– Master Unit Die (MUD) ejection systems rely on precise coupling between the press knockout bars and the modular insert’s ejector plate.

– Standard configurations utilize pre-drilled patterns for cost efficiency, while custom solutions accommodate complex part geometries.

– Proper alignment of the *mold knockout bars* is critical to prevent plate binding and uneven ejection force.

– Regular maintenance of rapid-change couplings and return pins prevents catastrophic mold damage.

What is a MUD Ejection System?

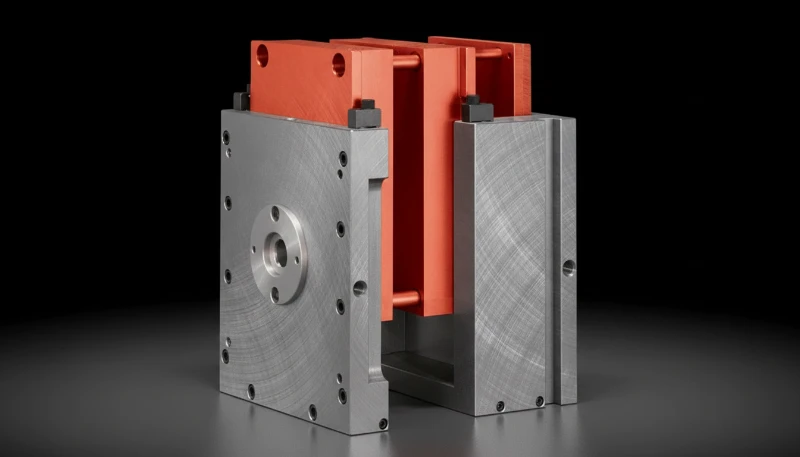

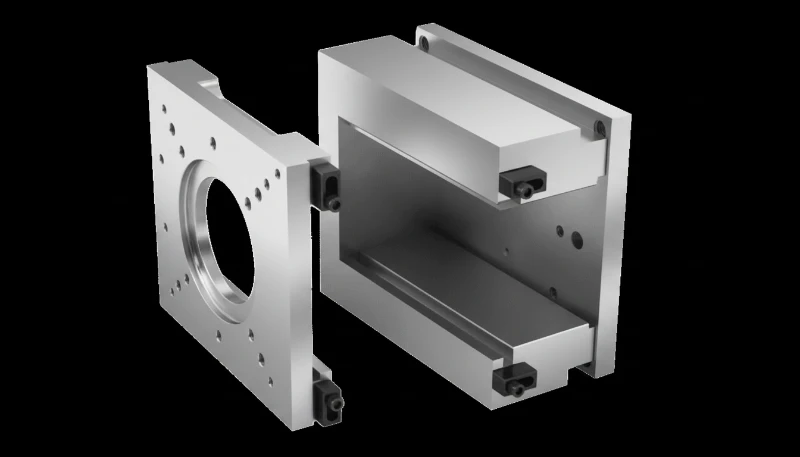

A Master Unit Die (MUD)1 ejection system is the mechanical interface within a quick-change modular mold2 frame that transfers force from the injection molding machine’s hydraulic or electrical knockout system to the molded part. Unlike a standalone mold base, the MUD system consists of a fixed frame (bolted to the platen) and interchangeable inserts.

The ejection architecture must bridge the gap between the machine’s generic knockout pattern and the specific ejection pin configuration required by the insert. This is typically achieved using specific "T-bar" or bridging mechanisms that allow the insert to slide in and out while engaging the ejection system without manual uncoupling.

What Are the Key Technical Parameters for MUD Ejection?

To ensure seamless operation and avoid molding troubleshooting issues, engineers must adhere to specific dimensional and material standards.

| Parámetro | Standard Specification / Range | Units | Notas |

|---|---|---|---|

| Frame Style | U-Frame / H-Frame | N/A | Defines the ejector plate accessibility and clamping method. |

| Ejector Stroke | 12.7 – 76.2 | mm | Varies by frame size (e.g., 08/09 vs. 84/90 standard frames). |

| K.O. Bar Material | AISI 4140 / 4130 (Pre-hardened) | N/A | High tensile strength required to resist buckling under load. |

| Plate Clearance | 0.025 – 0.050 | mm | Gap between ejector plate and housing to prevent binding. |

| Coupling Type | Quick-Disconnect / T-Slot | N/A | Allows insert removal without unbolting ejection bars. |

| Return Mechanism | Spring / Positive Return Pins | N/A | Positive return is mandatory for safety (ISO/EUROMAP standards). |

