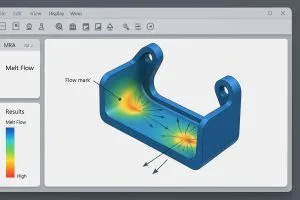

– Root cause analysis often points to the “Process-Mold-Material” triangle; adjustments must be isolated to one variable at a time.

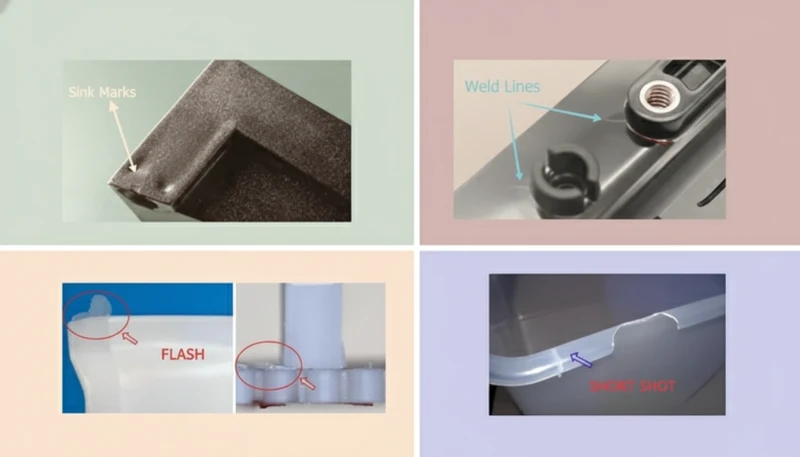

– Flash is typically a clamping force or tooling alignment issue, while sink marks result from thermal contraction in thick areas.

– Warpage is driven by differential shrinkage caused by uneven cooling or fiber orientation.

– Short shots indicate flow hesitation, often requiring venting improvements or temperature increases.

What is the Impact of Defects on Injection Molding Efficiency?

