Las máquinas de moldeo por inyección de alta velocidad están diseñadas para mejorar la eficacia del proceso de moldeo por inyección, permitiendo tiempos de ciclo más rápidos y una producción precisa de piezas de alta calidad.

Las máquinas de moldeo por inyección de alta velocidad ofrecen ciclos rápidos y alta precisión mediante automatización y control de temperatura avanzados, ideales para la producción a gran escala y de alta calidad en los sectores de automoción, electrónica y bienes de consumo.

Comprender la tecnología que hay detrás de las máquinas de moldeo por inyección de alta velocidad puede mejorar significativamente la eficacia de su producción. Descubra cómo estas máquinas pueden optimizar su proceso de fabricación para obtener resultados más rápidos y rentables.

Las máquinas de moldeo por inyección de alta velocidad reducen la duración de los ciclos.Verdadero

Al aumentar la velocidad de inyección y la precisión, estas máquinas acortan el tiempo de enfriamiento y moldeo, acelerando todo el proceso de producción.

Las máquinas de moldeo por inyección de alta velocidad sólo son adecuadas para grandes series de producción.Falso

Aunque estas máquinas están optimizadas para la producción de grandes volúmenes, también pueden utilizarse eficazmente para lotes más pequeños que requieren gran precisión y plazos de entrega rápidos.

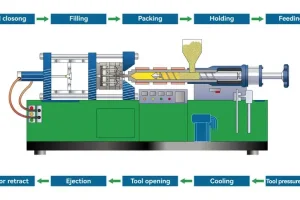

¿Cuál es el principio de funcionamiento de la máquina de moldeo por inyección de alta velocidad?

Las máquinas de moldeo por inyección de alta velocidad revolucionan el proceso de fabricación al reducir significativamente los tiempos de producción y mejorar la precisión en la creación de piezas.

Las máquinas de moldeo por inyección de alta velocidad inyectan rápidamente plástico fundido en los moldes, mejorando los índices de producción, los tiempos de ciclo y la calidad de las piezas, lo que las hace perfectas para la fabricación de grandes volúmenes en los sectores de la automoción y la electrónica de consumo.

Adición de gránulos de plástico

En primer lugar, se introducen pellets de plástico en la máquina. Estos pellets suelen recibir un tratamiento antes de entrar, como secarlos y mezclarlos, para asegurarse de que son todos iguales y de buena calidad.

Calentamiento y fusión

Cuando los gránulos de plástico entran en la abertura de alimentación de la máquina de moldeo por inyección, pasan a un cilindro calentado. Aquí, los gránulos de plástico se calientan gracias a la banda calefactora, se enroscan en el cilindro y se funden lentamente en un plástico fundido fluido.

Moldeo por inyección

Una vez fundidos los gránulos de plástico en plástico fundido, el tornillo los empuja a la cámara de inyección. La cámara de inyección es una cámara especialmente diseñada con una forma interna que se ajusta a la forma del producto de plástico deseado.

Enfriamiento y curado

En la cámara de inyección, el plástico fundido llenará la cavidad del molde y se enfriará rápidamente. A medida que el plástico se enfría, se va endureciendo hasta adquirir la forma deseada. Dependiendo del producto, es posible que necesite un equipo de refrigeración adicional para enfriarlo más rápido.

Expulsión

Una vez que el plástico está totalmente curado y suficientemente duro, un dispositivo de expulsión empuja la pieza moldeada fuera del molde.

Las máquinas de moldeo por inyección de alta velocidad reducen la duración de los ciclos en comparación con las máquinas estándar.Verdadero

Lo consiguen aumentando la velocidad de inyección y reduciendo los tiempos de enfriamiento, optimizando todo el proceso de moldeo.

Las máquinas de moldeo por inyección de alta velocidad no son adecuadas para producir piezas grandes.Falso

Muchas máquinas de alta velocidad están diseñadas para manipular piezas grandes, aunque depende de la capacidad de la máquina y del diseño del molde.

