Injection molding is a popular method for producing plastic products, which involves injecting molten plastic into a mold. After cooling, the material takes on its final shape. Manufacturers can use this process to make items of different shapes and sizes. Injection molding is widely used in manufacturing automotive parts, medical devices, and electronic products, etc. So why is injection molding particularly suitable for mass production? This article will delve into this question and fully analyze the advantages of injection molding in mass production.

High Production Efficiency

High-Speed Production

Compared with other manufacturing methods, injection molding has one major advantage: it is very fast. When you want to make something out of metal or wood using traditional techniques such as casting or woodworking, it usually takes a long processing and adjustment time. But with injection molding, the machine hardly needs to stop after the initial work of the mold is completed. The injection molding machine can run continuously, and each cycle usually takes only a few seconds to a few minutes. This means that you can produce a large number of items in a short period of time, greatly improving efficiency.

Injection molding also supports automation, so you can produce a virtually unlimited number of units using the same mold, even simultaneously. For example, it may take several minutes to complete a unit to make a simple plastic bottle cap by hand, but the injection molding machine can complete it in just a few seconds.

High Degree of Automation

Most current plastic injection molding machines are equipped with top-level automation control systems. They can automatically and continuously complete feeding, which not only reduces dependence on manual labor, but also minimizes human errors in the process, and improves production consistency and quality control. Highly automated injection molding machines can run around the clock, further improving production efficiency. The automation system can also be programmed to quickly switch between different products, greatly improving production flexibility and responsiveness.

Cost-Effectiveness

Raw Material Costs

The low cost of plastic raw materials, especially when purchased in large quantities, means significant cost savings. And these are not the only price advantages, the materials can also be recycled over and over, further reducing costs. Then there are the wastes generated during the injection molding process, which can be recycled, reducing waste disposal costs while saving materials.

For example, scrap and defective products can be ground up, melted down, and reused, minimizing material waste and production costs.

Labor Costs

Because injection molding is so highly automated, it needs very little human involvement. This means lower costs from labor as well as fewer mistakes and delays caused by humans, all of which can derail production or drive up prices. Today most such factories require just a handful of employees to oversee machinery and keep things running smoothly, significantly reducing labor demand. Compared to other manufacturing processes, injection molding has a clear labor cost advantage.

Economies of Scale in Mass Production

Injection molding is ideal for large-scale production because the molds’ design and manufacturing costs can be spread across many units. This lowers the cost per item significantly. For large-scale production, the unit cost of injection molding is more competitive than other manufacturing methods. Although injection mold costs are high, their long lifespan allows for the production of millions or even billions of products, resulting in very low mold costs per item.

Design Flexibility

Complex Shapes and Details

Injection molding can produce products with complex shapes and details. This is because liquid plastic can flow to every corner of the mold cavity under high pressure and accurately replicate the details of the mold. This ability allows designers to freely design a variety of complex shapes without having to worry about limitations in the manufacturing process.

For example, injection molding can produce complex mobile phone cases, automotive parts, and housings for household appliances, etc. These products usually require high precision and complex details.

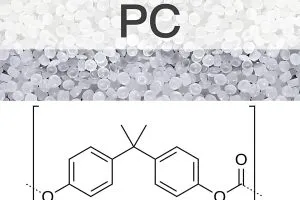

Variety of Material Choices

A versatile range of plastic materials, including thermoplastics, thermosetting plastics and elastomers. can be used in injection moulding. This offers greater flexibility in product design, as the appropriate material can be chosen based on the product’s functional requirements. Different materials have different properties, such as some stand up better than others to heat, while others are more resilient when confronted with corrosive chemicals; some are tougher and more impact-resistant, some have useful levels of transparency.

By selecting the best plastic material for their needs, designers can produce products which perform better for longer. For example, electronic product housings require heat-resistant materials, while food containers need to be non-toxic and environmentally friendly.

Insert Molding and Multi-Color Molding

Injection molding offers the capability for both multi-color molding and insert molding. For example, it is possible to embed metal parts into plastic components during molding – or to use different colors of plastic in one product. These techniques give designers greater flexibility when creating products with special requirements. This flexibility enables plastic injection molding to meet various special design requirements. Insert molding can integrate metal parts with plastic components, reducing subsequent assembly processes and improving product strength and reliability. Multi-color molding can produce products in various colors, meeting different market and consumer demands.

Quality Control and Consistency

High Precision and Consistency

Injection molding processes provides both repeatability and precision, delivering parts that have uniform dimensions and consistent quality. This is because each time plastic is injected into the mold, it does so in a controlled way, coupled with having fixed shapes and sizes for injection molds themselves. Such uniformity is needed when massive numbers of an item must be made all to the same standards. For example, automotive parts require strict dimensional tolerances and consistency to ensure assembly precision and performance.

