– Family molds reduce upfront tooling costs but introduce significant risks regarding flow balance and inconsistent process windows for disparate parts.

– Master Unit Die (MUD) systems offer superior production flexibility, allowing independent process optimization for each component while maintaining low tooling costs.

– Managing tooling risk requires evaluating part geometry; parts with different volumes or wall thicknesses should typically avoid family molds.

– Molding disparate parts in a single shot often leads to higher scrap rates and compromised cycle times compared to the rapid changeover capabilities of MUD systems.

What Are Family Molds and MUD Systems?

To make an informed decision on multi-cavity tooling1, it is essential to define the two architectures clearly.

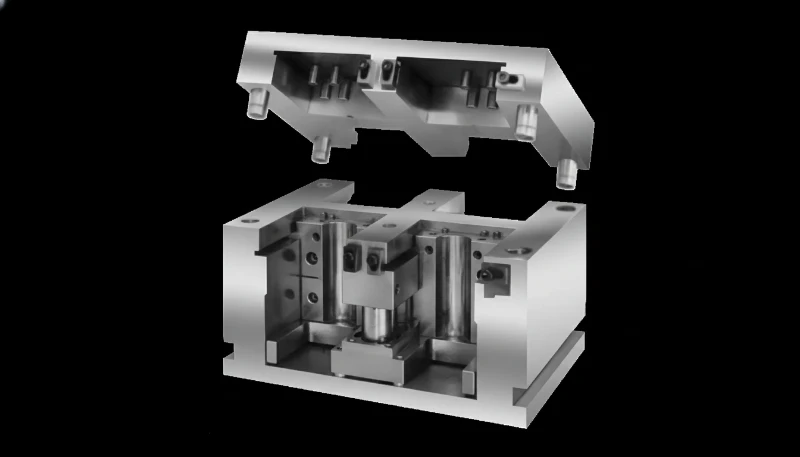

- Family Mold: A single mold base containing cavities for two or more different parts (e.g., a top housing and a bottom housing). Every injection cycle produces a complete set of these different components simultaneously.

