Introduction

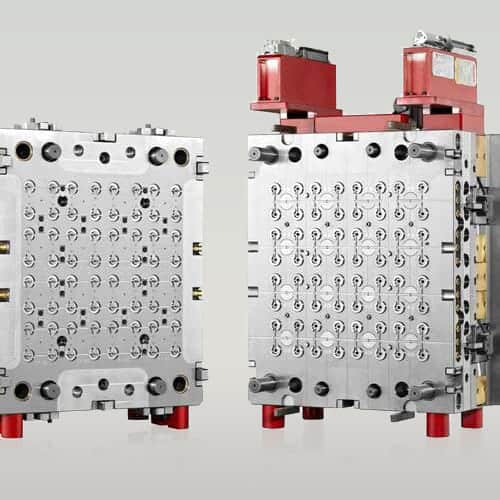

In the ever-evolving realm of fabrication, the significance of injection molds is monumental. These precision instruments form the cornerstone of the plastic injection molding sector, a domain encompassing a myriad of items, from vehicular elements to health apparatuses. The distinctiveness of these molds stems from their aptitude to craft plastics into complex, consistent, and superior quality components with exceptional adeptness. Their role transcends mere shaping; they are instrumental in fostering innovation, diminishing production expenditures, and augmenting uniformity in products.

Yet, the efficacy and financial viability of the injection molding procedure are intimately connected to the longevity of these molds. As any device of high precision, they experience attrition, confront thermal pressures, and may deteriorate due to continuous utilization. The more extended the mold’s capacity to retain its accuracy and functionality, the more substantial is the investment yield. Thus, the endeavor to amplify the full mold service life span of injection molds is not solely a technical quest but a paramount fiscal aspect. It necessitates a complex equilibrium of material choice, precision crafting, rigorous upkeep, and expert operation.

By investigating and applying methodologies to enhance the molds’ durability, manufacturers can reap considerable expense reductions, uphold elevated standards of production quality, and mitigate ecological impacts through reduced material wastage and energy consumption. The ensuing sections will probe into diverse dimensions and pragmatic methods aimed at this objective, confirming the endurance and ecological sustainability of this indispensable tool in manufacturing.

II.Understanding Injection Mold Wear and Tear

The durability and operational efficacy of injection molds are markedly influenced by a multitude of elements that precipitate attrition. Grasping these elements empowers manufacturers to devise strategies to augment and improve the service life lifespan of injection molds and uphold the caliber of plastic injection molds.

Elements Instigating Attrition Mechanical Exertion:

In the throes of the injection molding procedure, molds are subjected to incessant mechanical exertion. This stems from elevated injection pressures and the recurrent opening and shutting of the mold cavity. Progressively, this exertion can engender wear in the various mold components, constituents and on the mold surface.

Thermal Exertion:

Injection molds endure oscillating thermal stresses, with temperatures veering swiftly as heated, liquefied plastic is introduced and subsequently cooled. This incessant variation can culminate in thermal fatigue in the life of the mold material, impinging on its structural soundness.

Chemical Erosion:

Certain plastic substances utilized in injection molding can exhibit corrosive properties. As these substances interface with the mold surface, they can instigate chemical erosion, especially if the mold material is deficient in corrosion resistance.

Abrasive Erosion:

The unceasing flow of plastic material, notably when it encompasses fillers or reinforcements, can be abrasive to the mold surface, engendering gradual erosion.

Prevalent Types of Degradation Corrosion:

This emanates from chemical interactions between the mold material and the plastics or byproducts of the molding process. Over durations, corrosion can impair the mold surface, detracting from the quality of the molded components.

Abrasion:

Persistent contact with mobile plastic, particularly materials containing reinforcing agents, can result in abrasive erosion. This is manifested as erosion or wear on the mold surface, particularly in zones with elevated flow velocity or turbulence.

Thermal Fatigue:

Owing to repeated heating and cooling, micro-cracks can emerge in the mold material, enfeebling the mold structure. This is exacerbated by factors like excessive mold temperatures and inadequate heat treatment of the mold steel.

Comprehending these elements is crucial in formulating efficacious maintenance routines and operational methodologies that can diminish these damages, thereby prolonging mold life. The ensuing sections will explore material selection, design considerations, and maintenance strategies that are instrumental in enhancing mold life and preserving the longevity of injection molds.

III.Material Selection for Enhancing Mold Longevity

The pivotal aspect in amplifying the operational duration of injection molds lies in the judicious selection of materials. The apt selection not only influences the injection mold lifespan’s longevity but also its competence in withstanding wear, corrosion, and thermal fatigue.

Significance of Optimal Mold Material Selection Endurance and Abrasion Resistance:

The mold’s material necessitates resilience to endure the strenuous conditions of the injection molding process, including exposure to elevated pressures and abrasive plastic substances.

Thermal Conductivity and Equilibrium:

Superior thermal conductivity facilitates even heat dispersal, mitigating the likelihood of thermal fatigue and guaranteeing consistent mold temperatures.

Corrosion Resistance:

This characteristic is crucial for molds engaged with corrosive plastics, ensuring the preservation of the mold surface over prolonged use.

Delineation of Various Mold Materials Mold Steel:

Conventionally preferred for its robustness and endurance. High-caliber mold steel typically undergoes unique heat treatment methods to augment its resistance to wear and corrosion. It is exemplary for extensive-volume or prolonged-duration production due to its protracted mold life span.

