection molding eliminates secondary machining, drastically reducing total unit cost by up to 40%.

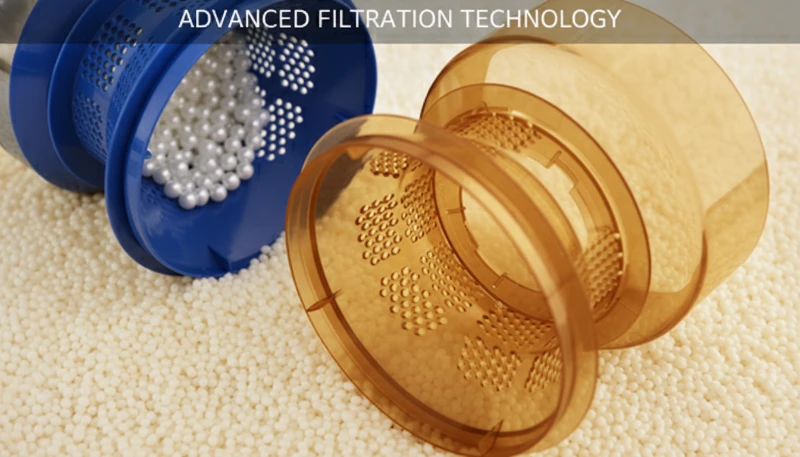

– Design Freedom: Plastics allow for part consolidation—molding multiple features (snaps, threads, bearings) into a single component, reducing assembly labor.

– Performance Parity: Fiber-reinforced engineering plastics (e.g., 50% Carbon-Filled Nylon) can match the tensile strength of die-cast aluminum and magnesium.

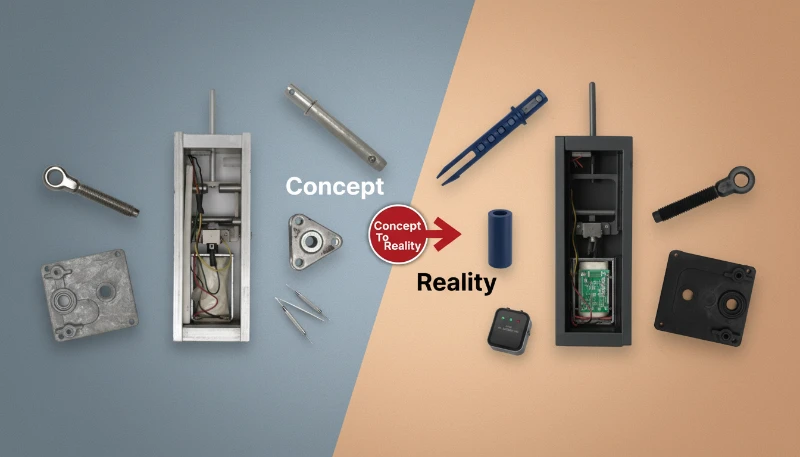

What Is Metal-to-Plastic Conversion?

Metal-to-plastic conversion is the engineering process of replacing metal components (typically machined steel, die-cast aluminum, or brass) with high-performance engineering thermoplastics. This shift is driven by the need for lightweighting industrial parts, corrosion resistance, and cost reduction.

It is not merely a material swap; it is a redesign process. A part originally designed for metal machining cannot simply be molded in plastic without modification. Wall thickness, ribbing structures, and gate locations must be re-engineered to handle structural loads using polymer physics (viscoelasticity) rather than metal elasticity.

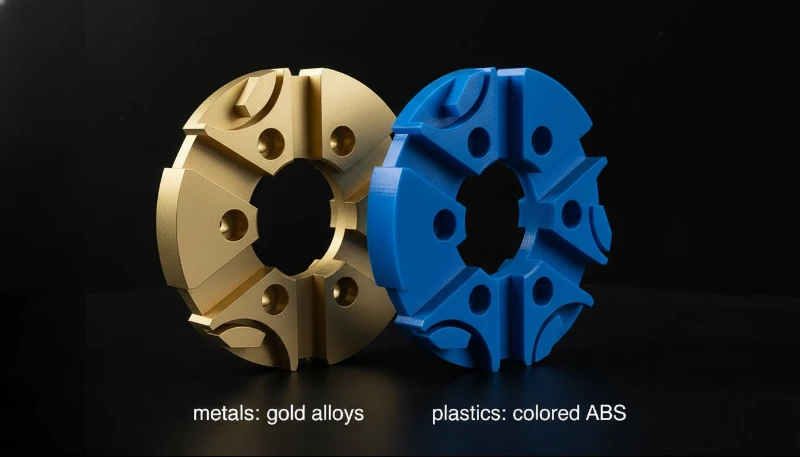

Technical Comparison: Metal vs. Structural Plastics

The decision to convert relies on matching the physical properties of metals with reinforced polymers.

