Injection mold polishing enhances the surface finish of molded parts, vital for achieving aesthetic and functional standards across industries like automotive, electronics, and healthcare.

Injection mold polishing smooths surfaces to improve aesthetics and functionality by eliminating defects, crucial for high-quality, competitive products across industries.

Although the basics of injection mold polishing are clear, mastering techniques and understanding material requirements are essential for optimizing production quality. Delve deeper to learn how various polishing methods can elevate your manufacturing results.

Injection mold polishing improves product aesthetics.Vrai

Polishing reduces surface defects, resulting in smoother finishes and visually appealing products.

Polished molds are only used in the automotive industry.Faux

Polished molds are used in various sectors, including electronics, healthcare, and consumer goods, apart from the automotive industry.

What is the Principle and Classification of Mold Polishing?

Mold polishing is essential in the manufacturing process, as it enhances the finish and accuracy of molds used in various industries.

Mold polishing enhances surface quality and minimizes production defects through mechanical, chemical, and electrochemical techniques, benefiting industries like automotive and electronics with extended mold life and superior product quality.

Principle of Mold Polishing

Mold polishing is all about smoothing out the rough and raised parts of the mold surface by grinding and rubbing. There are two ways to do it: mechanical polishing and chemical polishing.

Mechanical polishing is when you use machines to grind and polish, like grinding wheels, polishing paste, and sanding machines. Chemical polishing is when you use chemicals on the mold surface to get rid of the rust and dirt and make it shiny.

Classification of Mold Polishing

Classification according to the polishing method

-

Mechanical polishing: including manual polishing and mechanical equipment polishing. Manual polishing requires operators to have certain skills and experience, while mechanical equipment polishing can improve polishing efficiency and consistency.

-

Chemical polishing: To polish the mold, chemicals are used on the mold surface. These chemicals react with the mold surface to remove oxides and dirt, resulting in a polished mold.

-

Electrolytic polishing: Polissage électrolytique1 is a method that uses selective dissolution to smooth out the surface of a material by dissolving the tiny protruding parts. The process of electrolytic polishing can be divided into two steps: macro-leveling and micro-leveling. Macro-leveling is when the dissolution products diffuse into the electrolyte, reducing the geometric roughness of the material surface, with Ra > 1μm. Micro-leveling is when the surface brightness increases due to anodic polarization, with Ra < 1μm.

-

Fluid polishing:Fluid polishing is a method that uses the high-speed flow of liquid and abrasive particles to wash the surface of a workpiece in order to achieve a polishing effect. Common methods include abrasive jet machining, liquid jet machining, and hydrodynamic grinding.

-

Magnetic polishing: Magnetic polishing is the process of using magnetic abrasives to form abrasive brushes under the action of a magnetic field to grind the workpiece.

-

Polissage par ultrasons2:Place the workpiece in the abrasive solution and put it in the ultrasonic field. Relying on the ultrasonic vibration, the abrasive will grind and polish the surface of the workpiece.

Classification according to polishing granularity

-

Coarse Polishing: Use a rough grinding wheel or polishing paste to get rid of big chunks or scratches on the mold surface.

-

Medium polishing:Use a medium-grit grinding wheel or polishing compound to polish the mold surface and smooth out any small defects. This will help improve the surface roughness.

-

Fine polishing:fine grinding wheel or polishing paste for polishing, used to improve the surface finish and precision of the mold.

Mold polishing extends the life of the mold.Vrai

Polishing reduces surface defects, decreasing wear and tear, which prolongs the mold’s operational lifespan.

Chemical polishing is suitable for all mold types.Faux

Chemical polishing is not ideal for all materials, as it depends on the material properties and desired finish quality.

