Il raggiungimento di un'elevata precisione nello stampaggio a iniezione è fondamentale per garantire la qualità del prodotto. La messa a punto della progettazione dello stampo, la scelta del materiale e i parametri di lavorazione possono migliorare la precisione dello stampo.

Per migliorare la precisione degli stampi a iniezione è necessario ottimizzare la progettazione dello stampo, selezionare i materiali giusti e controllare le velocità e le temperature di iniezione. Anche la manutenzione regolare svolge un ruolo fondamentale nel garantire una precisione costante dello stampo.

Sebbene questi fattori contribuiscano a una maggiore precisione, è essenziale comprendere le sfumature di ciascun processo e il loro impatto sulla precisione dello stampo. Continuate a leggere per ottenere una precisione ottimale nelle vostre operazioni di stampaggio a iniezione.

L'ottimizzazione della progettazione dello stampo può migliorare la precisione nello stampaggio a iniezione.Vero

Uno stampo ben progettato assicura un flusso uniforme del materiale e riduce al minimo i difetti, garantendo una maggiore precisione del prodotto finale.

Velocità di iniezione più elevate migliorano sempre la precisione dello stampo.Falso

Le velocità di iniezione più elevate possono talvolta portare a difetti come deformazioni o riempimenti insufficienti, riducendo in alcuni casi la precisione.

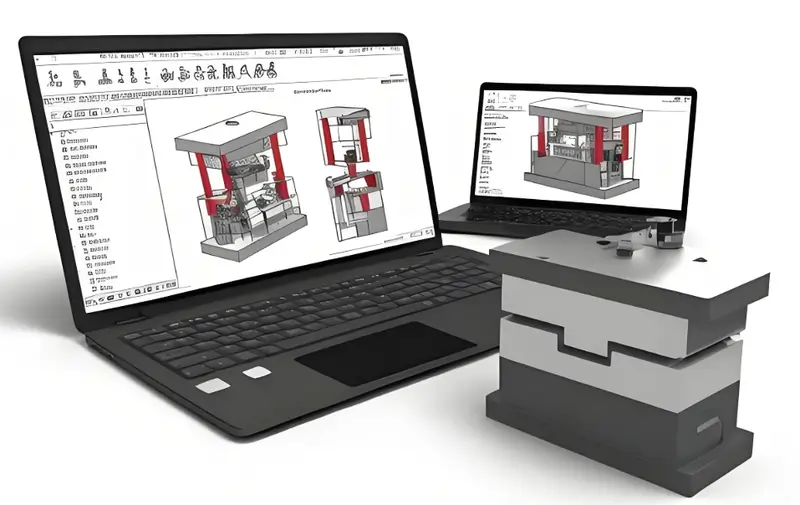

In che modo il processo di progettazione influisce sulla precisione degli stampi a iniezione?

Il processo di progettazione svolge un ruolo fondamentale per ottenere un'elevata precisione negli stampi a iniezione. Una progettazione adeguata garantisce tolleranze ristrette, superfici lisce e pezzi funzionali.

Il processo di progettazione influisce direttamente sulla precisione dello stampo, determinandone la struttura, i sistemi di raffreddamento e il flusso di materiale. Le considerazioni principali includono la geometria del pezzo, il ritiro dello stampo e gli angoli di sformo per garantire precisione e qualità elevate.

Progettazione strutturale ragionevole

Assicuratevi che lo stampo sia sufficientemente resistente per gestire la pressione e le variazioni di temperatura che si verificano quando vi si inietta la plastica. Ad esempio, utilizzare barre d'acciaio, colonne di supporto e altri elementi per rendere lo stampo più resistente.

Progettare un buon sistema di raffreddamento1 per rendere uniforme la temperatura dello stampo e ridurre le variazioni dimensionali causate da una temperatura non uniforme. La disposizione delle vie d'acqua di raffreddamento deve tenere conto della forma dello stampo e delle caratteristiche delle parti da iniettare per garantire un buon effetto di raffreddamento.

Calcolo dimensionale accurato

Calcolare accuratamente le dimensioni delle cavità e delle anime dello stampo in base al tasso di contrazione dei materiali plastici, ai parametri del processo di iniezione e ad altri fattori. Nel processo di progettazione, tenere conto delle differenze tra le caratteristiche dei diversi materiali plastici e dell'usura dello stampo durante l'uso, e riservare le opportune tolleranze di lavorazione.

