1. What is projected area injection molding?

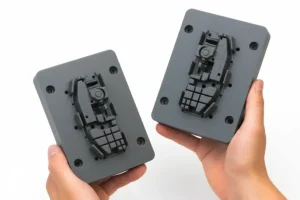

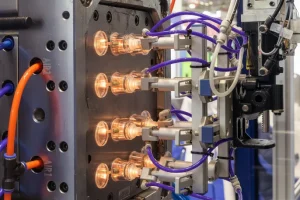

Through projected area injection molding, manufacturers can turn molten plastic into intricately-shaped and sized components that play a vital role in many products and industries.

This process offers the potential for improved production cycles, part quality, and cost savings over traditional manufacturing methods!

2. How important to calculate projected area injection molding?

Accurately determining the moldable area of an injection molded part is essential for all aspects of successful design.

The projected area, or “moldable area,” impacts not only the size and shape of a product’s final form but also determines how much material will be required to complete production.

To make sure your designs reach their full potential after being injected into a pressure-filled cavity, ensure that you accurately calculate this critical value before beginning any injection molding manufacturing process!

3. How to calculate projected area injection molding?

Calculating the projected area of a part for injection molding is easy when armed with the right information.

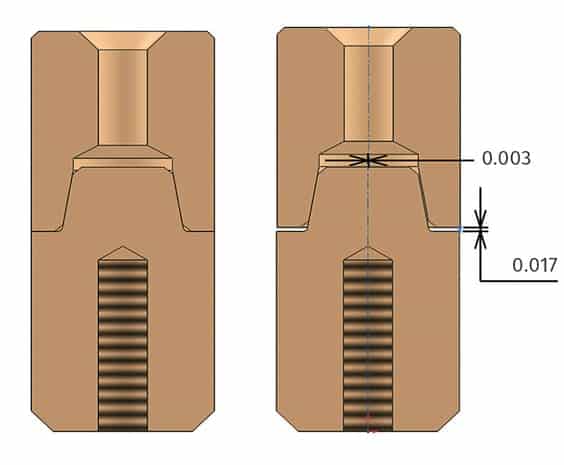

Begin by obtaining all available dimensions from your detailed drawing or 3D model, then specify which direction you’ll be measuring from – usually what will be visible once molded.

Finally, measure only those areas in that specific direction and plug them into square millimeters (mm²) or square inches (in²). Voilà! You’re ready to get an accurate projection of your product’s surface area.

With a 10mm x 20m rectangular block, the initial projected area is 200 mm².

However, when accounting for the part being angled or curved in its injection mold cavity, you must ascertain how much of your surface area will be making contact with this environment – usually through visual inspection and estimation.

For example: if 50% of that space comes into contact with the atmosphere inside there prior to solidification then it should provide an adjusted total dictated by multiplying both figures together; i.e., 100 mm² (200 mm ² x50%).

Determining the amount of plastic required for an injection mold is a critical step in the process and one that requires careful consideration.

By using projected area calculations to anticipate potential shrinkage during phase two it’s possible to accurately calculate how much raw material must be used.

However, as this method relies on estimated factors, professionals may wish to consult with experts or run trial injections before making final decisions about the quantities needed.

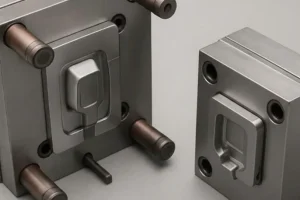

When designing a mold for injection molding, careful consideration must be given to more than just the projected area.

The type and properties of plastic utilized, as well as both the size and shape of the actual mould should all factor into your decision – in addition site evaluation to ensure that it is suitable for your chosen machine tonnage.

Conclusion

The injection molding process is a complex one, and understanding the projected area for clamp tonnage plays an integral role in successfully creating any part.

To measure this correctly requires careful consideration of both 2D drawings of the dimensions of the parts as well as factoring in what percentage will be touching the mold – all to accurately calculate how much material needs to go into production.