Subtitle: Comparing additive manufacturing tooling against traditional subtractive MUD inserts.

– 3D printed molds use photopolymers for ultra-low volume prototyping (10–50 shots) but suffer from poor heat transfer and cycle times.

– MUD (Master Unit Die) machined inserts utilize aluminum or soft steel within a standard frame to deliver 500–10,000+ parts with production-grade tolerances.

– Printed tooling is superior for complex geometries with undercuts that are difficult to machine, provided the resin requirements are low-temperature.

– For functional testing and bridge production requiring specific engineering thermoplastics (like Nylon or PEEK), machined MUD inserts are the only viable option.

What Defines 3D Printed Molds and MUD Machined Inserts?

To make an informed decision on rapid tooling, we must first define the technologies involved.

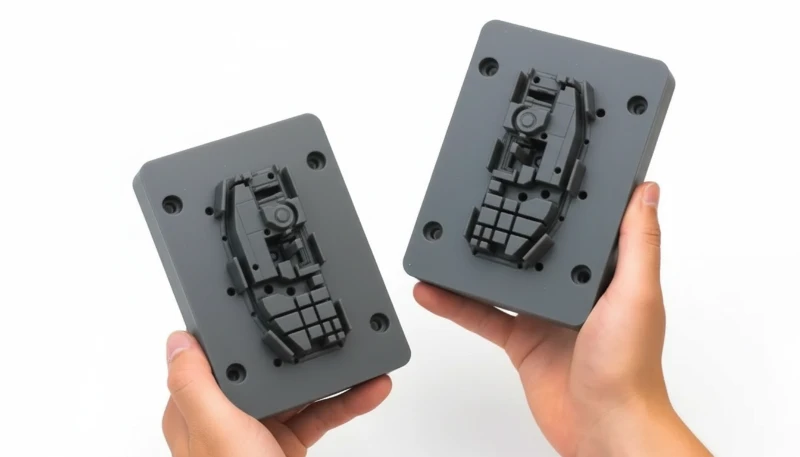

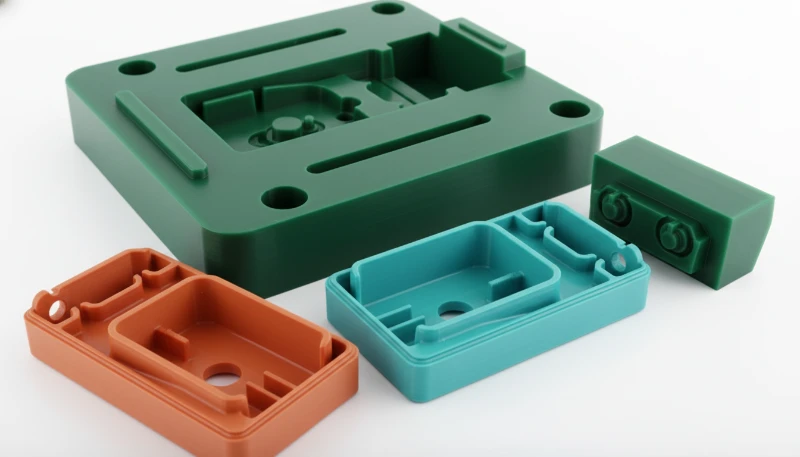

3D Printed Injection Molds

This process typically involves using PolyJet or Stereolitografia (SLA)1 technology to print mold cores and cavities from high-temperature photopolymers (thermoset plastics). These molds are inserted into a standard metal frame for injection. They are designed for speed and geometric freedom rather than durability.