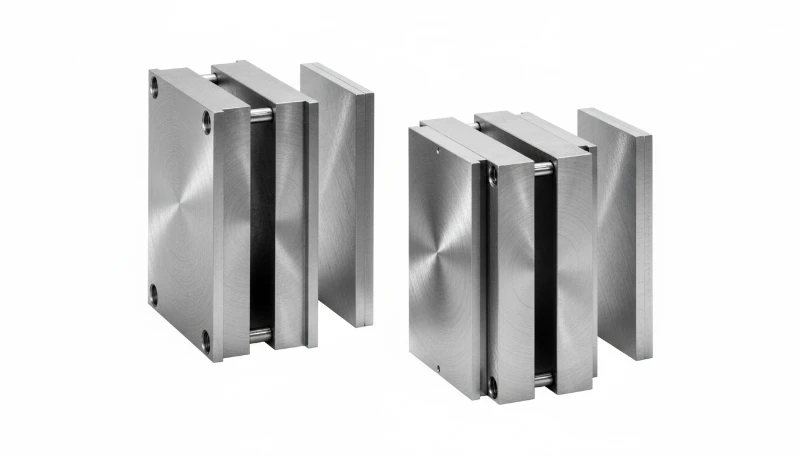

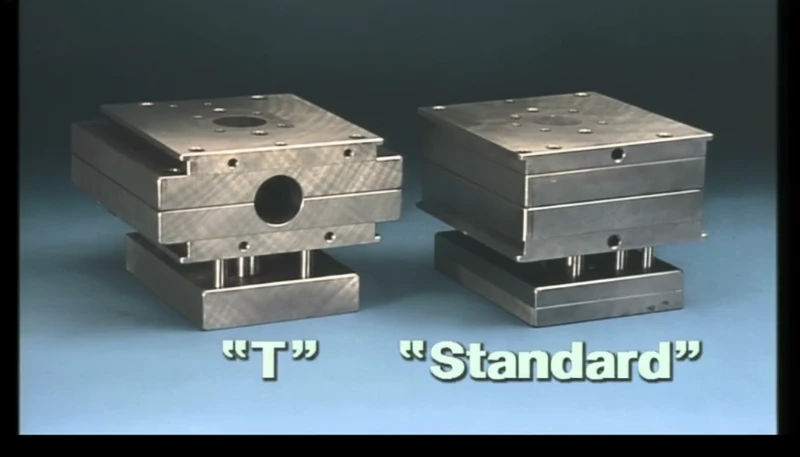

How Do Standard and Custom Configurations Differ?

The choice between standard and custom MUD inserts3 depends on the complexity of the part geometry and production volume.

Standard Ejection Configuration

Standard MUD frames come with pre-drilled ejector plates featuring a fixed grid pattern of holes.

- Mechanism: The molder places ejector pins only in the available pre-drilled locations.

- Pros: extremely low cost; rapid implementation; off-the-shelf availability.

- Contras: Severe design limitations; requires the part design to adapt to the tool (gate and ejector locations are restricted).

Custom Ejection Configuration

Custom solutions involve machining a blank ejector plate within the MUD insert to match the exact needs of the part.

- Mechanism: Engineers design a unique ejection pin configuration, potentially utilizing blade ejectors, sleeves, or strippers.

- Pros: Optimal ejection location for complex parts; reduced part warpage; allows for "spider" configurations (bridging force to specific areas).

- Contras: Higher initial machining cost; longer lead time compared to standard blanks.

Standard MUD frames require the use of specific bridging bars to connect the machine knockout to the insert ejector plate.Verdadero

The bridge or knockout bar extends from the machine ejector through the MUD frame to push the insert's ejector plate, enabling the quick-change functionality.

You can safely rely on spring return systems alone for all MUD insert ejection cycles.Falso

Springs can fatigue or break; positive return pins (push-back pins) are required to mechanically force the ejector plate back when the mold closes to prevent collision.

What Are the Pros and Cons of MUD Ejection Systems?

| Característica | Ventajas | Desventajas |

|---|---|---|

| Quick Changeover | Reduces setup time from hours to minutes; ejection couples automatically in many designs. | Slightly reduced rigidity compared to a solid standard mold base. |

| Eficiencia de costes | Shared ejection architecture reduces the cost of individual inserts. | MUD ejection systems have limited stroke length compared to standalone molds. |

| Mantenimiento | Ejector plates are easily accessible for pin replacement. | Debris accumulation in the frame can jam the coupling mechanism. |

| Flexibilidad | Allows mixing standard and custom plates in the same facility. | Heavy ejection force can cause plate bowing in U-frames if not guided properly. |

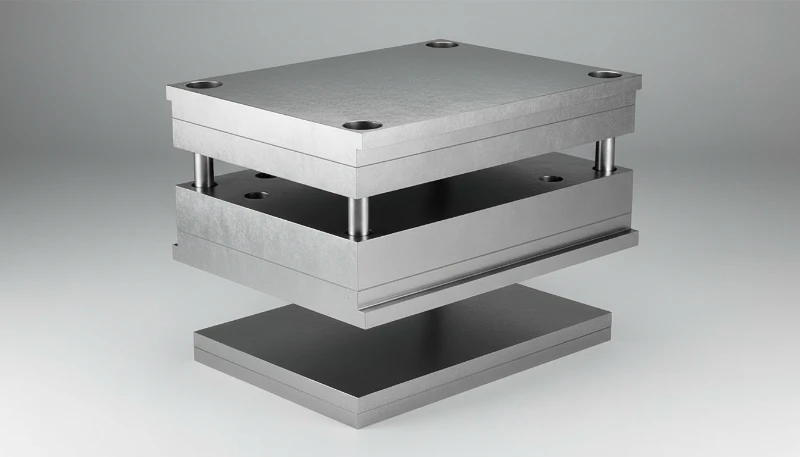

How to Configure Ejection Pins Step-by-Step?

