Formowanie wtryskowe to wszechstronny proces produkcyjny, który tworzy złożone części z wysoką precyzją, co czyni go niezbędnym w branżach takich jak motoryzacja i elektronika użytkowa.

Formowanie wtryskowe skutecznie wytwarza trwałe części poprzez wtryskiwanie stopionego materiału do form, charakteryzując się wysokim tempem produkcji, wszechstronnością materiału i minimalną ilością odpadów, dzięki czemu jest popularne w przemyśle motoryzacyjnym, elektronicznym i opakowaniowym.

Chociaż to podsumowanie podkreśla podstawowe zalety formowania wtryskowego, opanowanie jego mechaniki i wyboru materiałów jest niezbędne do maksymalizacji efektywności produkcji. Zanurz się głębiej, aby dowiedzieć się, jak różne techniki mogą poprawić wyniki produkcji.

Formowanie wtryskowe produkuje części z wysoką precyzją i powtarzalnością.Prawda

Formowanie wtryskowe pozwala na spójne tworzenie złożonych kształtów, zachowując wąskie tolerancje w dużych seriach produkcyjnych.

Formowanie wtryskowe jest odpowiednie tylko dla dużych partii.Fałsz

Chociaż jest to opłacalne w przypadku produkcji na dużą skalę, postęp technologiczny sprawił, że formowanie wtryskowe jest opłacalne w przypadku mniejszych partii, zwłaszcza w przypadku niestandardowych lub specjalistycznych części.

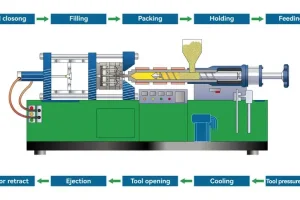

Jakie są etapy procesu formowania wtryskowego?

Proces formowania wtryskowego jest kluczową techniką wytwarzania złożonych części z tworzyw sztucznych w sposób wydajny i spójny w różnych branżach.

Proces formowania wtryskowego obejmuje topienie materiału, wtryskiwanie go do formy, chłodzenie i zestalanie oraz wyrzucanie gotowej części, zapewniając precyzję i powtarzalność w produkcji elementów z tworzyw sztucznych.

Przygotowanie i suszenie surowców

Pierwszy krok w Proces formowania wtryskowego1 jest przygotowanie surowców z tworzyw sztucznych. The surowce z tworzyw sztucznych2 są zwykle w postaci granulatu i muszą być odpowiednio wysuszone w zależności od rodzaju wybranego tworzywa sztucznego (np. polietylen, polipropylen, ABS itp.). Szczególnie w przypadku tworzyw sztucznych, które są wysoce higroskopijne (np. nylon, poliuretan itp.), należy je wysuszyć, aby zapobiec absorpcji wilgoci wpływającej na jakość formowania i powodującej wady, takie jak pęcherzyki i pęknięcia.

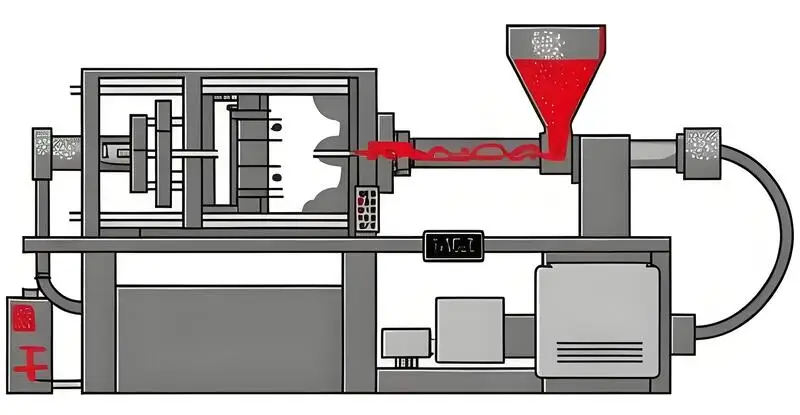

Topienie tworzyw sztucznych

Plastikowe granulki są umieszczane w cylindrze wtryskarki. Obracający się ślimak podgrzewa i topi tworzywo sztuczne. Temperatura musi być odpowiednia, aby plastik topił się i płynął prawidłowo. Temperatura, ciśnienie i przepływ stopionego plastiku są ważne dla dobrego wtrysku. Temperaturę, ciśnienie i przepływ należy dostosować do różnych tworzyw sztucznych.