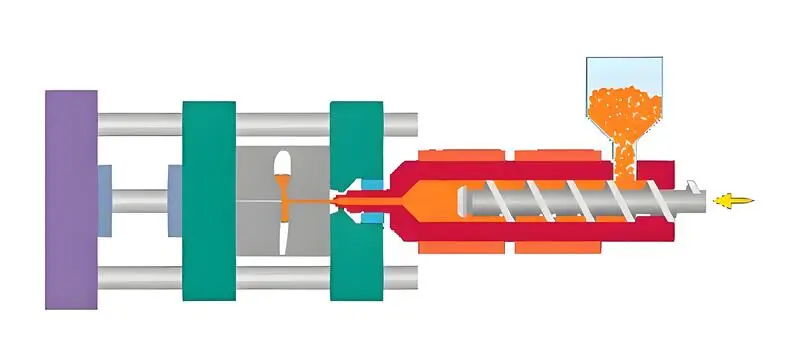

¿Cuáles son los componentes estructurales de una máquina de moldeo por inyección de alta velocidad?

Las máquinas de moldeo por inyección de alta velocidad son vitales para producir con eficacia piezas de plástico precisas y complejas, impulsando la innovación en varios sectores.

Las máquinas de moldeo por inyección de alta velocidad constan de unidades de sujeción e inyección, sistemas de control y una fuente de alimentación, cruciales para industrias como la automovilística y la electrónica debido a su precisión y alta repetibilidad en la producción de piezas.

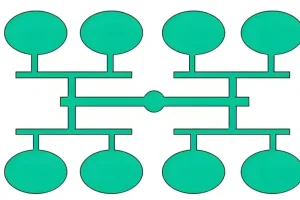

Sistema de inyección

En sistema de inyección1 es el corazón de un máquina de moldeo por inyección de alta velocidad2. Consta principalmente de una tolva, un tornillo, un cilindro de inyección, una boquilla de inyección, un molde y otras piezas. La tolva se utiliza para almacenar los gránulos de plástico. El tornillo transporta los gránulos de plástico de la tolva al cilindro de inyección mediante rotación.

A continuación, el plástico fundido se inyecta en el molde a través del cilindro de inyección. El sistema de inyección es la parte más importante de una máquina de moldeo por inyección de alta velocidad. Afecta directamente a la calidad de los productos acabados y a la eficiencia de la producción.

Sistema de sujeción de moldes

En sistema de sujeción de moldes3 de una máquina de moldeo por inyección de alta velocidad se acciona mediante un sistema hidráulico. Consiste en un motor hidráulico, una bomba hidráulica, un cilindro hidráulico y una parte de transmisión mecánica. Su función principal es bloquear el molde en el marco de la máquina de moldeo por inyección para asegurarse de que la presión y la temperatura en el espacio de moldeo se mantienen estables. La estabilidad del sistema de bloqueo del molde decide la precisión y la estabilidad de la máquina de moldeo por inyección de alta velocidad.

Sistema de lubricación

El sistema de lubricación se compone principalmente de bomba de aceite, tanque de aceite, tubería de aceite, filtro, etc. Su función es proporcionar al sistema hidráulico el aceite hidráulico que necesita, reducir el desgaste y la fricción, y asegurarse de que la máquina de moldeo por inyección de alta velocidad pueda funcionar de forma estable durante mucho tiempo.

Sistema de control

El sistema de control de la máquina de moldeo por inyección de alta velocidad utiliza un programa de control por ordenador y controla todo el proceso de inyección a través de la interfaz hombre-máquina. El sistema de control tiene un gran impacto en la calidad de los productos acabados, la eficiencia de la producción y el consumo de energía.

Las máquinas de moldeo por inyección de alta velocidad aumentan la eficacia de la producción.Verdadero

Estas máquinas permiten tiempos de ciclo más rápidos y una calidad constante de las piezas, lo que aumenta la productividad general de la fabricación.

Las máquinas de alta velocidad sólo son adecuadas para la producción a gran escala.Falso

Aunque son ideales para la producción a gran escala, estas máquinas también pueden beneficiar a tiradas más pequeñas gracias a su precisión y versatilidad en el uso de materiales.

¿Cuáles son las ventajas de las máquinas de moldeo por inyección de alta velocidad?