Adecuado ejection pin configuration is vital for cycle efficiency and part quality.

- Analyze Part Geometry: Identify bosses, ribs, and deep draw areas requiring ejection force. Calculate the required ejection surface area to prevent pin push-through.

- Select Frame Compatibility: Determine if the part fits a Standard U-Frame or requires a Double H-Frame based on size and required ejection stroke.

- Map Knockout (K.O.) Locations: Overlay the machine’s hydraulic K.O. pattern with the MUD frame’s access holes. Ensure the mold knockout bars contact the ejector plate evenly to prevent tilting.

- Design the Pin Layout:

- Para Estándar: Snap the desired pin locations to the nearest grid hole. If alignment is poor, add localized bosses to the part.

- Para Custom: CNC drill the specific coordinates on a blank ejector plate.

- Install Return Pins: Always install four return pins (surface pins) at the corners of the insert to ensure the mold closing action resets the ejection system.

- Verify Clearance: Check the clearance between the custom MUD insert ejector plate and the back of the insert cavity block. Ensure the heads of the pins do not protrude.

What Are Practical Tips for Troubleshooting MUD Ejection?

Effective molding troubleshooting4 often focuses on the ejection mechanics.

- Plate Binding: If the ejector plate binds, check the mold knockout bars. If they are unequal in length, they will push the plate at an angle (racking), causing it to jam.

- Short Shots or Ejection Stress: If the stroke is insufficient, verify that the correct "legs" or risers are installed on the MUD frame. Some frames allow adjustable risers to increase stroke.

- Wear on Couplings: The quick-disconnect feature wears over time. Inspect the T-bar or coupling slot on the insert for rounding, which can cause slop or failure to retract.

- Lubrication: Use non-migrating grease (e.g., PTFE-based) on guided ejection components. Excess grease in a MUD frame can migrate to the parting line easily due to the open frame design.

Using guided ejection components helps prevent wear on the ejector pins and plate holes.Verdadero

Guided ejection systems (bushings and guide pins) maintain alignment, reducing friction and preventing the pins from wearing out the plate holes prematurely.

Any standard ejector pin can be used in a MUD insert without checking the head diameter.Falso

MUD inserts often have tighter spacing; standard pin head diameters may overlap or interfere with the backing plate structures, requiring trimming or specific components.

Where Are MUD Ejection Systems Best Applied?

- Creación de prototipos: Where low tooling costs are prioritized, and standard ejection patterns can be tolerated.

- Family Molding: Running different parts with similar sizes on the same machine frame.

- Small to Medium Batch Production: Where the speed of changeover outweighs the limitation of ejection stroke.

- Electrónica de consumo: Small housings and clips often fit perfectly within standard MUD ejection system envelopes.

frequently asked questions (FAQ)

Q1: Can I use a hydraulic ejection system with a mechanical MUD frame?

Yes, provided the injection molding machine is equipped with hydraulic knockout capability. The hydraulic cylinder rod simply pushes the mold knockout bars, which in turn actuate the MUD ejector plate.

Q2: What is the maximum stroke length for a standard MUD frame?

It varies by frame size. Small frames (e.g., 08/09) may only offer ~12mm (0.5 inches) of stroke, while larger frames (10/12 or 84/90) can offer up to ~75mm (3 inches). Always consult the manufacturer’s (e.g., DME, PCS) specification sheet.

Q3: How do I prevent the ejector plate from bowing in a custom MUD insert?

If the ejection force is high, ensure you use support pillars (stop buttons) between the ejector plate5 and the back clamp plate. Additionally, ensure the mold knockout bars are spaced widely enough to distribute force across the plate.

Q4: Are return springs sufficient for MUD inserts?

No. While springs assist, they should never be the sole method of return. MUD systems are prone to friction; if a spring fails, the mold will close on the extended pins, destroying the cavity. Always use positive return pins.

Q5: What is the difference between U-Frame and H-Frame ejection?

In a U-Frame, the insert slides in from the top, and the ejection system is often open on three sides. In an H-Frame, the insert is more robustly supported on four sides, and the ejection system is generally more rigid, suitable for higher cavitation or tighter tolerances.

Resumen

En MUD ejection system offers a balance between cost-efficiency and operational speed. While standard configurations using pre-drilled plates provide the fastest route to production, they limit design flexibility. Custom configurations allow for precise ejection pin configuration, essential for complex geometries. Regardless of the type, rigorous maintenance of mold knockout bars and adherence to safety standards (such as positive return pins) are non-negotiable for successful, long-term operation.

-

Understanding MUD is crucial for grasping the mechanics of modular mold systems. ↩

-

Understand the advantages of quick-change systems in modern manufacturing. ↩

-

Explore how custom inserts can enhance production for complex parts. ↩

-

Find effective solutions to common molding issues for improved efficiency. ↩

-

Learn about the role of the ejector plate for effective part removal. ↩