Proces wtrysku

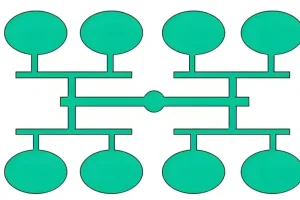

Gorące tworzywo sztuczne jest wtryskiwane do formy przez układ wtryskowy. Podczas procesu wtrysku śruba lub tłok wtryskarki wystrzeliwuje gorące tworzywo sztuczne do zamkniętej wnęki formy pod określonym ciśnieniem i z określoną prędkością.

Struktura i konstrukcja formy mają bezpośredni wpływ na precyzję, jakość powierzchni i efekt formowania produktu. Ciśnienie wtrysku, prędkość i czas utrzymywania muszą być dostosowane do złożoności produktu i charakterystyki formy.

Chłodzenie i utwardzanie

Po wtryśnięciu tworzywo sztuczne stygnie i twardnieje w formie, tworząc pożądany kształt. To, jak długo trwa chłodzenie, jest ważną częścią tego, jak działa formowanie wtryskowe. Jeśli ostygnie zbyt szybko, wytwarzana rzecz może zostać zepsuta lub nie zostać wykonana do końca. Jeśli chłodzi się zbyt wolno, produkcja może trwać zbyt długo. System chłodzenia musi być ustawiony w taki sposób, aby chłodził wszystko w ten sam sposób, aby nie doszło do wygięcia lub pęknięcia z powodu zbyt wysokiej lub zbyt niskiej temperatury w różnych miejscach.

Otwieranie i rozformowywanie form

Gdy plastikowa część ostygnie i zestali się, nadchodzi czas na otwarcie formy. Wtryskarka wykorzystuje urządzenie mechaniczne do otwierania formy. Forma musi być otwierana i zamykana z precyzją, aby uniknąć uszkodzenia części lub formy. Po wyrzuceniu części z formy jest ona zazwyczaj automatycznie usuwana przez robota lub inne urządzenie.

Obróbka końcowa i wykończenie

Po wyjęciu produktu z formy, może on wymagać obróbki końcowej, takiej jak pozbycie się wypływek (dodatkowego plastiku ze szczelin w formie), odcięcie wad powierzchniowych, szlifowanie itp. Te etapy przetwarzania końcowego3 może sprawić, że produkt będzie wyglądał lepiej i będzie bardziej precyzyjny.

Kontrola jakości i pakowanie

Wszystkie produkty z tworzyw sztucznych wymagają sprawdzenia, aby upewnić się, że mają odpowiedni rozmiar, dobrze wyglądają i działają prawidłowo. Sprawdzamy, jak wyglądają, mierzymy je i testujemy, aby upewnić się, że działają. Jeśli są dobre, wkładamy je do pudełka i wysyłamy do klienta. Jeśli produkujemy ich dużo, sprawdzamy niektóre z nich, aby upewnić się, że wszystkie są dobre.

Topienie materiału jest pierwszym etapem formowania wtryskowego.Prawda

Tworzywo sztuczne musi zostać podgrzane do stanu stopionego, aby mogło być skutecznie wtryskiwane do formy.

Formowanie wtryskowe nadaje się tylko do produkcji na dużą skalę.Fałsz

Chociaż jest to idealne rozwiązanie do produkcji masowej, formowanie wtryskowe może być również wykorzystywane do mniejszych serii produkcyjnych przy odpowiedniej konfiguracji i oprzyrządowaniu.

Jakie są cechy charakterystyczne formowania wtryskowego?

Formowanie wtryskowe jest szeroko stosowanym procesem produkcyjnym znanym ze swojej wydajności i wszechstronności, umożliwiającym wytwarzanie złożonych kształtów w różnych branżach.

Formowanie wtryskowe polega na wtryskiwaniu stopionego materiału do formy w celu wydajnego tworzenia precyzyjnych, złożonych części. Jest ono stosowane w branży motoryzacyjnej, produktów konsumenckich i urządzeń medycznych, oferując wysokie tempo produkcji i doskonałą dokładność wymiarową.

Ochrona środowiska, oszczędność energii

-

Przyjazny dla środowiska4:Formowanie wtryskowe5 jest lepsze dla środowiska. Podczas formowania wtryskowego z plastiku nie wydobywają się żadne szkodliwe substancje i jest to proces wolny od zanieczyszczeń. Ponadto plastikowe części wykonane metodą formowania wtryskowego można poddać recyklingowi, a ich recykling jest łatwy. Można wziąć zużyte plastikowe części, oczyścić je, zmiażdżyć, a następnie zrobić z nich nowe plastikowe części. W ten sposób nie wpływasz tak bardzo na środowisko. To bardziej ekologiczny sposób wytwarzania rzeczy.