Las máquinas de moldeo por inyección de alta velocidad aumentan la eficacia de la producción reduciendo considerablemente los tiempos de ciclo y mejorando la calidad de las piezas en diversos sectores.

Las máquinas de moldeo por inyección de alta velocidad mejoran la eficacia de la producción y la calidad de las piezas en los sectores de la automoción, la electrónica y el embalaje, ya que ofrecen tiempos de ciclo rápidos, reducen los costes y aumentan el rendimiento, lo que resulta ideal para la fabricación de grandes volúmenes.

Sistema hidráulico de alto ahorro energético

La máquina de moldeo por inyección de alta velocidad utiliza un servosistema hidráulico de ahorro de energía4. El servomotor está equipado con una bomba cuantitativa. El servomotor se puede arrancar, parar y la velocidad se puede ajustar arbitrariamente. El servo motor acciona la bomba de aceite para girar. La cantidad de escupida de la bomba de aceite y la velocidad de escupida pueden ser controladas.

De acuerdo con la velocidad real de cada acción de la máquina de moldeo por inyección, la velocidad y la posición de cada acción de la máquina de moldeo por inyección se controlan directamente. Puede entenderse que la velocidad y la posición de cada acción de la máquina de moldeo por inyección son controladas directamente por el sistema hidráulico servo de ahorro de energía.

Las máquinas de moldeo por inyección de alta velocidad tienen muchas ventajas en términos de ahorro de energía y protección del medio ambiente. Utiliza medidas avanzadas de recuperación de energía y ahorro energético para reducir el consumo de energía y la generación de residuos, lo que se ajusta a los requisitos del desarrollo sostenible.

Las máquinas de moldeo por inyección rápida también pueden lograr una programación óptima y una programación de la producción mediante sistemas de control inteligentes5minimizando el derroche de energía y los tiempos de inactividad de la producción.

Sistema hidráulico de alta eficiencia

La máquina de moldeo por inyección de alta velocidad utiliza dos conjuntos de sistemas servohidráulicos, que suministran aceite al mismo tiempo y actúan por separado. Esto permite la acción simultánea de dos ejes (apertura y expulsión del molde al mismo tiempo). También puede añadir una nueva fuente de alimentación en función de las necesidades reales del sistema para lograr la vinculación de tres ejes (almacenamiento, apertura y expulsión al mismo tiempo), lo que reduce en gran medida el tiempo de ciclo del moldeo por inyección.

La máquina de moldeo por inyección de alta velocidad es un tipo de equipo especialmente diseñado para la producción de moldeo por inyección de alta velocidad. En comparación con la máquina de moldeo por inyección tradicional, adopta un proceso avanzado y un sistema de control, lo que hace que el proceso de moldeo por inyección sea más rápido y eficiente.

Las máquinas de moldeo por inyección rápida suelen tener sistemas de accionamiento de alta potencia y estructuras hidráulicas o electromecánicas optimizadas, lo que significa que pueden inyectar más rápido y tienen tiempos de ciclo más cortos, por lo que pueden fabricar más cosas.

Alta precisión en la sección de control electrónico

Con Servoválvulas Moog6 y el control electrónico KEBA, junto con el sistema de inyección monocilíndrico, la posición de inyección es precisa y la repetibilidad del producto es alta.

La máquina de moldeo por inyección de alta velocidad es precisa y estable. Utiliza un sistema avanzado de control en bucle cerrado7 para controlar con precisión la temperatura, la presión, la velocidad y otros parámetros durante cada paso del proceso de moldeo por inyección. Esto permite a la máquina de moldeo por inyección de alta velocidad realizar inyecciones precisas y garantizar que los productos tengan el tamaño y la forma adecuados. Es perfecta para industrias que necesitan productos de alta calidad, como la automovilística y la de dispositivos médicos.

Alta rigidez del sistema de sujeción de moldes

El sistema de sujeción de la máquina de moldeo por inyección de alta velocidad ha sido sometido a análisis de elementos finitos8. La plantilla tiene baja deformación. La biela adopta un diseño de ángulo grande, y su punto de pivote está cerca del centro. La fuerza de sujeción se transmite a la parte central de la plantilla para lograr una distribución uniforme de la sujeción, mantener la precisión del molde y garantizar el movimiento de alta velocidad de la sujeción.

