– Implementation of Master Unit Die (MUD) systems converts Internal Exchange of Die (IED) tasks to External Exchange of Die (OED).

– MUD frames allow for insert swaps without removing the mold base, reducing changeover time by up to 75%.

– Pre-heating inserts and standardizing quick-connect couplings are critical for achieving sub-10-minute cycles.

– SMED principles combined with MUD technology significantly increase press uptime and overall manufacturing efficiency.

What Are Master Unit Die (MUD) and SMED?

To understand how to drastically reduce downtime, we must first define the two core methodologies: the hardware solution (MUD) and the operational philosophy (SMED).

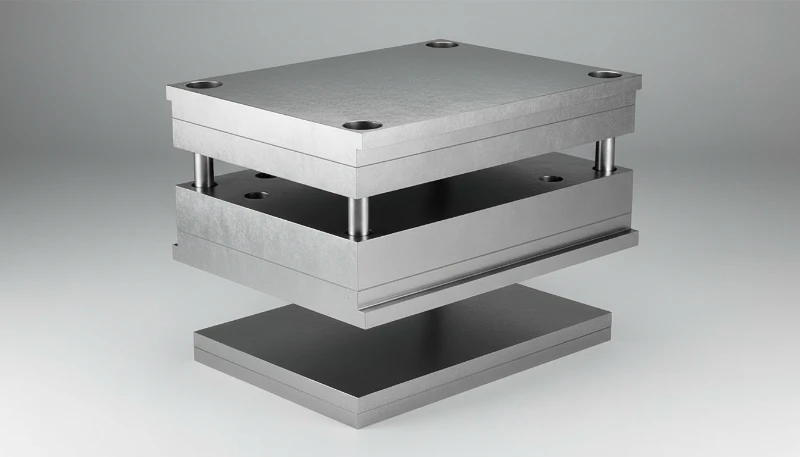

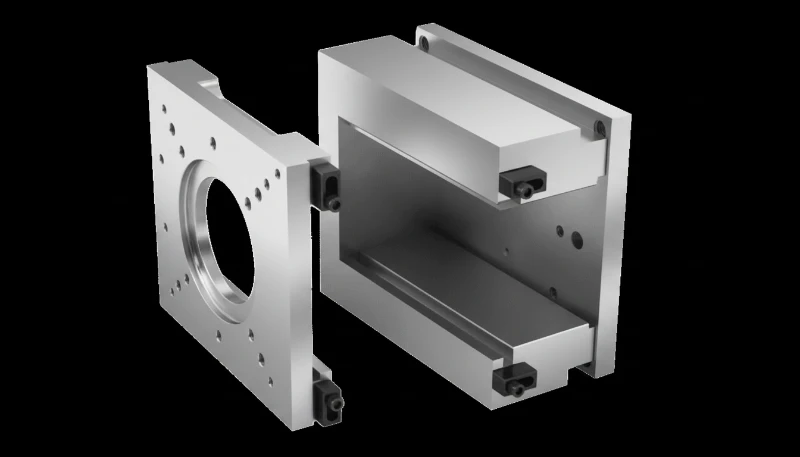

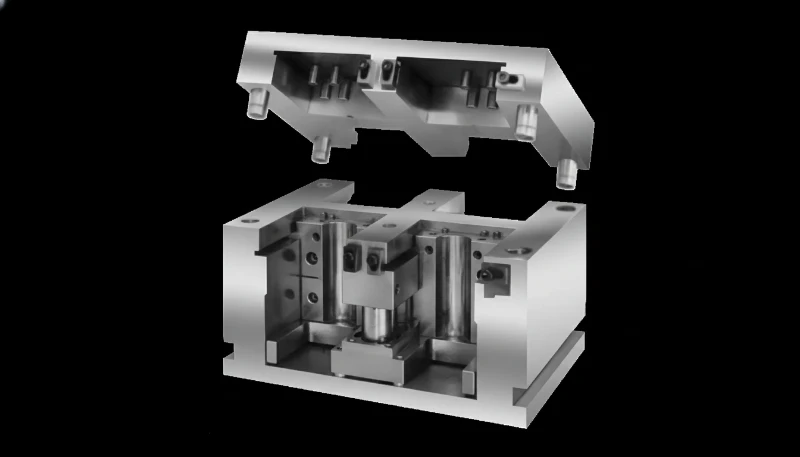

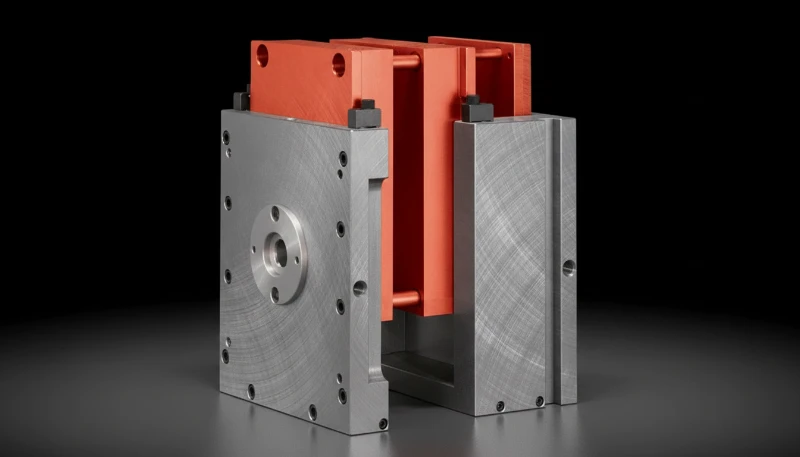

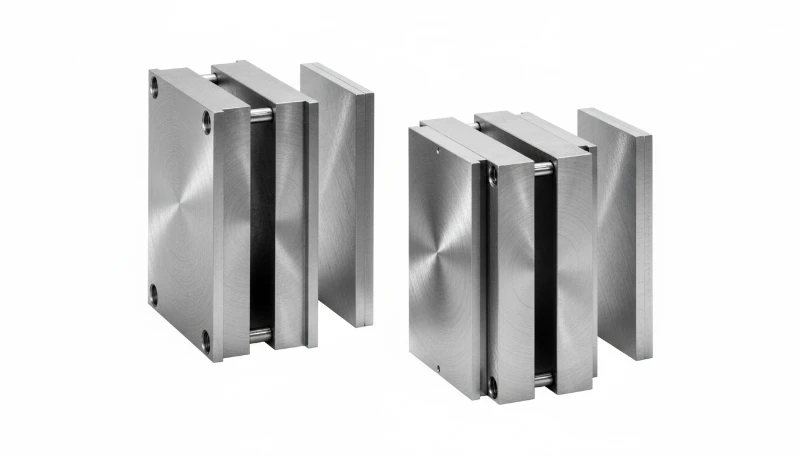

