Draft angles are essential in injection molding, ensuring easy part ejection and reducing defects. Proper design improves manufacturing efficiency and product quality.

Draft angles (1-3 degrees) prevent sticking and defects in molded parts for smooth release. Specific angles depend on material, texture, and mold complexity, enhancing production efficiency and aesthetics.

Understanding draft angles is key to optimizing mold design. Factors like material shrinkage, surface finish, and part geometry influence the ideal draft. Read on to explore best practices for designing draft angles in injection molding.

Draft angles reduce ejection force in injection molding.True

A proper draft angle minimizes friction between the part and the mold, making ejection smoother and preventing damage.

All injection molded parts require a draft angle.False

While most parts benefit from draft angles, certain low-friction materials or flexible designs may allow for zero or minimal draft.

What is the Definition And Importance of Draft Angle?

Draft angles are essential in injection molding, ensuring smooth part ejection and preventing damage to the mold or final product.

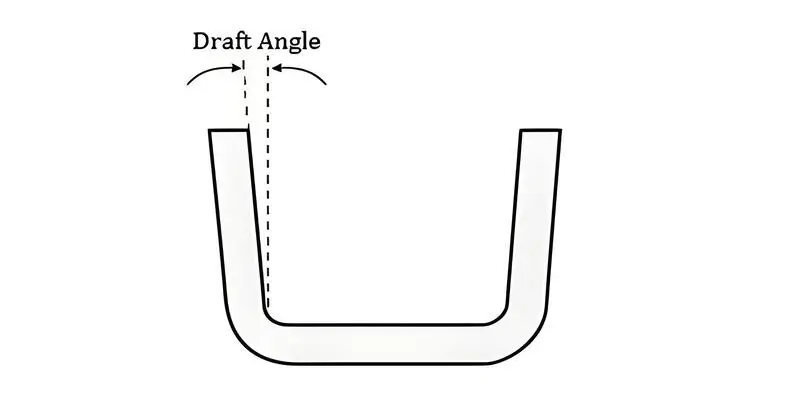

A draft angle is a slight taper on molded parts to aid removal from the mold, prevent defects, reduce ejection force, and extend mold life. It typically ranges from 1 to 3 degrees.

Definition of the Draft Angle

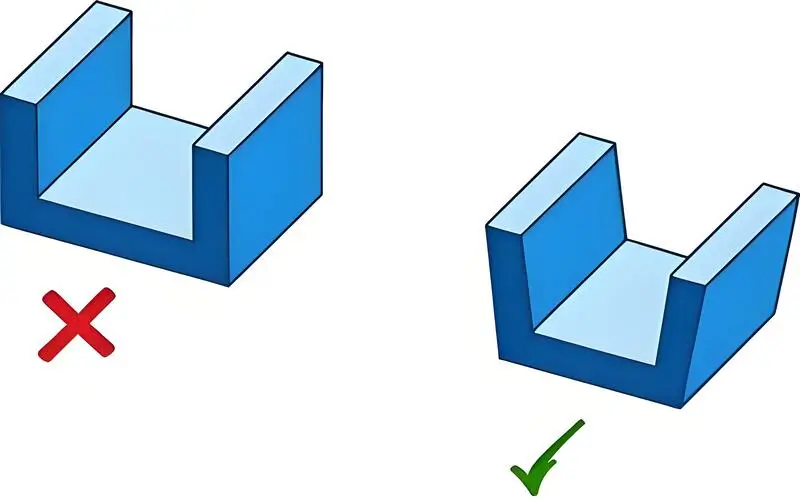

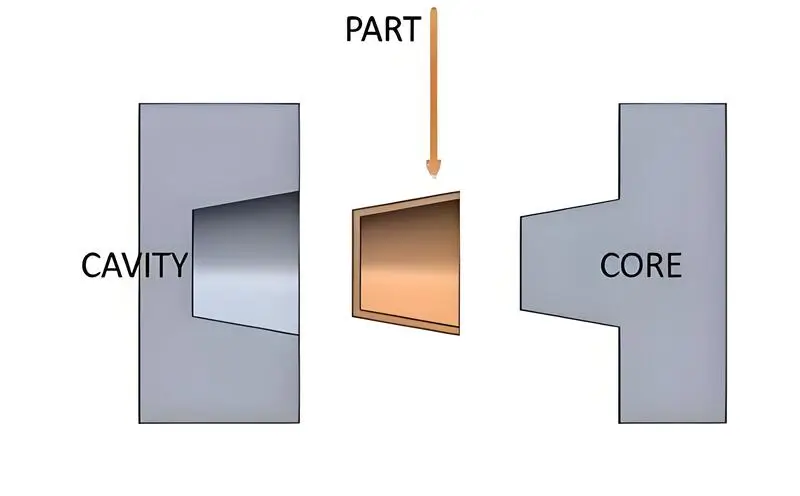

The draft angle is the angle made between the mold cavity or core and the direction of mold opening, that is, the slope of the mold wall to the direction of opening. This angle makes it easier to demould the mould plastic part without having to worry of damaging or deforming it.

