Formowanie wtryskowe przezroczystych produktów z tworzyw sztucznych wymaga precyzji i specjalistycznych technik w celu uzyskania przejrzystości i jednolitości, co czyni je niezbędnym w branżach od optyki po elektronikę użytkową.

Aby skutecznie formować przezroczyste tworzywa sztuczne, należy utrzymywać precyzyjną temperaturę i ciśnienie, wybierać odpowiednie materiały do form i żywice z tworzyw sztucznych, zapewniając przejrzystość i minimalizując wady, takie jak pęcherzyki i zamglenia.

Zrozumienie specyfiki formowania przezroczystych tworzyw sztucznych nie tylko poprawia jakość produktu, ale także zwiększa wydajność. Zanurz się głębiej, aby zrozumieć, w jaki sposób różne techniki i materiały mogą zoptymalizować proces produkcji ukierunkowany na przezroczystość.

Właściwa kontrola temperatury jest niezbędna do tworzenia przezroczystych produktów z tworzyw sztucznych.Prawda

Utrzymywanie precyzyjnej temperatury podczas formowania wtryskowego zapobiega powstawaniu wad, takich jak pęcherzyki powietrza, i zapewnia przejrzystość produktu końcowego.

Wszystkie przezroczyste produkty z tworzyw sztucznych wymagają identycznych procesów formowania wtryskowego.Fałsz

Różne przezroczyste tworzywa sztuczne mają unikalne właściwości, co wymaga zastosowania dostosowanych technik formowania wtryskowego w celu uzyskania optymalnej przejrzystości i trwałości.

Jak przygotowanie surowca wpływa na formowanie wtryskowe przezroczystych produktów z tworzyw sztucznych?

Właściwe przygotowanie surowca ma kluczowe znaczenie dla osiągnięcia optymalnej przejrzystości i jakości formowanych wtryskowo produktów z tworzyw sztucznych.

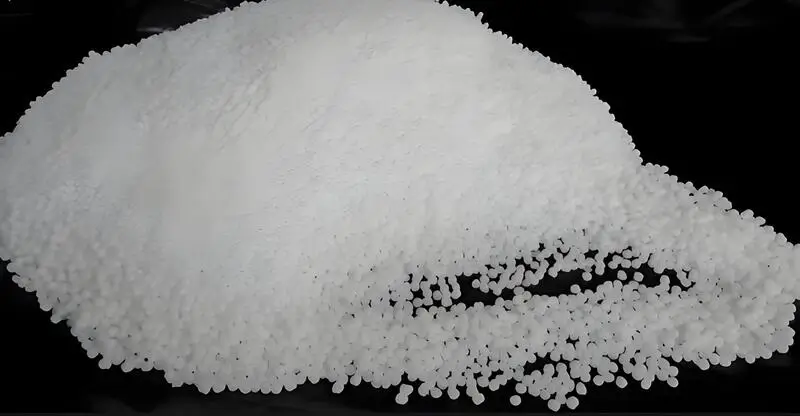

Właściwe przygotowanie surowców, w tym suszenie, czystość i wielkość cząstek, ma kluczowe znaczenie dla stałej jakości formowanych wtryskowo tworzyw sztucznych, zapobiegania wadom i zapewnienia przejrzystości produktów motoryzacyjnych i elektronicznych.

Wybór surowców

-

Poliwęglan (PC)1:Charakteryzuje się doskonałą przezroczystością optyczną, wysoką udarnością i dobrą odpornością na ciepło oraz może utrzymywać stabilne właściwości fizyczne w szerokim zakresie temperatur. Nadaje się do produkcji produktów o wysokich wymaganiach dotyczących przezroczystości i wytrzymałości, takich jak soczewki optyczne, przezroczyste obudowy wysokiej klasy produktów elektronicznych i klosze samochodowe. Jednak jego płynność przetwarzania jest stosunkowo niska, a proces formowania wtryskowego wymaga precyzyjnej kontroli parametrów procesu.

-

Polimetakrylan metylu (PMMA)2: Powszechnie znany również jako akryl, PMMA ma doskonałą przepuszczalność światła, porównywalną do szkła i dobrą odporność na warunki atmosferyczne. Jest powszechnie stosowany w produkcji stojaków ekspozycyjnych, kasetonów reklamowych, ozdób dekoracyjnych oraz różnego rodzaju lamp i latarni itp. Może prezentować bardzo dobry efekt wizualny. Jego twardość powierzchniowa jest jednak stosunkowo niska, przez co łatwo go zarysować. Dlatego należy zwrócić uwagę na ochronę podczas późniejszego użytkowania i przetwarzania.

-

Politereftalan etylenu (PET):Jest powszechnie stosowany w żywności, farmaceutykach i innych przezroczystych opakowaniach. Charakteryzuje się dobrą stabilnością chemiczną, przezroczystością i pewnymi właściwościami barierowymi. Koszt jest stosunkowo rozsądny. Jednak jego właściwości krystalizacyjne mają pewien wpływ na proces formowania wtryskowego. Przetwarzanie powinno rozsądnie kontrolować temperaturę i inne parametry w oparciu o potrzeby krystalizacji.

-

Inne przezroczyste tworzywa sztuczne:Polistyren (PS) jest tanim, przezroczystym materiałem, który jest często używany do produkcji prostych, przezroczystych produktów, takich jak jednorazowa zastawa stołowa i artykuły papiernicze. Cykliczna poliolefina (COC) jest często wykorzystywana w przemyśle optycznym, zwłaszcza do produkcji precyzyjnych soczewek. Świetnie się do tego nadaje, ponieważ nie ugina zbytnio światła, jest naprawdę czysty itp. Jest jednak droższa w produkcji.

Suszenie surowców

- Wybór sprzętu do suszenia3:Typowe urządzenia do suszenia obejmują piece z cyrkulacją gorącego powietrza, piece próżniowe i suszarki osuszające. Jeśli wykonujesz dużo suszenia i musisz uzyskać naprawdę niską zawartość wilgoci w przezroczystych surowcach z tworzyw sztucznych, najlepszym rozwiązaniem jest suszarka osuszająca. Zapewni ona przyjemne środowisko suszenia o niskiej wilgotności i usunie wilgoć z materiału. Jeśli wykonujesz małe lub średnie partie lub suszysz materiały, które nie muszą być bardzo suche, najlepszym rozwiązaniem będzie piec z cyrkulacją gorącego powietrza.

