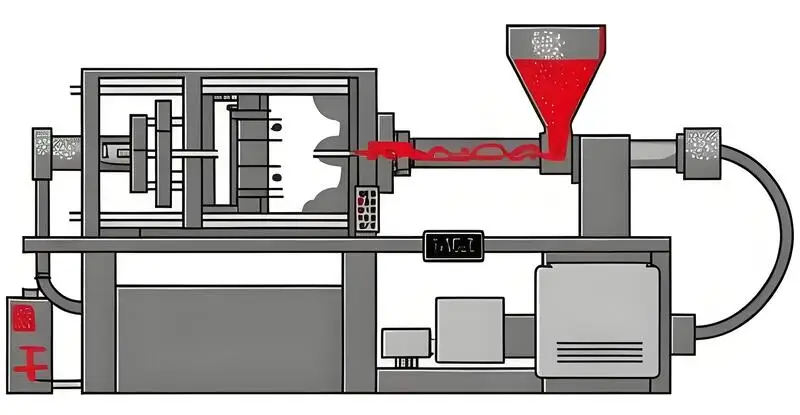

The injection molding process of TPU material is essential for producing flexible, durable products widely used in various industries.

TPU injection molding heats and injects TPU pellets into molds to create flexible, resilient parts, commonly used in footwear, automotive, and electronics.

This brief overview outlines the core steps in TPU injection molding, but mastering the nuances of the process can significantly enhance product performance and manufacturing efficiency. Delve deeper to learn how accurate mold design and process optimization can improve your results.

TPU materials are always biodegradable.False

Most TPU materials are not biodegradable, though there are some eco-friendly variants available.

TPU injection molding is less efficient than other methods.False

TPU injection molding can be highly efficient and is often selected for its ability to produce detailed and durable parts.

What is TPU Material?

TPU, or Thermoplastic Polyurethane, is a versatile material known for its excellent elasticity, transparency, and resistance to oil and abrasion, widely used in a variety of applications.

TPU material, prized for its flexibility, durability, and resistance to abrasion and chemicals, is used in footwear, automotive interiors, and phone cases for combining rubber-like elasticity with plastic toughness.

TPU stands for thermoplastic polyurethane elastomer rubber1. It’s not a textile in the traditional sense, let alone leather. TPU overcomes many of the shortcomings of PVC, PU leather, and PU coating, and has made major breakthroughs in the application of waterproof and breathable fabrics.

TPU2 not only has most of the characteristics of rubber and ordinary plastics, but also has excellent comprehensive physical and chemical properties. It is a new type of polymer environmentally friendly material between rubber and plastic. It has both the softness of rubber and the hardness of hard plastic.

TPU is both flexible and durable.True

TPU's unique composition allows it to maintain flexibility while providing strength and resistance to wear and tear, making it ideal for diverse applications.

TPU is only used in clothing and footwear.False

While TPU is popular in clothing and footwear, its applications extend to automotive, medical, and electronics industries due to its adaptable properties.

What are the Basic Characteristics of TPU Materials?

TPU materials are renowned for their versatility, offering a unique combination of flexibility, durability, and resistance, serving industries from footwear to automotive.

TPU materials offer high elasticity, excellent abrasion resistance, and flexibility across temperatures, making them ideal for footwear, medical devices, and automotive parts in demanding environments.

Wide Hardness Range

By changing the ratio of each reaction component of TPU, you can get products of different hardness, and with the increase of hardness, the products still maintain good elasticity and wear resistance.The stiffness of TPU can be measured by the elastic modulus.

The elastic modulus of rubber is usually 1~10Mpa, TPU is 10~1000Mpa, and plastics such as nylon, ABS, PC, POM, etc. are 1000~10000Mpa. The hardness range of TPU is quite wide, from Shore A 60~Shore D 85, and it has high elasticity in the entire hardness range.

Outstanding Cold Resistance

TPU has a low glass transition temperature and remains elastic and flexible even at minus 35 degrees. It is flexible over a wide temperature range of -40 to 120 degrees Celsius without the need for plasticizers.