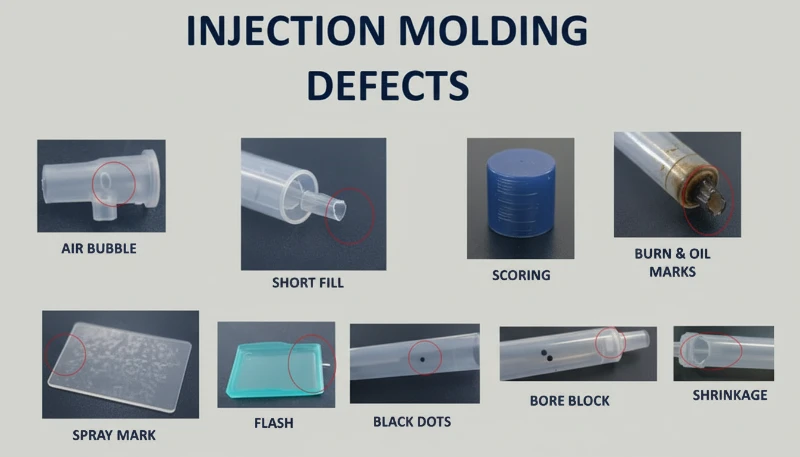

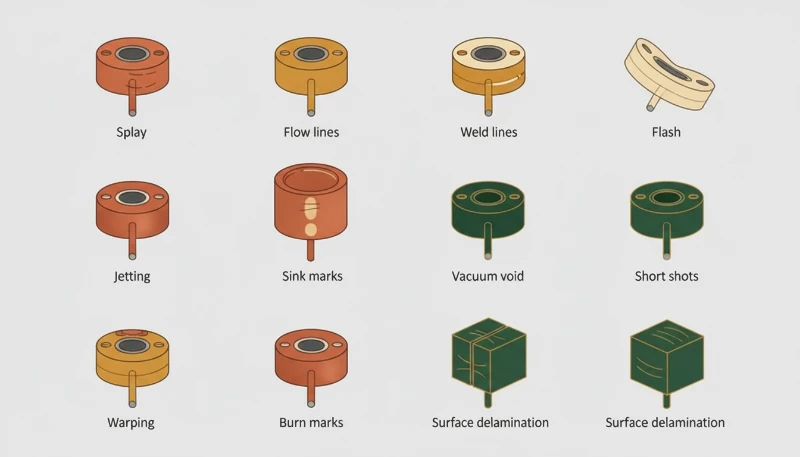

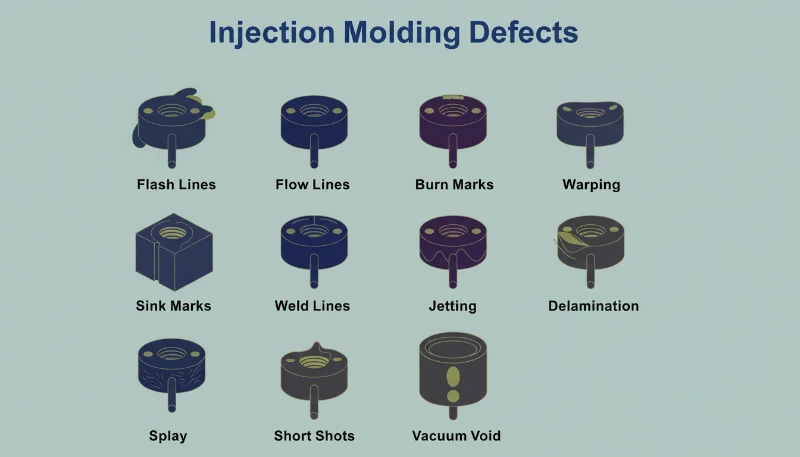

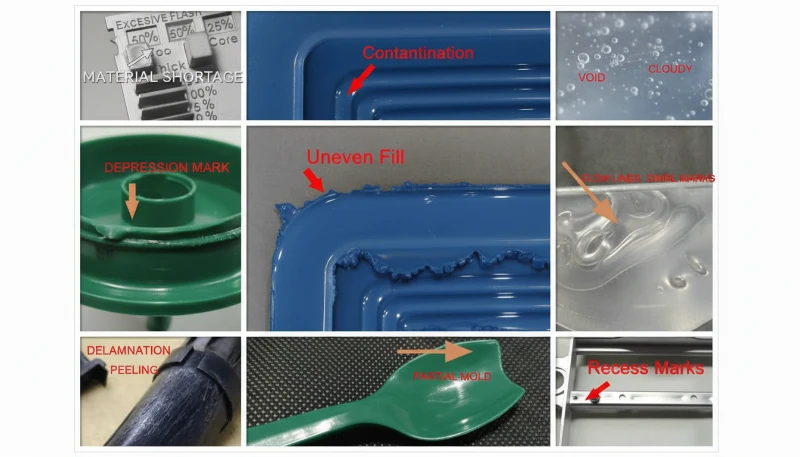

In the injection molding industry, defects are not merely cosmetic issues; they represent significant financial losses, cycle time extensions, and compromised structural integrity. An effective injection molding defect guide1 requires a systematic approach to identifying whether the issue stems from the machine parameters, il progettazione di stampi, or the raw material characteristics.

Understanding the behavior of polymers—such as the high shrinkage rates of Semi-crystalline plastics like Polypropylene (PP) versus the lower shrinkage of Amorphous plastics like Acrylonitrile Butadiene Styrene (ABS)—is critical for troubleshooting.

What Causes Flash and How Can It Be Removed from Plastic Parts?

Flash (or burr) is the escape of molten plastic from the mold cavity, typically occurring at the parting line or ejector pins. It appears as a thin, unwanted flap of material.