-

Oszczędność energii:Formowanie wtryskowe6 to bardziej ekologiczny sposób wytwarzania rzeczy. Zużywa mniej energii niż inne sposoby wytwarzania plastikowych rzeczy. Może również wykorzystywać stary plastik do produkcji nowych rzeczy. I może tworzyć rzeczy, które się rozpadną i znikną.

Wysoka wydajność i precyzja

-

Wydajność: Formowanie wtryskowe jest bardzo wydajne. Umożliwia wytwarzanie większej ilości tworzyw sztucznych szybciej niż inne metody, takie jak wytłaczanie i rozdmuchiwanie. Ponadto można do tego użyć maszyn, więc nie trzeba płacić za to ludziom i można wyprodukować jeszcze więcej rzeczy.

-

Wydajność:Formowanie wtryskowe jest bardzo wydajnym procesem, ponieważ jest to ciągły proces produkcyjny. Wtryskarka wtryskuje roztopiony plastik do formy w krótkim czasie, a następnie można wyjąć gotowy produkt po jego ostygnięciu i stwardnieniu. W porównaniu z innymi sposobami wytwarzania przedmiotów z tworzyw sztucznych, formowanie wtryskowe jest znacznie szybsze, co czyni je bardziej wydajnym.

-

Wysoka precyzja7:Proces formowania wtryskowego może wytwarzać produkty z tworzyw sztucznych o wysokiej precyzji. Dostosowując parametry wtryskarki i konstrukcji formy, można bardzo dobrze kontrolować rozmiar, kształt i jakość powierzchni produktów z tworzyw sztucznych. Proces formowania wtryskowego jest więc preferowaną metodą produkcji precyzyjnych wyrobów z tworzyw sztucznych.

-

Wysoka precyzja:Proces formowania wtryskowego może wytwarzać produkty z tworzyw sztucznych o wysokiej precyzji wymiarowej i dobrej jakości powierzchni. Dzieje się tak, ponieważ formy stosowane w procesie formowania wtryskowego są bardzo precyzyjne, a tworzywo sztuczne nie kurczy się zbytnio po schłodzeniu i stwardnieniu. Ponadto można kontrolować precyzję wymiarową i jakość powierzchni produktu, zmieniając formę i sposób wtryskiwania tworzywa sztucznego.

-

Wysoka wydajność i precyzja:Formowanie wtryskowe to proces znany ze swojej precyzji i wydajności. Może tworzyć wszelkiego rodzaju złożone kształty w krótkim czasie przy użyciu odpowiednich form i materiałów. Pozwala również kontrolować rozmiar i jakość gotowego produktu oraz tworzyć produkty z tworzyw sztucznych, które są naprawdę dokładne i świetnie wyglądają.

-

Wysoka wydajność i precyzja:Cykl roboczy wtryskarki jest krótki i umożliwia ciągłą produkcję. Wysoka prędkość i ciągła produkcja wtryskarki znacznie poprawia wydajność produkcji. Formowanie wtryskowe jest więc wydajną i wysoce precyzyjną metodą przetwarzania, która może zaspokoić potrzeby różnych branż.

Niski koszt i dobre korzyści ekonomiczne

-

Niski koszt8: W porównaniu z innymi sposobami wytwarzania rzeczy, formowanie wtryskowe jest tanie, ponieważ jest szybkie i wykorzystuje dużo materiału. Dzięki formowaniu wtryskowemu można wyprodukować wiele rzeczy w krótkim czasie i łatwo jest użyć do tego maszyn, więc nie trzeba płacić za to ludziom. I jest to tanie. Ponadto do formowania wtryskowego można używać maszyn, dzięki czemu można naprawdę szybko wyprodukować wiele rzeczy.

-

Niski koszt: Koszt produkcji formowania wtryskowego jest stosunkowo niski. W porównaniu z innymi metodami przetwarzania tworzyw sztucznych, formowanie wtryskowe nie wymaga wysokich surowców i mniejszego zużycia energii w procesie produkcyjnym. Ponadto formowanie wtryskowe może realizować produkcję masową, zmniejszając koszt produkcji na jednostkę produktu.

-

Niski koszt, dobra wydajność ekonomiczna:Formowanie wtryskowe to tani i wydajny proces. Wymaga mniej sprzętu i ma niższe koszty produkcji w porównaniu z innymi metodami przetwarzania tworzyw sztucznych. Ponadto produkty formowane wtryskowo mają wysoką wartość dodaną, co pomaga firmom zarabiać więcej pieniędzy.