- Ustawienia parametrów suszenia:W przypadku surowców PC zwykle używamy suszarki osuszającej. W przypadku temperatura suszenia4 jest zwykle ustawiona na 110-130 stopni Celsjusza, a czas suszenia wynosi 4-8 godzin. Konkretny czas suszenia powinien być dostosowany do początkowej zawartości wilgoci w surowcach i wielkości partii. Jednocześnie wilgotność środowiska suszenia powinna być ściśle kontrolowana i powinna być utrzymywana poniżej 10%, aby zapewnić, że zawartość wilgoci w końcowych surowcach można zmniejszyć do 0,02%. W przypadku surowców PMMA temperaturę suszenia można ustawić na 70-90 stopni Celsjusza, a czas suszenia wynosi około 3-6 godzin. Jego wrażliwość na wilgoć jest stosunkowo niska, ale konieczne jest również zapewnienie, że zawartość wilgoci po suszeniu spełnia wymagania, aby uniknąć wad, takich jak srebrny drut i pęcherzyki w produkcie.

Odpowiednie suszenie surowców zwiększa przejrzystość przezroczystych produktów z tworzyw sztucznych.Prawda

Suche materiały zapobiegają powstawaniu pęcherzyków i niedoskonałości, które są niezbędne do osiągnięcia wysokiej przejrzystości formowanych produktów.

Przygotowanie surowca nie ma wpływu na trwałość przezroczystych tworzyw sztucznych.Fałsz

Odpowiednie przygotowanie, w tym czystość materiału i suszenie, bezpośrednio wpływa na integralność strukturalną i trwałość produktu końcowego.

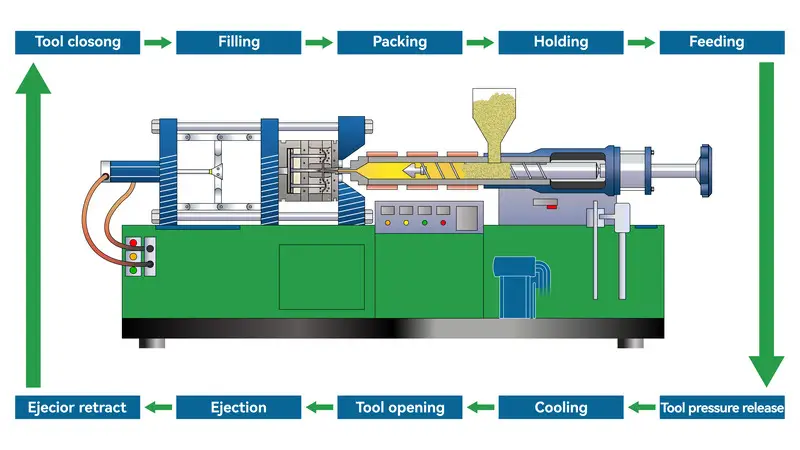

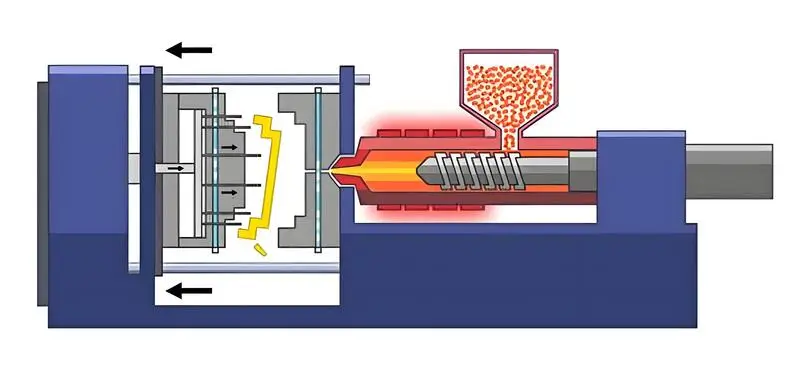

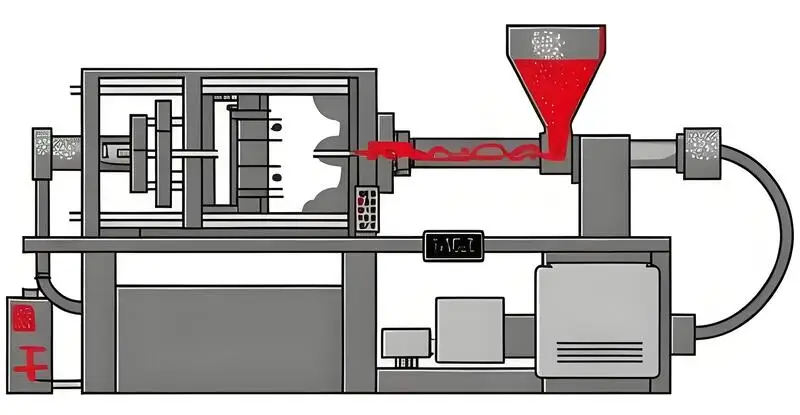

Jaki jest wpływ wyboru i debugowania wtryskarki na formowanie wtryskowe przezroczystych produktów z tworzyw sztucznych?

Wybór odpowiedniej wtryskarki i precyzyjne debugowanie są kluczem do osiągnięcia optymalnej przejrzystości i jakości produktów z tworzyw sztucznych.

Wybór odpowiedniej wtryskarki i precyzyjne debugowanie mają kluczowe znaczenie dla przezroczystych tworzyw sztucznych, wpływając na przejrzystość i jakość poprzez redukcję wad, takich jak zamglenie i przebarwienia, co ma zasadnicze znaczenie w motoryzacji, medycynie i produktach konsumenckich.