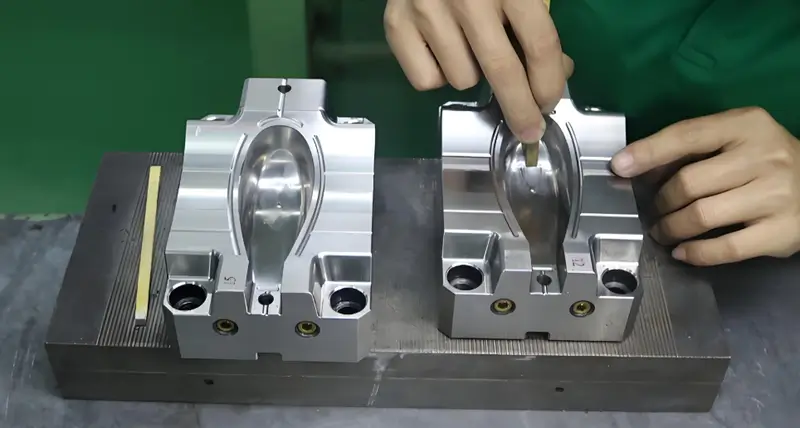

What is the Process Flow of Mold Polishing?

Mold polishing enhances the surface finish of molds, crucial for achieving high-quality end products in industries like automotive, electronics, and medical devices.

Mold polishing is a multi-step process—rough grinding, semi-finishing, fine polishing, and super finishing—essential for achieving smooth surfaces and reducing defects in molded products.

Préparation

Before you start polishing, you need to inspect and prepare the mold first. Check the surface of the mold for any defects such as damage, cracks, or dents. If there are any, you need to repair them first. Also, make sure the surface of the mold is clean and free of dust, oil, or other impurities.

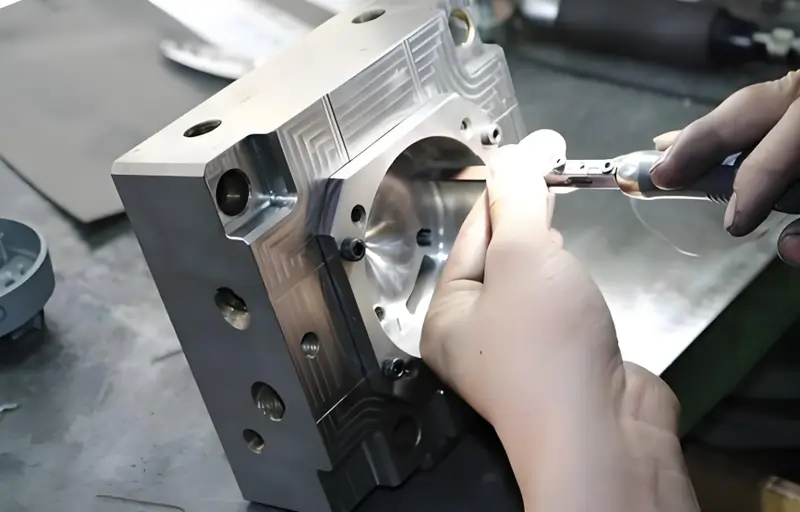

Rough Polishing Process

Rough polishing is the process of smoothing the roughness of the mold surface to a certain extent. Rough polishing is usually done with an abrasive wheel or belt to remove bumps and depressions from the mold surface. This process needs to pay attention to controlling the strength and speed of polishing to avoid excessive wear of the mold.

Intermediate Polishing

After you’ve done the rough polish, you’ll want to do an intermediate polish3. The purpose of the intermediate polish is to further smooth and refine the surface of the mold. Common tools used for this step include sandpaper, emery cloth, and polishing compound.

When you’re doing the intermediate polish, you want to make sure you apply the polishing compound evenly so you get a consistent polish. Also, make sure you use different grits of polishing compound and work your way down to a finer grit to get the surface of the mold as smooth as possible.

Fine Polishing Process

Fine polishing is the last step in mold polishing, but it’s also the most important. During fine polishing4, you’ll use high-precision polishing tools like polishing liquid, polishing paste, and polishing cloth. These tools will help you get an even better surface finish and shine on your mold. When you’re fine polishing, make sure you pay attention to the direction and pressure you’re using to polish so you get the best results on your mold surface.