Szeroki wybór materiałów i produktów

- Szeroki zakres materiałów: Formowanie wtryskowe to wszechstronny proces, który może być stosowany z różnymi tworzywami sztucznymi, w tym zarówno termoplastycznymi, jak i termoutwardzalnymi. Materiały te mają różne właściwości, dzięki czemu można wybrać odpowiedni dla swojego produktu. Wybierając odpowiedni materiał z tworzywa sztucznego do formowania wtryskowego, można upewnić się, że produkt spełnia wymagania dotyczące wydajności.

-

Szeroki zakres materiałów:Proces formowania wtryskowego może być stosowany z szeroką gamą tworzyw sztucznych, w tym polietylenem, polipropylenem, polichlorkiem winylu, polistyrenem, ABS, PC, POM i innymi. Różne rodzaje tworzyw sztucznych mają różne właściwości, takie jak odporność na ciepło, odporność chemiczna, wytrzymałość, sztywność itp. Dlatego proces formowania wtryskowego może wybrać odpowiedni materiał z tworzywa sztucznego w oparciu o wymagania dotyczące wydajności produktu.

-

Bogata różnorodność produktów:Proces formowania wtryskowego może wytwarzać wszelkiego rodzaju produkty z tworzyw sztucznych, takie jak rzeczy, których używasz na co dzień, rzeczy dla fabryk, części samochodowe, części komputerowe i wiele innych. Możesz tworzyć różne kształty, rozmiary i rodzaje tworzyw sztucznych, zmieniając formę i sposób wykonywania procesu.

Wysoki stopień automatyzacji i złożone kształty

-

Wysoki stopień automatyzacji:Formowanie wtryskowe jest procesem wysoce zautomatyzowanym. Można go zautomatyzować od przygotowania surowca, formowania wtryskowego, chłodzenia, rozformowywania i przetwarzania końcowego, co zmniejsza koszty pracy i poprawia wydajność produkcji. Wtryskarka jest wysoce zautomatyzowana i zapewnia stabilny proces produkcji dzięki takim funkcjom jak przełączanie form, kontrola temperatury, ciśnienia i regulacja prędkości.

-

Wysoki stopień automatyzacji:Proces formowania wtryskowego można zautomatyzować. Korzystając z robotów, zautomatyzowanych linii produkcyjnych i innego sprzętu, można zautomatyzować formowanie wtryskowe, wyjmowanie z formy, chłodzenie i inne procesy, co poprawi wydajność produkcji i jakość produktu.

-

Wysoki stopień automatyzacji:Formowanie wtryskowe to proces, który może automatycznie wytwarzać rzeczy, dzięki czemu nie trzeba tak ciężko pracować i można wytwarzać więcej rzeczy. Nowe maszyny mogą same wkładać materiał do formy, zamykać ją, chłodzić i otwierać. Są łatwe w obsłudze. Formowanie wtryskowe jest również bardzo zautomatyzowanym procesem, dzięki czemu można produkować wiele rzeczy jednocześnie.

-

Złożony kształt:The Proces formowania wtryskowego9 może wytwarzać wszelkiego rodzaju produkty o złożonych kształtach, w tym części wydrążone, cienkościenne itp. Odpowiednie zaprojektowanie struktury formy pozwala na dokładne odwzorowanie szczegółów, dzięki czemu formowane produkty charakteryzują się wysoką precyzją i jakością.

Duża zdolność adaptacji i elastyczna konstrukcja formy

-

Silna zdolność adaptacji: Proces formowania wtryskowego może być stosowany z różnymi rodzajami tworzyw sztucznych i konstrukcji form. Różne rodzaje tworzyw sztucznych mają różne właściwości fizyczne i charakterystyki przetwarzania. Proces formowania wtryskowego może być stosowany z różnymi rodzajami tworzyw sztucznych poprzez wybór odpowiedniej wtryskarki, formy i parametrów procesu. Ponadto proces formowania wtryskowego może być stosowany z różnymi rodzajami złożonych struktur form, aby spełnić wymagania projektowe różnych produktów.

-

Silna zdolność adaptacji:Formowanie wtryskowe to dobry sposób na wytwarzanie wszelkiego rodzaju produktów z tworzyw sztucznych, takich jak pudełka, skorupy, rury, folie, arkusze, rury i kształtki. Formowanie wtryskowe można również wykorzystać do wytwarzania różnego rodzaju produktów z tworzyw sztucznych, takich jak rzeczy, których używasz na co dzień, rzeczy dla fabryk, części samochodowych i elektroniki. Możesz także użyć formowania wtryskowego do tworzenia rzeczy o różnych kształtach, rozmiarach i rodzajach plastiku. Formowania wtryskowego można również używać do wytwarzania rzeczy na różne sposoby, takie jak formowanie wtryskowe i rozdmuchowe, formowanie wtryskowe i ciągnięcie wtryskowe oraz formowanie wtryskowe i prasowanie na gorąco.

