Injection molding is one of the popular molding technologies used in the production of plastics nowadays. It is a process of heating the plastic to its moldable state, then injecting it into a mold then hardening the plastic to the required shape. But, it is quite evident that gates are inevitable in the process of injection molding. It is the opening through which the molten plastic is fed into the mould cavity by use of an injection machine. If the product is molded, then gate has to be removed from the molding. This paper will coupled with some case studies and future trend, this article will explain and describe the methods and techniques and precautions for gate removal after injection molding etc.

Types and Characteristics of Gates

When you’re doing injection molding, the type of gate you put on your layout and the type of gate you specify for your layout actually do affect the quality of your finished product and how easy it is to get it out. When it comes to getting it out, there are basically two gates; what gate type you decide to use is what determines what kind of getting it out method you use in a particular situation.

Direct Gate

Direct gates are the most common type, usually used for large or simple-shaped products. This type of gate is located directly at the product’s injection point, making it relatively easy to remove but may leave noticeable marks.

Submarine Gate

Submarine gate, also known as tunnel gate, is located inside the mold, and the gate location is not easily visible from the surface of the part. The latter is more distinct than the former, but it is less noticeable on the surface after it is removed, but the removal process is more complicated and requires special tools and techniques.

Edge Gate

Edge gates are located at the edge of the part and are useful where the part is thin, that is, the part has thin walls. The result is faint scratches that may affect the edge quality of the part, which requires delicate techniques to remove without damaging the part.

Pin Gate

Pin gates are defined for small and compact devices and typically have very small gates. Looking at the residual appearance, one can note that only tiny traces remain, but the mold is extremely precise in terms of processing and the removal is even more detail-oriented, tools are very precise.

Disk Gate

Disk gates are often used as tools to create thin-walled and large-area products to ensure uniform distribution of the plastic deformation zone and cooling. However, removal is a very demanding process, so it requires special equipment to be used and experienced operators to handle.

Methods for Removing Gates

Gate removal is a very important process that is done after the injection molding process is complete. There are a few different ways to remove the gate, such as mechanical cutting, thermal cutting, and chemical cutting. Each method has its pros and cons, and which one you choose depends on the situation with your product.

Mechanical Cutting

Mechanical cutting is the most commonly used gate removal method, including the following tools and techniques:

1. Shearing Tools

Scissors and pliers are other shearing tools that can be used to cut off sprues and runners. It is easy to use but requires a skilled operator and leaves a rough edge. It is best for small metal forming jobs where you are making a small number of simple parts.

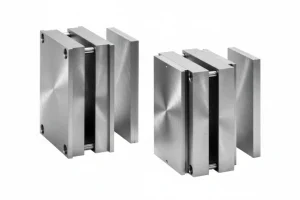

2. Machine Cutting

If you need to remove complex shapes and larger gates, you can use specialized machines like milling machines and lathes to make precise cuts. The advantage of machine cutting is that it’s very precise and leaves a smooth surface. But the equipment is expensive, so it’s best for mass production and high-precision products.

3. Cutting Tools

Hand knives and electric knives are good for removing small and fine gates. They are flexible to use, but you need to be careful to avoid accidents. Hand tools are good for flexible operations, while electric tools are good for getting things done faster.

4. Grinding Tools

Using grinders or handheld grinding tools to polish and finish the gates is suitable for further fine processing of the product during the removal process. Grinding tools can remove fine burrs and irregular surfaces, ensuring the final product quality.

Thermal Cutting

Thermal cutting uses high temperatures to melt the gate for removal, suitable for thermoplastic materials. Common thermal cutting methods include:

1. Hot Knife

A hot knife gets hot by electricity, melts and cuts the gate. The hot knife cuts fast, good for making a lot of parts, but you have to control the temperature of the knife so you don’t get it too hot and mess up the part. Good for all kinds of gates, especially big gates that go straight in.

2. Laser Cutting

Laser cutting is the use of a high-energy laser beam for precise gate cutting, suitable for high-precision products. The advantages of laser cutting are high precision and speed, but the equipment cost and maintenance expenses are high. It is widely used in precision industries and high-end manufacturing.

3. Ultrasonic Cutting

Ultrasonic cutting is a method that uses high-frequency vibrations to locally melt the gate area. It is suitable for small and thin-walled products. Ultrasonic cutting has high precision, but it requires high equipment and operational skills. It is suitable for high-end precision manufacturing.