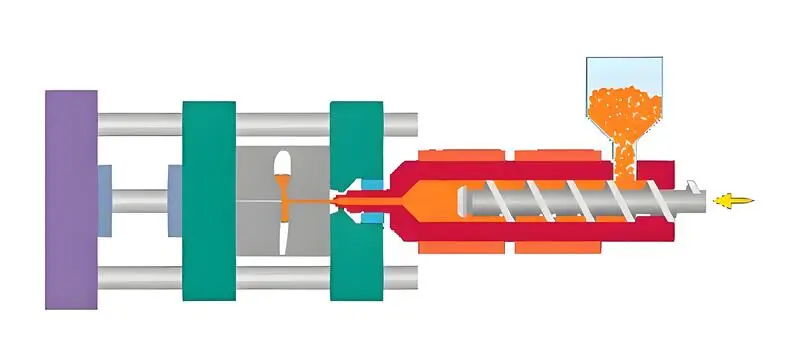

Wybór maszyny do formowania wtryskowego

-

Konstrukcja śrubowa: Podczas formowania przezroczystego plastiku należy użyć śruby ze stożkiem. Śruba powinna mieć stożek, który zmniejsza się w miarę przechodzenia od tylnej do przedniej części śruby. Pomoże to lepiej stopić plastik i sprawi, że temperatura i lepkość plastiku będą bardziej spójne. Pomoże to w tworzeniu lepszych części, które będą bardziej przejrzyste. Należy również użyć długiej śruby. Śruba powinna być około 20 do 25 razy dłuższa niż jej szerokość. Dłuższa śruba da plastikowi więcej czasu na stopienie. Jest to szczególnie ważne w przypadku formowania przezroczystego plastiku o wysokiej lepkości.

-

Precyzja układu wtryskowego:System wtrysku wtryskarki powinien być w stanie kontrolować objętość wtrysku z dużą precyzją. Powtarzalność objętości wtrysku powinna być w stanie osiągnąć ±1%. Ma to na celu zapewnienie, że objętość stopionego tworzywa sztucznego wtryskiwanego do gniazda formy jest dokładna przy każdym wtrysku. Ma to również na celu uniknięcie problemów jakościowych, takich jak odchylenia wymiarowe, brak materiału lub latające krawędzie produktów spowodowane odchyleniem objętości wtrysku.

- Stabilność systemu mocowania:System mocowania musi mieć wystarczającą siłę mocowania, aby upewnić się, że wnęka formy może być szczelnie zamknięta podczas procesu wtrysku, aby zapobiec przelewaniu się stopionego tworzywa sztucznego z powierzchni podziału pod wysokim ciśnieniem, tworząc latającą krawędź. Jednocześnie otwieranie i zamykanie systemu zaciskowego powinno być płynne i precyzyjne, aby uniknąć niestabilnych czynników, takich jak gwałtowny wpływ formy na jakość formowania produktów i żywotność formy.

Regulacja parametrów

- Prędkość wtrysku: Nie wtryskiwać zbyt szybko, ponieważ plastik stopi się i wytworzy turbulencje, zatrzymując powietrze i powodując powstawanie pęcherzyków. Wpłynie to na przezroczystość i wygląd produktu. W przypadku prostych, przezroczystych produktów o równych ściankach, prędkość wtrysku może być stabilna, zwykle około 10-30 cm³/s. Jednak w przypadku złożonych, cienkościennych produktów przezroczystych prędkość wtrysku musi być stabilna. W przypadku złożonych produktów z cienkimi ściankami, wzmocnionymi ściankami lub przejściami od cienkich do grubych ścianek, często trzeba stosować wieloetapowe prędkości wtrysku. Na przykład na początku wtrysku należy napełniać z mniejszą prędkością (5-10 cm³/s), aby stopiony materiał mógł płynnie dostać się do głównego kanału przepływu i głównej części wnęki. Podczas wypełniania cienkościennych lub złożonych części należy zwiększyć prędkość do 20-40 cm³/s, aby zapewnić całkowite wypełnienie tych części. Następnie, gdy zbliżysz się do końca wnęki, zmniejsz prędkość, aby uniknąć błysku.

-

Ciśnienie utrzymujące prędkość:Prędkość etapu utrzymywania ciśnienia jest stosunkowo niska, głównie w celu płynnego uzupełniania stopu, a jego prędkość jest zwykle ustawiona na 1 - 5 cm³ / s, co należy dostosować do konkretnych wymagań produktów i parametrów, takich jak ciśnienie utrzymywania ciśnienia, aby zapewnić, że jakość produktów jest stabilna podczas procesu utrzymywania ciśnienia.

-

Ciśnienie wtrysku:Podczas ustawiania ciśnienie wtrysku5Na przykład w przypadku cienkościennych przezroczystych produktów z tworzyw sztucznych, ponieważ stopiony materiał we wnęce szybko się ochładza, należy użyć wyższego ciśnienia wtrysku, aby upewnić się, że stopiony materiał może szybko i całkowicie wypełnić całą wnękę, aby nie uzyskać krótkiego strzału. Konieczne może być użycie ciśnienia 100-150 MPa lub nawet wyższego. W przypadku produktów grubościennych ciśnienie wtrysku jest niższe, zwykle około 50-100 MPa. Należy uważać, aby nie użyć zbyt dużego ciśnienia, ponieważ może to spowodować duże naprężenia szczątkowe wewnątrz produktu, co może spowodować jego późniejsze pęknięcie lub deformację. Podczas ustawiania formy zazwyczaj trzeba wypróbować kilka różnych form, aby znaleźć najlepsze ciśnienie wtrysku.

-

Ciśnienie trzymania:Ciśnienie trzymania jest zwykle niższe niż ciśnienie wtrysku. Jego główną rolą jest uzupełnienie stopionego tworzywa sztucznego podczas chłodzenia i kurczenia się produktu, tak aby gęstość produktu była jednolita, aby uniknąć śladów skurczu. W przypadku produktów PC ciśnienie utrzymywania wynosi zazwyczaj 60% - 80% ciśnienia wtrysku, a czas utrzymywania wynosi przeważnie od 5 do 20 sekund w zależności od grubości ścianki produktu; ciśnienie utrzymywania produktów PMMA wynosi około 50% - 70% ciśnienia wtrysku, a czas utrzymywania wynosi około 3 - 10 sekund; ciśnienie utrzymywania produktów PET wynosi około 70% - 90% ciśnienia wtrysku, a czas utrzymywania może wynosić 8 - 20 sekund, określone parametry należy zoptymalizować poprzez formowanie próbne. Konkretne parametry należy zoptymalizować i dostosować poprzez formowanie próbne.