| Parámetro | Die-Cast Aluminum (A380) | Stainless Steel (304) | PEEK (30% Carbon Fiber) | Nylon 66 (50% Glass Fiber) |

|---|---|---|---|---|

| Densidad (g/cm³) | 2.76 | 8.00 | 1.41 | 1.58 |

| Resistencia a la tracción (MPa) | 317 | 515 | 230 | 250 |

| Flexural Modulus (GPa) | 71 | 193 | 20 | 17 |

| Max Service Temp (°C) | >300 | >800 | 260 | 180 |

| Resistencia a la corrosión | Moderate (Oxidizes) | Excelente | Excelente | Good (Hydroscopic) |

| Production Method | Die Casting + Machining | Mecanizado CNC | Moldeo por inyección | Moldeo por inyección1 |

Data Sources: ASTM Standards / MatWeb.

Replacing metal with plastic always results in a weaker, less durable part.Falso

High-performance thermoplastics reinforced with long glass or carbon fibers can match or exceed the specific strength (strength-to-weight ratio) of metals like aluminum and zinc, while offering superior fatigue resistance and chemical immunity.

Plastics creep (deform) under load over time, whereas metals do not.Verdadero

Viscoelastic creep is a real limitation of plastics under constant load; however, this is managed by designing 'creep modules'—using ribs and geometry to distribute stress—and selecting creep-resistant materials like PEEK or PPS.

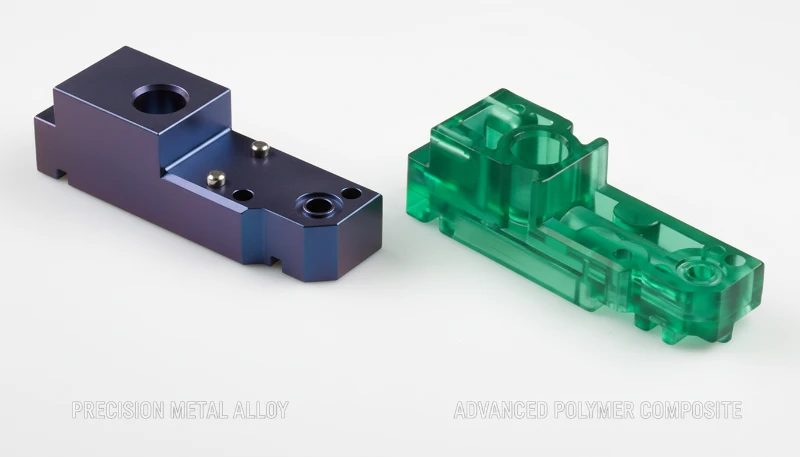

Case Study: Replacing Aluminum with PEEK in Aerospace

El desafío

A manufacturer of aerospace fuel pump housings was using machined Aluminio 6061. The part required intricate internal channels, 5-axis CNC machining, and anodizing for corrosion protection. The weight was critical, and the multi-step manufacturing process created a bottleneck.

La solución

The engineering team converted the housing to Polieteretercetona (PEEK)2 reinforced with 30% carbon fiber.

- Proceso: Injection Molding (Single shot).

- Material: PEEK 450CA30.

- Design Change: Wall thicknesses were unified to 3mm to prevent sink marks. Ribs were added to the external housing to match the stiffness of the original aluminum part.

The Results

- Reducción de peso: 48% lighter (Specific Gravity drop from 2.7 to 1.4).

- Cost Savings: 35% reduction per unit. Although PEEK material cost is 10x higher than aluminum, the elimination of 4 hours of CNC machining and anodizing per part offset the raw material cost.

- Rendimiento: The PEEK part offered superior chemical resistance to jet fuel compared to the anodized aluminum, which was prone to pitting over time.

Step-by-Step Process for Structural Plastic Design

To successfully execute metal to plastic conversion case studies, engineers follow this workflow:

- Load Analysis: Determine the mechanical loads (tensile, compressive, torque). If the temperature exceeds 200°C continuously, options narrow to PEEK, PPS, or LCP.

- Selección de materiales3:

- High Load/Impact: Nylon 66 (PA66) + Glass Fiber.

- High Heat/Chemicals: PEEK, PPS, or Ultem (PEI).

- Precision/Dimensional Stability: Polycarbonate (PC) or PBT.

- Geometry Optimization4:

- Replace Mass with Ribs: Do not mimic solid metal blocks. Use coring techniques to remove mass and add ribs for stiffness.

- Add Draft Angles: Metal parts often have 0° walls; plastic requires 0.5°–1.0° draft for ejection.