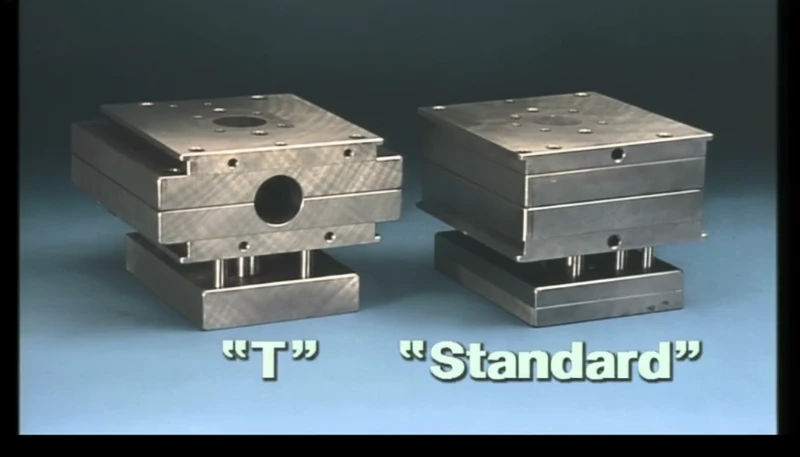

Master Unit Die (MUD)1, often referred to as a quick-change insert system2, utilizes a standard master frame (mold base) that remains bolted to the injection molding machine platens. Instead of removing the entire heavy mold base, the operator only removes and replaces a lightweight insert containing the cavity and core. This approach is instrumental in reducing mold changeover time.

Single-Minute Exchange of Die (SMED)3 is a lean manufacturing methodology developed by Shigeo Shingo. The goal is to reduce the time it takes to change over a machine from the last good part of the previous run to the first good part of the next run to a single-digit minute (less than 10 minutes). SMED distinguishes between:

- Internal Setup (IED): Operations performed while the machine is stopped (e.g., physically swapping the insert).