Importance of the Draft Angle

A well designed draft angle1 is capable of avoiding imperfections such as scratched and deformed products during the ejection process hence enhancing the surface finish of the product and incorporating sharp accuracies. Furthermore, getting a right draft angle can increase the mold’s life and lower the production expenses. If the draft angle chosen is too small, high ejection resistance is created which in turn creates surface scratches or deforms the plastic part; again if it is too large, the dimensional stability and mold life is affected. Hence, reasonable design about the draft angle contributes to promote the production quality and efficiency.

Draft angles help prevent damage to molded parts during ejection.True

Without draft angles, parts can stick to the mold, leading to deformation or surface defects during ejection.

All injection-molded parts require a draft angle.False

While most parts benefit from draft angles, some designs, such as flexible materials or specific geometries, may not require them.

What are the Factors That Affect the Design of Draft Angle?

Draft angles are essential in injection molding, ensuring easy part ejection and reducing defects. Proper design enhances manufacturing efficiency and product quality across industries.

Draft angles are shaped by material type, surface finish, mold complexity, and part geometry, typically ranging from 1° to 3°. Proper design minimizes friction, prevents defects, and prolongs mold life, considering material shrinkage and texture needs.

Plastic Material

The degrees of shrinkage and the friction levels of the various kinds of plastics will also vary, and thus different draft angles are needed. For instance, for polyethylene and polypropylene, smaller values of draft angles are desirable, but for nylon, injection molding draft angle is relatively larger. Recommended draft angles for common plastic materials2 are as follows:

Polyethylene (PE): 0.5°-1.5°

Polypropylene (PP): 1°-2°

Polystyrene (PS): 0.5°-1.5°

ABS: 1°-2°

Nylon (PA): 2°-3°

Product Structure

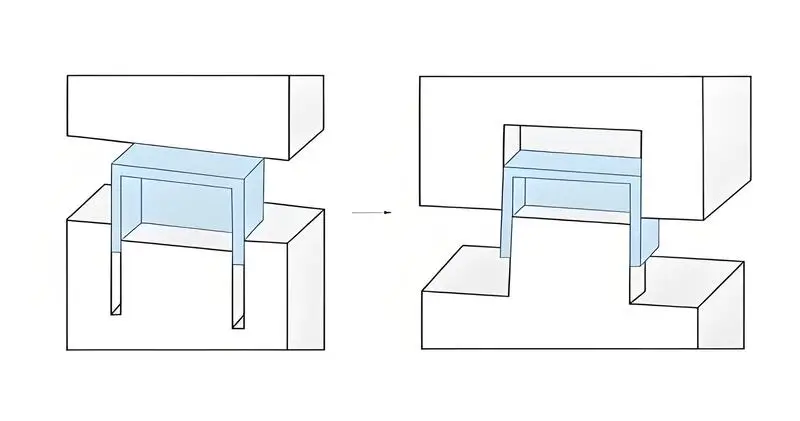

The draft angle is also affected by the shape and structure of the product. It should be noted that products with complex shapes and uneven wall thickness should have a larger draft angle for easy demolding. For example, parts with complex geometric features or micro features such as internal ribs will generate a lot of resistance during demolding, so the draft angle needs to be increased.

Mold Processing Precision

The higher the mold processing accuracy3 and the smoother the surface, the smaller the required draft angle. On the contrary, if the mold surface is rough, the draft angle needs to be increased to reduce the ejection force. Lubrication, high-precision processing, and surface treatments such as polishing and chrome plating can help reduce friction and improve ejection efficiency.

Injection Process Parameters

Other important process parameters such as injection pressure4, temperature and speed also affect the draft angle design. Higher injection pressure and temperature have effect in terms of increasing the shrinkage rate of plastic part and may demand a bigger draft angle. Varying process conditions impact the material’s behaviour in terms of its flow and solidification, meaning that these elements must be addressed in the design process.