Root Cause Analysis: Flash

| Category | Potential Root Cause | Engineering Parameter Check |

|---|---|---|

| Processo | Injection pressure too high | Reduce injection pressure by 5-10%. |

| Processo | Clamping force too low | Ensure clamp tonnage is 2.5–5 tons per square inch of projected area. |

| Processo | Melt temperature too high | Reduce barrel temperature (reduces viscosity). |

| Stampo | Parting line mismatch | Check for debris (plastic residue) preventing full closure. |

| Stampo | Tooling deflection | Verify mold plate support pillars are sufficient. |

Increasing the clamp tonnage is always the first and safest solution to eliminate flash.Falso

While low clamp tonnage causes flash, excessively increasing it can crush vents, damage the mold parting line, and worsen gas entrapment. Optimize injection pressure and melt temperature first.

Reducing the injection speed can help eliminate flash by lowering the cavity pressure at the moment of filling.Vero

Slower injection speeds reduce the sheer heat and peak cavity pressure, reducing the force trying to push the mold open.

Post-Processing: Removing Flash

While prevention is the goal, removing flash from plastic parts2 is often a necessary secondary operation.

- Manual Trimming: Using exacto-knives or scrapers (high labor cost).

- Cryogenic Deflashing: Using liquid nitrogen to embrittle the flash, followed by tumbling (efficient for batch processing).

- Robotic Routing: For large automotive parts requiring high precision.

What Engineering Fixes Solve Sink Marks Effectively?

Sink marks are localized depressions on the surface of a part, usually occurring over thick sections, ribs, or bosses. They occur when the inner core of the plastic cools slower than the outer skin, pulling the surface inward as it shrinks.

Step-by-Step: How to Fix Sink Marks

- Verify Packing Phase: Ensure the pressione di mantenimento is high enough and applied long enough (until the gate freezes). A common rule of thumb is packing time should be 1-2 seconds longer than the gate freeze time.

- Check Melt Temperature: Excessive heat requires longer cooling times. Lower the melt temperature within the manufacturer’s recommended range.

- Inspect Cushion: Monitor the screw cushion position. If the cushion creates zero bottoming out, pressure cannot be transferred to the cavity.

Design Guidelines for Sink Mark Prevention

Engineers looking for how to fix sink marks3 must often look at the part design itself.

- The Rib Rule: Rib thickness should be 40% to 60% of the adjacent wall thickness.

- Coring Out: Remove material from thick sections to maintain uniform wall thickness.

- Posizione del cancello: Gate into the thickest section of the part to allow packing pressure to reach the areas prone to shrinking.

What Strategies Work for Preventing Part Warpage?

Curvatura is the distortion of the part shape after ejection. It is caused by differential shrinkage—where different areas of the part shrink at different rates due to uneven cooling or molecular orientation.

Troubleshooting Warpage: The Cooling Factor

| Fattore | Descrizione | Mitigation Strategy |

|---|---|---|

| Cooling Uniformity | One side of the mold is hotter than the other. | Ensure distinct cooling circuits for Core and Cavity. Target a temperature differential ( △T ) across the mold of <5°C. |

| Fiber Orientation | Glass fibers align with flow, causing anisotropic shrinkage. | Adjust gate location to alter flow direction; use randomizing processing techniques. |

| Ejection Stress | Ejecting the part while too hot causes it to bend. | Increase cooling time; check ejector pin balance. |

Cooling channels should be placed as far from the mold cavity as possible to prevent thermal shock.Falso

Cooling channels should be conformal or placed close to the cavity surface to ensure rapid and uniform heat removal, which is critical for preventing warpage.

Differential shrinkage is the primary cause of warpage in injection molded parts.Vero

When different regions of a part shrink at different rates due to uneven cooling or wall thickness variations, internal stresses are created that lead to warping.

For high-precision industries like automotive, preventing part warpage4 often involves using Conformal Cooling channels (3D printed metal inserts) to follow complex part geometries exactly.

How Should Engineers Approach Short Shots Troubleshooting?

Short shots occur when the molten plastic fails to fill the mold cavity completely. This results in incomplete parts.

Checklist for Short Shots Troubleshooting

To address short shots troubleshooting5, systematically check the following:

- Material Feed: Is the hopper empty or is the feed throat bridged?

- Ventilazione: Trapped gas creates backpressure that prevents filling. Check vents (typically 0.0005" – 0.0015" depth).