- External Setup (OED): Operations performed while the machine is still running the previous job (e.g., retrieving the next insert, pre-heating).

What Are the Key Technical Parameters for Quick Mold Change Systems?

Implementing quick mold change requires adherence to specific technical parameters to ensure safety and repeatability. The following table outlines typical parameters when comparing standard mold bases to MUD systems.

| Parametre | Standard Mold Base | MUD (Master Unit Die) System | Impact on Efficiency |

|---|---|---|---|

| Changeover Time | 30 – 120 Minutes | < 10 Minutes | Drastic increase in manufacturing efficiency. |

| Tool Weight (Swap) | 100 kg – 5,000+ kg | 10 kg – 50 kg (Insert only) | Reduces need for heavy cranes during swap. |

| Cooling Connection | Manual threading (often) | Quick-disconnect manifolds | Faster water hookup; lower leak risk. |

| Heating Method | Cold start in press | Pre-heated externally | Elimination of warm-up downtime in-press. |

| Clamping Method | Manual bolts/clamps | Integrated Frame Clamps / H-Frame | tool-less or semi-tool-less locking. |

| Tolerance Class | SPI Class 101-103 | SPI Class 103-104 (Typical) | Suitable for most non-ultra-precision parts. |

How Does the MUD System Facilitate SMED Workflows?

The integration of MUD frames is the physical enabler of SMED. By leaving the heavy frame in the press, the "Internal Setup" time is minimized.

MUD systems allow operators to perform 80% of the changeover tasks while the machine is still running the previous job.Doğru

By using a master frame, the next insert can be prepared, cleaned, and pre-heated externally (OED), leaving only the physical slide-in swap for the internal downtime.

MUD frames require the removal of the entire mold base from the platen for every product change.Yanlış

The primary advantage of MUD is that the master frame remains bolted to the platens; only the core and cavity inserts are exchanged.

What Is the Step-by-Step Process to Achieve Sub-10 Minute Changeovers?

To achieve SMED injection molding targets, the process must be disciplined. Below is a standard operating procedure (SOP) for a MUD changeover.

Phase 1: External Setup (OED) – Machine Running

Do this while the previous job is still running.

- Preparation: Locate the next MUD insert (core and cavity blocks).

- Inspection: Check the insert surfaces for damage or rust. Verify ejector pin functionality.

- Pre-Heating: Place the insert on a warming station or connect to a portable temperature control unit (TCU). Heat to operating temperature (e.g., 80°C for Polycarbonate (PC)).

- Not: Installing a cold mold into a hot frame can cause thermal shock or dimensional variation during start-up.

- Staging: Place the pre-heated insert, required resin, and auxiliary equipment next to the press.

Phase 2: Internal Setup (IED) – Machine Stopped

The clock starts now. Target: < 10 Minutes.

- Purge and Retract: Purge the injection unit (if material change is required) and retract the sled.

- Open Mold: Open the clamp to the "Insert Change" position.

- Unlock Insert: Release the mechanical clamps or hydraulic locks holding the current MUD insert in the H-frame.

- Disconnect Utilities: Disconnect water lines (if not manifolded through the frame) and ejector coupling.

- İpucu: Use non-drip quick-connect couplers to prevent water on the mold face.

- Remove Insert: Slide the old insert out of the frame. (Manual or assisted lift).

- Install New Insert: Slide the pre-heated new insert into the master frame.

- Lock Insert: Engage clamps/locks to secure the insert.

- Connect Utilities: Connect water lines and ejector coupling.

- Load Program: Select the pre-saved process parameters on the HMI (Human-Machine Interface).

Phase 3: Post-Changeover – Machine Running

- Start-Up: Begin the cycle. Since the mold is pre-heated, the "first good part" should be achieved almost immediately.

- Cleanup: Move the previous insert to the maintenance area for cleaning and preservation.

What Are the Advantages and Disadvantages of Using MUD Inserts?