Soft Aluminum Molds:

These molds are lighter and exhibit superior thermal conductivity compared to steel, resulting in swifter cooling durations and abbreviated cycle times. Nevertheless, their durability might not rival steel, particularly in high-volume production scenarios. Aluminum molds are frequently utilized in prototype development or short-run production.

IV. Pioneering Stratagems to Prolong Mold Longevity

The realm of injection molding is in a constant state of flux, marked by an influx of novel methodologies and cutting-edge technologies aiming to augment both the durability and efficacy of the injection mold life lifecycle. For manufacturers eager to secure a strategic advantage and escalate their production prowess, staying informed about these innovations is paramount.

Delving into Sophisticated Technologies in Injection Molding

3D Printing for Mold Fabrication: The fusion of 3D printing, or additive manufacturing, into the realm of mold crafting, facilitates the creation of more labyrinthine and meticulous mold designs. This avant-garde technique is capable of generating molds with elaborate cooling channels, enhancing thermal regulation, and mitigating thermal duress.

Intelligent Mold Sensors: The integration of sensors within molds empowers the real-time acquisition of pivotal data concerning temperature, pressure, and cycle durations. Such insights are instrumental in refining the molding process and circumventing scenarios that might precipitate premature mold degradation.

Automated Maintenance Mechanisms: The advancements in robotics and automation have given rise to automated maintenance systems. These contrivances can execute tasks like cleansing, scrutiny, and lubrication with unparalleled precision and uniformity.

Prospective Trends in Mold Fabrication Process and Material Election

Nano-coatings for Mold Exteriors: Implementing nano-coatings on mold surfaces can drastically elevate their resistance to wear and diminish the necessity for recurrent upkeep. These coatings also augment the mold’s part-release attributes, reducing the mechanical strain during component expulsion.

Advanced Composite Materials: Investigating novel composite materials presents auspicious prospects for mold creation. These materials amalgamate the virtues of metals and polymers, offering formidable strength-to-weight ratios and superior thermal attributes, potentially ushering in molds with extended longevity.

Bespoke Alloy Formulation: Forging custom alloys, specifically tailored for distinct molding applications, could transform the mold fabrication process. These alloys are envisioned to offer unmatched strength, thermal stability, and corrosion resistance, catering to the specific requisites of various injection molding procedures.

Sustainable Materials and Methods: In alignment with the industry’s pivot towards environmental stewardship, there’s an escalating interest in employing eco-conscious materials and methodologies in mold fabrication. This encompasses the utilization of recycled substances for mold construction and the innovation of more energy-efficient molding techniques.

V.Sustaining the Integrity of Injection Molds

Ensuring the longevity of injection molds is an integral task, necessitating scrupulous and methodical upkeep. This vigilant care not only augments the injection molding machine’s operational duration but also guarantees a uniform caliber in the injection molding sequence.

Essentiality of Habitual Upkeep

Thwarting Degradation: Habitual upkeep facilitates the precocious recognition and rectification of complications such as abrasion, oxidation, or misalignment, which, if unaddressed, hasten mold degradation.

Uniform Mold Efficacy: Molds that receive regular attention exhibit unwavering performance, yielding components of superior quality while diminishing the likelihood of operational interruptions stemming from mold malfunctions.

Cost-Effectiveness: Proactive mold maintenance emerges as a more economical strategy over time, in comparison to the expenditures linked with mold mending or substitution.

Optimal Procedures for Mold Cleansing and Thermal Regulation

Periodic Cleansing: To avert corrosion or accumulations within the mold cavities and on its surface, it’s crucial to execute routine cleansing. This encompasses both mechanical and chemical methods, as suitable.

Thermal Management: Managing mold temperatures judiciously is imperative to preclude thermal weariness and tension. This entails sustaining ideal coolant temperatures and flow rates within the life of the mold’s cooling apparatus.

Tactics to Curtail Excessive Abrasion

Lubrication: Diligent lubrication of components in motion, such as ejector pins and slides, is essential to mitigate friction and consequent abrasion.

Wear Plates Utilization: Implementing wear plates in areas subjected to high friction assists in uniformly distributing wear and allows for simpler replacement compared to mold repairs.

Surface Fortification: The application of protective layers on the mold surface bolsters its resistance to abrasion, particularly for molds employed with coarse materials.

Management of Parting Line Abrasion

Regular Surveillance: It’s pivotal to conduct frequent examinations of the parting lines for indications of wear or impairment. This region, where the mold halves converge, is especially susceptible to wear due to the repetitive opening and closing actions.

Accurate Alignment: Guaranteeing precise alignment of the mold halves in each cycle is vital in diminishing parting line abrasion.

Surface Enhancement: Administering hardening treatments or coatings to the parting line zone can amplify its wear resistance.

In conclusion, the adoption of comprehensive and regular maintenance protocols for injection molds transcends mere problem-solving. It embodies a forward-thinking strategy to elongate their functional life. This includes a blend of routine cleansing, temperature control, lubrication, and the strategic incorporation of wear-resistant materials and coatings for injection mold lifespan, all converging towards minimizing wear and upholding the quality of the molding operation.

conclusion

To encapsulate, the augmentation of an injection mold’s longevity is an integrative endeavor, encompassing the synergy of material sciences, engineering acumen, scrupulous upkeep, proficient handling, and innovative methodologies extending mold life. Such a harmonious orchestration of these facets empowers producers to bolster the resilience and operational efficacy of their molds, culminating in amplified productivity, economic prudence, and a fortified stance in the realm of manufacturing.