Polishing Inspection

Do the final inspection. Common inspection methods include visual inspection, hand inspection, and light inspection. By using these methods, we can determine if the surface finish of the mold meets the requirements, and fix any areas that don’t meet the requirements to improve the quality of the mold.

Finally, we do anti-rust treatment5 on the polished mold. We can use rust inhibitor or other methods to protect the mold from rusting and corroding.

Mold polishing improves the surface finish of products.Vrai

Polishing eliminates tool marks and imperfections, resulting in smoother surfaces and enhanced aesthetic appeal.

Mold polishing is unnecessary for achieving high-quality molds.Faux

Polishing is crucial for removing surface defects and is essential for producing high-quality molded products with precise surface textures.

What are the Advantages of Mold Polishing?

Mold polishing enhances quality and efficiency in the manufacturing process by producing smoother surfaces and reducing defects in molded parts.

Mold polishing enhances surface finish, reduces friction, and improves appearance, benefiting industries like automotive and electronics. It extends mold lifespan, improves part release, and reduces cycle times.

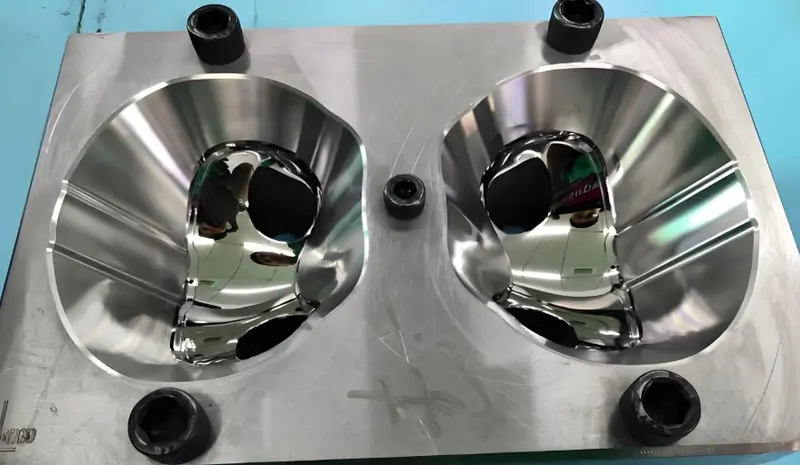

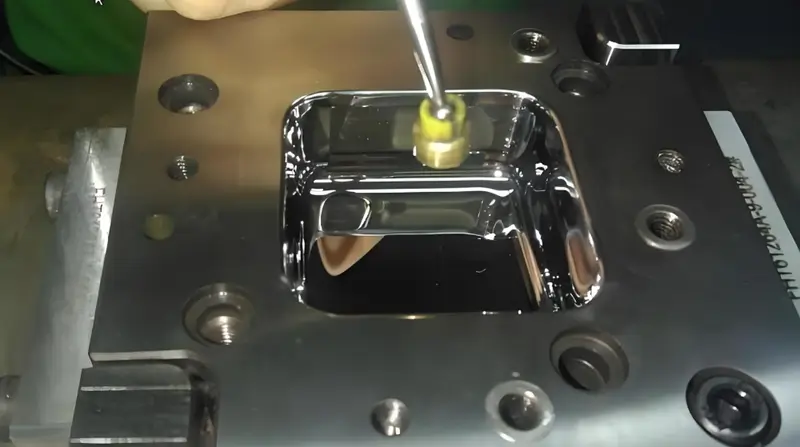

Improvement of Mold Surface Quality

Polishing the mold can remove the roughness on the surface of the mold, and adjust the roughness and shape of the surface to achieve the desired surface quality.

For products that require high-precision processing, the quality of the mold surface directly affects the precision and quality of the product. After the polishing process, the finition de la surface6, flatness, and brightness of the mold can be significantly improved, thereby ensuring the quality of the parts.

Prolonger la durée de vie du moule

Mold in the production process, often with the metal material hard contact, easy to damage. And the roughness of the mold surface is easy to cause cracking and damage to the coating, affecting the life of the mold. Through polishing treatment, it can reduce friction and increase the service life of the mold.