Alta respuesta del sistema de inyección

La máquina de moldeo por inyección de alta velocidad utiliza un acumulador como fuente de energía para la inyección. Cuenta con un sensor de servoválvula Moog y un mecanismo de inyección de baja inercia. La respuesta de inyección es estable a 30 ms.

La máquina de moldeo por inyección de alta velocidad también tiene una rápida respuesta y capacidad de ajuste. Adopta algoritmos de control avanzados y sensores de alta velocidad, que pueden supervisar los cambios en el proceso de inyección en tiempo real y realizar rápidamente los ajustes correspondientes.

Esto permite a la máquina de moldeo por inyección de alta velocidad hacer frente a las demandas de producción de ciclo corto, personalización de lotes pequeños, etc. Puede cambiar rápidamente los parámetros del proceso y mejorar la flexibilidad de la producción y la velocidad de respuesta.

Alta plastificación del sistema de inyección

El tornillo de la máquina de moldeo por inyección de alta velocidad es L/D=24~26, y es de doble rosca + tipo de mezclado, por lo que el plástico se mezcla uniformemente.

La máquina de moldeo por inyección de alta velocidad tiene una amplia gama de velocidades de inyección ajustables para adaptarse a los diferentes requisitos del producto. Puede realizar una producción continua y estable y garantizar el ciclo de suministro. Con modo de ahorro de energía para reducir el consumo de energía cuando no funciona a plena carga. Puede mejorar eficazmente el acabado superficial de los productos de plástico.

La función de comunicación del equipo es potente, lo que es conveniente para realizar la gestión inteligente de la fábrica9. Puede completar rápidamente la producción de sustitución del producto.

La máquina de moldeo por inyección de alta velocidad tiene una alta precisión de inyección, lo que reduce la tasa de productos defectuosos. Tiene una buena capacidad anti-interferencia y funciona de forma estable y fiable. Puede optimizar el proceso de producción y mejorar la eficiencia general de la producción. El equipo tiene un gran espacio para la actualización y transformación, que es conveniente para las actualizaciones tecnológicas. Puede producir micropartes de alta precisión.

Sistema de control inteligente

Con esta máquina de moldeo por inyección puede fabricar productos de pared fina de alta calidad. El sistema de control es inteligente y fácil de usar. Puede manejar altos estándares de producción y satisfacer la demanda del mercado. La máquina es pequeña y no ocupa mucho espacio. Puede autodiagnosticarse e indicarle si hay algún problema. Puede utilizarla para fabricar piezas diminutas para productos especiales.

La máquina de moldeo por inyección de alta velocidad capacidad de plastificación10 y mejora el efecto plastificante del plástico. Puede realizar la conversión precisa de la inyección a alta velocidad y el mantenimiento de la presión. Tiene una buena función de escape para reducir los defectos de burbujas de aire de los productos. El equipo tiene buena durabilidad y larga vida útil.

Rapidez de respuesta para garantizar la puntualidad y precisión de la operación.

La máquina de moldeo por inyección de alta velocidad tiene una rápida acción de apertura y cierre, lo que acorta el ciclo de moldeo. Tiene un control de inyección de alta precisión para garantizar la consistencia del tamaño del producto. Puede reducir eficazmente la tensión interna de los productos y mejorar su calidad. Su gestión del consumo de energía11 es excelente, lo que ahorra costes de producción.

La máquina de moldeo por inyección de alta velocidad tiene una gran estabilidad y reduce la aparición de fallos en la producción. Puede realizar el moldeo por inyección de productos de formas complejas, ampliando el campo de aplicación. Tiene buena compatibilidad y se adapta al procesamiento de una gran variedad de materiales plásticos.

El equipo tiene un alto grado de automatización, lo que reduce la intensidad del trabajo manual

Puede completar rápidamente el moldeo por inyección de un molde con múltiples cavidades y aumentar la producción por unidad de tiempo. Con función avanzada de control de temperatura, para garantizar la calidad de la fusión del plástico. La presión de inyección de la máquina de moldeo por inyección de alta velocidad es uniforme, lo que mejora la calidad de la apariencia de los productos. El volumen de inyección se puede controlar con precisión para reducir el desperdicio de material.