- Elastyczna konstrukcja formy: Konstrukcja formy w procesie formowania wtryskowego jest bardzo elastyczna i może być zaprojektowana zgodnie z kształtem, rozmiarem i wymaganiami dotyczącymi wydajności produktu. Ponadto struktura formy wtryskowej jest prosta, łatwa w produkcji i utrzymaniu.

Szeroki zakres zastosowań i łatwa personalizacja

-

Szeroki zakres zastosowań:Formowanie wtryskowe może być stosowane z wszelkiego rodzaju tworzywami sztucznymi, w tym termoplastycznymi i termoutwardzalnymi tworzywami sztucznymi, i może wytwarzać wszelkiego rodzaju produkty o różnych rozmiarach i kształtach, takie jak części plastikowe, zabawki, meble, urządzenia elektryczne, części samochodowe i tak dalej. Formowanie wtryskowe jest więc wykorzystywane w wielu różnych branżach.

-

Spersonalizowane dostosowanie: Formowanie wtryskowe to proces, który może zaspokoić zapotrzebowanie na Spersonalizowane dostosowanie10. Dostosowując projekt formy i parametry procesu, możemy wytwarzać produkty z tworzyw sztucznych o spersonalizowanych właściwościach. Dlatego właśnie formowanie wtryskowe jest preferowaną metodą produkcji spersonalizowanej.

Stała jakość produktów i łatwość wprowadzania innowacji produktowych

-

Stabilna jakość produktu:Formowanie wtryskowe jest znane ze stałej jakości produktu. Dzięki ścisłej kontroli parametrów wtryskarki, projekt formy11i procesu produkcyjnego, możesz mieć pewność, że Twoje produkty z tworzyw sztucznych będą niezmiennie wysokiej jakości. Ponadto formowanie wtryskowe pozwala na ciągłą produkcję, co oznacza mniejsze wahania jakości produktu.

-

Łatwa realizacja innowacji produktowych:Formowanie wtryskowe to proces, który ułatwia wprowadzanie innowacji do produktów. Można tworzyć nowe produkty z tworzyw sztucznych, ulepszając konstrukcję formy i ustawienia procesu. Formowanie wtryskowe można również łączyć z innymi procesami tworzyw sztucznych, aby tworzyć bardziej skomplikowane produkty.

Formowanie wtryskowe pozwala na wysokie tempo produkcji.Prawda

Proces ten pozwala na szybką produkcję dużej liczby części dzięki krótkim czasom cyklu i możliwości automatyzacji.

Formowanie wtryskowe nadaje się tylko do dużych serii produkcyjnych.Fałsz

Chociaż jest to idealne rozwiązanie dla dużych ilości, postęp technologiczny sprawia, że formowanie wtryskowe jest opłacalne dla mniejszych partii z opłacalnymi rozwiązaniami narzędziowymi.

Jakie są wady formowania wtryskowego tworzyw sztucznych?

Formowanie wtryskowe tworzyw sztucznych jest szeroko stosowanym procesem produkcyjnym, ale ma pewne wady, które wpływają na produkcję i efektywność kosztową.

Wady formowania wtryskowego tworzyw sztucznych obejmują kosztowne oprzyrządowanie, wydłużony czas realizacji, ograniczenia projektowe, potencjalne wady, takie jak wypaczenie, oraz obawy środowiskowe związane z odpadami, które nie ulegają biodegradacji.

Wysokie koszty początkowe

Formowanie wtryskowe tworzyw sztucznych12 jest skomplikowana. Tylko doświadczeni inżynierowie wiedzą, jak je zaprojektować i zbudować, co oznacza wysokie koszty pracy. Ponadto, istnieje wiele kroków związanych z tworzeniem formy, a z czasem będzie ona produkować miliony identycznych części. Prosta forma jednogniazdowa zaczyna się od $2,000-$3,000. A wielkoseryjna, wielogniazdowa forma wykonana z hartowanej stali narzędziowej może kosztować $100,000 lub więcej.