When the mold is used, the surface of the mold will produce pits or scratches due to wear and tear, which will affect the manufacturing quality of the product.

Mold polishing can smooth the surface of the mold, eliminate surface cracks and fatigue defects, and improve the surface toughness, thereby improving the wear resistance of the mold and prolonging the life of the mold.

After polishing, the surface of the mold can remove the oxide layer and rust, reduce the speed of oxidation and corrosion. At the same time, the polished surface of the mold can remain smooth and clean, preventing corrosive media from invading the mold, thus improving the résistance à la corrosion7 of the mold, and then extending the life of the mold.

Enhance Product Aesthetics

Some mold products require high aesthetic requirements, such as household goods and electronic products. Through the polishing process8, the surface of the mold can become smooth, with a high finish and good brightness, thus enhancing the visual effect and overall aesthetics of the product.

Mold is a big deal for making stuff, and how good the mold is made affects how good the stuff looks and fits. If the mold is rough, it will leave marks and bumps on the stuff, and the stuff won’t look as good or fit as well. Polishing makes the mold smooth and flat, so it doesn’t make marks on the stuff, and the stuff looks and fits better.

Mold polishing improves the surface finish of molded parts.Vrai

Polishing removes surface imperfections, resulting in smoother and aesthetically pleasing parts.

Mold polishing is only necessary for aesthetic purposes.Faux

Beyond aesthetics, polishing enhances mold durability and part release, reducing manufacturing defects and downtime.

What are the Factors Affecting the Polishability of Mold Appearance?

The polishability of mold appearance plays a crucial role in ensuring the quality and aesthetic value of molded products, impacting industries from automotive to consumer electronics.

Mold polishability is influenced by material hardness, surface finish, and polishing tools. Key factors include mold design, material selection, and manufacturing precision to achieve desired gloss levels.

Workpiece Appearance Condition

When machining, the surface layer of the material can be damaged by heat, internal stress, or other factors. If the cutting parameters are not correct, it will affect the polishing effect. The surface after EDM is more difficult to grind than the surface after machining or heat treatment, so the EDM should be finished by EDM before it is finished, otherwise the surface will form a hardened thin layer.

Si le EDM finishing9 tool is not selected properly, the depth of the heat-affected layer can reach 0.4mm. The hardness of the hardened thin layer is higher than that of the substrate, and it must be removed. Therefore, it is best to add a rough grinding process to provide a good foundation for the polishing process.

Quality of Steel

Influence of different hardness on the polishing process Increasing hardness makes grinding more difficult, but the roughness after polishing decreases. Due to the increase in hardness, the polishing time required to achieve a lower roughness increases accordingly. At the same time, the possibility of over-polishing is reduced by the increase in hardness.

Good polishing quality requires high-quality steel. Any inclusions or porosity in the steel will affect the polishing effect. To achieve a good polishing effect, the workpiece must be rough polished at the beginning of the mechanical processing.

When a workpiece needs to be mirror polished, you must choose steel with good polishing performance and that has been heat treated. Otherwise, you will not achieve the desired effect.

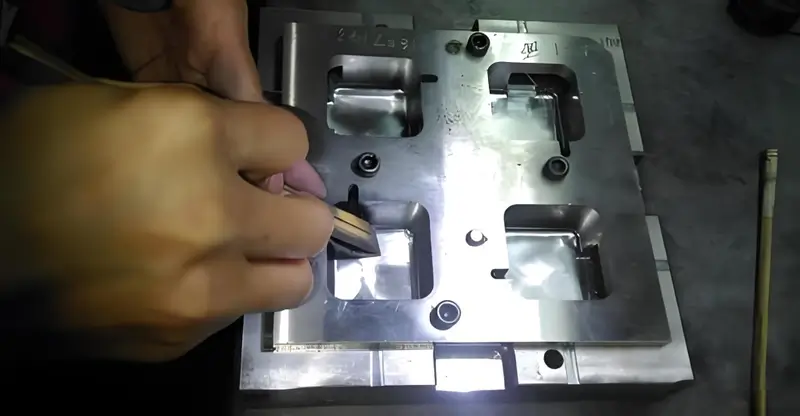

Polishing Technology

Since polishing is mostly done by hand, human skill is still the main factor in the quality of the polish.