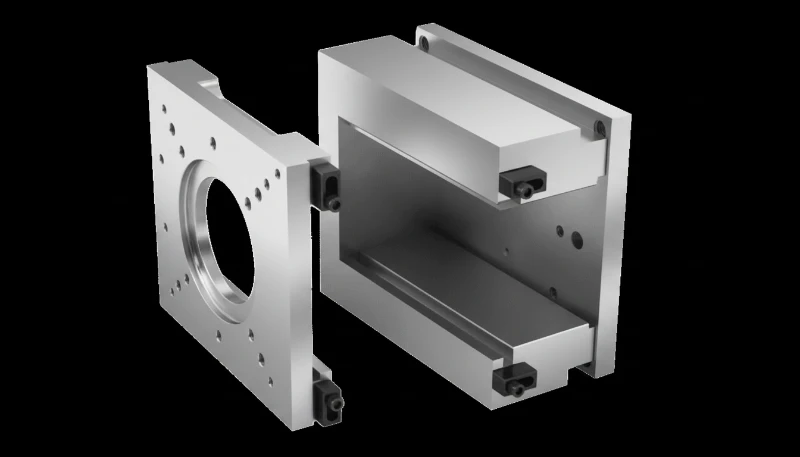

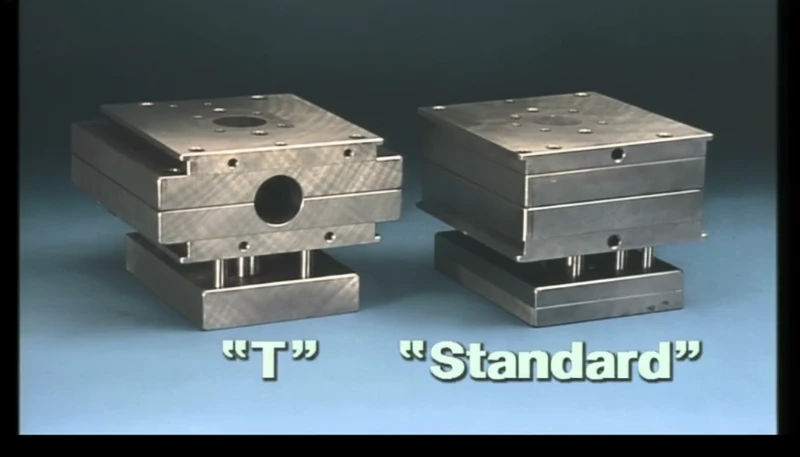

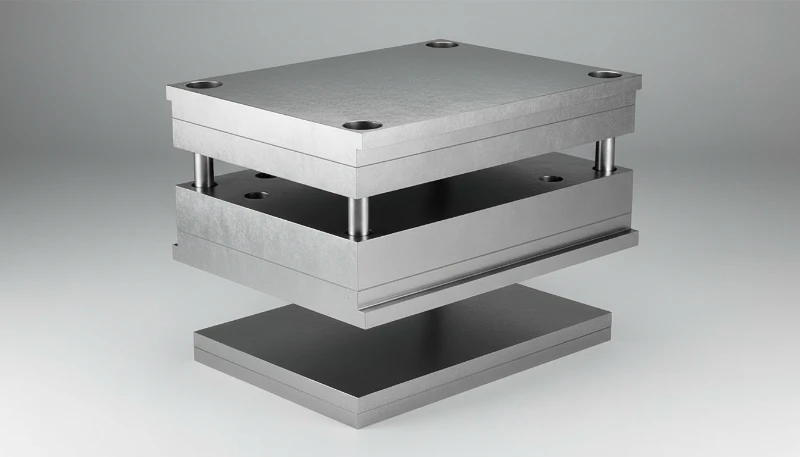

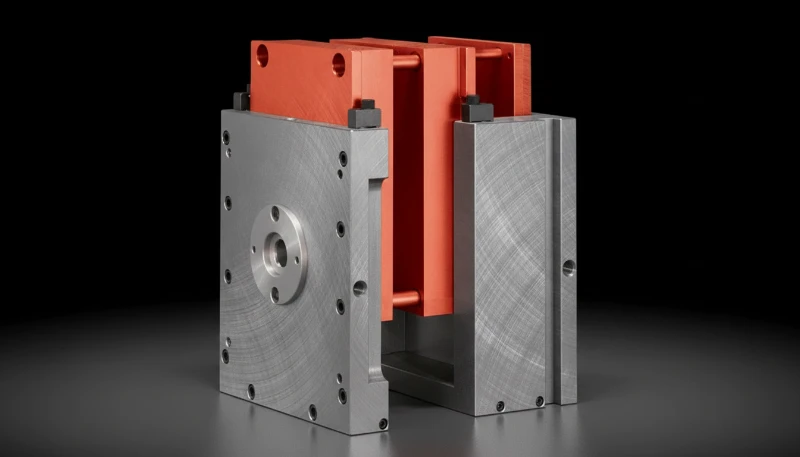

- MUD (Master Unit Die) System2: A modular tooling standard (originally developed by DME) consisting of a fixed H-frame installed in the machine and interchangeable inserts (containing the cavity and core). While a MUD frame can technically function as a family mold (holding two different inserts), the strategy typically implies running inserts sequentially or independently to maximize flexibility and process control.

Comparative Parameters: Risk, Cost, and Performance

The choice between family mold vs separate molds (via MUD) hinges on specific project metrics. The following table outlines standard industrial benchmarks.

| Parametro | Family Mold (Fixed) | MUD System (Modular Inserts) |

|---|---|---|

| Upfront Tooling Cost | Basso. One mold base for multiple parts. | Da basso a medio. One frame (asset) + separate inserts for each part. |

| Controllo del processo | Povero. One process window must satisfy all parts simultaneously. | Eccellente. Each insert runs with its own optimized pressure/temperature profile. |

| Tempo di ciclo | Compromised. Limited by the cooling time of the thickest part. | Optimized. Each part runs at its fastest possible cycle. |

| Gating/Runner System | Complex. Requires artificial balancing (runner shut-offs or variable diameters). | Simple. Standard gating optimized for the single part geometry. |

| Production Flexibility | Rigid. Must mold Part A and Part B in equal quantities. | High. Can mold 500 of Part A, then switch to Part B. |

| Scrap Rate | High. A defect in Part A rejects the whole shot or wastes Part B. | Low. Defects are isolated to the specific production run. |

Family molds are the most cost-effective solution for all multi-part projects.Falso

While tooling costs are lower, family molds often incur higher piece-part costs due to high scrap rates, slower cycle times (limited by the thickest part), and the inability to mold different quantities of each part.

