Injection molds are vital for producing plastic parts, consisting of multiple components that shape and form products in numerous industries.

An injection mold comprises core and cavity plates, sprue and runner systems, cooling channels, and ejector pins, collaboratively shaping, cooling, and releasing plastic products efficiently.

While this summary outlines the basic components of an injection mold, deeper insights into their specific functions and applications can further enhance your understanding. Continue reading to explore how each component contributes to efficient manufacturing processes.

Injection molds require both core and cavity plates.True

Core and cavity plates are essential in defining the shape of the molded part, working together to form its interior and exterior surfaces.

All injection molds include hot runner systems.False

Not all molds utilize hot runners; some employ cold runners, especially for less complex or lower-volume productions.

What is an Injection Mold?

Injection molds are essential tools in manufacturing, allowing for precise and repeatable production of plastic parts in various shapes and sizes.

Injection molds are intricate tools used to shape plastic with precision and efficiency, crucial for industries such as automotive, electronics, and consumer goods manufacturing.

An injection mold is a tool that produces plastic products by injecting molten plastic into a mold cavity1 using an injection molding machine. After the plastic cools and hardens, the desired plastic product can be produced. An injection mold consists of a movable mold and a fixed mold, which are installed on the movable mold plate and the fixed mold plate of the injection molding machine. During the plastic injection molding process, the movable mold and the fixed mold jointly complete the injection, cooling and ejection of the plastic.

Injection molds ensure high precision in part production.True

The molding process allows for tight tolerances, consistent quality, and reduced material waste, ensuring precise part production.

All injection molds are made from steel.False

While many molds are made from steel for durability, others can be made from aluminum or other materials depending on the application and production volume.

What are the Main Components of an Injection Mold?

Injection molds are essential in manufacturing, defining the shape and function of countless plastic products by providing a precise and repeatable structure.

An injection mold consists of a mold base, guide pins, cavities, cores, ejector system, cooling channels, and runner system, all collaborating to efficiently shape, cool, and eject molded parts.

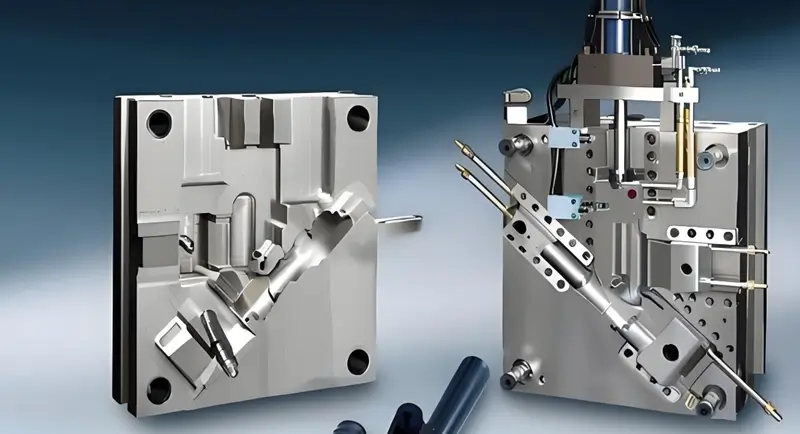

Fixed Mold and Moving Mold

The fixed mold and the movable mold are two parts (mold halves) of the injection mold, which are installed on the fixed and movable mold plates of the injection molding machine respectively. During injection, the movable mold and the fixed mold are combined, and there is a space in the middle, which is called a cavity. The molten plastic is injected into the cavity and cooled to form a product.

-

Fixed Mold: The fixed mold is provided on the fixed platen of the injection molding machine and does not shift while the machine is opening and closing. These are the fixed mold base plate and the fixed mold base and the fixed mold core among them. The fixed mold core combined with the moving mold core provides the cavity.

-

Moving Mold: The moving mold is installed on the moving plate of the injection molding machine2. The moving mold is generally composed of the moving mold base, the moving mold seat and the moving mold core. The moving mold core and the fixed mold core form the mold cavity.