People usually think that the polishing technique is what makes a rough surface look smooth. Actually, a good polishing technique should be used in conjunction with high-quality steel10 and the right heat treatment process to achieve a satisfactory polishing effect. Conversely, if the polishing technique is not good, even if the steel is good, it won’t achieve a mirror effect. Here are some technical points for polishing molds.

-

Surface flatness: The surface of the injection mold should be flat and smooth, with no unevenness, scratches, or other defects. This can be achieved by using appropriate grinding tools and techniques, such as sandpaper, grinding wheels, lapping machines, and so on.

-

Maintien dimensional accuracy11:The dimensional accuracy of the injection mold is very important for the size and shape of the molded product. During the polishing process, we need to pay attention to maintaining the dimensional accuracy of the mold to avoid the dimensional deviation of the mold due to polishing.

-

Avoid deformation and damage:When polishing injection molds, you need to be careful not to deform or damage the mold. Use the right amount of pressure and speed when polishing so you don’t overdo it or do it unevenly and mess up the mold.

-

Cleaning and rust prevention12: After polishing, the injection molds need to be cleaned and rust-proofed to keep the surface of the molds smooth and prolong the service life of the molds. Cleaning can be done by using special cleaning agents and tools, and rust prevention can be done by using rust preventive agents or coating a thin layer of rust preventive oil.

-

Finish: The surface of the injection mold should have a certain degree of finish to ensure the surface quality of the molded product. The polishing process requires using abrasive materials of different grain sizes to gradually remove the imperfections and roughness of the mold surface until you get the desired finish.

-

Remove oxidized layer: When using injection molds, an oxidized layer can form. This layer can mess up the surface quality and the life of the molds. So, when you polish the mold, you need to get rid of the oxidized layer to make sure the mold works right.

-

Removing scratches and imperfections:When you make injection molds, you don’t want scratches or imperfections on the surface. They make your molded parts look bad and not work right.

When you polish your mold, you have to look at it really close and get rid of all the scratches and imperfections. You have to use the right tools and do it the right way to make your mold smooth and perfect.

Material hardness directly impacts the polishability of the mold surface.Vrai

Harder materials can resist scratches better, making them more challenging to polish to a high gloss but offering superior durability.

All molds can be polished to the same degree regardless of material choice.Faux

Different materials have varying hardness and characteristics, affecting how well they can be polished to achieve the desired finish.

How to Solve the Common Problems of Destruction in Mold Polishing ?

Mold polishing is essential in manufacturing, ensuring high-quality finishes and extending the lifespan of molds across diverse industries.

Effective mold polishing improves surface imperfections and enhances durability through techniques like precision grinding and suitable abrasives, essential for maintaining mold integrity in automotive, aerospace, and electronics industries.

Excessive Polishing

The biggest problem we have in our daily polishing process is “over-polishing”. This means that the longer we polish, the worse the mold looks. There are two things that happen when we over-polish: “orange peel” and “pitting”. We over-polish when we use mechanical polishing.

Workpiece Destruction “Orange Peel” Causes

The rough appearance of the workpiece is called "orange peel13". There are many reasons for the occurrence of "orange peel". The most common reason is that the appearance of the mold is overheated or carburized. More CNC learning, please pay attention to WeChat public number (CNC programming teaching).The main reason for the occurrence of "orange peel" is that the polishing pressure is too large and the polishing time is too long.

For example: when using a polishing wheel for polishing, the heat generated by the polishing wheel will easily cause "orange peel". The harder the steel, the greater the polishing pressure it can withstand, and the softer the steel, the easier it is to produce "orange peel" due to excessive polishing.

Abatement of the Workpiece “Orange Peel” Measures

When the exterior quality is not good, many people will increase the pressure of polishing and extend the time of polishing, which often makes the exterior quality worse.