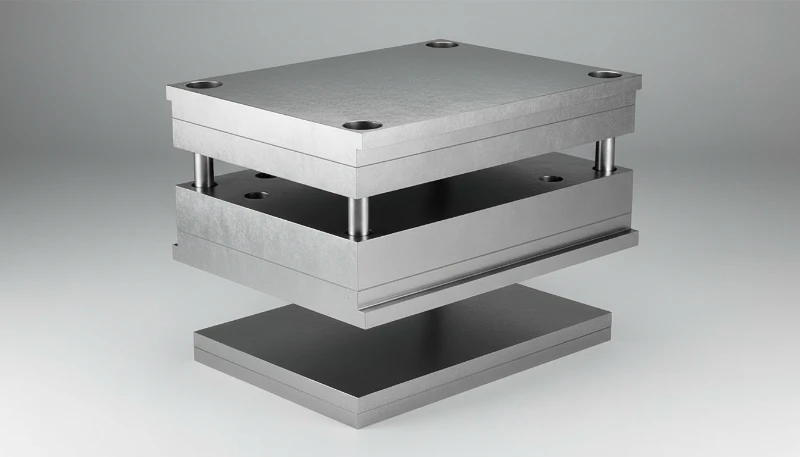

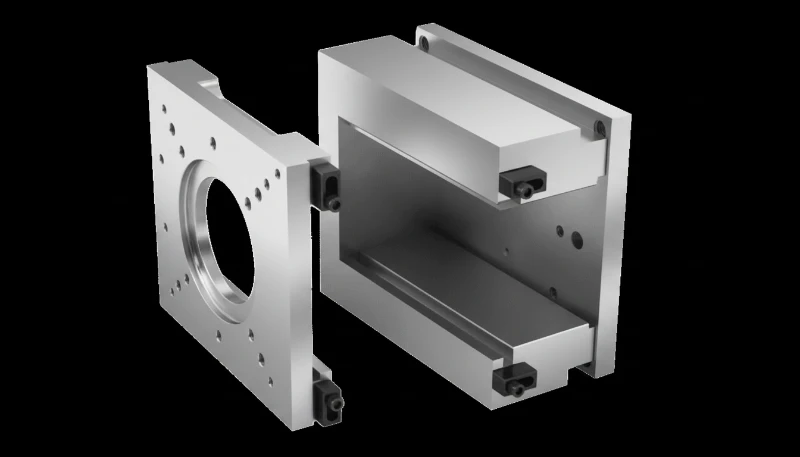

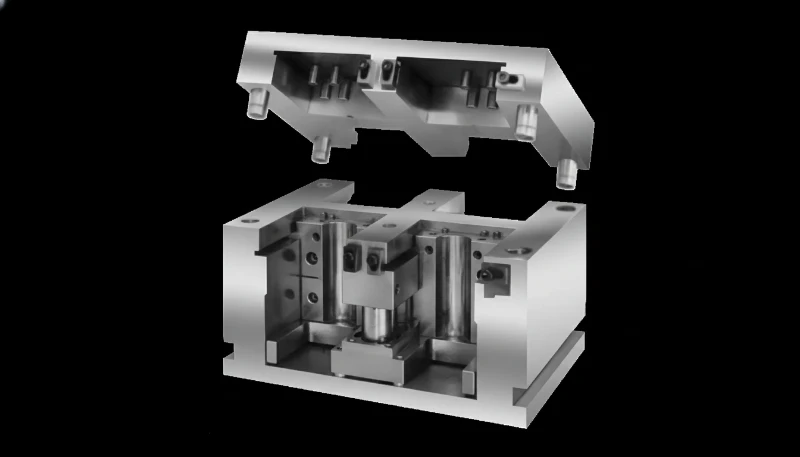

MUD Machined Inserts2

A Master Unit Die (MUD) system is a quick-change mold base standard. The "mold" consists of interchangeable inserts (usually aluminum 7075 or P20 steel) that slide into a permanent frame mounted in the injection molding machine. This "subtractive" method removes metal to create the cavity, offering physical properties identical to production molds but at a lower cost due to the shared frame.

3D printed molds are always the fastest way to get injection molded parts.Falso

While printing the mold is fast, the injection cycle time is significantly slower (often 5x-10x) due to poor thermal conductivity, making total project time longer for volumes over 50 units.

MUD inserts offer tighter tolerances than 3D printed molds.Vero

CNC machining of metal inserts consistently achieves tolerances of ±0.005mm to ±0.025mm, whereas printed molds usually hold ±0.1mm due to shrinkage and deflection under pressure.

How Do 3D Printed Molds Compare to MUD Inserts? (Technical Comparison)

The following table contrasts the performance of Stampi PolyJet against MUD machined inserts (Aluminum 7075-T6).

| Caratteristica | 3D Printed Molds (PolyJet/SLA) | MUD Machined Inserts (Alu 7075) |

|---|---|---|

| Primary Method | Fabbricazione additiva | Subtractive (CNC Machining) |

| Typical Lead Time | 24 – 48 Hours | 3 – 10 Days |

| Tool Life (Shots) | 10 – 100 (Geometry dependent) | 1,000 – 10,000+ |

| Tempo di ciclo | High (3–5 minutes/shot) | Standard (15–45 seconds/shot) |

| Conduttività termica | Very Low (~0.2 W/mK) | High (~130 W/mK) |

| Tolleranza dimensionale | ± 0.100 mm (0.004 in) | ± 0.025 mm (0.001 in) |

| Melt Temp Limit | < 300°C (Non-abrasive only) | < 400°C (Includes Engineering Resins) |

| Cost Driver | Material Volume (Resin cost) | Machining Time & Complexity |

What Are the Critical Advantages and Disadvantages?

3D Printed Tooling

Pro:

- Velocità: A mold can be printed overnight.

- Geometria complessa: Capable of creating conformal cooling channels or complex undercuts that are impossible to machine.

- Low Initial Cost: For very small parts with low complexity, printer material costs are lower than CNC setup fees.

Contro:

- Heat Dissipation: Plastic acts as an insulator. The mold cannot cool the molten plastic quickly, leading to extreme cycle times and potential warping.

- La fragilità: Printed molds are prone to cracking under high injection pressures or flash due to deflection.

- Finitura superficiale: Layer lines from printing may transfer to the final part unless labor-intensive hand polishing is applied.

MUD Machined Inserts

Pro:

- Material Fidelity: Allows the use of high-temperature, glass-filled, or abrasive materials (e.g., Polyamide 66 (PA66) with 30% Glass Fiber).