Cavity and Core

The cavity and the core are identified as the main part of the injection mold because they define the shape and size of the final plastic product.

-

Cavity:The cavity is the depression on the interior side of the mold together with the moving mold core in the creation of the final products shape. Cavity design entails precise work so that the dimensions and look of the fabricated plastic product can be satisfactory.

-

Core: The core is the protruding part of the mold, which together with the fixed core constitutes the interior of the final product. The core consists of multiple sub-parts, namely the main core and auxiliary core, to accommodate complex product structures.

Guiding System

The guide system ensures that the movable mold and the fixed mold are accurately aligned during the opening and closing process to avoid inaccurate final products due to mold misalignment. The guide system3 is mainly composed of a main guide pin and a guide sleeve.

-

Guide Pins4: Guide pins are installed on the movable mold base plate to guide the opening and closing movement of the mold base and ensure that the mold can be accurately centered. Guide pins are generally made of high-strength steel and are precision-machined to ensure their straightness and wear resistance.

-

Guide Bushings: The guide bushings are installed on the fixed mold base plate and used in conjunction with the guide pin. The coaxiality requirements between the guide sleeve and the guide pin are relatively high, and the inner diameter of the guide sleeve needs to be closely matched with the outer diameter of the guide pin.

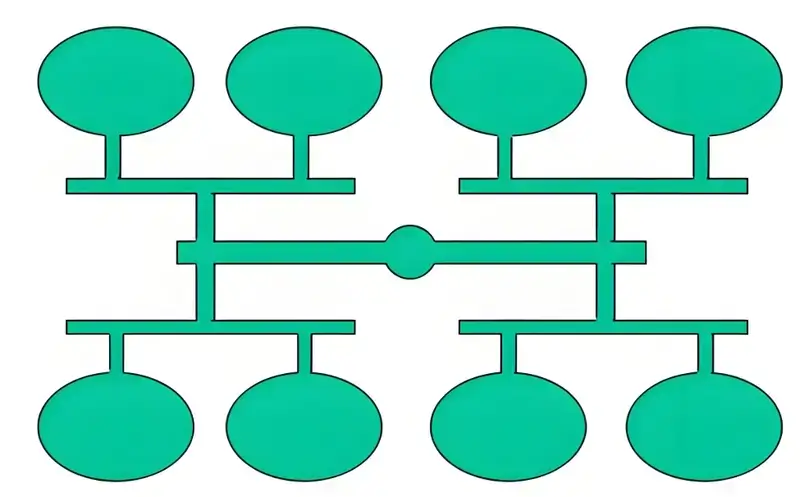

Runner System

The runner system directs the molten plastic to the cavity of the box, and it consists of the main runner, sub-runner, gate and cold slug well.

-

Main Runner: The main runner is that part of the mold via which the molten plastic is fed from the nozzle of injection molding machine directly to the mold cavity and is preferably on the fixed mold side. The main runner design should ensure smooth plastic flow and minimize pressure loss.

-

Sub-runner: Sub-runner dispenses the flowing molten plastic to each cavity, usually set between the moving and fixed molds. The cross-sectional shape and size of the sub-runner needs to be well designed to ensure even distribution of plastic to each cavity.

-

Gate: The gate is the final segment of the channel through which the plastic enters the cavity. That figure and dimension do impact on the quality of the products which it manufactures. Common gates types involves pin gate, edge gate, and submarine gate.

-

Cold Slug Well: Cold slug well is the one that holds waste material which forms after the cooling of the mold to avoid it interfere with the next injection. Cold slug well is normally positioned at the end of the sub-runner and shall be capable of efficiently removing cold material.

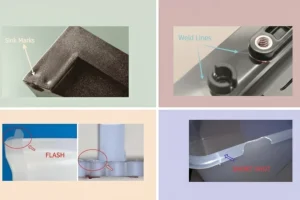

Venting System

The function of the exhaust system is to exhaust air and other gases from the cavity to avoid the formation of bubbles or voids that may affect product quality. The exhaust system can be exhaust grooves, exhaust holes or the space between the parting surfaces.