Oil-Resistant, Water-Resistant, Chemical Resistance , and Mildew-Resistant

TPU is good at resisting oils (mineral oils, animal and vegetable oils and lubricants) and many solvents. TPU\’s oil resistance3 is better than nitrile rubber, and it has an excellent oil resistance life.

Its Taber wear value is 0.5-0.35mg, which is the smallest among plastics. If MoS2, silicone oil graphite, etc. are added, the friction coefficient can be reduced and the wear resistance can be improved.

Tensile strength and elongation: TPU has a tensile strength4 that is 2-3 times that of natural rubber and synthetic rubber. The tensile strength of polyester TPU is almost 60MPa, and the elongation is almost 410%. The tensile strength of polyether TPU is 50MPa, and the elongation is >30%.

TPU materials enhance product durability in harsh environments.True

TPU's resistance to abrasion and chemicals makes it suitable for use in challenging conditions.

TPU materials are only suitable for footwear applications.False

While widely used in footwear, TPU materials are also ideal for automotive, medical, and industrial applications due to their versatility and resilience.

What are the Process Conditions for Tpu Injection Molding Process?

Thermoplastic polyurethane (TPU) injection molding requires precise control of process conditions to ensure material integrity and product quality.

Optimal TPU injection molding requires a melt temperature of 200-220°C, mold temperature of 20-50°C, and precise pressure settings for consistent flow, crucial for applications in footwear and automotive parts.

Temperature

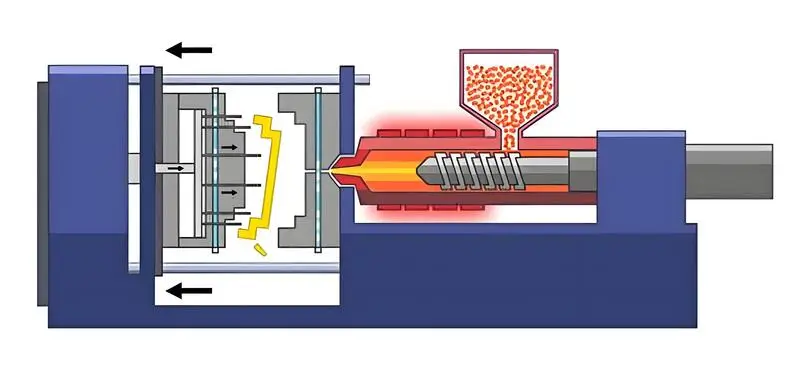

The temperatures you need to control in the TPU molding process are the barrel temperature5, nozzle temperature, and mold temperature6. The first two temperatures mainly affect the plasticization and flow of TPU, and the last temperature affects the flow and cooling of TPU.

-

Barrel Temperature:The choice of barrel temperature is related to the hardness of TPU. TPU with high hardness has high melting temperature and high maximum temperature at the end of the barrel. The barrel temperature range used for processing TPU is 177~232℃.The distribution of barrel temperature is generally from one side of the hopper (rear end) to the nozzle (front end), and gradually increases, so that the temperature of TPU rises steadily to achieve the purpose of uniform plasticization.

-

Nozzle Temperature:The nozzle temperature is usually slightly lower than the maximum temperature of the barrel to prevent the molten material from drooling out of the straight-through nozzle. If a self-locking nozzle is used to prevent drooling, the nozzle temperature can also be controlled within the maximum temperature range of the barrel.

- MoldTemperature:The mold temperature is very important for the intrinsic performance and appearance quality of TPU products. It is determined by many factors such as the crystallinity of TPU and the size of the product. The mold temperature is usually controlled by a constant temperature cooling medium such as water. TPU has high hardness, high crystallinity, and high mold temperature.For example, Texin, hardness 480A, mold temperature 20~30℃; hardness 591A, mold temperature 30~50℃; hardness 355D, mold temperature 40~65℃. The mold temperature of TPU products is generally 10~60℃.When the mold temperature is low, the melt freezes prematurely and produces streamlines, which is not conducive to the growth of spherulites, resulting in low crystallinity of the product and a late crystallization process, which causes post-shrinkage and performance changes of the product.