Chemical Removal

Chemical removal uses solvents or reactants to dissolve or decompose the gate, suitable for specific types of plastics. Common chemical removal methods include:

1. Solvent Removal

To remove the gate, you can use a solvent that dissolves the gate material but not the injection molded plastic part. You can use this method for both thermoplastic and some thermosetting materials. The advantage of using a solvent to remove the gate is that you will get a smooth surface without any marks or scratches that you can see. However, you need to be careful when you choose the solvent and how you use it so you don’t damage the part. This method is used in industries that need a high-quality surface, like the medical and food industries.

2. Chemical Reaction Removal

Using chemicals to break down the gate, especially for those special materials that are likely to be suitable for this structure. The major advantage of chemical removal is that it is precise. When using two chemicals, you have to be very careful to avoid dangerous things. This is very good for removing gates in high molecular weight materials and composites.

3. Soluble Coating

Using an inlay that is applied at the gate location before the actual molding process, and that can be washed off after molding. Mainly used for products with high surface roughness requirements, which is perfect for products with high accuracy.

Electrical Discharge Removal

EDM (Electrical Discharge Machining) uses electrical sparks to erode the metal and remove the gate. It is suitable for very hard and complex-shaped gates. This method is highly precise but less efficient, and is usually used in high-end applications in precision manufacturing.

Precautions for Removing Gates

Several precautions need to be taken during the gate removal process:

Ensuring Safety

Whether you’re using a mechanical cutter or a thermal cutter, you need to wear the right personal protective equipment (PPE), like gloves and goggles, to keep yourself safe. And remember, you’ve got to use and maintain your equipment properly to avoid accidents caused by equipment failure.

Controlling Cutting Precision

During gate removal, you need to be careful with how much force you use and the angle of your cutting tools so you don’t leave marks on the surface of the thing you’re cutting. If you’re using a machine to cut, you have to be careful not to use too much force or you’ll mess up the thing you’re cutting.

Selecting Appropriate Methods

To avoid quality issues, you need to choose the right way to remove the product based on the material, shape, and gate type. For example, high-precision products should use precision cutting or laser cutting methods, while ordinary products in mass production can use shearing tools or hot knives.

Avoiding Secondary Processing

As a rule, after removing the gate, it is necessary to exclude any influences affecting the secondary processing of the product as it can influence its structure and performance. If necessary, fine polishing or surface treatment techniques can be employed to ensure product quality.

Maintaining Cleanliness

When removing the gate, you expose the work area to the outside world. You want to make sure that the area is clean so you don’t drop any plastic or cutting residue on your part. It’s important to keep your work area and your tools clean. It will help you make more parts and make better parts.

Inspection and Quality Control

After removing the gate, it is necessary to strictly inspect and control the quality of the product to ensure a smooth and defect-free cutting surface that meets the design and performance requirements. Advanced inspection equipment and techniques such as laser scanning and ultrasonic testing should be used to ensure high product quality.

Automated Gate Removal Technologies

With the development of industrial automation, people pay more and more attention to the technology of automatic gate removal. The technology of automatic gate removal includes the use of robot cutting, CNC machine tools, and automatic production lines. The use of automatic technology can improve production capacity, reduce labor costs, and ensure product quality.

Robotic Cutting

You can buy and use industrial robots to cut more accurately with mechanical arms, which makes it easier to remove gates. Robotic cutting is especially good for making a lot of parts because humans aren’t as good at it. Modern robotic cutting systems have cameras and software that help them find the gates and cut them really well.

CNC Machines

CNC machines are programmed to automatically cut through other materials using previous programs, which makes it convenient when trying to remove high-precision or complicated shapes in the gates. Comparatively, the advantages of CNC machines are that they operate stably and guarantee high cutting quality; nevertheless, the necessary investment in the equipment is rather high. CNC machines are essential in different industries, including aviation, automobile industry, electronics industry because of its high precision and accuracy.

Automated Production Lines

Integrating the gate removal process into automated production lines achieves integrated operations. Automated production lines can improve production efficiency and reduce labor costs, but require high initial investment and maintenance expenses. Automated production lines are usually equipped with multiple functional modules such as cutting, polishing, inspection, and packaging, achieving comprehensive automation operations.

Vision-Guided Systems

Vision-guided systems combine machine vision technology with hardware to autonomously identify objects and locations and autonomously perform actions. It is commonly used in the production of new, high-precision products to increase efficiency in manufacturing processes and improve the quality of the end product.