Quando progettiamo e produciamo parti di macchine, dobbiamo assicurarci che l'errore di forma sia rigorosamente controllato all'interno della tolleranza posizionale e, allo stesso tempo, che l'errore posizionale sia inferiore alla tolleranza dimensionale.

In breve, per i pezzi di precisione o per le loro superfici critiche, è necessario che la precisione della forma sia superiore alla precisione della posizione, mentre precisione di posizionamento2 deve essere superiore alla precisione dimensionale per garantire le prestazioni complessive e la durata dello stampo.

Precisione di posizionamento

L'effettiva differenza di posizione tra le superfici rilevanti di un pezzo lavorato è chiamata precisione di posizione. È una parte importante della qualità della lavorazione dello stampo. Esistono molti modi per misurare la precisione di posizionamento. Alcuni di essi sono il parallelismo, la perpendicolarità, l'inclinazione, la coassialità, la simmetria, l'accuratezza posizionale, il runout circolare e il runout completo. Esistono 12 diverse classi di precisione per le tolleranze di posizione.

Il processo di progettazione determina la precisione dello stampo.Vero

Una progettazione ben pianificata dello stampo migliora l'accuratezza concentrandosi su fattori come il flusso del materiale e la geometria.

Il processo di progettazione non influisce sulla precisione dello stampo.Falso

Una cattiva progettazione dello stampo può portare a imprecisioni, difetti e risultati incoerenti, evidenziando l'importanza di un'attenta pianificazione per ottenere la precisione.

Che ruolo ha la lavorazione nel migliorare la precisione degli stampi a iniezione?

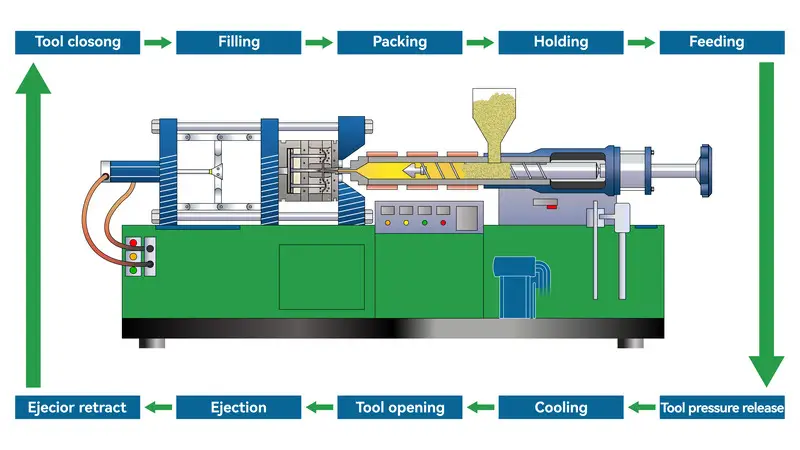

La lavorazione degli stampi a iniezione svolge un ruolo cruciale nel migliorare l'accuratezza dello stampo, controllando fattori quali la temperatura, la pressione e la velocità di raffreddamento. La precisione di questi processi garantisce una maggiore coerenza e qualità dei pezzi.

Una lavorazione efficace degli stampi ottimizza la temperatura, la pressione e il raffreddamento, riducendo i difetti e migliorando la precisione dei pezzi. I fattori chiave sono il controllo del flusso di materiale, il mantenimento di un riscaldamento uniforme e la riduzione dei tempi di ciclo per ottenere risultati uniformi.

Apparecchiature di lavorazione

Scegliere attrezzature di lavorazione di alta precisione, come ad esempio Centri di lavoro CNC3macchine per elettroerosione, macchine utensili per il taglio a filo e altre attrezzature, per garantire una lavorazione accurata dei pezzi stampati. Queste macchine sono dotate di sistemi di controllo ad alta risoluzione e meccanismi di trasmissione di precisione, che consentono di ottenere una lavorazione di alta precisione.

Mantenere le apparecchiature di lavorazione ben curate e calibrate per assicurarsi che siano precise e stabili.

Ottimizzare il processo di lavorazione

Utilizzando processi di lavorazione avanzati come i centri di lavoro CNC, la lavorazione a scarica elettrica a bassa velocità, la lavorazione ad alta velocità e così via, è possibile garantire una lavorazione accurata e precisa dello stampo, che migliorerà la precisione dello stampo a iniezione.