Draft angles help prevent part damage during ejection.True

A proper draft angle reduces friction between the molded part and the tool, allowing for smooth ejection and minimizing defects.

All injection molded parts require a draft angle.False

While most parts benefit from draft angles, some designs with flexible materials or special ejection mechanisms may not require them.

What are the Basic Principles of Draft Angle Design?

Draft angles are essential in injection molding, ensuring easy part ejection and reducing defects. Proper draft angle design enhances manufacturing efficiency and extends mold lifespan.

Draft angles, typically 1° to 3°, aid in smooth ejection of molded parts, preventing sticking and deformation. They enhance part quality, reduce wear, and boost production efficiency, depending on material and texture.

Select Draft Angle Based on Plastic Type

Different plastic materials have specific draft angle requirements. Reference draft angles for common plastic materials are as follows:

Polyethylene (PE): 0.5°-1.5°

Polypropylene (PP): 1°-2°

Polystyrene (PS): 0.5°-1.5°

ABS: 1°-2°

Nylon (PA): 2°-3°

Consider Product Wall Thickness and Shape

The greater the shrinkage of thick-walled products, the greater the draft angle required. Products with complex shapes, such as internal threads or grooves, also require increased draft angles.

Ensure Smooth Mold Surface

Enhancing the mold surface finish will definitely help to minimize the ejection resistance, implying that it will minimize the draft angle which is required in the molding process. The common practices used are polishing and chrome plating.

Ensure Reasonable Injection Process Parameters

When designing draft angle the necessary parameters of injection process have to be taken into consideration in order to guarantee the mold design compliance with the injection process. For example, decreasing injection pressure and temperature will decrease the shrinkage rate of the designed plastic part and in turn, enhance the draft angle design.

Draft angles help prevent part sticking during ejection.True

A proper draft angle reduces friction between the part and mold, allowing for easier removal without damage.

All injection-molded parts require a draft angle.False

Some parts, especially those using flexible materials or specific mold designs, may not require a draft angle.

What is the Relationship Between Draft Angle And Mold Life?

Draft angles play a crucial role in injection molding, directly impacting mold longevity and part ejection efficiency. Proper draft angles reduce wear and tear, extending the mold’s service life.

Draft angles reduce friction during part ejection, minimizing mold stress and preventing sticking and damage. Proper angles extend mold life, improve efficiency, and lower production costs by reducing maintenance needs and preventing early mold failure.

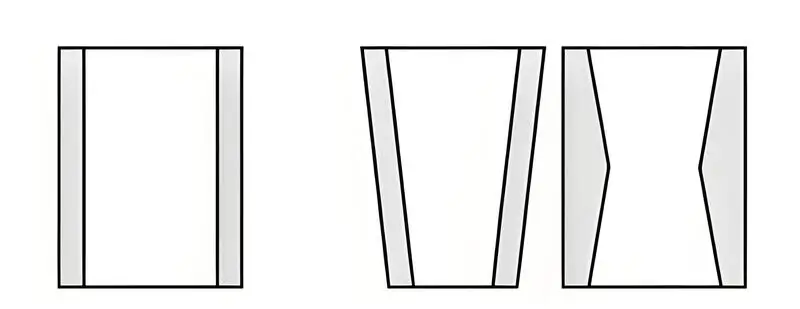

A reasonable draft angle can not only affect the quality of the plastic parts, but it also directly acts on the lifetime of the mold. When the draft angle is too small, there comes a lot of friction between the plastic part and the mold and therefore wears the surface; when the draft angle is too large, it will influence the dimensions of the product. Thus, angle designs required in a draft feature the kind of material used in the mold, the kind of surface treatment required, and other factors that will ensure a longer mold life and improved efficiency.

Larger draft angles extend mold life by reducing friction.True

Increased draft angles allow easier part release, reducing mechanical stress and prolonging mold durability.

Draft angles are unnecessary for injection molding.False

Without draft angles, parts may stick to the mold, causing defects, increased wear, and frequent maintenance, ultimately shortening mold life.

What are the Methods for Optimizing Draft Angle?

Optimizing the draft angle in injection molding enhances part ejection, reduces defects, and improves overall production efficiency. Proper draft angles minimize friction and ensure high-quality molded parts.

Draft angle optimization adjusts angles considering material, thickness, and geometry, typically 1-3 degrees. Textured surfaces need more. Proper angles enhance mold release, reduce wear, and boost durability.