Reduced Defect Rate

Today’s advanced injection machines are equipped with the most advanced control systems and monitoring technologies. These systems can detect problems in real time and make immediate adjustments. By doing so, manufacturers can improve both quality and efficiency. Real-time monitoring systems can detect problems during the plastic injection molding manufacturing process, such as abnormal temperature, pressure, and flow, and make timely adjustments to ensure that each product meets quality standards.

Quality Inspection and Control

There are multiple ways to check the quality of items as they’re made through injection molding. This includes techniques like X-ray, optical and ultrasonic inspections. By using these methods together injection molding manufacturers can keep an eye on each product in real time and make sure it meets certain standards.

For instance while an optical inspection would find flaws on surfaces; an X-ray one checks there are no hidden structural problems; and ultrasonic testing makes sure materials have been spread evenly throughout products and that they are all same density across entire item.

Environmental Impact and Sustainability

Material Recycling

The waste generated during the injection molding process can be recycled, reducing raw material waste. This not only lowers production costs but also minimizes environmental impact. For instance, waste generated during production can be ground up, melted, and re-injected, reducing material waste and environmental pollution.

Energy Efficiency

Most of today’s injection molding machines use energy-saving electric or hybrid systems, which have high energy utilization, reduce energy consumption, and are more energy-saving and environmentally friendly. For example, modern injection molding machines use servo motors and variable frequency control technology, which can adjust power output according to production needs and reduce unnecessary energy waste.

Use of Eco-Friendly Materials

Due to a rise in environmental consciousness, injection molders are increasingly turning to green materials. Biodegradable plastics and bioplastics, which come from renewable sources, allow manufacturers to produce plastic parts that are more earth friendly.Biodegradable plastics can break down into harmless substances under specific conditions, reducing plastic waste’s environmental pollution.

Wide Range of Applications

Automotive Industry

The automotive industry extensively relies on injection molding for manufacturing an array of plastic parts. This process is ideal for creating components like bumpers, door panels and dashboards because they need to be durable, attractive, precise, and this is all achievable with plastic injection molding.

For example, automotive dashboards require complex shapes and details, and injection molding can precisely replicate mold details, ensuring the quality and consistency of each part.

Consumer Electronics

Injection molding is used in the consumer electronics sector for manufacturing phone, TV and computer housings. These goods must not only look good but also have a degree of mechanical strength and durability, areas where injection molding excels.

For instance, phone housings need to be lightweight, attractive, and durable, and injection molding can produce high-quality housings to meet market demand.

Medical Devices

Injection molding is used extensively in the production of medical devices including syringes, test tubes and surgical tools. These products must be made with extreme cleanliness and precisionand injection molding can provide a sterile production environment and high-precision products.

For example, syringes need precise dimensions and sterile production, and injection molding can ensure the quality and safety of each syringe.

Daily Consumer Goods

Injection molding is also utilized to manufacture a range of everyday consumer items, for example, plastic bottles, food containers, and children’s toys. These are products which require both mass production and a low cost price structure, which injection molding can meet.

For instance, plastic bottles need to be produced in large quantities to meet market demand, and injection molding can quickly and efficiently produce a large number of high-quality plastic bottles.

Technological Advances and Innovation

3D Printing Technology

Although 3D printing technology excels in small batch production and prototyping, injection molding still dominates mass production. However, the development of 3D printing technology has also driven advancements in injection molding technology, such as rapid mold manufacturing technology, which can shorten mold manufacturing time and improve production efficiency.

For instance, 3D printing technology can quickly create complex mold prototypes, shortening the mold development cycle.

Advances in Mold Design and Manufacturing

Advances in modern mold design and manufacturing technologies, such as CNC plastic machining and EDM, have made mold manufacturing more precise and efficient. This not only improves product quality, but also shortens production cycles and reduces production costs.

For example, CNC machining technology can precisely machine molds with complex shapes, thereby improving mold accuracy and quality.

Smart Manufacturing and Industry 4.0

Incorporating smart manufacturing and Industry 4. 0 principles into injection molding has led to smarter, more automated production processes. This enables real-time monitoring and optimization using IoT devices plus big data analytics – so efficiency as well as overall quality can both improve. For instance, injection molding machines can use IoT technology to monitor production parameters in real-time and optimize production processes through big data analysis, reducing waste and quality issues during production.

Conclusion

Injection molding is suitable for mass production because it’s fast, cheap, and can make anything. It’s also good for the environment and can be used to make all kinds of stuff. Plus, people are always coming up with new ways to make it even better. So, whether you want to make a lot of stuff, save money, or make sure your stuff is good, injection molding is the way to go.

Injection molding is super important in modern industrial production because it’s got some really cool advantages. As technology gets better and we find more ways to use it, injection molding is gonna be even more important in the future. It’s gonna help us make stuff faster, cheaper, and better for the environment.