Pressure

The pressure in the injection molding process includes plasticizing pressure (back pressure) and injection pressure7. When the screw retreats, the pressure on the top melt is the back pressure, which is adjusted by the overflow valve.

Increasing the back pressure will increase the melt temperature, reduce the plasticizing speed, make the melt temperature uniform, mix the colorants evenly, and discharge the melt gas, but it will extend the molding cycle. The back pressure of TPU is usually 0.3~4MPa.

Injection pressure is the pressure applied by the top of the screw to TPU. It’s used to overcome the flow resistance of TPU from the barrel to the cavity, increase the rate of melt filling, and compact the melt. TPU flow resistance and filling rate are closely related to melt viscosity, and melt viscosity is directly related to TPU hardness and melt temperature.

In other words, melt viscosity8 is determined by temperature and pressure, as well as TPU hardness and deformation rate. The higher the shear rate, the lower the viscosity. When the shear rate remains unchanged, the higher the hardness of TPU, the greater the viscosity.

When the shear rate is constant, the viscosity decreases as the temperature increases, but at high shear rates, the viscosity is not as affected by temperature as it is at low shear rates. The injection pressure of TPU is generally 20~110MPa. The holding pressure is about half of the injection pressure, and the back pressure should be below 1.4MPa to make the TPU plasticized evenly.

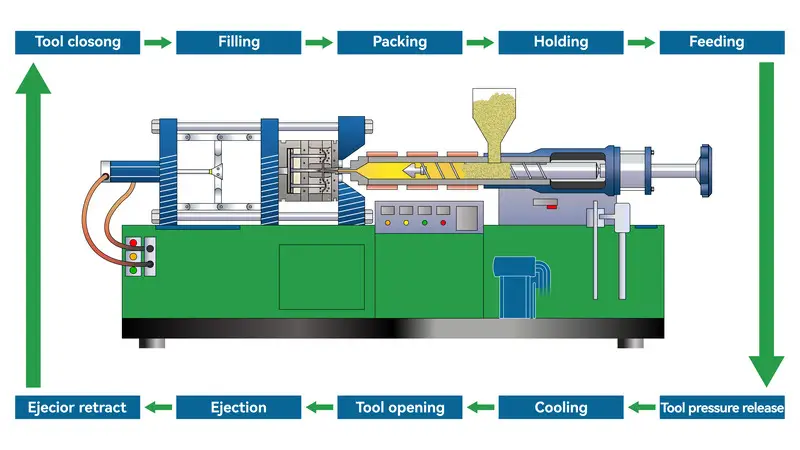

Time

The time it takes to do an injection is called the molding cycle. The molding cycle includes the time it takes to fill the mold, the time it takes to hold the mold, the time it takes to cool the mold, and other times (like the time it takes to open the mold, take the part out of the mold, and close the mold), which all affect how much work you can get done and how much you can use your equipment.

The molding cycle for TPU is usually determined by how hard the TPU is, how thick the part is, and what shape the part is. The cycle is short for hard TPU, long for thick parts, and long for parts that have a lot of shapes. The molding cycle is also related to how hot the mold is. The molding cycle for TPU is usually between 20 and 60 seconds.

Injection Speed

The injection speed is mainly determined by the configuration of TPU products. Products with thick end faces require lower injection speeds, while products with thin end faces require faster injection speeds.

Screw Speed

When you process TPU products, you need to use a low shear rate, so you need to use a lower screw speed. The screw speed of TPU is generally 20~80r/min, and 20~40r/min is better.

Shutdown Treatment

Since TPU may degrade after being exposed to high temperature for a long time, it should be cleaned with PS, PE, acrylic plastics or ABS after shutdown; if the shutdown exceeds 1 hour, the heating should be turned off.

Product Post-Processing

TPU often has uneven crystallization, orientation, and shrinkage due to uneven plasticization in the barrel or different cooling rates in the mold cavity. This results in internal stress in the product, which is more prominent in thick-walled products or products with metal inserts.

Products with internal stress9 often experience a decrease in mechanical properties during storage and use, silver streaks on the surface, and even deformation and cracking. The way to solve these problems in production is to anneal the product. The annealing temperature depends on the hardness of the TPU product.