Computer-Aided Design (CAD)

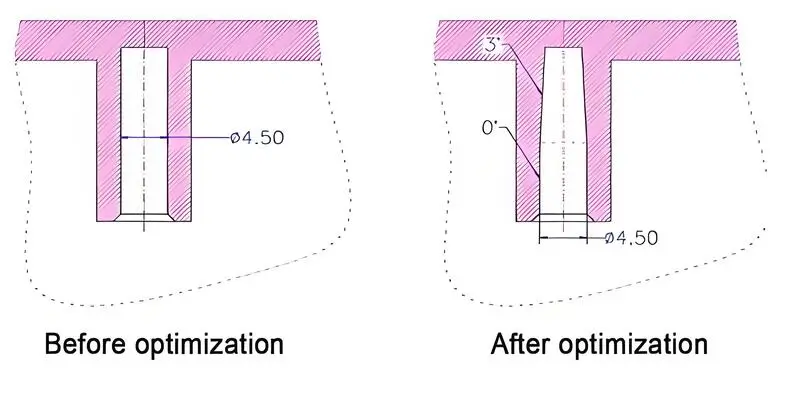

CAD software can accurately calculate and simulate draft angles for injection molds. Pre-calculating and simulating ideal angles can reduce the possibility of blind design and thus improve design efficiency. For example, when using software for draft analysis, areas where there may be problems can be found and modified.

Numerical Simulation

In mold design, numerical simulation technology can forecast the effects of different draft angles on the quality of end product and the service life of mold which helps to select the most appropriate design schemes. Calculations that are possible with Finite Element Analysis (FEA)5 software include stress distribution and deformation during the injection process which can help in choosing the right draft angle for the micro mold.

Experimental Verification

In the real production process, it is necessary to compare the effects of different draft angles by experimental confirmation in order to gradually optimize the angle. In the course of experiments, measuring ejection force6 and observing product surface quality7 can evaluate the rationality of the draft angle.

Comprehensive Consideration

During draft angle design should take into account the characteristics of the material, structure of the product, processing of the mold and the injection process parameters so that the designed angle of the draft should be capable of sparing the quality of the product and durability of the mold.

A proper draft angle reduces ejection force in injection molding.True

With an appropriate draft angle, parts release smoothly from the mold, reducing stress on both the part and the tooling.

All injection-molded parts require a draft angle.False

Some parts, like flexible materials or those using specialized ejection methods, may not require a draft angle.

What are the Common Problems And Solutions for Draft Angle of Injection Molds?

The draft angle is critical for the smooth ejection of parts in injection molding. Improper angles can cause defects, inefficiencies, and high costs.

A balanced draft angle in molding ensures easy part release, prevents distortion, minimizes ejection difficulty, and reduces mold wear, promoting smooth production and fewer defects.

Difficult Ejection

When ejection difficulty happens during production, the draft angle should be measured for a possibility of being small. In order to optimize separation, draft angle should be increased and the mold surface can be polished or chromed plated to decrease friction.

Product Deformation

Even when the product is ejected, it bends due to an overly extended draft angle or, in other cases, due to the lack of reasonable mold design. The mold design should be assessed regarding the compatibility of the product’s geometric shape, while the appropriate angle of the draft should be selected.

Surface Scratches

Common causes of a surface scratch include lack of draft angle or a rough surface of the mold. This problem can be solved by raising the angle of the draft and increasing the surface quality of the mold8.

Excessive Ejection Force

High ejection force can be attributed to small draft angle and or improper selection of the injection process parameters. The ejection force can be minimized by modifying the draft angle on the parts and improving the injection process variables such as decreasing the injection pressure and temperature.

Incorrect draft angles cause ejection problems.True

An improper draft angle can make it difficult to eject parts, leading to defects and increased wear on the mold.

Excessive draft angles are always better.False

While excessive draft angles may ease ejection, they can lead to structural weaknesses in parts and unnecessary material waste.

What are the Practical Application Cases of Draft Angle of Injection Molds?

Draft angles are critical in injection molding, ensuring easy part ejection and preventing damage to the mold. This feature is widely applied in various industries to enhance production efficiency.

Draft angles minimize friction during part ejection from molds, enhancing efficiency in automotive, consumer goods, and electronics by reducing cycle times and mold wear.

Case 1: Draft Angle Design for Polypropylene Plastic Parts

A company designed a polypropylene cap with a wall thickness of 2mm. The recommended draft angle of polypropylene is about 1.5°. In the early stage of production, it was found that there were scratches on the edge surface when the product was ejected. After increasing the draft angle to 2°, the scratch problem was solved and the product qualification rate was improved.