Multi-Axis Systems

Multi-axis systems can achieve precise cutting in multiple directions and angles, suitable for complex-shaped and high-requirement products. These systems usually combine robotic and CNC technologies to perform high-precision removal operations.

Case Studies

The following are some case studies demonstrating the effectiveness of different gate removal methods in specific applications:

Case Study 1: Mechanical Cutting of Large Injection-Molded Products

A manufacturer of large glass reinforced products mainly uses direct gates and removes them by using shearing tools. The operators adjust the cutting force and angle very precisely to get a good finish on the faces that need cutting and the final product meets the customers’ specifications. The company also tried to put some computerization into the production line to make it more productive.

Case Study 2: Laser Cutting of Small Precision Parts

Electronics Components manufacturers make miniaturized accurate plastic elements through pin gate design and laser cutting to get rid of. Laser cutting seem to be more accurate with fewer burn marks and kerf width on the cut part of the material. Moreover, to ensure quality parts, the company employs vision inspection systems to check for quality.

Case Study 3: Chemical Removal for Special Material Products

A medical device company makes special plastic products, and many of these gates are removed with chemicals. The process of removing the chemicals makes the surface non-porous and clean, without any damage that could be critical to medical use. This company has to do a lot of things to use and dispose of the chemicals in a way that doesn’t hurt the environment.

Case Study 4: Automated Gate Removal in Automotive Parts

A car company makes big plastic parts with a robot that cuts off the extra plastic. They use a machine to make sure the parts are the right size and shape. This way, they can make a lot of parts really fast and not have to pay a lot of people to do it.

Case Study 5: Electrical Discharge Removal of High-Polymer Composite Materials

The drive removal method of a high-tech company focuses on electrical discharge removal technology and high-polymer composite material products. It makes it easier to eliminate gates with such elaborate shapes hence improved precision and efficiency. And also provides the latest inspection equipment to ensure the quality of the products it sells meets the customer’s expectations.

Future Trends

As technology continues to gain foothold in the global market and consumerism gradually progresses, gate removal technology also becomes more sophisticated over time. Future trends in gate removal technology include the following:

Intelligence: The smart technology option will complement the gate removal efficiency and precision in the future. It is proposed to apply artificial intelligence and machine learning to control the process of removal and apply intelligent algorithms for its optimization. Its a technique of intelligent systems to recognize product types and gate positions and logical planning of the cutting paths and modification of the existing paths in a real time way.

Environmental Protection: The attention to the environment grows higher, and that means that in the case of choosing the methods of gate removal, the companies will also fit more attention to the protection of the environment. Such kinds of methods will turn to be harmless and subsequently can be recycled in the future. For instance, the utilization of environmentally friendly solvents in the process manufacturing and biodegradable materials in other production processes helps in minimizing on the pollution of the environment.

Multi-Function Integration: Gate removal equipment of the future will be designed with better integration of multiple functionalities which will include the gate removal feature and will also perform surface treatment, inspection and packaging making the main manufacturing processes automated. Flexible hardware can be helpful in raising the level of output or work rate and also help in cutting costs of investment in equipment and maintenance too.

High Efficiency and Low Cost: To establish improved gate removal images and technologies which should conform to the needs of small and big scale businesses. For example, to enhance the efficiency of small and medium enterprises to counter large-scale industries, the creation of low-cost automatic devices and equipment.

Precision and Miniaturization: Due to the development of the microelectronic and precision engineering industry it will increase the need for gate removal technology to go through higher level of precision and minuted size. Miniaturization in manufacturing and increased precision will lead to micro laser cutting and ultra-precision mechanical cutting becoming two vital areas of future development.

Digitization and Data-Driven: Aggregating and analyzing target data for better understanding and constant optimization of the production cycle, the results of which are gate removals, as well as using digital technologies in improving the quality of the final product. Instrumentation and control technology can also use digital technology for on-line monitoring or remote control of production process, in order to enhance utility-production flexibility and responsiveness.

Conclusion

Gate removal is an important step in the injection molding process to ensure good product quality. By choosing the right gate removal method and technology, you can effectively improve the appearance and performance of your products. In the future, with the development of intelligent, environmentally friendly, and multi-functional integrated technologies, the gate removal process will become more efficient and environmentally friendly. When choosing a gate removal method, companies need to consider the characteristics of their products, production costs, and environmental impacts in order to achieve the best production results. By continuously innovating and optimizing the production process, you can improve the competitiveness of your products and meet the diverse needs of the market.