– Modular tooling reduces tooling costs by 30–50% by utilizing shared Master Unit Die (MUD) bases.

– Lead times for EV components are shortened from months to days, enabling rapid iteration of battery and connector designs.

– Supports production-grade materials (e.g., PA66, PBT) for valid functional testing under automotive standards.

– Facilitates the transition from rapid prototyping automotive strategies to low-volume bridge production.

What is Modular Tooling in the Context of Automotive Injection Molding?

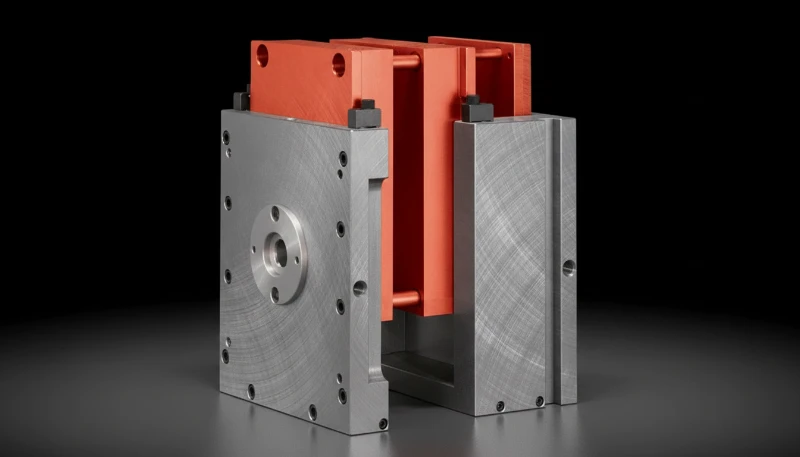

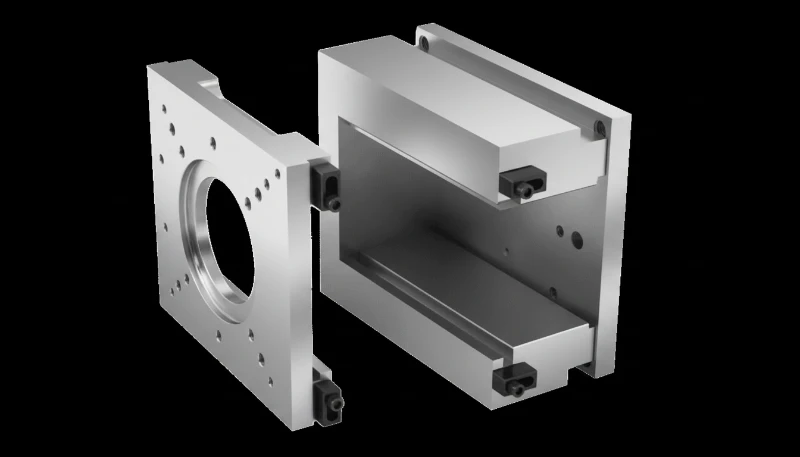

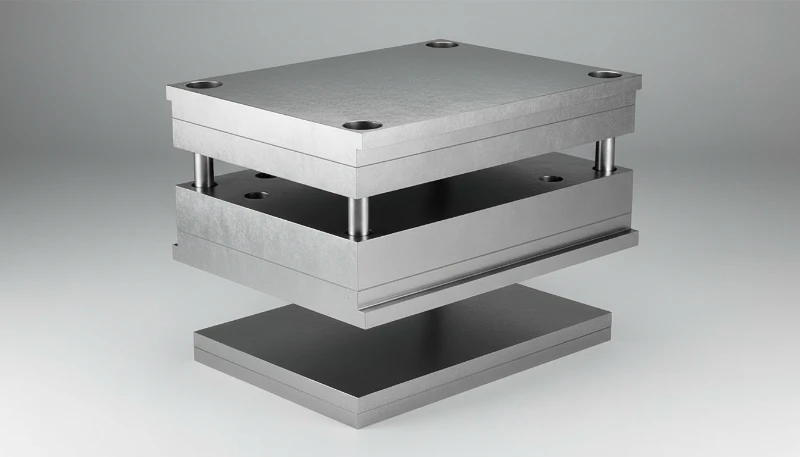

In the high-stakes arena of automotive injection molding1, modular tooling refers to a mold design strategy that separates the mold base from the cavity and core inserts. Often referred to as Master Unit Die (MUD) systems, this approach utilizes a standardized, reusable mold frame (the base) that stays in the injection molding machine. Only the unique core and cavity inserts—specific to the part design—are machined and swapped in and out.