-

Temperatura beczki:W przypadku surowców PC, temperatura beczki jest zwykle ustawiona na 260℃ - 280℃ w przedniej części, 240℃ - 260℃ w środkowej części i 220℃ - 240℃ w tylnej części. Ten gradient temperatury pomaga surowcowi uplastyczniać się stopniowo i równomiernie. W przypadku surowców PMMA temperatura cylindra jest zwykle ustawiana na 200 ℃ - 230 ℃ w przedniej części i 200 ℃ - 230 ℃ w środkowej części oraz 200 ℃ - 230 ℃ w środkowej części. Temperatura cylindra surowców PMMA mieści się zazwyczaj w zakresie 200 ℃ - 230 ℃, 180 ℃ - 200 ℃ w środkowej części i 160 ℃ - 180 ℃ w tylnej części. Powinien być precyzyjnie dostosowany do stosunkowo wąskiego okna temperatury przetwarzania, aby zapobiec rozkładowi spowodowanemu zbyt wysoką temperaturą, co wpływa na przezroczystość i kolor produktów. temperatura cylindra surowców PET w przedniej części mieści się głównie w zakresie 270 ℃ - 290 ℃, temperatura środkowej części mieści się w zakresie 250 ℃ - 270 ℃, a temperatura tylnej części mieści się w zakresie 230 ℃ - 250 ℃, na co należy zwrócić uwagę. PET w procesie krystalizacji, poprzez kontrolę temperatury w celu regulacji stopnia krystaliczności, co z kolei wpływa na wydajność i wygląd produktów.

-

Temperatura dyszy: Temperatura dyszy jest zwykle nieco niższa niż temperatura dyszy. temperatura beczki6. W przypadku PC temperaturę dyszy można ustawić na 250-270°C. Zapewnia to płynne topienie tworzywa sztucznego i wtryskiwanie go do formy przez dyszę. Może to również zapobiec ślinieniu się spowodowanemu zbyt wysoką temperaturą dyszy. W przypadku PMMA temperatura dyszy wynosi 190-210°C. W przypadku PET temperatura dyszy wynosi 260-280°C. Konkretna temperatura powinna być ustawiona rozsądnie w zależności od lepkości stopu i charakterystyki przepływu różnych tworzyw sztucznych.

Prawidłowy dobór maszyny zmniejsza liczbę defektów w przezroczystych tworzywach sztucznych.Prawda

Właściwy wybór i ustawienia maszyny minimalizują typowe wady, takie jak zamglenie, zapewniając lepszą przejrzystość optyczną i jakość.

Każda maszyna do formowania wtryskowego nadaje się do przezroczystych tworzyw sztucznych.Fałsz

Nie wszystkie maszyny są w stanie sprostać specyficznym wymaganiom dotyczącym przezroczystych tworzyw sztucznych, które wymagają precyzyjnie dostosowanych ustawień w celu uzyskania optymalnej przejrzystości.

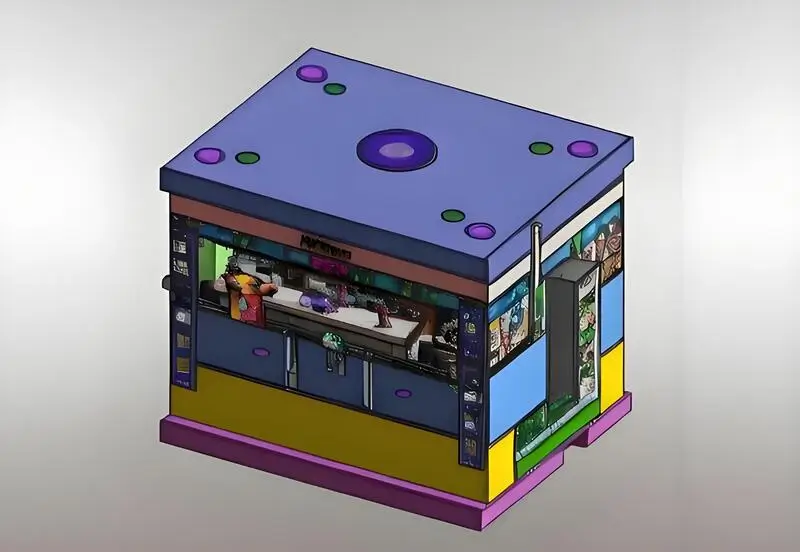

Punkty projektowania i produkcji form Jak wpłynąć na formowanie wtryskowe przezroczystych tworzyw sztucznych?

Efektywne projektowanie i wytwarzanie form ma kluczowe znaczenie dla optymalizacji formowania wtryskowego przezroczystych tworzyw sztucznych, zapewniając wyraźne i wysokiej jakości produkty końcowe.

Przezroczyste formowanie tworzyw sztucznych zależy od wyboru materiału, polerowania formy i precyzji projektu. Optymalne warunki zwiększają przejrzystość i redukują defekty, przynosząc korzyści branży motoryzacyjnej, elektronicznej i opakowaniowej.

Konstrukcja układu wydechowego

-

Rowki wydechowe:Głębokość, szerokość i długość rowków wylotowych muszą być starannie zaprojektowane. Głębokość wynosi zwykle od 0,02 mm do 0,05 mm. Jeśli jest zbyt płytka, efekt wydechu będzie słaby. Jeśli jest zbyt głęboki, stopiony plastik łatwo się przeleje i utworzy latającą krawędź. Szerokość wynosi zwykle około 3-8 mm, w zależności od rozmiaru i struktury formy. Długość kanału odpowietrzającego powinna sięgać na zewnątrz wnęki formy, aby powietrze mogło być płynnie odprowadzane z formy. Lokalizację kanału odpowietrzającego należy wybrać w ostatniej części wypełnianego stopu, takiej jak narożnik wnęki, koniec zbrojenia i inne miejsca, w których powietrze może się gromadzić, w celu poprawy wydajności odpowietrzania.