Case 2: Draft Angle Design for Nylon Plastic Parts

An electronic product housing made from nylon was encompassed a quite complicated structure and the thickness of shells was uneven. The first design of the draft angle was at 2°, yet, based on the production trials, some problems were identified as follows: Ejection and appearance of surface deformities. Thus, raising the angle of a draft to 3° and having a glossy finish of the mold allowed for the ejection without any hindrances.

Case 3: Draft Angle Design for Complex-Shaped Plastic Parts

The shell of a certain household appliance is made of ABS material, with a complex structure, many grooves and ribs. When calculating the draft angle, the initial draft angle is set as the first parameter to 1.5°. During the trial production, some grooves had difficulty in ejection. By increasing the draft angle of the groove to 2.5° and chrome-plating the mold surface, the ejection problem was solved and a perfect product was produced.

Case 4: Small Electronic Product Housing

A company created housing of a small electronic product of its own using ABS material. Thus, the initial draft angle used was 1 degree. Based on the trial production, the following problems were observed; ejection difficulties9 and surface scratc

Case 5: Automotive Component

An automotive parts manufacturer needs to produce a high-precision nylon body injection molded part with an initial draft angle of 2.5°. Small batch tests found that demolding was difficult and the mold surface wear rate was high. Increasing the draft angle to 3.5° and chrome-plating the mold surface solved the demolding problem and extended the mold life.

Case 6: Household Product Plastic Part

A daily necessities factory produces polypropylene plastic containers with a wall thickness of 3mm. The initial draft angle is 1.5°. During the trial production, the product is easy to deform when demolding. The draft angle is increased to 2.5°, the injection process parameters are optimized, the demolding is smooth, and the product quality is improved.

Draft angles improve part ejection and reduce molding defects.True

Draft angles ease the ejection process by reducing friction, which minimizes part damage and mold wear.

A higher draft angle always leads to better results.False

While a larger draft angle can ease part removal, too steep of an angle may compromise the structural integrity of the part and increase mold complexity.

What is the Future Development Direction of Draft angle of Injection Molds?

The draft angle in injection molding plays a crucial role in part ejection, improving moldability and cycle times. Its future development focuses on precision and design optimization for efficiency and cost savings.

Future injection mold draft angles focus on reducing parting line visibility, enhancing mold release, and minimizing waste, utilizing advanced designs for improved product quality and faster production.

As injection molding technology enhances draft angle design also enhances and adopts the best method. As the computer and numerical simulation technology progresses, the draft angle design will be even more accurate and faster created. At the same time, application of the new materials and processes will also introduce the new challenges and possibilities for the draft angle design. For example, the innovation of 3D printing technology provides new opportunities to design and create the molds of complex shapes.

Draft angles help reduce mold ejection issues.True

Draft angles reduce friction during ejection, preventing damage to the molded part and improving cycle times.

Increasing draft angles always improves mold efficiency.False

While draft angles improve ejection, excessively large angles can reduce the strength of the molded part and affect design aesthetics.

Conclusion

Draft angle is one of the essential parameters in injection mold design, which directly affects product quality and the production speed of molded products.

Therefore, on the basis of a reasonable draft angle, a reasonable choice of comprehensive consideration of factors such as plastic material type, product structure, mold processing accuracy, injection molding 10 process parameters, etc. can achieve a high success rate and high economic benefits of injection molding. In practical applications, the continuous improvement and verification of draft angle design can enable molds and products to play a greater role.

-

Understanding the significance of draft angle can enhance your knowledge of mold design and improve production quality. ↩

-

This resource will provide valuable insights into material-specific requirements, ensuring better design choices. ↩

-

Exploring this topic will provide insights into optimizing mold design for better efficiency and product quality. ↩

-

Injection pressure plays a vital role in the molding process. Discover how it impacts quality and efficiency by checking this resource. ↩

-

FEA is essential for predicting mold performance. Learn how it can enhance your design process and improve outcomes by visiting this link. ↩

-

Exploring the relationship between ejection force and molding can help optimize your production techniques and product quality. ↩

-

Learning about surface quality improvement can lead to better product aesthetics and functionality, crucial for market success. ↩

-

Learning about the impact of mold surface quality can lead to better product finishes and reduced defects in your manufacturing. ↩

-

Exploring the causes of ejection difficulties can help you troubleshoot and improve your production processes effectively. ↩

-

Learn about How to Optimize an Injection Molding Process?: Injection molding is the process of making semi-finished parts of a certain shape by pressurizing, injecting, cooling, and separating the molten raw materials. ↩