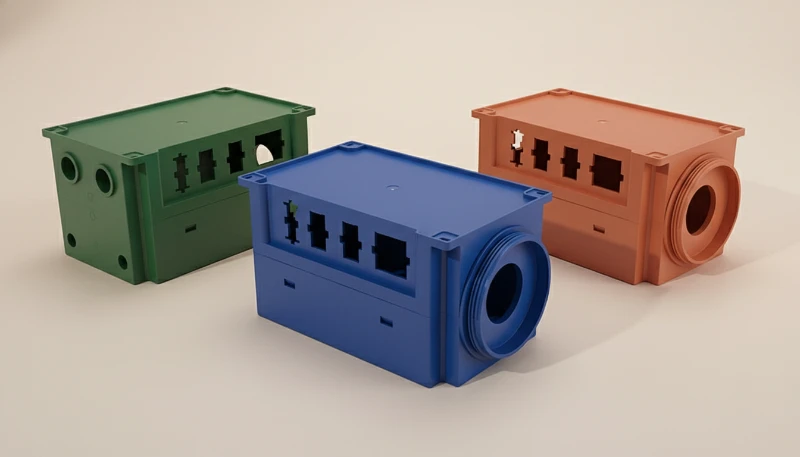

Para EV parts manufacturing2, where components like high-voltage connectors and battery brackets undergo frequent design revisions, modular tooling bridges the gap between 3D printing and full steel production tooling. It allows engineers to mold parts using production-grade engineering thermopolstics, such as Glass-Filled Polyamide (PA66-GF) or Polybutylene Terephthalate (PBT), without the capital expenditure and lead time of a standalone Class 101 production mold.

Why is Speed Critical in EV Parts Manufacturing? (Trend Analysis)

The Electric Vehicle (EV) market is defined by an aggressive race to market. Unlike internal combustion engines, which evolved over a century, EV architectures are evolving annually. Quick turn tooling has become a cornerstone of this evolution for several reasons:

- Battery Technology Iteration: Battery pack geometries change rapidly to accommodate higher energy densities. Housings and spacers must be prototyped and tested for thermal management properties within weeks, not months.

- Lightweighting Initiatives: To extend range, manufacturers are replacing metal components with high-strength engineering plastics. These metal-to-plastic conversions require functional prototypes to validate structural integrity under load.

- Cumplimiento de la normativa: EV components must pass rigorous safety standards (e.g., UL 94 flammability ratings). Rapid prototyping automotive processes using modular tooling allow for parts to be molded in the final material for UL and ISO validation before mass production tooling is cut.

How Does the Modular Mold System Process Work?

The workflow for modular mold systems is optimized for speed and flexibility.

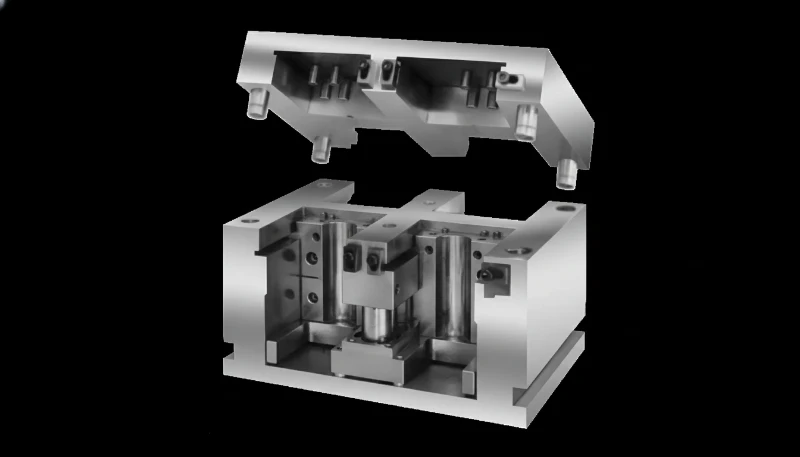

- Design Separation: The CAD model is analyzed. The mold designer separates the specific part geometry (cavity/core) from the structural mold base features (ejection system, runner system).