The annealing temperature of products with high hardness is also high, and the annealing temperature of products with low hardness is also low. Too high temperature may cause the product to warp or deform, and too low temperature cannot achieve the purpose of eliminating internal stress.

Recycling of Recycled Materials

In the TPU processing process, waste materials such as runners, sprues, and off-spec parts can be recycled and reused. From the test results, 100% recycled materials without mixing with new materials do not significantly reduce the mechanical properties, and can be fully utilized .

But in order to maintain the physical and mechanical properties and injection conditions at the best level, it is recommended that the proportion of recycled materials be 25% to 30%.

Correct TPU injection molding conditions prevent defects in final products.True

Adhering to ideal temperature and pressure settings maintains material properties and reduces defects like warping and bubbles.

You can use any mold temperature for TPU without affecting the outcome.False

Incorrect mold temperatures can lead to poor surface finish and structural issues, emphasizing the importance of specific temperature ranges.

What are the Precautions in the Injection Molding Process of TPU Materials?

In the injection molding process of TPU materials, careful attention to temperature, injection speed, and mold conditions ensures optimal product quality and consistency.

For successful TPU injection molding, maintain precise temperature, minimize moisture, and adjust injection speed to material needs, preventing defects and ensuring high-quality results in diverse industries.

Material Drying

Because TPU is easy to absorb moisture and easy to hydrolyze, if the TPU raw materials are not dried thoroughly, it will easily cause processing difficulties. The surface of the injection molded product will have bubbles or silver streaks, and the surface of the extruded product will show unevenness, dullness, foam and foam.

In order to ensure zero defects in production and product quality, it is recommended that the TPU raw materials must be fully dried to a moisture content of less than 0.05% before processing.

If carbon powder or masterbatch is used for dyeing, it must be fully mixed with TPU natural colorant and dried together. Generally, a circulating air dryer or a dehumidifying dryer is used to dry TPU. Depending on the hardness, the recommended drying temperature is 80-110℃ and the drying time is about 3 hours.

Recycled Material Processing

Nozzle materials, washing machine materials, or bad final products can be crushed and mixed with new materials, but they must be dried again before use. For some mechanical physical requirements, recycled materials cannot be used in injection molding processes.

More than 30% of all raw materials. Extruded recycled materials should be processed separately or added to new injection molding materials. Also, recycled materials should not be stored for too long. Use dry tops. Waste materials that cannot be recycled can be incinerated to get heat.

Control Injection Speed and Pressure

The speed and pressure of the injection are important for how well the TPU material flows and fills the mold. If the speed and pressure are too high, the material can break or make bubbles. If the speed and pressure are too low, the material won’t fill the mold well or the product will have a rough surface. So, you need to set the speed and pressure right for the material and the mold.

Control Mold Temperature

Mold temperature is very important for TPU material crystallinity and shrinkage. The right mold temperature can help the material crystallize and improve the mechanical properties and dimensional stability of the product.

But if the mold temperature is too high, it can cause the material to overheat and decompose or bubble. If the mold temperature is too low, it can cause cold flow marks or shrinkage marks on the surface of the product. So, it is necessary to control the mold temperature accurately to get the best molding effect.

Avoid Excessive Heating and Shearing

TPU materials can get too hot and get sheared too much when you’re injection molding them. This can make the material not work as well or make it have problems. So, you want to make sure you don’t get the material too hot and you don’t shear it too much when you’re injection molding it so you don’t mess it up.

Maintain a Clean Injection Molding Environment

The cleanliness of the injection molding environment is very important for the injection molding quality of TPU materials. If there are impurities and oil stains, they may stick to the mold surface or mix into the material, which will cause defects on the surface of the product or performance degradation.

Therefore, it is necessary to keep the injection molding environment clean and regularly clean and maintain the equipment and molds .

Injection molding of TPU requires precise temperature management.True

TPU's thermoplastic nature demands consistent temperature regulation to maintain material integrity and prevent defects.

All TPU materials can be molded under the same conditions.False

Different TPU formulations may require varied settings in temperature, speed, and pressure to achieve desired results, highlighting the need for tailored processing conditions.

What is the Process Flow of TPU Material Injection Molding?