-

Stalowe wkładki przepuszczające gaz7:Stal gazoprzepuszczalna jest materiałem o dobrej przepuszczalności gazu, który zostanie wykonany w części wkładek formy, aby wspomóc efekt wydechu jest znaczący. W przypadku stosowania stalowych wkładek przepuszczających powietrze, należy zwrócić uwagę na ich położenie montażowe i inne części formy, wkładki o porowatości wynoszą zazwyczaj między 15% - 30%, rozmiar porów jest jednolity, tak aby zapewnić, że powietrze przechodzi płynnie, a jednocześnie nie spowoduje, że tworzywo sztuczne stopi dużą liczbę infiltracji i zatykania porów. Liczbę i rozmieszczenie przepuszczających powietrze stalowych wkładek w formie należy określić zgodnie z kształtem i rozmiarem produktu, a także zapotrzebowaniem na spaliny, na przykład w przypadku dużej i złożonej struktury przezroczystych form produktów może wymagać więcej niż jednej przepuszczającej powietrze stalowej wkładki rozmieszczonej w różnych częściach, aby zapewnić efekt wydechu.

- Inne metody odprowadzania spalin:Można również użyć pompy próżniowej, aby wspomóc proces odpowietrzania. Podłączając pompę próżniową do formy, można wyciągnąć powietrze z gniazda przed wstrzyknięciem tworzywa sztucznego. Wprowadza to wnękę w stan podciśnienia, ułatwiając stopionemu plastikowi wypełnienie wnęki i zmniejszając ryzyko powstania pęcherzyków powietrza. Innym prostym sposobem wentylacji jest wykorzystanie naturalnej szczeliny na linii podziału. Metoda ta ma jednak ograniczoną skuteczność i jest zwykle stosowana w połączeniu z innymi metodami odpowietrzania. Należy również uważać, aby kontrolować rozmiar szczeliny na linii podziału, aby zapobiec przelaniu się stopionego materiału.

Optymalizacja układu chłodzenia

- Układ kanałów chłodzących8:Układ kanałów chłodzących powinien być zaprojektowany zgodnie z kształtem i grubością ścianki produktu. W przypadku produktów o regularnych kształtach i jednolitej grubości ścianek, kanały chłodzące mogą być ułożone w linii prostej lub w okręgu w celu równomiernego rozprowadzenia. W przypadku produktów o nieregularnych kształtach i dużych różnicach w grubości ścianek, kanały chłodzące powinny być podzielone. Kanały chłodzące w grubszych częściach ścianki powinny być gęstsze lub kanały chłodzące powinny znajdować się bliżej powierzchni wnęki, aby przyspieszyć chłodzenie tych części i zapewnić ogólne chłodzenie produktu. Na przykład, dla przezroczystej formy produktu z cienkościennym wzmocnieniem i grubościenną strukturą korpusu, odstęp kanałów chłodzących poniżej grubościennego korpusu można ustawić na 20-30 mm, podczas gdy odstęp kanałów chłodzących w pobliżu cienkościennego wzmocnienia można zawęzić do 10-15 mm. Kierunek kanałów chłodzących powinien być rozsądnie zaprojektowany, aby uniknąć tworzenia się martwych stref chłodzenia.

-

Rozmiar kanału chłodzącego:Średnica kanału chłodzącego wynosi zwykle od 8 mm do 12 mm. Jeśli średnica jest zbyt mała, wpłynie to na przepływ chłodziwa i wydajność chłodzenia. Jeśli średnica jest zbyt duża, spowoduje to, że struktura formy będzie zbyt złożona, zwiększy koszty i zajmie zbyt dużo miejsca w formie. Odległość między kanałem chłodzącym a powierzchnią wnęki powinna być również dostosowana do grubości ścianki produktu i innych czynników. Zazwyczaj wynosi ona około 10-20 mm. Jeśli odległość jest zbyt bliska powierzchni produktu, łatwo jest uzyskać zimne ślady, co wpływa na jakość wyglądu. Jeśli odległość jest zbyt duża, efekt chłodzenia jest słaby, co skutkuje dłuższym czasem chłodzenia produktu i dłuższym cyklem produkcyjnym.

-

Wybór i kontrola płynu chłodzącego:Chłodziwo jest powszechnie stosowane w maszynach do formowania wtryskowego, w tym woda, olej i specjalne chłodziwo do form. Woda ma dobry efekt chłodzenia i niski koszt, ale łatwo powoduje rdzę formy, więc musi dodać inhibitor rdzy i inną ochronę; olej ma stosunkowo niską prędkość chłodzenia, ale ma dobre właściwości antykorozyjne i smarne, odpowiednie dla niektórych form o wyższych wymaganiach kontroli temperatury i ścisłych wymaganiach dotyczących precyzji. Temperatura chłodziwa powinna być dostosowana do rodzaju produktów z tworzyw sztucznych i wymagań procesu, zwykle kontrolowana w zakresie 5 ℃ - 30 ℃, a jednocześnie system kontroli temperatury służy do precyzyjnej kontroli temperatury chłodziwa, aby zapewnić, że proces chłodzenia jest stabilny i jednolity.

Projekt mechanizmu rozformowywania

-

Wybór metody rozformowywania:Istnieje kilka popularnych metod demontażu, takich jak demontaż płyty dociskowej, demontaż nachylonego blatu, demontaż pręta dociskowego itp. Rozformowywanie za pomocą płyty dociskowej jest odpowiednie dla przezroczystych produktów o prostym i płaskim kształcie. Produkty są wypychane z gniazda formy jako całość przez płytę dociskową. Siła wypychania jest jednolita i nie jest łatwo uszkodzić powierzchnię produktów. Formowanie z pochylonym blatem jest najczęściej stosowane w przypadku produktów o odwróconej strukturze klamry. Pochylony blat może być używany do płynnego usuwania produktów z odwróconymi klamrami poprzez pochylony ruch podczas procesu otwierania i zamykania formy. Rozformowywanie za pomocą popychacza jest bardziej elastyczne. W zależności od konkretnego kształtu produktu i potrzeby ustawienia pozycji wielu popychaczy, należy jednak zwrócić uwagę na konstrukcję części kontaktowej między popychaczem a produktem, aby uniknąć pozostawienia widocznych śladów popychacza na powierzchni produktu.