-

Vent Grooves: Vent grooves are thin longitudinal spaces on the edges of the mold cavity, normally provided at the thickest part or farthest from the gate. The parameters of the vent grooves must be defined very accurately to provide proper venting and not compromise the look of the product.

-

Vent Holes5: The vents are the thin openings located on the mold that assist in the release of gases within the cavity. The vent holes has to be designed and placed appropriately this to ensure they are not easily blocked by the molten plastic.

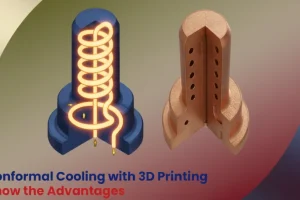

Cooling System

The main function of the cooling system is to control the mold temperature to ensure that the plastic product cools and solidifies within a reasonable time. The cooling system usually consists of cooling water channels and coolant. The cooling water channels are usually set near the mold cavity and core, and the circulating coolant takes away the heat of the mold to ensure product quality and production efficiency.

-

Cooling Channels6: Cooling channels are water circulation channels that are made in the mold and commonly created through drilling a machining operation. The distribution of a cooling channel should be reasonable mainly for proper cooling of the mold.

-

Cooling Fluid: Cooling medium for the mold is using a liquid either water or oil to take the heat away. The rate at which the cooling fluid flows and the temperature at which is matters a lot in the whole process hence needs to be regulated depending on the products to be produced.

Ejection System

The release system removes the cooled and solidified plastic product from the mold cavity with the help of ejector pins, ejector plates, and ejection system.

-

Ejector Pins7: The ejector pins are an important component of the ejection system. It moves under the action of the ejector plate to eject the product from the cavity. The type and position of the ejector should be selected according to the shape and size of the molded product to ensure uniform ejection force.

-

Ejector Plates: Ejector plates are plates in which ejector pins are fixed and are operated by the ejection system. The ejector plates normally slide against the moving mold base plate, so that the actions of ejection coincide.

-

Ejection Mechanisms: Ejection means operates the ejector plates and ejector pins and is usually by ejection cylinders or ejection hydraulic cylinder. The design of the ejection mechanisms should ensure sufficient ejection force and smooth action.

Support and Positioning System

The support and positioning system is responsible for supporting and fixing the mold components while maintaining the stability and accuracy of the mold during use. In most cases, the system requires a mold frame, support columns and positioning pins.

-

Mold Frame8: The mold frame supports the entire mold structure, normally choose steel material. Mold frame design should be in such a way that to manage the rigidity and stability of the mold for managing the forces for[injection molding.

-

Support Columns: Support columns support and fix the moving and fixed molds Usually it locates at the corner and some key points of moving and fixed molds. The design of support columns should depend with the size as well as the weight of the mold in order to consider the stability or not of the structure.

-

Positioning Pins:Positioning pins are used to ensure the correct positioning of the moving and fixed molds. These pins are usually located on the parting surface. The design and processing accuracy of the positioning pins directly determine the position centering of the mold.

Injection molds consist of multiple components working in harmony.True

No explanation available.

The ejector system is unnecessary in modern injection molds.False

The ejector system is crucial for releasing the finished parts from the mold, preventing damage and ensuring smooth production cycles.

What are the Auxiliary Components of an Injection Mold?

Auxiliary components are critical for enhancing the functionality and efficiency of injection molds, impacting various manufacturing processes.

Auxiliary components in injection molds, such as mold bases and ejector pins, enhance molding precision, cooling efficiency, and part ejection, optimizing overall performance.

Runner Plate

The runner plate gives direction to the molten plastic to every cavity, normally located on the stationary mold. The structure of runner plate mainly including the design and the machining precision will impact the qualification of the plastic products and the stability of the injection process largely.