- Insert Fabrication: High-speed CNC machining or Electrical Discharge Machining (EDM) is used to cut the inserts. Because the volume of metal to be removed is significantly less than a full mold, this step is much faster. Materials typically range from Aluminum (Al 7075) for pure prototypes to pre-hardened steel (P20 or NAK80) for abrasive materials.

- Installation: The inserts are slid into a compatible Master Unit Die (MUD)3 frame already mounted or ready for the press.

- Injection & Ejection: The standard injection cycle occurs. The MUD frame provides the ejection actuation and cooling channels (though conformal cooling can be machined into inserts if necessary).

- Changeover: To switch to a new design iteration, the press operator simply unclamps the inserts and installs the new set, reducing setup time from hours to minutes.

Modular tooling systems utilizing MUD frames can reduce tooling lead times by 40–70% compared to standalone steel molds.Verdadero

By eliminating the need to machine a custom mold base for every part, machining time is strictly focused on the cavity and core, significantly accelerating the timeline.

Modular tooling is strictly limited to non-functional prototyping and cannot handle glass-filled automotive resins.Falso

Modular inserts can be machined from P20 or NAK80 steel, allowing them to process abrasive, glass-filled engineering resins (like PA66+30%GF) suitable for functional automotive testing.

What Are the Technical Specifications and Material Compatibilities?

To ensure EV parts manufacturing meets industry standards, modular tooling must adhere to specific technical parameters.

| Parámetro | Standard Modular Tooling Spec | Automotive Requirement Relevance |

|---|---|---|

| Insert Material | Aluminum 7075, QC-10, P20, NAK80 | Al 7075 for speed; P20 for abrasive glass-filled EV connectors. |

| Typical Lead Time | 5 – 15 Days | Critical for meeting agile EV development sprints. |

| Shot Life | 500 – 50,000 shots | Covers prototyping through bridge production (Pilot runs). |

| Tolerance Accuracy | ± 0.05 mm (ISO 2768-m) | Sufficient for snap-fits and seal surfaces in battery modules. |

| Resin Compatibility | All Thermoplastics (PEEK, PA66, PC, PBT) | Essential for testing high-voltage and high-heat EV applications. |

| Part Size Limit | Typically < 400mm x 400mm footprint | Fits most connectors, brackets, and small interior trim. |

| Acabado superficial | SPI-A2 to SPI-C3, VDI 3400 Texture | Allows aesthetic validation for interior EV components. |

What Are the Advantages and Disadvantages of Quick Turn Tooling?

En quick turn tooling4 via modular systems is powerful, it is not a universal replacement for production molds.

Ventajas

- Cost Efficiency: Eliminates the cost of the mold base, which can represent 30–40% of total tooling cost.

- Velocidad: First shots (T1) are often available in under two weeks.

- Material Reality: Parts are molded in the actual production resin, providing accurate data on shrinkage, warpage, and mechanical strength.

- Flexibilidad de diseño: Minor modifications can be made to the inserts via welding or re-machining without scrapping the entire tool.

Desventajas

- Size Constraints: MUD frames have defined pockets; large EV parts like bumper fascias or large battery trays cannot fit.

- Cooling Limitations: Space for complex cooling channels is limited within the insert, potentially extending cycle times compared to production molds.

- Parting Line Restrictions: The standardized frame dictates certain gating and parting line locations, which may not be optimal for complex geometries.

Where is Modular Tooling Applied in EV Development?