-

Ustawienie pochylenia formowania9:Podczas rozformowywania przezroczystych produktów z tworzyw sztucznych ważny jest kąt rozformowywania. Ogólnie, kąt rozformowania wynosi od 1° do 3°. W przypadku produktów o wysokich wymaganiach dotyczących precyzji powierzchni i miękkiej teksturze, kąt rozformowania można zwiększyć do 3° do 5°. Projektując gniazdo formy, musimy wziąć pod uwagę ustawienie nachylenia rozformowania, tak aby produkt mógł być chłodzony i kurczony wzdłuż kierunku nachylenia w celu płynnego rozformowania. Jednocześnie musimy upewnić się, że nachylenie nie ma wpływu na dokładność wymiarową i jakość wyglądu produktu. Zwłaszcza w przypadku produktów przezroczystych z wymaganiami optycznymi, konstrukcja nachylenia powinna być bardziej delikatna, aby uniknąć zmian właściwości optycznych spowodowanych problemami z załamaniem światła z powodu nachylenia.

- Obróbka powierzchni części rozformowywanych:Powierzchnie części, które wchodzą w kontakt z produktami, takie jak płyta dociskowa, nachylony blat, popychacz itp., powinny być wypolerowane w drobnym stopniu, tak aby chropowatość powierzchni była poniżej Ra0,8 μm, tak aby zadrapania na powierzchni produktów można zminimalizować podczas procesu wyjmowania z formy, zapewniając, że produkty mają wysoki stopień wykończenia i przezroczystości. Ponadto można również zastosować metody obróbki powierzchni, takie jak twarde chromowanie na powierzchni części do rozformowywania, aby poprawić ich odporność na zużycie i odporność na korozję, przedłużyć żywotność części do rozformowywania i dodatkowo chronić płynny proces rozformowywania i jakość produktów.

Konstrukcja formy decyduje o przejrzystości przezroczystych tworzyw sztucznych w procesie formowania wtryskowego.Prawda

Odpowiednie względy projektowe, takie jak polerowanie i wybór materiału, znacząco wpływają na przejrzystość i jakość produktu końcowego.

Wszystkie przezroczyste tworzywa sztuczne wymagają takiego samego podejścia do projektowania form.Fałsz

Różne przezroczyste tworzywa sztuczne mają unikalne właściwości i mogą wymagać dostosowanych strategii projektowych w celu osiągnięcia optymalnych wyników.

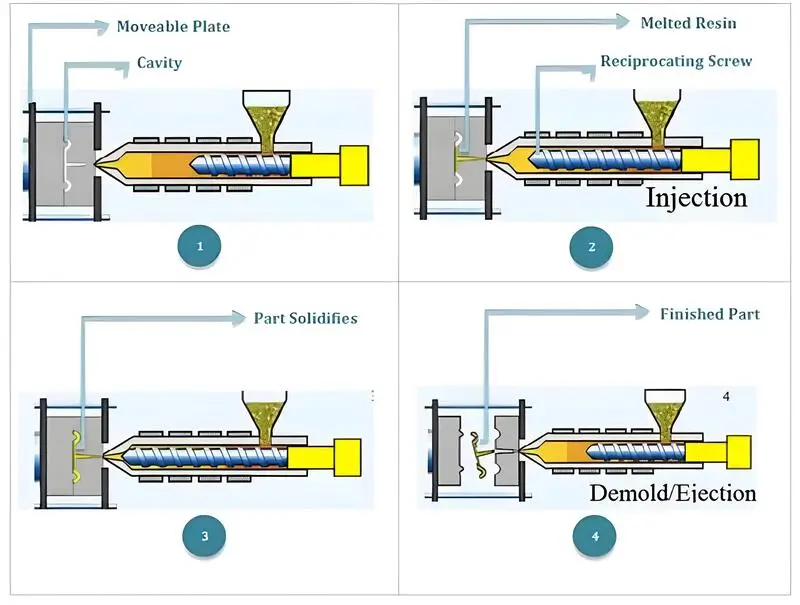

Jak kontrola procesu wtrysku wpływa na formowanie wtryskowe przezroczystych tworzyw sztucznych?

Kontrola procesu wtrysku ma kluczowe znaczenie dla formowania wysokiej jakości przezroczystych tworzyw sztucznych, zapewniając przejrzystość i wytrzymałość mechaniczną w różnych zastosowaniach.

Kontrolowanie warunków procesu wtrysku zwiększa przejrzystość i jakość tworzyw sztucznych poprzez zapewnienie stałej temperatury i ciśnienia, co ma kluczowe znaczenie dla przemysłu optycznego i elektronicznego.

Wielostopniowa kontrola wtrysku

Podczas korzystania z Wieloetapowy proces wtrysku10Zazwyczaj dzieli się go na 3-5 etapów w celu kontroli. Na początku procesu wtrysku, który jest pierwszym etapem, wtryskuje się z bardzo małą prędkością (np. 3-5 cm³/s) i niskim ciśnieniem (około 30-40% końcowego ciśnienia wtrysku), aby stopiony materiał powoli i płynnie wypełniał główne ścieżki przepływu i bramy wnęk formy oraz aby uniknąć wirowania i porywania powietrza spowodowanego uderzeniem stopionego materiału z dużą prędkością.