TPU material injection molding streamlines the production of flexible and durable components, widely utilized in industries such as automotive and consumer products.

TPU injection molding melts TPU pellets to form flexible, resilient parts ideal for phone cases, sports equipment, and medical devices. Key steps include material preparation, mold design, and cooling.

The TPU material injection molding process mainly includes material preparation, mold design, injection molding machine selection, injection molding process parameter setting, and product post-processing.

Material Preparation

Before you start injection molding tpu pellets, you need to get them ready. This means drying them, preheating them, and mixing them. Drying gets rid of any moisture in the material so you don’t get bubbles or cracks when you’re injection molding. Preheating makes the material flow better and helps it fill the mold. Mixing makes sure all the material is the same and makes the product better.

Mold Design

Mold design is a key link in the injection molding process. The structure, size, and precision of the mold directly affect the molding quality and production efficiency of the product.

When designing a TPU material injection mold, factors such as material fluidity, shrinkage, and demolding of the product need to be considered. Reasonable mold design can effectively reduce the defect rate of the product and improve production efficiency.

Injection Molding Machine Selection

Choosing the right injection molding machine is key to ensuring the stability of the TPU material injection molding process and the quality of the product. When choosing an injection molding machine, you need to consider factors such as the characteristics of the material, the size and complexity of the product, and the production efficiency.

Make sure that the injection pressure, injection speed, temperature, and other parameters of the injection molding machine can meet the injection molding requirements of TPU materials.

Injection Molding Process Parameter Setting

Setting the injection molding process parameters is crucial for ensuring the quality of TPU material injection molding. These parameters include injection pressure, injection speed, holding time, mold temperature, and so on.

By setting the process parameters properly, you can make sure that the TPU material flows and fills the mold completely during the injection molding process, while avoiding defects like bubbles and shrinkage holes. Moreover, you might need to adjust the process parameters to achieve the best molding effect based on the characteristics of the TPU material and the product requirements.

Product Post-Processing

After injection molding, TPU products need to be post-processed to eliminate internal stress, improve dimensional stability, and improve surface quality. Common post-processing methods include heat treatment, cooling, and surface treatment.

Heat treatment can eliminate the internal stress generated by the product during the injection molding process and improve its dimensional stability. Cooling helps the product to quickly shape and reduce deformation. Surface treatment can improve the appearance and performance of the product.

TPU injection molding results in durable and flexible products.True

TPU's unique properties make it ideal for producing parts that require elasticity and resilience.

TPU is the same as TPE in injection molding.False

While TPU and TPE share similarity in flexibility, they are distinct materials with different compositions and performance characteristics.

What are the Defects in the Injection Molding Process of TPU Materials?

Understanding the defects in TPU injection molding is crucial for improving the quality and performance of the final product.

Common TPU injection molding defects include warping, incomplete filling, burn marks, and sink marks, often resulting from improper temperature, injection speed, or mold design, impacting product durability and appearance.

The Product has Cracks

Cracks are a killer for TPU products, usually appearing as hairline cracks on the surface of the product. When the product has sharp edges and corners, it often cracks in this part, which is very dangerous for the product. The main reasons for cracking in the production process are demoulding difficulties, overfilling, low mold temperature, and defects in the product structure.

To avoid cracks caused by poor demolding, the mold cavity must have enough demolding slope, and the size, position, and shape of the ejector pin must be appropriate. When ejecting, the demolding resistance of each part of the product must be uniform.

Overfilling happens when you shoot too much plastic into the mold. This can be caused by too much injection pressure or too much material being metered. When you overfill the mold, you put too much internal stress into the part, and it cracks when you try to get it out of the mold.

When you overfill the mold, you also put more stress on the mold components, which makes it harder to get the part out of the mold, and it makes the part crack (or even break). When you see this happening, you need to reduce the injection pressure to stop overfilling.

The internal stress from overfilling usually stays in the gate area. The area near the gate is brittle, especially the direct gate area, and it will break because of the internal stress.

Poor Surface Gloss of Products

When the surface of TPU products loses its original gloss and becomes dull or blurry, it is referred to as poor surface gloss.