Długie czasy realizacji

Dobra plastikowa forma wtryskowa przetrwa całe życie. Dlatego też jej prawidłowe wykonanie wymaga wiele planowania i testowania. Etapy projektowania, prototypowania, testowania i obróbki mogą trwać miesiącami. Formowanie wtryskowe tworzyw sztucznych ma długą cykl produkcyjny13 w porównaniu z innymi rodzajami produkcji tworzyw sztucznych.

Jeśli potrzebujesz formy, która może wytwarzać wiele plastikowych części za jednym razem, może to potrwać jeszcze dłużej. W przypadku tego typu form, producent może nawet zaprojektować, zbudować i przetestować narzędzie z pojedynczą wnęką, zanim spróbuje wykonać formę z pojedynczą wnęką. Narzędzie wielogniazdowe14. Oczywiście fazy projektowania, prototypowania, budowy i testowania muszą być powtarzane również w przypadku narzędzi z wieloma wnękami.

Jednak po zakończeniu fazy planowania i przetwarzania, formy wtryskowe z tworzyw sztucznych mogą produkować miliony części przez cały okres ich użytkowania. Skala produkcji części z tworzyw sztucznych często przekracza koszty początkowe i stracony czas.

Materiały nie do wygięcia

W przeciwieństwie do obróbki CNC, która tworzy fizyczne części z komputerowych plików projektowych, które mogą być zmieniane przez inżynierów oprogramowania w dowolnym momencie, trudno jest wprowadzić duże zmiany w plastikowej formie po obróbce, ponieważ jest ona zwykle wykonana ze stali.

Istnieją dwa sposoby zmiany formy plastikowej. Jednym z nich jest powiększenie wnęki formy poprzez wycięcie metalowej części formy. Powoduje to dodanie plastiku do części. Usunięcie plastiku z części jest trudniejsze. Czasami można przyspawać metal do wnęki, ale czasami nie można i potrzebna jest nowa wnęka lub zupełnie nowa forma. Oznacza to powrót do fazy projektowania.

Ograniczenia projektowe

Formowanie wtryskowe tworzyw sztucznych polega na podgrzewaniu i chłodzeniu plastiku. Jeśli kształt formy powoduje, że tworzywo sztuczne stygnie nierównomiernie, część z tworzywa sztucznego będzie miała wady. Można zmniejszyć to ryzyko, upewniając się, że ścianki formy mają ten sam rozmiar, aby części utwardzały się równomiernie. Idealnie, plastikowe formy wtryskowe15 powinny mieć ścianki nie grubsze niż 4 mm i nie cieńsze niż 0,5 mm. Należy pamiętać, że im grubsze ścianki, tym dłużej będzie trwał każdy cykl.

Ograniczenia rozmiaru

Jeśli trzeba wykonać duże plastikowe części, formowanie wtryskowe ma swoje ograniczenia. Istnieją wtryskarki wystarczająco duże, aby produkować kadłuby, ale scenariusze formowania, o których mówię w tym artykule, dotyczą mniejszych części, o wadze do trzech funtów. Jeśli potrzebujesz większych części, czas realizacji i koszty mogą wzrosnąć wykładniczo.

Formowanie wtryskowe tworzyw sztucznych wiąże się z wysokimi kosztami oprzyrządowania.Prawda

Początkowa inwestycja w formy do formowania wtryskowego tworzyw sztucznych może być znaczna, często czyniąc ją nieopłacalną w przypadku małych serii produkcyjnych.

Procesy formowania wtryskowego tworzyw sztucznych wytwarzają odpady ulegające biodegradacji.Fałsz

Odpady tworzyw sztucznych z procesów formowania wtryskowego zazwyczaj nie ulegają biodegradacji, co przyczynia się do problemów środowiskowych, chyba że zastosowane zostaną odpowiednie środki recyklingu.

Jakie branże wykorzystują formowanie wtryskowe?

Formowanie wtryskowe jest wszechstronnym procesem produkcyjnym stosowanym w wielu branżach w celu wydajnego wytwarzania wysokiej jakości, skomplikowanych części z tworzyw sztucznych.

Formowanie wtryskowe jest niezbędne w branżach takich jak motoryzacja, elektronika i lotnictwo, oferując wysoką precyzję, skalowalność i opłacalność produkcji masowej.

Artykuły gospodarstwa domowego

Formowanie wtryskowe to proces, w którym można wytwarzać wszelkiego rodzaju plastikowe przedmioty, których używamy na co dzień, takie jak szczoteczki do zębów, plastikowe kubki, pojemniki na żywność, butelki na leki i grzebienie. Możemy tworzyć plastikowe rzeczy do naszych domów i plastikowe pojemniki na nasze rzeczy w różnych kształtach i rozmiarach. Formowanie wtryskowe to szybki i tani sposób na wytwarzanie plastikowych przedmiotów, których używamy na co dzień.