W drugim etapie, gdy stopiony materiał zaczyna wchodzić do głównej części wnęki, zgodnie z rozmiarem i grubością ścianki wnęki, prędkość wtrysku powinna zostać odpowiednio zwiększona do 8-15 cm³/s, a ciśnienie powinno zostać zwiększone do 50%-60% końcowego ciśnienia wtrysku, aby zapewnić, że stopiony materiał może być równomiernie rozprowadzony i wypełniony wokół wnęki. W trzecim etapie, w przypadku produktów cienkościennych, prędkość wtrysku należy zwiększyć do.

W trzecim etapie, jeśli występują obszary cienkościenne, pręty wzmacniające i inne złożoności strukturalne, prędkość jest dalej zwiększana do 15 - 25 cm³/s, a ciśnienie jest odpowiednio zwiększane, aby zapewnić, że stopiony materiał może w pełni wypełnić te trudne do wypełnienia części. W przypadku niektórych dużych lub szczególnie złożonych produktów może być również konieczne ustawienie czwartego i piątego etapu w celu dalszego dostrojenia prędkości wtrysku i ciśnienia w celu uzyskania idealnego wypełnienia.

Kontrola przepływu stopionego materiału

Podczas wtryskiwania należy zawsze zwracać uwagę na przepływ stopionego tworzywa sztucznego we wnęce. Można obserwować ciśnienie, prędkość i inne parametry krzywej wtryskarki oraz korzystać z okna wizualizacji formy (np. używając przezroczystych wkładek lub otwierając otwory obserwacyjne itp.

W przypadku stwierdzenia turbulencji, stagnacji przepływu lub niestabilnej powierzchni czołowej, prędkość wtrysku, ciśnienie i inne parametry należy dostosować w odpowiednim czasie, aby zapewnić płynne wypełnienie wnęki przez stopiony materiał w przepływie laminarnym. Jest to bardzo ważne dla zapewnienia przejrzystości i wewnętrznej jakości produktu.

Optymalizacja krzywej utrzymywania ciśnienia

The proces utrzymywania ciśnienia11 nie jest pojedynczym ciśnieniem, które należy utrzymywać na stałym poziomie, ale można je ustawić w celu uzyskania dokładniejszej kontroli krzywej ciśnienia utrzymywania. Zwykle na początku ciśnienia utrzymywania, wyższe ciśnienie utrzymywania (takie jak górna granica zakresu ciśnienia utrzymywania opisanego powyżej), wraz z chłodzeniem i kurczeniem się produktu, stopniowo zmniejsza ciśnienie utrzymywania, tworząc krzywą malejącego ciśnienia, która może lepiej dostosować się do procesu kurczenia się produktu stopu w celu uzupełnienia zapotrzebowania na zmiany w celu uniknięcia wad spowodowanych ciśnieniem utrzymywania jest nierozsądne, co prowadzi do śladów skurczu produktu, wewnętrznych pustek i innych wad.

Określając, jak długo należy utrzymywać ciśnienie, należy wziąć pod uwagę grubość ścianki, rozmiar części, charakterystykę skurczu tworzywa sztucznego i inne czynniki. Będziesz musiał uruchomić kilka form testowych i spojrzeć na część po wyjściu z formy, aby zobaczyć, jak wygląda i jak dokładna jest wymiarowo. Następnie można wprowadzić poprawki w celu optymalizacji.

Monitorowanie procesu utrzymywania ciśnienia

Podczas utrzymywania ciśnienia należy kontrolować ciśnienie i czas. Należy również obserwować ciśnienie zwrotne z wnęk formy (w formach można umieścić czujniki ciśnienia). Należy upewnić się, że ciśnienie utrzymywania jest stabilne i dokładne. Jeśli ciśnienie przytrzymywania jest rozproszone lub czas przytrzymywania nie jest wystarczająco długi, należy dokonać regulacji. Po zakończeniu docisku należy upewnić się, że części mają taką samą gęstość i pełną strukturę wewnętrzną. W ten sposób ostygną i wyjdą z formy we właściwy sposób.

Określanie czasu chłodzenia

Obliczenie czasu chłodzenia jest bardziej skomplikowane i jest związane z grubością ścianki produktu, przewodnością cieplną tworzywa sztucznego, wydajnością chłodzenia formy i temperaturą otoczenia. Ogólnie rzecz biorąc, czas chłodzenia można wstępnie oszacować za pomocą wzoru teoretycznego w połączeniu z praktycznym doświadczeniem, a następnie dokładnie określić za pomocą formy testowej.

Na przykład, dla produktu PC o grubości ścianki 2 mm, wstępne oszacowanie czasu chłodzenia może wynosić około 10-15 sekund, ale rzeczywista forma testowa może wymagać zwiększenia lub zmniejszenia w zależności od ostatecznej jakości produktu. Podczas określania czasu chłodzenia konieczne jest obserwowanie deformacji, dokładności wymiarowej i jakości powierzchni produktu po rozformowaniu, aby upewnić się, że produkt jest wystarczająco schłodzony i ukształtowany, tak aby wypaczenie, deformacja i odchylenie wymiarowe nie wystąpiły po rozformowaniu z powodu niewystarczającego chłodzenia.

Gwarancja równomierności chłodzenia

Aby upewnić się, że produkty chłodzą się równomiernie, trzeba zrobić więcej niż tylko zoptymalizować układ chłodzenia, rozmiar i inne rzeczy, o których wspomniałem wcześniej. Należy również upewnić się, że płyn chłodzący przepływa równomiernie i ma wszędzie taką samą temperaturę.

Można to zrobić, umieszczając zawory sterujące przepływem, czujniki temperatury i inne elementy w każdym kanale chłodzenia. W ten sposób można kontrolować i obserwować przepływ chłodziwa w każdym kanale. Dzięki temu każda część będzie chłodzona w ten sam sposób. Zapobiegnie to również zbyt szybkiemu lub zbyt wolnemu chłodzeniu niektórych części. W ten sposób unikniesz problemów z nadmiernym naprężeniem lub wygięciem części.

Kontrola procesu wtrysku gwarantuje nieskazitelną przejrzystość tworzyw sztucznych.Fałsz

Chociaż znacznie poprawia przejrzystość, osiągnięcie nieskazitelnej przejrzystości zależy od wielu czynników, w tym jakości materiału i projektu formy.