Flow leaders and restrictors can be used to balance filling in family molds.Vero

Adjusting runner diameters (flow leaders/restrictors) is a standard method to artificially balance flow so disparate parts fill at the same time, though it narrows the processing window.

Detailed Comparison: Analyzing the Critical Trade-Offs

Quando molding disparate parts, the decision often comes down to three critical factors: Rheology, Inventory Management, and Risk.

1. Rheological Balance and Process Windows

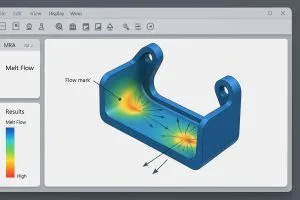

In a Family Mold3, the molten plastic enters the runner system and splits to fill different cavities.

- The Problem: If Part A is small/thin and Part B is large/thick, Part A fills first and may flash (over-pack) while Part B is still filling. If you lower the pressure to save Part A, Part B may suffer from short shots (incomplete filling).

- The MUD Advantage: By running Part A in its own MUD insert, you set the machine to a fast injection speed and low hold pressure. You then swap to the Part B insert and run high pressure and long cooling times. There is no compromise.

2. Inventory and Production Flexibility

Family molds lock production into a 1:1 ratio.

- The Scenario: If Part A (a button) is lost or damaged during assembly more often than Part B (the housing), you will eventually need to mold more buttons. In a family mold, you must mold the housing as well, creating "regrind" or waste.

- The MUD Advantage: MUD systems excel at production flexibility. You can install the "Button" insert, run 5,000 extra units, perform a 10-minute changeover, and return to standard production.

3. Tooling Risk Management

Tooling risk management involves predicting potential failure points.

- Family Mold Risk: If the cavity for Part A is damaged and requires repair, the entire mold (including Part B production) is down.

- MUD Advantage: If Insert A needs repair, it can be removed and sent to the toolroom. The frame remains in the machine, and production can continue with Insert B or C.

Pros and Cons of Each Approach

| Caratteristica | Stampi per la famiglia | MUD Systems (Modular) |

|---|---|---|

| Vantaggi | 1. Lowest initial mold base cost. 2. Guarantees color match between parts. 3. Single setup charge for the "set." | 1. Decoupled process windows (zero compromise). 2. Independent inventory control. 3. Rapid changeovers (<10 mins). 4. Scalable (add new inserts later). |

| Svantaggi | 1. High risk of molding disparate parts (imbalanced fill). 2. "Over-molding" the small part causing sticking/flash. 3. Zero flexibility in production ratios. | 1. Higher initial investment if buying the first MUD frame. 2. Slightly reduced usable platen area due to frame rails. 3. Requires disciplined storage of inserts. |

MUD systems are strictly reserved for prototyping and cannot handle high-volume production.Falso

MUD systems are widely used for high-volume production of small precision parts. Hardened steel MUD inserts can withstand hundreds of thousands of cycles.

Molding parts in a family mold ensures perfect color consistency between components.Vero

Since both parts are molded from the exact same barrel of resin in the same shot history, family molds provide the best possible color matching for adjacent aesthetic parts.

Practical Tips for Managing Multi-Part Tooling

If you must choose between these strategies, apply these engineering insights to mitigate risk.

- When using Family Molds: Attuare runner shut-offs. These are rotating dowels in the mold base that allow you to block flow to one cavity. This enables you to mold only Part A if Part B has sufficient inventory, although it disrupts the rheological balance of the system.