Produkty elektroniczne

Proces formowania wtryskowego jest szeroko stosowany w produkcji wyrobów elektronicznych. Może być stosowany do wytwarzania różnych produktów, takich jak obudowy telefonów komórkowych, klawiatury komputerowe, myszy komputerowe, piloty zdalnego sterowania, obudowy baterii itp. Proces formowania wtryskowego może zapewnić szeroki zakres opcji wyglądu i struktury produktów elektronicznych.

Komponenty te muszą charakteryzować się nie tylko dobrymi właściwościami mechanicznymi i wyglądem, ale także doskonałymi właściwościami izolacji elektrycznej, aby zapewnić stabilne działanie produktów elektronicznych.

Formowanie wtryskowe może wytwarzać produkty z tworzyw sztucznych o dobrym wyglądzie i wysokiej precyzji, aby spełnić wymagania dotyczące wyglądu i rozmiaru produktów elektronicznych. Technologia formowania wtryskowego z jej wysoką precyzją i niskimi kosztami, w produkcji produktów elektronicznych zajmuje ważną pozycję.

Części samochodowe

Jeśli chodzi o produkcję samochodów, formowanie tworzyw sztucznych może stworzyć prawie wszystko w samochodzie. Od nadwozia, przez światła, wnętrze, aż po silnik, formowanie wtryskowe może tworzyć części, które dobrze wyglądają i dobrze działają. Na przykład deska rozdzielcza, konsola środkowa, klamki drzwi i tym podobne. Części te muszą być mocne i dobrze wyglądać, a formowanie wtryskowe jest najlepszym sposobem na ich wykonanie.

Co więcej, wraz z pojawieniem się nowych pojazdów energetycznych, formowanie wtryskowe części w akumulatorze, obudowie silnika i innych kluczowych elementach produkcji również odgrywa ważną rolę. Dzięki formowaniu wtryskowemu można osiągnąć masową produkcję i zapewnienie jakości części samochodowych. Dzięki formowaniu wtryskowemu można osiągnąć masową produkcję i zapewnienie jakości części samochodowych.

Urządzenia medyczne

Urządzenia medyczne są wytwarzane metodą formowania wtryskowego. Części formowane wtryskowo16 są ważne w branży urządzeń medycznych. Formowanie wtryskowe jest wykorzystywane do produkcji strzykawek medycznych, worków infuzyjnych i obudów urządzeń medycznych. Części te muszą być biokompatybilne i odporne na korozję, aby zapewnić bezpieczeństwo pacjentów i prawidłowe działanie sprzętu.

Technologia formowania wtryskowego może produkować części spełniające standardy branży urządzeń medycznych, zapewniając silną gwarancję rozwoju branży medycznej. Urządzenia medyczne wymagają wysokiego poziomu precyzji i higieny, a proces formowania wtryskowego może wytwarzać urządzenia z tworzyw sztucznych, które spełniają te wymagania.

Przemysł urządzeń gospodarstwa domowego

Jeśli chodzi o produkcję urządzeń domowych, formowanie tworzyw sztucznych jest wykorzystywane do produkcji części do urządzeń domowych na całym świecie. Obudowy telewizorów, panele klimatyzatorów, obudowy pralek i inne części urządzeń domowych, takie jak ich wygląd i sposób montażu, są w większości wykonane przy użyciu formowania wtryskowego.

Części te muszą być wytrzymałe i odporne na zużycie. Muszą być również w stanie wytrzymać próbę czasu i zapewnić ludziom bezpieczeństwo. Formowanie wtryskowe może tworzyć części, które są po prostu odpowiednie i dlatego jest tak ważne dla branży AGD.

Części te nie tylko muszą charakteryzować się wysoką wytrzymałością i odpornością na ścieranie, ale także muszą mieć dobre właściwości przeciwstarzeniowe, aby zapewnić żywotność i bezpieczeństwo urządzeń gospodarstwa domowego. Technologia formowania wtryskowego może produkować precyzyjne części, które spełniają te wymagania, zapewniając silne wsparcie dla rozwoju branży AGD.

Budowa

Formowanie wtryskowe jest szeroko stosowane w przemyśle budowlanym, gdzie jest wykorzystywane do produkcji rur PVC, zaworów, kanałów kablowych i innych materiałów budowlanych. Części te są nie tylko wytrzymałe i odporne na korozję, ale także mają dobrą odporność na warunki atmosferyczne i są łatwe w montażu. Spełnia to wymagania branży budowlanej dotyczące materiałów, które dobrze się sprawdzają i są łatwe w obróbce.