- Runner Plate Design: The runner plate design should reflect on ways of having a smooth flow and proper dispersion of the molten plastic material. Cross-sectional dimensions of the runner plate have to be decided in order to reduce the flow resistance and the injection pressure drop.

Inserts

Inserts form complex structures or special shapes in the mold, usually designed to be removable for easy maintenance and replacement. When designing inserts, assembly and specific machining concerns should be taken into account so that the final product will be of high quality.

Seals

Seals do not allow the leakage of the already-formed molten plastic or the cooling fluid, ensuring the smooth injection process. Common sealing elements are O-rings, sealing rings and so on, which should be placed at the key sealing sections of the mold.

-

O-ring: O-ring9 is a commonly used seal, usually used in the cooling water circuit and hydraulic system of the mold. The material and size of the O-ring should be selected according to the use conditions to ensure its sealing performance and durability.

-

Sealing Rings: Sealing rings are used at the parting surfaces and guiding systems of the mold to prevent leakage of plastic pellets molten material or cooling fluid. Selection of the sealing rings should be done in order to match the application environment to obtain the best sealing efficiency and durability.

Springs and Buffers

Springs and buffers help to reduce and absorb the impact force during the opening and closing of the mold, helping in protecting the molds and injection molding machine. Specifications and parameters of the springs and buffers shall be chosen depending on the size of the mold and its weight to provide the designed spring and buffer function and durability.

-

Springs: Springs are used in ejection systems and guide systems to provide elastic force for ejection action and guide systems. The springs and their specifications and parameters should be selected and designed according to the structure and use of the mold.

-

Buffers: The buffer can protect the mold and injection molding machine during operations such as mold opening and closing. The mold\’s buffer must effectively disperse the impact force according to the quality of the mold and the closing speed of the mold.

Auxiliary components improve the precision of injection molds.True

Components like guide pins and ejector pins are designed to ensure accuracy and consistency, leading to precise molding outcomes.

All injection molds require the same auxiliary components.False

Different molds require different auxiliary components, depending on factors like design complexity and production requirements.

How is an Injection Mold Designed and Manufactured?

Injection mold design and manufacturing are vital processes in producing efficient, high-quality plastic parts, serving industries from automotive to consumer products.

Injection mold design focuses on crafting detailed templates for shaping plastic parts with precision. Essential elements include mold cavity design, material selection, and manufacturing techniques, ensuring accurate production and mold longevity.

Mold Design

Mold design is a crucial factor during the creation of an injection mold as it influences the mold efficiency as well as durability. Thus, it is necessary to consider organizational and technological factors such as the structure and size of a product, characteristics of the material and its shrinkage, injection molding machine, and process specifications to judge the rationality and manufacturability of the chosen mold design.

-

Product Structure Design: The structure and dimensions of the product are the fundamental aspect of the mold design, that is why there are exact requirments to the mold size and form. Designers should decide a reasonable structure and size according to the function of the product and the specific processing technique. Important manufacturing aspects of the design should include the mold’s manufacturing difficulty and cost if the latter yields the best results in manufacturing.

-

Material Selection10: The selection of mold materials significantly impacts the mold\’s performance and longevity. Popular mold materials are steel, aluminum alloy and engineered plastic. The decisions about the material selection must depend on the product material, production batch size, and usage of molds.

-

Flow Characteristics and Shrinkage: The flow of the plastic material and the shrinkage that occurs during the molding process affect the design of the mold strongly. It proposed that according to the flow of the material and the shrinkage tendency, designers should decide a suitable cavity and core structure to improve the dimensional accuracy of the final product, as well as the appearance quality.

-

Injection Molding Machine Parameters11: Injection molding machine parameters are closely related to mold design and manufacturing. Designers should determine reasonable mold structure and size based on parameters such as maximum injection volume, clamping force, and mold size to ensure mold compatibility and production efficiency.

Mold Manufacturing

Mold manufacturing involves material selection and subsequent processing, assembly and debugging of parts. Any mold manufacturing should follow the design drawings and process flow to ensure the accuracy and high quality of the mold.