Get rid of the rough look, grind with a slightly coarser grit than the last time you used sandpaper number one, then move up to a finer grit, sanding less hard than you did before.

To relieve stress, cool the blade to below 25°C. Then, start grinding with the finest grit until you’re happy with the result. Finally, polish with less pressure.

Workpiece Appearance “Pitting” the Cause of Formation

When you polish steel, you can get pits in the surface. These pits are caused by non-metallic impurities in the steel, usually hard and brittle oxides, that get pulled out of the steel during the polishing process.

The main causes of pitting14 are: too much pressure when you polish, polishing for too long, steel that isn’t pure enough, and steel that has too many hard impurities. Pitting can also be caused by rust on the mold surface or by not removing the black skin from the material.

Measures to Abate Workpiece Pitting

Take a few passes with the next grit, which is one level coarser than the previous grit, on a soft, well-dressed oilstone before moving on to the final grinding step before moving on to the polishing regimen.

When the grit size is less than 1mm, avoid the softest polishing tools. Tolerate the shortest possible polishing time and the smallest possible polishing effort.

Quality Control of Mold Polishing

-

Pre-polishing surface treatment: Clean, polish, and descale the mold surface to ensure a good surface condition before polishing.

-

Monitoring of polishing process:Control the time, speed, pressure, and temperature of polishing to make sure it’s consistent and stable.

-

Surface inspection after polishing:Look at the mold surface and touch it with your hands to see if it looks and feels right.

-

Record and analyze the polishing effect:Track and analyze the impact of editing, identify issues, and make adjustments as needed.

Proper polishing techniques reduce mold degradation.Vrai

Appropriate polishing methods eliminate surface defects, ensuring longer mold life and better product quality.

Mold polishing is only necessary for aesthetic improvements.Faux

While aesthetics are improved, polishing also prevents mold wear, reducing maintenance costs and extending mold lifespan.

Conclusion

Polishing molds is a way to make them smoother and more precise. There are a few ways to do it, like rubbing them with a machine, using chemicals, or using electricity. You can also do it a little bit, a medium amount, or a lot, depending on how rough the mold is.

Polishing makes the mold look better, last longer, and makes the things it makes look better. The things that make a difference are how the mold looks, what kind of steel it’s made of, how it was heated up and cooled down, and how you polish it. If you use good acier 15and do it right, you can make a mold that’s really precise and lasts a long time, and you can make things that look good and you can make a lot of them.

-

Learn about electrolytic polishing, a unique method for achieving a smooth mold surface through selective dissolution. ↩

-

Discover the advantages of ultrasonic polishing, a modern technique that enhances surface finish using ultrasonic vibrations. ↩

-

Understanding intermediate polishing techniques can enhance your mold finishing skills and improve product quality. ↩

-

Exploring fine polishing tools will help you achieve superior surface finishes and precision in your molds. ↩

-

Learning about anti-rust treatments can prolong the life of your molds and maintain their quality over time. ↩

-

Understanding surface finish can help improve manufacturing processes and product outcomes. ↩

-

Learn about techniques to enhance corrosion resistance, ensuring longer mold life and better product quality. ↩

-

Understanding the polishing process is crucial for achieving high-quality finishes in mold making, enhancing product aesthetics. ↩

-

EDM finishing plays a vital role in mold preparation, impacting the overall polishing quality and final product appearance. ↩

-

High-quality steel is essential for effective polishing, ensuring durability and a superior finish in mold production. ↩

-

Understanding dimensional accuracy is crucial for producing high-quality molded products. Explore this link to learn more about its significance. ↩

-

Effective rust prevention extends the life of injection molds. Discover best practices and techniques to keep your molds in top condition. ↩

-

Learn about the causes of orange peel and how to prevent it for better surface quality in molded products. This knowledge is essential for mold maintenance. ↩

-

Understanding the causes of pitting can help you avoid common pitfalls in the polishing process, ensuring better results. ↩

-

Learn about What are the Commonly Used Steel Materials for Injection Molds?Commonly used steel materials for injection molds include P20, H13, and S7 steels. ↩