- Injection Speed/Pressure: If the material freezes before filling, increase injection speed (fill rate).

- Flow Leaders: In mold design, thicken wall sections slightly to encourage flow to the last-to-fill areas.

What are the Recommended Application Scenarios for High-Quality Molding?

Maintaining a defect-free process is critical in specific sectors where tolerances are tight and aesthetics are paramount.

- Dispositivi medici: Syringes and vials cannot have flash, as loose plastic particles can contaminate fluids.

- Interni per autoveicoli: Dashboards and panels must be free of segni di lavandino e deformazione to ensure proper assembly fit and aesthetic appeal.

- Elettronica: Connectors and housings require precise filling; short shots compromise electrical insulation properties.

FAQ: Common Injection Molding Defects

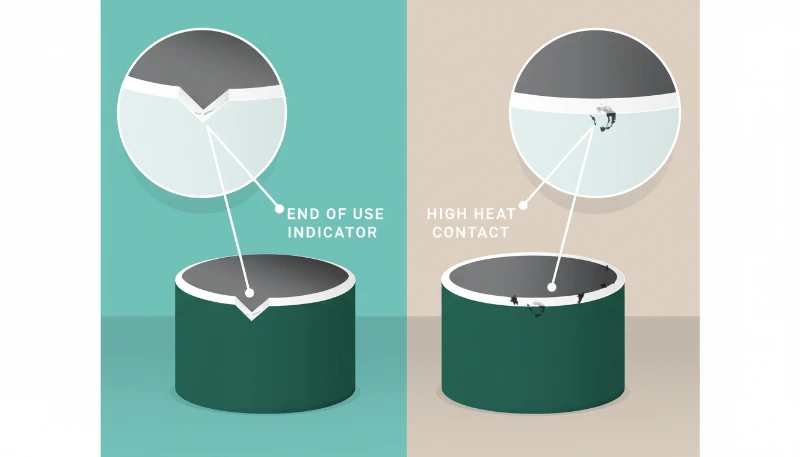

Q: Can mold temperature affect flash?

A: Yes. Higher mold temperatures decrease the viscosity of the plastic, making it flow easier. If the viscosity drops too low, the material can seep into the parting line gaps, causing flash.

Q: Why do sink marks appear near ribs?

A: Ribs add mass to the wall thickness. If the intersection of the rib and the wall is too thick, that area retains heat longer. As the center cools and shrinks, it pulls the surface down.

Q: How does back pressure influence short shots?

A: Low back pressure can result in an inconsistent melt density and insufficient material volume in front of the screw, leading to a short shot. Increasing back pressure ensures a homogenous melt.

Q: Is warpage always a cooling issue?

A: No. While cooling is the most common cause, warpage can also stem from excessive packing pressure (creating internal stress) or poor material selection (high shrinkage materials like Polyethylene (PE) warp more than Polycarbonate (PC)).

Q: What is the difference between a short shot and a gas trap?

A: A short shot is a lack of material. A gas trap (diesel effect) occurs when air cannot escape, is compressed, and burns the plastic. Gas traps often leave black burn marks, whereas short shots generally leave clean, rounded edges where the flow stopped.

Final Thoughts

Successfully resolving injection molding defects requires a disciplined approach to process variables. By referencing a structured injection molding defect guide, engineers can isolate whether the root cause lies in the short shots troubleshooting flow dynamics, the thermal management required for preventing part warpage, or the packing parameters needed for how to fix sink marks. A balanced process window minimizes waste and maximizes profitability.

-

This guide provides a comprehensive overview of defect categorization, serving as a baseline for troubleshooting protocols. ↩

-

Practical techniques for post-process finishing, crucial for salvaging parts where process adjustments cannot fully eliminate flash. ↩

-

An authoritative source on the thermal dynamics of plastic cooling and the relationship between wall thickness and surface depressions. ↩

-

Detailed strategies on managing differential shrinkage and mold temperature control to maintain dimensional stability. ↩

-

Focuses on flow mechanics and venting solutions specifically for incomplete filling issues. ↩