-

Material Processing: Mold manufacturing mainly involves material processing that includes cutting, drilling, milling and heat treatment. Essentially, the high standards in working precision and suitable material working influence the mold decisively and its durability.

-

Parts Assembly:This is the process of bringing together of individual mold component to make a complete mold. In carrying out the assembly process, every assembly must meet the stipulated design requirements to enhance the fit precision of the individual parts; and the performance of the mold.

-

Mold Debugging: Mold debugging is the final process after mold manufacturing, whereby it becomes possible to check the mold design and manufacturing to standards and fix any problems. Debugging normally involves several mold injection and modification until the desired performance and quality are observed.

Mold Trial

After injection mold manufacturing, the mold trial should be conducted to check if the mold meets the design and manufacturing requirements as well as to find out existing problems. The mold trial, in most of the cases, involves several shots in the mold and subsequent modifications to align the mold with the desirable performance and quality standards.

-

Trial Preparation: One has to prepare for the trial whereby processes such as mold cleaning and lubrication, debugging of injection molding machines and preparing the raw material for use are carried out. The trial preparation ensures smooth trial processes and accurate trial results.

-

Trial Process: The performed injections and adjustments make up several stages of a trial, which allows checking the design and manufacturing of the mold. Throughout the trial period, the outcome of each injection should be documented for performance and quality evaluation to identify and resolve issues until the mold achieves the expected performance and quality.

-

Trial Result Analysis12: Trial result analysis is an important step, which serves as a reference for the confirmation of mold design and manufacturing. An evaluation of the results obtained from the trial will help reveal such flaws that would have affected the final quality of the mold. The analysis should include aspects such as dimensions of a product and its appearance quality, the working conditions of the moulds, etc. , durability, etc.

Injection molds are always made from metal.False

While metal is commonly used for durability, some molds for low-volume or prototype production can be made from plastics or silicone.

Precision in mold design impacts the final product quality.True

Accurate mold design ensures that parts are produced with correct dimensions and tolerances, leading to high-quality final products.

Conclusion

Injection molds play an important role in today\’s production. Because the structure of injection molds is very complex and the main components are also diverse, injection molds13 have become the key to the manufacturing process of plastic injection molded parts.

Understanding the injection mold components and their functions is more conducive to improving the level of mold design and manufacturing and promoting the upgrading of the manufacturing industry. I believe that this article\’s detailed introduction to injection molds and their components will be helpful to readers.

-

Exploring the concept of mold cavity will enhance your knowledge of how plastic products are shaped and formed. ↩

-

Understanding the injection molding machine is crucial for grasping the entire injection molding process and its applications. ↩

-

Learning about the guide system will help you understand how precision and alignment are maintained in the injection molding process. ↩

-

Understanding guide pins is crucial for ensuring accurate mold alignment and enhancing product quality in injection molding processes. ↩

-

Learning about vent holes can help in preventing defects in molded products by ensuring proper gas release during the injection process. ↩

-

Exploring cooling channels can provide insights into optimizing mold temperature control, leading to better product quality and production efficiency. ↩

-

Understanding ejector pins is crucial for optimizing the ejection process in injection molding, ensuring product quality and efficiency. ↩

-

Exploring mold frame design can enhance your knowledge of stability and rigidity in injection molding, leading to better product outcomes. ↩

-

Learning about O-ring selection can significantly improve sealing performance and durability in your injection molding processes. ↩

-

Exploring this resource will provide insights into choosing the right materials for optimal mold performance and longevity. ↩

-

Understanding these parameters is crucial for ensuring your mold design aligns with machine capabilities, enhancing production efficiency. ↩

-

This link will guide you through the essential steps in evaluating trial results, ensuring your mold meets quality standards. ↩

-

Learn about Everything You Need to Know about Plastic Injection Molds : Plastic injection molds shape plastic by injecting molten material into a mold cavity, where it cools and solidifies into a part. ↩