Poor surface gloss is usually caused by inadequate polishing of the mold surface. When the surface condition of the mold cavity is good, increasing the material and mold temperature can improve the surface gloss of the product. Using too much non-fusible agent or oily non-fusible agent can also result in poor surface gloss.

Additionally, if the material absorbs moisture or is contaminated with volatile substances or foreign matter, it can lead to poor surface gloss. Therefore, attention should be paid to factors related to the mold and materials.

The Product Has Burrs

TPU products often have burrs. When the pressure of the raw material in the mold cavity is too large, the parting force generated is greater than the clamping force, forcing the mold to open, causing the raw material to overflow and form burrs.

There are many reasons for burrs, such as problems with the raw materials, problems with the injection molding machine, improper adjustment, or even the mold itself. Therefore, when determining the cause of burrs, proceed from easy to difficult.

Check whether the raw materials are thoroughly dried, whether there are foreign objects mixed in, whether different types of raw materials are mixed, and the influence of raw material viscosity .

correctly adjust the pressure control system of the injection molding machine and the adjustment of the injection speed must be coordinated with the clamping force used; whether certain parts of the mold are worn, whether the exhaust holes are blocked, and whether the flow channel design is reasonable .

whether there is a deviation in the parallelism between the injection molding machine templates, whether the template tie rod force distribution is uniform, and whether the screw check ring and the melt barrel are worn.

Insufficient Filling of Products

When the molten material doesn\’t flow through all the corners of the mold, it\’s called insufficient filling. There are a few reasons for this: the molding conditions aren\’t set right, the mold isn\’t designed or made well, the product has thick parts and thin parts, and so on.

To fix this, you can raise the temperature of the material and mold, increase the injection pressure and speed, and make the material flow better. You can also make the runner or flow channel bigger, or change the gate\’s position, size, or number to make the material flow better. You can also put some holes in the mold to let the air out.

Product Warping and Deformation

The reasons for the warping and deformation of TPU injection molded products are too short cooling and shaping time, too high and uneven mold temperature, and asymmetric flow channel system.

Therefore, when designing the mold, try to avoid too large a difference in thickness in the same plastic part; avoid excessive sharp angles; avoid too short a buffer zone, so that the thickness turns differ greatly; in addition, pay attention to setting the appropriate number of ejectors and designing a reasonable cavity cooling flow channel.

Warping is a common defect in TPU injection molding.True

Warping occurs due to uneven cooling rates which cause internal stresses, leading to distortion in the molded parts.

Sink marks are only a cosmetic issue in TPU molding.False

Sink marks indicate potential structural weaknesses, affecting both the appearance and the integrity of the final product.

Conclusion

The injection molding process of TPU materials is a complex and delicate technology that requires comprehensive consideration of multiple factors such as material properties, mold design10, injection molding machine selection, and process parameter setting.

By accurately controlling the key links and technical points in the injection molding process, we can produce high-quality and high-precision TPU products. In the future, with the continuous improvement of TPU material performance and the continuous innovation of injection molding technology, we have reason to believe that TPU material injection molding technology will be widely used in more fields and promote the sustainable development of related industries.

-

Explore this link to understand the versatile applications and benefits of TPU in various industries. ↩

-

Explore the advantages of TPU materials, including their unique properties and applications in various industries. ↩

-

Learn how TPU’s oil resistance outperforms other materials, making it ideal for demanding applications. ↩

-

Discover the impressive tensile strength of TPU and how it compares to natural and synthetic rubber. ↩

-

Barrel temperature plays a vital role in the plasticization and flow of TPU. Discover its impact on the molding process by checking this resource. ↩

-

Understanding mold temperature is crucial for achieving optimal performance and quality in TPU products. Explore this link to learn more. ↩

-

Injection pressure is key to overcoming flow resistance and ensuring quality in TPU products. Learn more about its significance in the molding process. ↩

-

Understanding the factors influencing melt viscosity can enhance your TPU processing efficiency and product quality. ↩

-

Learning about internal stress in TPU can lead to better product durability and performance, crucial for quality assurance. ↩

-

Learn about What is injection mold design?Injection mold design involves the process of producing a mold to a particular specification. ↩