El mantenimiento del equipo es sencillo, lo que reduce los costes de mantenimiento. Puede cambiar entre diferentes moldes rápidamente, lo que mejora la flexibilidad de la producción. La máquina de moldeo por inyección de alta velocidad es silenciosa, lo que mejora el ambiente de trabajo. El sistema de protección de seguridad es perfecto, lo que mantiene a los operadores seguros. El sistema de refrigeración es eficiente, lo que acelera el enfriamiento y el moldeo de los productos.

Las máquinas de moldeo por inyección de alta velocidad reducen considerablemente la duración de los ciclos.Verdadero

Al funcionar a mayor velocidad, estas máquinas completan el proceso de moldeo más rápidamente, reduciendo así la duración de cada ciclo.

Las máquinas de moldeo por inyección de alta velocidad son adecuadas para todos los entornos de fabricación.Falso

Aunque destacan en entornos de producción de gran volumen, es posible que las operaciones más pequeñas no obtengan las mismas ventajas económicas debido a los mayores costes de maquinaria y mantenimiento.

¿En qué sectores se utilizan las máquinas de moldeo por inyección de alta velocidad?

Las máquinas de moldeo por inyección de alta velocidad mejoran los índices de producción y la precisión, y desempeñan funciones vitales en numerosos sectores.

Las máquinas de moldeo por inyección de alta velocidad, muy utilizadas en los sectores de la automoción, la electrónica, el envasado y la medicina, ofrecen tiempos de ciclo rápidos, gran eficacia y precisión, ideales para la producción en serie y diseños complejos.

Industria electrónica

Las máquinas de moldeo por inyección también se utilizan ampliamente en la industria electrónica. Con la tendencia de la inteligencia y la miniaturización, las piezas de plástico se utilizan cada vez más, y la eficiencia de producción de las máquinas de moldeo por inyección se ha mejorado aún más. Las máquinas de moldeo por inyección pueden producir una variedad de productos plásticos como carcasas de teléfonos móviles, partes internas de productos electrónicos.

Una de las aplicaciones más populares de las máquinas de moldeo por inyección es la fabricación de fundas para teléfonos móviles. Las fundas para móviles fabricadas con máquinas de moldeo por inyección tienen una superficie lisa, se hacen de una sola vez y están disponibles en muchos colores. A la gente le encantan.

Productos sanitarios

En la industria de dispositivos médicos, las máquinas de moldeo por inyección también son importantes. La gran demanda de materiales y precisión en productos sanitarios12 requiere una tecnología de producción de máquinas de moldeo por inyección más sofisticada. Las máquinas de moldeo por inyección pueden producir varias piezas de dispositivos médicos, como la carcasa, los botones y los conectores.

Como equipos de infusión, jeringuillas, nebulizadores, etc. Los dispositivos médicos fabricados por máquinas de moldeo por inyección tienen buena calidad de material, alta precisión, no toxicidad y otras ventajas, y se han convertido en un método de procesamiento insustituible para la producción de dispositivos médicos.

Industria juguetera

Las máquinas de moldeo por inyección también se utilizan en la industria de fabricación de juguetes. Los juguetes fabricados con máquinas de moldeo por inyección suelen ser coloridos, de alta calidad, resistentes, duraderos y seguros. Es muy importante que los fabricantes de juguetes utilicen máquinas de moldeo por inyección para fabricar buenos juguetes.

Industria de electrodomésticos

La industria de los electrodomésticos también utiliza ampliamente las máquinas de moldeo por inyección. Las máquinas de moldeo por inyección pueden producir carcasas de electrodomésticos, botones, interruptores, enchufes y otros accesorios.

Uno de los usos más comunes de las máquinas de moldeo por inyección es la fabricación de carcasas para aires acondicionados y lavadoras. Las carcasas de electrodomésticos fabricadas con máquinas de moldeo por inyección tienen la ventaja de ser bonitas, tener el tamaño adecuado y estar disponibles en muchos colores. Esto es lo que la gente quiere cuando compra electrodomésticos.