Utilizzare un buon ordine di lavorazione e un buon percorso utensile per ridurre gli errori di lavorazione. Ad esempio, eseguire prima la sgrossatura per eliminare la maggior parte del materiale in eccesso, quindi eseguire la semifinitura e la finitura per rendere il pezzo più preciso.

Controllare i parametri di lavorazione, come la velocità di taglio, l'avanzamento, la profondità di taglio, ecc. per ottenere la migliore qualità della superficie lavorata e l'accuratezza dimensionale. Per i materiali di stampo di elevata durezza, è possibile utilizzare una bassa velocità e un piccolo avanzamento per ridurre l'usura dell'utensile e la deformazione della lavorazione.

Misurazione e ispezione di precisione

Quando si misura, è necessario utilizzare strumenti di misura di alta precisione4 e strumenti, come CMM, proiettori ottici, ecc. per ispezionare le parti dello stampo. Per garantire l'accuratezza e l'affidabilità dei risultati di misura, è necessario misurare più volte durante la lavorazione, in modo da poter individuare e correggere in tempo gli errori di lavorazione.

Allo stesso tempo, il personale addetto alla misurazione deve possedere una ricca esperienza e competenze professionali, per essere in grado di utilizzare correttamente gli strumenti di misura e leggere con precisione i dati di misurazione. Inoltre, è necessario stabilire un perfetto sistema di registrazione delle misure e di analisi dei dati, statistiche e analisi dei risultati di misura, rilevamento e correzione tempestivi degli errori di misura.

Un test rigoroso è un modo importante per garantire l'accuratezza dello stampo. Stabilire un rigoroso sistema di controllo qualità5e condurre test completi sulle dimensioni, la forma e la rugosità superficiale delle parti dello stampo per garantire la conformità ai requisiti di progettazione.

Al termine della lavorazione dello stampo, sono necessarie ispezioni e test completi, tra cui l'ispezione delle dimensioni, l'ispezione della forma, l'ispezione della qualità della superficie, ecc. Grazie ai test, è possibile individuare in tempo i difetti e i problemi dello stampo e adottare le misure corrispondenti per ripararli e migliorarli.

Allo stesso tempo, è necessario stabilire un perfetto sistema di ispezione della qualità e un sistema di gestione dei file, registrare e analizzare i risultati dei test, per fornire un forte supporto alla produzione successiva e al miglioramento dello stampo.

Una lavorazione corretta migliora la precisione dello stampo.Vero

L'ottimizzazione di fattori come la temperatura, la pressione e il tempo di raffreddamento riduce i difetti, portando a stampi più precisi e coerenti.

Le sole tecniche di lavorazione garantiscono una perfetta precisione dello stampo.Falso

Se la lavorazione è fondamentale, anche altri fattori come la qualità del materiale e la progettazione dello stampo giocano un ruolo importante per ottenere stampi di alta precisione.

In che modo il processo di assemblaggio influisce sulla precisione degli stampi a iniezione?

Il processo di assemblaggio svolge un ruolo cruciale nel determinare la precisione e le prestazioni degli stampi a iniezione, incidendo sull'efficienza della produzione e sulla qualità dei prodotti in diversi settori industriali.

Il corretto assemblaggio degli stampi a iniezione garantisce tolleranze ristrette e riduce il rischio di difetti. Influisce in modo significativo sulla longevità dello stampo, sulla consistenza del prodotto e sull'efficienza della produzione, soprattutto nei mercati ad alta precisione come quello automobilistico, elettronico e dei dispositivi medici.

Pulizia e ispezione

Prima dell'assemblaggio, pulire accuratamente le parti dello stampo per rimuovere i residui di lavorazione e l'olio. Controllare le dimensioni, la forma e la qualità della superficie dei pezzi per garantire la conformità ai requisiti di assemblaggio.

Eseguire lavorazioni fini e rettifiche su parti di accoppiamento importanti per migliorare la precisione di accoppiamento. Ad esempio, il gioco di accoppiamento tra anima e cavità deve essere controllato entro un intervallo ragionevole per garantire la precisione dimensionale dei pezzi stampati a iniezione.

Processo di assemblaggio preciso

Adottare strumenti e attrezzature di assemblaggio professionali per garantire l'accurata posizione di installazione delle parti dello stampo. Ad esempio, utilizzare strumenti come perni di posizionamento e maschere per garantire la precisione della posizione relativa dei pezzi.