Niekontrolowanie procesu wtrysku może prowadzić do powstawania wad w przezroczystych tworzywach sztucznych.Prawda

Niespójne warunki wtrysku mogą powodować wady wizualne i zagrażać integralności strukturalnej formowanych części.

Jakie metody obróbki końcowej są stosowane w przypadku przezroczystych produktów z tworzyw sztucznych po formowaniu wtryskowym?

Metody obróbki końcowej poprawiają jakość i trwałość przezroczystych produktów z tworzyw sztucznych, co ma kluczowe znaczenie w branżach wymagających przejrzystości i precyzji.

Metody obróbki końcowej przezroczystych tworzyw sztucznych, takie jak wyżarzanie, powlekanie UV i polerowanie, zwiększają przejrzystość optyczną, wykończenie powierzchni i odporność na środowisko, zapewniając trwałość i wydajność produktu po formowaniu wtryskowym.

Wyżarzanie

Podczas produkcji przezroczystych produktów z tworzyw sztucznych, mogą one ulegać naprężeniom podczas wkładania ich do formy. Naprężenia te mogą powodować pęknięcia i sprawiać, że plastik będzie wyglądał źle podczas użytkowania. Naprężeń można się pozbyć poprzez wyżarzanie plastiku. Na przykład, jeśli wytwarzasz produkty PC, możesz umieścić je w piekarniku w temperaturze 120-130 stopni C na 1-2 godziny. Następnie można pozwolić im powoli ostygnąć do temperatury pokojowej. Temperaturę i czas należy zmieniać w zależności od grubości plastiku, jego rozmiaru i rodzaju używanego plastiku.

Obróbka powierzchni

Aby produkty wyglądały lepiej i były gładsze, możemy wykonać pewną obróbkę powierzchni. Na przykład, możemy użyć szlifowania, aby usunąć małe defekty na powierzchni produktów po ich wyjęciu z formy, a następnie użyć pasty polerskiej do wypolerowania powierzchni produktów, aby wyglądały jak lustro; w przypadku niektórych produktów o wyższych wymaganiach optycznych może być konieczne wykonanie specjalnej obróbki powierzchni, takiej jak powlekanie, aby uzyskać lepszą przepuszczalność światła, odporność na zużycie i inne właściwości.

Wyżarzanie zmniejsza naprężenia wewnętrzne w przezroczystych tworzywach sztucznych.Prawda

Wyżarzanie pomaga złagodzić wewnętrzne naprężenia powstałe podczas formowania wtryskowego, minimalizując wypaczenia i poprawiając właściwości optyczne materiału.

Wszystkie przezroczyste tworzywa sztuczne wymagają powlekania UV po obróbce.Fałsz

Nie wszystkie przezroczyste tworzywa sztuczne wymagają powlekania UV; zależy to od rodzaju materiału i wymagań aplikacji w zakresie odporności na promieniowanie UV i trwałości.

Wnioski

Niniejszy artykuł dotyczy formowania wtryskowego przezroczystych produktów z tworzyw sztucznych. Po pierwsze, wybór surowca ma kluczowe znaczenie dla przejrzystości i wytrzymałości. Powszechnie stosowane przezroczyste tworzywa sztuczne obejmują poliwęglan, polimetakrylan metylu i politereftalan etylenu.

Po drugie, wybór i oddanie do użytku wtryskarka12a precyzyjna regulacja parametrów procesu, zwłaszcza prędkości wtrysku, ciśnienia i czasu utrzymywania, ma znaczący wpływ na jakość formowania.

Ponadto konstrukcja formy, konstrukcja układu wydechowego i optymalizacja układu chłodzenia mają również kluczowe znaczenie dla zapewnienia stabilności i jakości produktu podczas procesu wtrysku. Wreszcie, obróbka końcowa, taka jak wyżarzanie i obróbka powierzchni, pomaga wyeliminować naprężenia wewnętrzne i poprawić przejrzystość produktu.

-

Poznaj różnorodne zastosowania i właściwości poliwęglanu (PC), aby zrozumieć jego znaczenie w różnych branżach. ↩

-

Odkryj zalety i zastosowania PMMA, wszechstronnego materiału znanego z doskonałej przepuszczalności światła i odporności na warunki atmosferyczne. ↩

-

Poznaj różne opcje urządzeń do suszenia tworzyw sztucznych, aby zoptymalizować proces produkcji. ↩

-

Zrozumienie optymalnej temperatury suszenia może znacznie poprawić jakość produktów z tworzyw sztucznych i zmniejszyć liczbę wad. ↩

-

Poznanie ciśnienia wtrysku ma kluczowe znaczenie dla osiągnięcia najlepszych wyników w formowaniu tworzyw sztucznych, zapewniając integralność i jakość produktu. ↩

-

Zbadanie ustawień temperatury beczki może zwiększyć zrozumienie procesu przetwarzania tworzyw sztucznych, prowadząc do lepszych wyników produktu. ↩

-

Dowiedz się, w jaki sposób gazoprzepuszczalne wkładki stalowe zwiększają wydajność formy i jakość produktu, zapewniając optymalną wydajność wydechu. ↩

-

Poznaj najlepsze praktyki w zakresie projektowania kanałów chłodzących, aby poprawić wydajność chłodzenia i jakość produktu w formowaniu wtryskowym. ↩

-

Dowiedz się, w jaki sposób prawidłowe ustawienia nachylenia przy rozformowywaniu mogą poprawić jakość produktu i ułatwić rozformowywanie, zwłaszcza w przypadku produktów przezroczystych. ↩

-

Zrozumienie wieloetapowego procesu wtrysku ma kluczowe znaczenie dla optymalizacji technik formowania tworzyw sztucznych i poprawy jakości produktu. ↩

-

Zbadanie procesu docisku może pomóc w osiągnięciu lepszej dokładności wymiarowej i zmniejszeniu liczby defektów w formowanych produktach. ↩

-

Kompleksowy przewodnik po wtryskarkach: Wtryskarka to urządzenie szeroko stosowane w produkcji przemysłowej. ↩