While MUD systems are excellent for increasing press uptime, they are not a universal solution for every molding scenario.

| Özellik | Avantajlar | Dezavantajlar |

|---|---|---|

| Maliyet | Tooling costs reduced by 40-50% (shared mold base). | Initial investment in Master Frames (H-Frames) is required. |

| Hız | Changeovers < 10 minutes; enables Just-In-Time (JIT) manufacturing. | Not ideal for ultra-high volume (>1M cycles) due to wear on insert fitments. |

| Depolama | Inserts require significantly less shelf space than full mold bases. | Limited cavity size; cannot accommodate very large parts. |

| Esneklik | Ideal for product families and prototyping. | Cooling channels may be restricted by the insert geometry/frame limits. |

What Practical Tips Ensure Consistent Quick Changeovers?

Experience in the field suggests that equipment alone does not guarantee speed; the workflow is equally important.

- Standardize Water Manifolds: Hard-plumb the water lines on the Master Frame. Use specific quick-disconnect patterns so the operator does not have to look up plumbing diagrams. The water inputs should be "Plug and Play."

- Dedicated Tool Cart: Have a "Crash Cart" specific to MUD changes containing the specific Allen wrenches, hoses, and cleaner required, so no time is wasted searching for tools.

- Ejector System Coupling: Use "Quick-Stick" or similar rapid-coupling systems for the ejector bar to avoid manually screwing in ejector rods behind the platen.

- Floating Plates: Ensure the MUD frame is aligned perfectly. If the frame is misaligned, the inserts will bind during insertion, killing the 10-minute target.

Pre-heating the MUD insert externally allows the press to produce quality parts immediately upon restart.Doğru

Pre-heating eliminates the 20-45 minute 'warm-up' period usually required for the mold to reach thermal equilibrium inside the press.

MUD systems are only useful for prototyping and cannot be used for production runs.Yanlış

MUD systems are widely used for low-to-medium volume production runs and are a standard for high-mix, low-volume manufacturing environments.

Where Are MUD Systems Best Applied?

- High-Mix / Low-Volume Production: Scenarios where job runs are short (e.g., 500 – 5,000 units), and changeover time represents a significant percentage of total available time.

- Family Molds: Producing different sized parts of the same material (e.g., small, medium, and large clips) where the resin stays the same, but the geometry changes.

- Prototipleme: Rapid iteration where mold cost must be kept low.

- Cleanroom Molding: Where crane access is limited or particulate generation from heavy mold movement must be minimized.

Frequently Asked Questions About MUD and SMED

Q: Can MUD frames handle high-temperature engineering resins?

A: Yes. However, for materials like Polyphenylene Sulfide (PPS) or Polyether Ether Ketone (PEEK) requiring high mold temperatures (>140°C), the Master Frame must be insulated from the platens to prevent heat loss and protect the machine hydraulics.

Q: Does using a MUD system affect part tolerances?

A: Generally, no, provided the insert fits tightly within the frame. However, for SPI Class 101 (Ultra-precision) molds, a dedicated mold base is preferred over a swappable insert to guarantee absolute rigidity.

Q: How do I calculate the ROI of switching to MUD4?

A: Calculate the cost of downtime (machine hourly rate). If a standard change takes 1 hour and a MUD change takes 10 minutes, you save 50 minutes per change. Multiply this by the number of changes per year and the machine rate. The savings often pay for the MUD frame in less than 6 months.

Q: Are MUD inserts compatible between different machine brands?

A: The inserts are compatible with the frame, not the machine. As long as the Master Frame fits the platen and tie-bar spacing of the injection molding machine, the inserts will work.

Q: Can I retrofit existing molds into MUD inserts?

A: It is difficult and usually cost-prohibitive to machine a standard mold down to fit a MUD frame. It is better to design for MUD from the start.

Özet

Reducing mold changeover time to under 10 minutes is achievable by combining SMED injection molding methodologies with MUD (Master Unit Die) hardware. By moving setup tasks externally (OED) and utilizing the quick-swap capabilities of MUD frames, manufacturers can drastically reduce downtime, lower tooling costs, and increase manufacturing efficiency. Success relies not just on the frame, but on a disciplined adherence to pre-heating, preparation, and standardized connection protocols.

-

Understanding MUD is crucial for optimizing changeover times in injection molding. ↩

-

Discover how quick-change systems can streamline your injection molding processes. ↩

-

Learn how SMED can drastically reduce downtime and improve manufacturing efficiency. ↩

-

Get insights on calculating ROI to justify investments in MUD systems. ↩