- Radius Corners: Sharp corners in plastic concentrate stress (notch sensitivity), leading to failure. Add radii (fillets) to all internal corners.

- Creación de prototipos5: Use CNC machining of the plastic stock or 3D printing (SLS) with comparable reinforced powders to validate fit and assembly before cutting the steel mold.

- Tooling: Build the mold, usually from hardened steel (H13), anticipating the high abrasion of glass/carbon fillers.

Plastic resin is far more expensive than raw steel, making conversion cost-prohibitive.Falso

While the raw material cost per pound is higher for engineering plastics, the 'total landed cost' drops because injection molding produces a net-shape part in seconds, eliminating expensive machining, welding, and finishing labor.

Injection molding tooling is too expensive for low-volume heavy industrial parts.Verdadero

This is often true for volumes under 500-1,000 units/year. The ROI for a $50,000 mold is hard to justify against CNC machining unless the weight savings or part consolidation provides massive functional value.

Benefits and Limitations

| Aspecto | Advantages of Conversion | Risks & Limitations |

|---|---|---|

| Manufacturing | Consolidation: One molded part can replace an assembly of 5 metal parts (screws, brackets, housing). | Tolerancias: Plastic cannot hold the tight tolerances of machined metal (e.g., ±0.005mm is rare in plastic, standard in metal). |

| Rendimiento | Damping: Plastics naturally absorb vibration and noise (NVH) better than ringing metals. | Expansión térmica: Plastics expand/contract 5-10x more than metals (CLTE), causing fit issues in mixed-material assemblies. |

| Mantenimiento | Corrosion: Plastics do not rust; no painting or plating required. | Degradación UV: Many plastics require UV stabilizers or painting for outdoor use. |

Practical Tips for Engineering Success

- The "Steel Safe" Rule: When designing the mold, leave the plastic "steel safe" (leave more metal on the mold, resulting in less plastic on the part) in critical fit areas. It is easy to remove metal from the mold to add plastic; it is expensive to weld metal back in.

- Moldeo por inserción6: If you need metal-like thread strength, don’t tap threads into the plastic. Use moldeo por inserción to encapsulate brass nuts or steel bushings directly into the part during the molding cycle.

- Orientation Matters: In fiber-reinforced plastics, strength is anisotropic (stronger in the direction of flow). Analyze gate locations to ensure fibers align with the primary stress vectors.

Preguntas más frecuentes (FAQ)

Q: Can plastic really replace stainless steel?

A: For structural housing and brackets, yes. Long-fiber reinforced thermoplastics (LFRT)7 can replace steel. However, for applications requiring high surface hardness (knife edges) or extreme heat (>300°C), steel remains superior.

Q: What is the biggest mistake in metal-to-plastic conversion?

A: "Same-shape replacement." Designers often try to mold the exact shape of the machined metal part. This leads to thick wall sections that cause sink marks, voids, and long cycle times. The part must be redesigned with uniform wall thickness.

Q: How much weight can I save?

A: Typically 30-50%. Aluminum has a specific gravity of ~2.7; reinforced Nylon is ~1.5. PEEK is ~1.3.

Q: Is PEEK the only option for metal replacement?

A: No. PEEK is for extreme performance. For general industrial replacement (brackets, handles, covers), Glass-Filled Nylon (PA66) o Polybutylene Terephthalate (PBT) are standard, cost-effective choices.

Q: How does plastic handle impact compared to metal?

A: Unfilled plastics can be brittle. However, "impact-modified" grades (like PC/ABS blends or toughened Nylon) can actually survive drops better than cast metal because they flex and recover rather than permanently deforming or cracking.

Resumen

Metal-to-plastic conversion is a strategic engineering choice that yields injection molding cost savings and performance benefits in weight and chemical resistance. By leveraging materials like Glass-Filled Nylon o replacing aluminum with PEEK, manufacturers can consolidate complex assemblies into single molded parts. The key to success lies in redesigning the component to respect the rules of plastic flow and thermal behavior, rather than treating plastic as a direct substitute for metal blocks.

-

Understand the injection molding process and its advantages in producing complex plastic parts efficiently. ↩

-

Learn why PEEK is a preferred material in aerospace for its lightweight and high-performance characteristics. ↩

-

Discover the criteria for choosing the best plastic materials for specific industrial applications. ↩

-

Explore how optimizing geometry can enhance the performance and efficiency of plastic parts. ↩

-

Understand the role of prototyping in validating design and fit before full-scale production. ↩

-

Learn about insert molding and how it enhances the strength and functionality of plastic parts. ↩

-

Explore the applications and benefits of using LFRTs in replacing metal components. ↩