- Efficienza di raffreddamento: Aluminum dissipates heat rapidly, allowing for realistic cycle times and reducing part stress.

- Precisione: CNC machining ensures critical features like snap fits function correctly.

Contro:

- Geometry Constraints: Restricted by CNC tool access; sharp internal corners often require EDM (Electrical Discharge Machining), increasing cost.

- Tempi di consegna: requires CAM programming and machining time, usually taking days rather than hours.

When Should You Choose 3D Printed Molds vs. MUD Inserts?

Use the following scenarios to guide your rapid tooling comparison.

Scenario A: Design Verification (10–20 Parts)

Recommendation: 3D Printed Molds

If you need to verify a shape or fit and the material is a standard resin like Polypropylene (PP) or ABS, 3D printing is sufficient. The cost of machining does not justify a run of 20 parts unless tolerances are critical.

Scenario B: Functional Testing (100–500 Parts)

Recommendation: MUD Machined Inserts

For functional testing, the part must behave exactly like the final product. Printed molds often result in different internal stresses due to slow cooling. MUD inserts allow for the use of the actual production resin and cooling rates, providing valid data for drop tests or thermal cycling.

Scenario C: Bridge Production (1,000+ Parts)

Recommendation: MUD Machined Inserts

3D printed molds3 will likely fail before reaching 100 shots. For bridge production (filling supply chain gaps while the steel production mold is cut), aluminum MUD inserts are the industry standard standard.

You can mold any thermoplastic in a 3D printed mold.Falso

High-temperature resins like PEEK or abrasive glass-filled nylons will erode or melt the printed mold surface rapidly. 3D printed molds are generally limited to non-abrasive resins like PP, PE, and ABS.

MUD inserts are cost-effective because you only pay for the insert, not the frame.Vero

The Master Unit Die system uses a reusable universal frame. The customer only pays for the small block of metal (the insert) that contains the part geometry, reducing tooling costs by up to 66% compared to standalone molds.

Practical Tips for Optimizing Your Choice

- Angoli di sformo: 3D printed molds require larger angoli di sformo4 (2°–3°) to facilitate ejection because the printed surface has higher friction than polished aluminum.

- Spessore della parete: Avoid thick walls in parts destined for printed molds. The heat retention will degrade the mold rapidly.

- Insert Hybridization: A common hybrid strategy involves using a standard metal MUD base with 3D printed inserts placed inside it. This provides the mechanical support of metal with the geometric speed of printing.

Domande frequenti (FAQ)

1. Can I use glass-filled nylon in a 3D printed mold?

Generally, no. Glass fibers are abrasive and will scour the soft surface of a photopolymer mold, destroying the details after only a few shots. Furthermore, the high melt temperature of Nylon (PA) risks softening the printed tool.

2. How much cheaper are MUD inserts compared to full production molds?

MUD inserts are typically 50% to 70% cheaper than standalone Class 101 steel5 production molds because they eliminate the need for a custom mold base, ejector plates, and guided pins—you only pay for the cavity and core machining.

3. What is the finitura superficiale6 difference between the two?

MUD inserts can be polished to an SPI-A2 (mirror) finish or textured. 3D printed molds typically yield a matte finish (SPI-C or D equivalent) and may show build lines unless significantly post-processed, which alters dimensional accuracy.

4. Why is cooling time such a major factor in this comparison?

In injection molding, cooling accounts for 70-80% of the cycle. Metal molds conduct heat away efficiently. Plastic printed molds act as insulators; if you eject too soon, the part warps. Therefore, you must wait minutes for the part to solidify in a printed mold, versus seconds in a metal MUD insert.

5. Can MUD inserts be used for mass production?

Yes, depending on the material. MUD inserts made from P20 steel or hardened H13 steel can withstand 100,000 to 500,000 shots. Even Aluminum 7075 inserts can often run 10,000+ shots of non-abrasive plastics.

Sintesi

The choice between 3D printed injection molds e MUD machined inserts is a trade-off between speed and fidelity. 3D printing offers the fastest route to a physical part for geometry checks (1-50 units), provided the tolerances are loose. However, for any requirement involving functional testing, tight tolerances, engineering-grade materials, or volumes exceeding 50 units, MUD machined inserts provide a "reality check"—delivering production-quality parts at a fraction of the cost of full steel tooling.

References & Standards:

- ASTM F2971: Standard Practice for Reporting Data for Test Specimens Prepared by Additive Manufacturing.

- SPI Mold Classifications: Standards for mold life and tolerance (Society of the Plastics Industry).

- ISO 2768: General Tolerances for machined parts (relevant to MUD inserts).

-

Understand the principles of SLA and its role in producing detailed 3D printed parts. ↩

-

Learn how MUD machined inserts can enhance production efficiency and reduce costs. ↩

-

Explore the benefits of 3D printed molds for rapid prototyping and complex geometries. ↩

-

Discover the significance of draft angles in ensuring successful mold ejection. ↩

-

Explore the properties of Class 101 steel and its applications in mold manufacturing. ↩

-

Understand the factors that influence surface finish and its importance in product aesthetics. ↩