Eseguire l'assemblaggio in conformità alla sequenza di assemblaggio e ai requisiti di processo, evitando assemblaggi forzati e martellamenti. Durante il processo di assemblaggio, è necessario controllare lo spazio tra le parti, il parallelismo, la perpendicolarità e altri parametri per garantire l'accuratezza complessiva dello stampo.

Dopo il assemblaggio dello stampo6 è stato completato, il debug e il prova di muffa7 vengono eseguiti. Ottimizzare le prestazioni e la precisione dello stampo regolando i parametri del processo di iniezione, la temperatura dello stampo, la pressione e altri fattori.

Messa in servizio e ottimizzazione

Dopo il completamento dell'assemblaggio dello stampo, vengono eseguiti il debug e la prova dello stampo. Ottimizzare le prestazioni e la precisione dello stampo regolando i parametri del processo di iniezione, la temperatura dello stampo, la pressione e altri fattori.

Analizzare e risolvere i problemi emersi nel processo di prova dello stampo, come deviazioni dimensionali, difetti superficiali, ecc. In base ai risultati dello stampo di prova, apportare le necessarie modifiche e miglioramenti allo stampo per migliorarne la precisione.

La precisione degli stampi a iniezione dipende esclusivamente dal processo di assemblaggio.Falso

Se l'assemblaggio è fondamentale, anche altri fattori come la qualità dei materiali, la progettazione dello stampo e la manutenzione influiscono in modo decisivo sulla precisione dello stampo.

L'ottimizzazione dei processi di assemblaggio può portare a una riduzione dei tassi di difettosità nello stampaggio a iniezione.Vero

Un assemblaggio preciso garantisce tolleranze più strette e un migliore allineamento, riducendo al minimo l'insorgere di difetti nei pezzi stampati.

In che modo la scelta del materiale nello stampo a iniezione influisce sulla precisione dello stampo?

La scelta di materiali appropriati negli stampi a iniezione migliora significativamente la precisione, influenzando la qualità e la durata dei pezzi prodotti.

La scelta dei materiali negli stampi a iniezione influisce sulla precisione determinando la conducibilità termica, la resistenza all'usura e la stabilità dello stampo. I materiali ideali mantengono la temperatura ottimale, riducono la distorsione e migliorano la durata, fattori cruciali per la produzione di pezzi precisi in settori come quello elettronico e aerospaziale.

Acciaio per stampi di alta qualità

Scegliere acciaio per stampi8 con elevata durezza, alta resistenza all'usura, buona stabilità termica e lavorabilità. Queste caratteristiche possono garantire la durata dello stampo e migliorarne la precisione. L'acciaio per stampi di alta qualità può garantire che lo stampo mantenga la stabilità dimensionale e riduca l'usura e la deformazione durante l'uso a lungo termine.

Attualmente, in termini di materiali per stampi, sono stati ampiamente utilizzati l'acciaio temprato per stampi, l'acciaio per stampi di precisione della metallurgia delle polveri, l'acciaio ad alta velocità, il carburo e altri materiali.

In base ai diversi requisiti dei pezzi stampati a iniezione e al lotto di produzione, è necessario scegliere il materiale di acciaio per stampi più adatto. Ad esempio, per i pezzi stampati a iniezione di alta precisione e in grandi volumi, si può scegliere l'acciaio per stampi importato di alta qualità.

Raccordi standard

Scegliere raccordi standard per stampi6come pilastri di guida, boccole di guida, perni di espulsione e così via. La precisione e la qualità dei raccordi standard sono garantite e possono migliorare la precisione complessiva dell'assemblaggio dello stampo. Ispezionare e sostituire regolarmente i raccordi dello stampo per garantirne le buone prestazioni.

La scelta del materiale influisce sulla conducibilità termica e sulla precisione degli stampi.Vero

La scelta del materiale influisce sulla regolazione termica, essenziale per mantenere la precisione dello stampo attraverso un controllo costante della temperatura.

Tutti i materiali utilizzati negli stampi a iniezione sono ugualmente resistenti.Falso

I diversi materiali offrono diversi livelli di durata; ad esempio, l'acciaio temprato è più resistente rispetto all'alluminio, con un impatto sulla longevità dello stampo.

Qual è il ruolo della formazione e della gestione del personale nel mantenimento della precisione degli stampi a iniezione?

Una formazione e una gestione efficaci del personale svolgono un ruolo fondamentale nel mantenere la precisione e la qualità degli stampi a iniezione, essenziali per diverse industrie manifatturiere.