Zastosowanie technologii formowania wtryskowego w budownictwie nie tylko poprawia wydajność i jakość materiałów budowlanych, ale także pomaga branży budowlanej stać się bardziej zrównoważoną.

Formowanie wtryskowe jest idealne do produkcji wielkoseryjnej.Prawda

Jego zdolność do szybkiej produkcji identycznych części sprawia, że idealnie nadaje się do produkcji na dużą skalę.

Wszystkie branże wykorzystują formowanie wtryskowe do swoich produktów.Fałsz

Nie wszystkie branże wymagają produkcji wielkoseryjnej, jaką oferuje formowanie wtryskowe; niektóre mogą wykorzystywać alternatywne metody produkcji.

Wnioski

Formowanie wtryskowe ma wiele zalet. Jest super precyzyjne, super wydajne i może tworzyć wszelkiego rodzaju złożone kształty. To sprawia, że idealnie nadaje się do robienia mnóstwa rzeczy na raz i jest świetne, aby upewnić się, że wszystko wyjdzie tak samo.

Jest to również bardzo zautomatyzowane, więc nie trzeba robić wielu rzeczy ręcznie, co pozwala zaoszczędzić pieniądze. Rozpoczęcie pracy jest kosztowne i trzeba mieć do tego czyste miejsce, ale można używać wszelkiego rodzaju tworzyw sztucznych, więc jest używany wszędzie.

-

Zrozumienie procesu formowania wtryskowego ma kluczowe znaczenie dla każdego, kto zajmuje się produkcją. Ten zasób zapewnia kompleksowy przegląd. ↩

-

Zapoznanie się z rodzajami surowców z tworzyw sztucznych może pomóc w wyborze odpowiedniego dla danego projektu, zapewniając jakość i wydajność. ↩

-

Poznanie etapów obróbki końcowej może poprawić jakość formowanych produktów, czyniąc je bardziej precyzyjnymi i atrakcyjnymi wizualnie. ↩

-

Dowiedz się, w jaki sposób formowanie wtryskowe minimalizuje zanieczyszczenie środowiska i promuje recykling, co czyni je zrównoważonym wyborem do produkcji tworzyw sztucznych. ↩

-

Poznaj zalety formowania wtryskowego, w tym wydajność i korzyści dla środowiska, aby zrozumieć jego znaczenie w produkcji. ↩

-

Poznaj zalety formowania wtryskowego, w tym wydajność, precyzję i opłacalność, aby lepiej zrozumieć nowoczesne techniki produkcji. ↩

-

Dowiedz się, w jaki sposób wysoka precyzja formowania wtryskowego prowadzi do najwyższej jakości i spójności produktu, co czyni ją niezbędną w różnych branżach. ↩

-

Dowiedz się, dlaczego formowanie wtryskowe jest opłacalnym rozwiązaniem dla produkcji masowej, pomagającym firmom zaoszczędzić pieniądze przy jednoczesnym zachowaniu jakości. ↩

-

Zrozumienie procesu formowania wtryskowego może poszerzyć wiedzę na temat technik produkcji i ich zastosowań w różnych branżach. ↩

-

Zapoznanie się ze spersonalizowaną personalizacją może pomóc w zrozumieniu, jak sprostać konkretnym wymaganiom rynku i zwiększyć atrakcyjność produktu. ↩

-

Dowiedz się, jak konstrukcja formy wpływa na jakość i wydajność procesów formowania wtryskowego tworzyw sztucznych. ↩

-

Poznaj zalety formowania wtryskowego tworzyw sztucznych, aby zrozumieć jego wpływ na wydajność produkcji i jakość produktu. ↩

-

Odkryj zawiłości cyklu produkcyjnego w formowaniu wtryskowym tworzyw sztucznych i jego implikacje dla produkcji. ↩

-

Zapoznanie się z narzędziami wielogniazdowymi może poszerzyć wiedzę na temat zaawansowanych technik produkcyjnych i ich korzyści w zakresie wydajności produkcji. ↩

-

Zrozumienie form wtryskowych z tworzyw sztucznych ma kluczowe znaczenie dla każdego, kto zajmuje się produkcją, ponieważ są one kluczem do wydajnego wytwarzania wysokiej jakości części z tworzyw sztucznych. ↩

-

Dowiedz się wszystkiego, co musisz wiedzieć o częściach formowanych wtryskowo: Części formowane wtryskowo są tworzone poprzez wtryskiwanie stopionego materiału do formy. ↩