Industria cosmética y de cuidado personal

Las máquinas de moldeo por inyección de alta velocidad también se utilizan mucho en la industria cosmética y de cuidado personal. Se utilizan para fabricar todo tipo de envases de plástico, botellas, tapas y piezas de envasado como aerosoles.

Las máquinas de moldeo por inyección rápida pueden fabricar envases y piezas detalladas con rapidez y precisión, cumpliendo los requisitos de la industria cosmética y de cuidado personal en cuanto a su aspecto e imagen de marca.

Industria de bienes de consumo

Las máquinas de moldeo por inyección de alta velocidad se utilizan en las industrias de bienes de consumo y del hogar para fabricar un montón de cosas de plástico, como piezas de muebles, tapas, envases, juguetes, artículos para el hogar y materiales de embalaje. Pueden fabricar muchas cosas muy rápido, lo que es bueno porque la industria de bienes de consumo necesita muchas cosas y quiere tener muchas opciones.

Industria del automóvil

La industria automovilística es una de las aplicaciones más comunes para máquinas de moldeo por inyección13. Para la producción de piezas de automóviles, las máquinas de moldeo por inyección pueden lograr una alta precisión y alta eficiencia.

Las máquinas de moldeo por inyección de alta velocidad reducen considerablemente la duración de los ciclos de producción.Verdadero

Estas máquinas funcionan a mayor velocidad, lo que permite aumentar el ritmo de producción y reducir los tiempos por ciclo.

Las máquinas de moldeo por inyección de alta velocidad no son adecuadas para producir piezas complejas.Falso

Estas máquinas están diseñadas con precisión para manejar diseños complejos e intrincados con gran precisión, gracias a sus avanzados sistemas de control y su capacidad de procesamiento rápido.

Conclusión

La máquina de moldeo por inyección de alta velocidad es ahorradora de energía, respetuosa con el medio ambiente, estable y flexible. Es un equipo esencial en la fabricación moderna. Puede adaptarse a diferentes necesidades de producción y se utiliza ampliamente en muchas industrias.

-

Conozca el papel fundamental del sistema de inyección para garantizar la calidad y la eficacia del proceso de moldeo. ↩

-

Explore las ventajas de las máquinas de moldeo por inyección de alta velocidad para mejorar la eficacia y la calidad del producto. ↩

-

Descubra cómo afecta el sistema de sujeción del molde a la precisión y la estabilidad en el moldeo por inyección a alta velocidad. ↩

-

Conozca el innovador sistema servohidráulico de ahorro de energía que optimiza el rendimiento y reduce el consumo de energía en el moldeo por inyección. ↩

-

Descubra cómo los sistemas de control inteligentes pueden revolucionar los procesos de fabricación minimizando los residuos y mejorando la eficacia. ↩

-

Descubra el papel de las servoválvulas Moog para lograr precisión y estabilidad en las operaciones de moldeo por inyección. ↩

-

Descubra cómo los avanzados sistemas de control de bucle cerrado mejoran la precisión y la calidad de los procesos de moldeo por inyección. ↩

-

Descubra cómo el análisis de elementos finitos mejora el diseño y el rendimiento de los sistemas de moldeo por inyección, garantizando mejores resultados del producto. ↩

-

Descubra cómo los sistemas de gestión inteligentes pueden optimizar las operaciones de la fábrica y mejorar la eficacia de la producción en la fabricación moderna. ↩

-

Descubra por qué la capacidad de plastificación es crucial para conseguir productos de alta calidad en el moldeo por inyección y cómo afecta al rendimiento general. ↩

-

Descubra cómo una gestión eficaz del consumo de energía puede suponer un importante ahorro de costes en los procesos de fabricación. ↩

-

Descubra el papel fundamental de las máquinas de moldeo por inyección en la producción de dispositivos médicos de alta calidad y su importancia en la asistencia sanitaria. ↩

-

Conozca las máquinas de moldeo por inyección una guía completa: Una máquina de moldeo por inyección es una pieza de equipo que se utiliza ampliamente en la producción industrial. ↩