- When using MUD Systems: Standardize your insert sizes (e.g., 84/90 series). This allows any insert to fit into any compatible frame across your factory floor, maximizing machine utilization.

- Simulation is Mandatory: Before cutting steel for a family mold, run Moldflow® simulation. If the software shows a pressure imbalance greater than 15-20% between cavities, abandon the family mold concept and switch to MUD/separate molds.

Application Scenarios: Which to Choose?

Choose Family Molds When:

- Matched Sets: The parts are always sold/assembled together (e.g., left and right halves of a disposable casing).

- Similar Geometry: Both parts have nearly identical volume, wall thickness, and projected area.

- Material Consistency: Absolute color matching is the highest priority (e.g., automotive interior trim).

Choose MUD Systems When:

- Disparate Geometries: One part is thick/large, and the other is thin/small.

- Variable Demand: Spares or replacements are expected for specific components.

- Iterative Design: One part design is final, but the other is still undergoing revisions. You can modify one insert without touching the other.

- Resin Variety: You need to mold Part A in ABS and Part B in Polycarbonate (PC). This is impossible in a family mold.

Stepwise Decision Process Recommendations

Follow this logic flow to determine the correct tooling strategy:

- Analyze Geometry: Calculate the volume and wall thickness of Part A and Part B. Are they within 10% of each other?

- No: Stop. Use MUD Systems or Separate Molds.

- Yes: Proceed to step 2.

- Analyze Volume: Will these parts always be consumed at exactly a 1:1 ratio?

- No: Stop. Use MUD Systems.

- Yes: Proceed to step 3.

- Analyze Tolerance: Does either part have critical dimensions (< ±0.05 mm)?

- Yes: Avoid Family Molds. Use MUD to isolate the process window.

- No: Family Mold is a viable candidate for cost savings.

FAQ: Family Molds vs. MUD Systems

Can I run different materials in a family mold?

No. A family mold injects a single shot of material into multiple cavities. You cannot inject Nylon (PA) into one cavity and Polypropylene (PP) into another simultaneously. If you need different materials, you must use separate molds or MUD inserts run sequentially.

How do I fix filling imbalances in an existing family mold?

If the mold is already built, you can try:

- Adjusting Gate Sizes: Open the gate on the larger/harder-to-fill part to reduce pressure drop.

- Profiled Injection: Use multi-stage injection speeds to fill the runner system quickly, then slow down as the material enters the smaller cavity.

- Flow Leaders: Machine flow leaders (thicker flow paths) into the runner feeding the larger part.

Is a MUD frame expensive?

A standard MUD H-frame typically costs between $2,000 and $4,500 depending on size. However, this is a one-time asset. Subsequent inserts (which hold the actual part shape) are significantly cheaper than standalone mold bases, often resulting in ROI after just 2-3 projects.

Why do family molds have higher scrap rates?

In a family mold, if one cavity produces a defect (e.g., flash on the small part), the entire shot (including the good large part) is often scrapped because automatic sorting is difficult. Furthermore, the compromised process window makes defects more likely to occur.

Can MUD systems support sistemi a canale caldo4?

Yes. MUD frames and inserts can be designed to accept hot runner manifolds and hot drops. This reduces sprue waste, similar to standalone hot runner molds, though the plumbing connections add complexity to the quick-change process.

Sintesi

Deciding between Family Molds vs. MUD Systems requires balancing upfront budget against long-term operational efficiency. While family molds offer an attractive initial price point for multi-cavity tooling, they inherently couple the quality of disparate parts, leading to high tooling risk management challenges. For projects involving molding disparate parts with different volumes or variable demand, MUD systems provide the production flexibility and rigorous process control necessary to ensure consistent quality and minimize scrap.

-

Learn about multi-cavity tooling to optimize production efficiency and reduce costs in your projects. ↩

-

Gain insights into MUD systems and their benefits for flexible and efficient injection molding processes. ↩

-

Discover the pros and cons of Family Molds to make informed decisions for your injection molding projects. ↩

-

Explore the advantages of hot runner systems for reducing waste and improving efficiency in injection molding. ↩