Automotive injection molding for EVs heavily utilizes modular systems in the following areas:

- High-Voltage Connectors: These intricate parts use orange-colored PBT or PA66. Modular tooling allows for the testing of snap-fits and dielectric properties.

- Busbar Holders: Overmolding busbars requires precise fixtures. Modular inserts can be customized to hold metal inserts for prototype overmolding trials.

- Battery Module Spacers: These components require high dimensional stability. Modular steel inserts allow for the molding of dimensionally stable resins like Polycarbonate (PC) or Polyphenylene Sulfide (PPS).

- Carcasas de sensores: ADAS (Advanced Driver Assistance Systems) sensors require radar-transparent materials. Modular tooling allows for material testing to ensure signal permeability.

Modular tooling supports overmolding processes, which are essential for creating insulated EV busbars.Verdadero

Modular inserts can be designed to accommodate hand-loaded or semi-automated metal inserts, enabling functional prototyping of complex overmolded electrical components.

Parts molded from modular tooling always possess inferior physical properties compared to mass production parts.Falso

If the same resin and processing parameters are used, parts from modular tools exhibit identical physical properties; the main difference lies in the tool's longevity and cycle time, not part quality.

What Are Practical Tips for Implementing Modular Systems?

For procurement teams and engineers looking to integrate modular mold systems into their workflow:

- Standardize Frames: Adopt industry-standard frames (e.g., DME or HASCO compatible) to ensure compatibility across different molders or regions.

- Design for the Insert: When designing the part, keep the "steel safe" rule in mind. It is easier to remove metal from the insert (adding plastic to the part) than to add metal back. This is crucial for iterative EV prototypes.

- Select the Right Insert Material: Do not default to aluminum if you are running Glass-Filled Nylon (PA66-GF). The glass fibers will scour the gate area of an aluminum mold quickly. Use P20 steel inserts for these applications to ensure the tool lasts through the validation run.

- Plan for Ejection: Ensure the part geometry allows for ejection within the standard knockout pattern of the chosen MUD frame. Custom ejection plates can negate the cost/speed benefits.

Preguntas más frecuentes (FAQ)

Q1: Can modular tooling be used for mass production of EV parts?

Generally, no. Modular tooling is designed for prototypes and low-volume bridge production (up to 50,000 shots). For high-volume EV production (hundreds of thousands of parts), a dedicated Class 101 hardened steel mold is required for optimal cooling and durability.

Q2: How does the cost of modular tooling compare to 3D printing for 100 parts?

For 100 parts, 3D printing is usually cheaper and faster. However, if those 100 parts need to be tested for thermal resistance, chemical resistance, or structural load in the actual material (e.g., PPS or PBT), modular tooling becomes the necessary choice despite the higher upfront cost, as 3D printed simulants often fail these tests.

Q3: Is it possible to add texture to modular molds?

Yes. Inserts can be textured using chemical etching or sandblasting to meet VDI or SPI standards. This is essential for validating the aesthetic finish of EV interior parts.

Q4: What is the typical lead time for a modular mold insert?

Depending on complexity, lead times range from 5 to 15 business days. Simple open-and-shut parts can be ready in as little as 3 days.

Q5: Can I move my modular inserts to a different supplier?

Yes, provided the new supplier uses the same standard MUD frame system (e.g., a standard 84/90 frame). This portability offers supply chain flexibility.

Conclusión

The rapid evolution of the electric vehicle sector demands manufacturing strategies that balance speed, accuracy, and cost. Modular mold systems provide a critical solution by enabling quick turn tooling that delivers production-quality parts without the massive lead times of traditional molds. For EV parts manufacturing, where material validation of high-voltage and structural components is non-negotiable, modular tooling serves as the bridge between digital design and road-ready reality.

-

Explore this resource to understand how automotive injection molding works and its significance in manufacturing. ↩

-

This link provides insights into the unique challenges faced in the manufacturing of electric vehicle parts. ↩

-

Learn about MUD systems and how they revolutionize the tooling process in manufacturing. ↩

-

Discover the benefits of quick turn tooling and how it impacts production timelines. ↩