Un'adeguata formazione del personale garantisce un'impostazione e un funzionamento accurati, riducendo al minimo gli errori e migliorando la coerenza. Comprende la progettazione dello stampo, il funzionamento, la manutenzione e la risoluzione dei problemi, contribuendo in modo significativo alla precisione e alla qualità complessiva dei pezzi stampati a iniezione.

Formazione tecnica professionale

Fornire una formazione tecnica professionale al personale in materia di progettazione, lavorazione e assemblaggio degli stampi per migliorare il livello di competenza e la consapevolezza della qualità. La formazione comprende i principi di progettazione degli stampi, le tecniche di lavorazione, le abilità di assemblaggio, il controllo qualità e altri aspetti. Incoraggiare il personale a imparare e padroneggiare continuamente nuove tecnologie e metodi per migliorare il livello generale di produzione degli stampi.

Gestione rigorosa della qualità

Stabilire una perfetta sistema di gestione della qualità7 e di effettuare un rigoroso controllo di qualità su tutti gli aspetti della produzione degli stampi. Formulare standard di qualità e specifiche di ispezione, rafforzare l'ispezione delle materie prime, della lavorazione, del processo di assemblaggio e dei prodotti finiti. Analizzare e affrontare tempestivamente i problemi di qualità, adottare misure correttive e preventive efficaci per evitare il ripetersi dei problemi.

La formazione del personale riduce gli errori nei processi di stampaggio a iniezione.Vero

Il personale ben addestrato ha meno probabilità di commettere errori di impostazione o di funzionamento, garantendo una maggiore precisione e qualità dei pezzi stampati.

La gestione ha un impatto minimo sulla precisione degli stampi a iniezione.Falso

Una gestione efficace è fondamentale per implementare le migliori pratiche di manutenzione e funzionamento degli stampi, essenziali per mantenere un'elevata precisione nella produzione.

Riassumere

La chiave per migliorare la precisione degli stampi in plastica risiede in una progettazione ragionevole, in un calcolo dimensionale accurato, in una lavorazione di precisione, in un rigoroso controllo di qualità e nell'ottimizzazione del processo di assemblaggio. La fase di progettazione deve assicurare che la struttura dello stampo sia stabile, la sistema di raffreddamento1è efficace e la precisione di posizionamento è rigorosamente controllata.

La fase di lavorazione deve scegliere attrezzature di alta precisione e ottimizzare il processo per garantire una precisione stabile. Attraverso misure e test di alta precisione, è possibile individuare e correggere tempestivamente gli errori di lavorazione.

Per quanto riguarda la scelta dei materiali, l'acciaio per stampi di alta qualità e gli accessori standard possono migliorare la durata e la precisione dello stampo. Infine, formazione del personale9 e il miglioramento del sistema di gestione della qualità è la base per garantire la precisione dello stampo.

-

Esplorate questo link per capire come ottimizzare i sistemi di raffreddamento per gli stampi a iniezione, garantendo una temperatura uniforme e variazioni dimensionali ridotte. ↩ ↩

-

Imparate a conoscere i vari metodi di misurazione dell'accuratezza posizionale, fondamentale per garantire la qualità dei pezzi lavorati e degli stampi. ↩

-

Scoprite i vantaggi dei centri di lavoro CNC nella costruzione di stampi, tra cui la precisione e l'efficienza, fondamentali per ottenere stampi di alta qualità. ↩

-

Scoprite l'importanza degli strumenti di misura ad alta precisione per garantire l'accuratezza e l'affidabilità degli stampi durante le ispezioni. ↩

-

Imparate a conoscere gli efficaci sistemi di controllo della qualità che garantiscono la conformità ai requisiti di progettazione nella produzione degli stampi. ↩

-

La comprensione dei raccordi standard per stampi è fondamentale per garantire precisione e qualità nella produzione di stampi, migliorando le prestazioni complessive. ↩ ↩

-

Un solido sistema di gestione della qualità è essenziale per mantenere standard elevati e prevenire i difetti nella produzione degli stampi. ↩ ↩

-

Informazioni suQuali sono i diversi tipi di sistemi di raffreddamento per stampi a iniezione? Lo stampaggio a iniezione è un processo produttivo che ci permette di creare pezzi di precisione con una resistenza, un'accuratezza dimensionale e una finitura superficiale stellari. ↩

-

Investire nella formazione del personale migliora le competenze e la consapevolezza della qualità, portando a un miglioramento della progettazione e della produzione degli stampi. ↩