Injection molds are a common industrial manufacturing tool that is widely used in the production process of plastic products. It involves heating plastic until it melts, injecting it into a mold, and then cooling and solidifying it into the desired shape. Injection molds are known for their efficiency, precision, and good repeatability, making them widely applicable in industries such as automotive, electronics, household appliances, and medical devices. This article will introduce the basics of injection molds, including types, structures, design principles, material selection, and more.

Ⅰ. What is an Injection Mold?

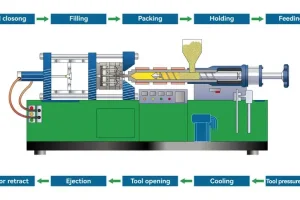

An injection mold is a tool used to make plastic products. It gives them their shape and size. Injection molding is a way to make a lot of parts that are the same shape. It works by melting plastic and putting it into a mold. The plastic cools and becomes a solid. Many things we use every day, like computers, phones, and car parts, are made with injection molds. The main things you need to make parts with injection molding are an injection molding machine and a mold.

Ⅱ. Components of an Injection Mold

1. Injection Mold Sprue System

The sprue system of an injection mold is the passage through which plastic material flows from the nozzle of the injection molding machine to the product. It includes the main runner, sub-runners, cold wells, and gates, and can also include hot runner systems that inject directly onto the product’s surface.

2. Injection Mold Frame

The mold frame, also called the mold base, is the main assembly of the mold where all components are mounted. It precisely fixes the mold onto the injection molding machine, completing the injection process.

3. Mold Cavity Forming Section

The mold cavity is a sealed space formed by the combination of the mold’s core and cavity, sliders, angle pins, inserts, and other components, according to the structure of the plastic product. Plastic enters this sealed cavity under pressure from the injection machine, solidifying to form the actual product with the same structural shape as designed. This sealed space is the mold cavity.

4. Mold Cooling System

Hot plastic fills the mold at high temperatures and needs to cool quickly for the plastic part to harden. To meet the temperature requirements of the injection process, a temperature control system adjusts the mold’s temperature. For thermoplastic injection molds, cooling systems are designed to cool the mold. Common cooling methods include opening cooling water channels inside the mold to remove heat through circulating water; heating the mold can also be achieved by using hot water or steam in addition to cooling water channels, electric heating elements can be installed inside and around the mold. Besides cooling, the cooling system can also be used to control product deformation.

5. Mold Positioning System

The positioning system of an injection mold usually has three levels of positioning. The first level is guide pillar positioning, which is mainly used for rough positioning of the front and rear molds over long distances; the second level is right-angle block positioning, also known as side locking positioning, which is used to position the front and rear mold bases; the third level is precise positioning of the front and rear mold cores, and each level is more precise than the previous one.

6. Injection Mold Ejection System

Once the mold opens, it’s important to make sure the part stays on the back side of the back mold and is held tightly there. The ejection system uses the ejection force transmitted by the injection machine’s ejector rod and the mechanisms installed on the mold ejection plate to push the part off the back side of the back mold core, so the part can be taken off the mold surface. The ejection mechanism includes ejector pins, sleeves, ejector plates, angle pins, etc.

7. Injection Mold Venting System

The venting system of the mold is very important in mold design. When molten plastic fills the mold cavity at a very fast rate, air inside the cavity must be rapidly expelled to make space for the molten plastic to flow smoothly. Injection speeds can be as fast as bullets, so a fast and effective venting system is very important. Gas venting mainly relies on: clearance of ejector pins, clearance of inserts, clearance of vent inserts, and parting surface venting.

Ⅲ. Classification of Injection Molds

1. Based on the molding process: hot runner molds and cold runner molds.

2. Based on the molding material: metal molds and non-metal molds.

3. Based on the production volume: prototype molds (simple molds) and production molds.

4. Based on the mold materials: soft molds and hard molds.

5. Based on the product shape:

- Flat molds: used for making flat-shaped products, like covers, panels, etc.

- Long strip molds: used for making long strip-shaped products, like pipes, cable trays, etc.

- Box molds: used for making products with a certain volume, like boxes, containers, etc.

6. Based on the mold structure:

- Single-cavity molds: only one cavity, suitable for producing one product.

- Multi-cavity molds: multiple identical cavities, can produce multiple products at the same time.

- Multi-component molds: can inject multiple materials at the same time, producing composite products.

Ⅳ. Injection Mold Design

1. Design Basis, Dimensional Accuracy, and Correctness of Related Dimensions

Determine which category your plastic products belong to based on their specific requirements and functions. For example, toys are plastic products that require high aesthetic quality but don’t need to be dimensionally accurate. Functional plastic products, on the other hand, need to be dimensionally accurate. Cameras are plastic products that need to be both aesthetically pleasing and dimensionally accurate. Is the draft angle for demolding reasonable? The draft angle for demolding directly affects the demolding and quality of your plastic products. In other words, it determines whether the injection process can proceed smoothly.

Here are some things to consider when determining whether your draft angle is reasonable: Is the draft angle enough? The draft angle should be compatible with the split or parting surface of your plastic product during molding. Will it affect the appearance and dimensional accuracy of your product? Will it affect the strength of certain parts of your plastic product?

2. Preliminary Design, Analysis, and Digestion of Plastic Product Drawings and Samples

① Product geometric characteristics.

② Product dimensions and tolerances.

③ Product technical requirements.

④ Types and grades of plastic particles.

⑤ Product appearance requirements.

⑥ Product inspection standards.

3. Determination of Cavity Number and Cavity Arrangement

① Is the maximum injection volume of the injection machine met?

② Is the clamping force of the injection machine met?

③ Are the external dimensions of the mold within the machine’s requirements?

Product accuracy, color.

④ Are there any side cores on the product and how are they handled?

⑤ Production batch of products.

⑥ Economic benefits (production value per mold).

⑦ Mold cycle evaluation.

4. Determination of Parting Surface

① Minimize appearance impact.

② Ensure product accuracy and facilitate subsequent mold machining.

③ Facilitate gating system, venting system, and cooling system design.

④ Facilitate mold opening (splitting, demolding) to ensure product stays on movable mold side during opening.

5. Design of Gating System

Designing the gating system involves choosing the main runner, deciding on the shape and size of the sub-runners, picking gate locations, determining the gate type, and selecting the gate cross-sectional area. When using a point gate, you also need to consider how to remove the gate so that the sub-runners break off. When designing the gating system, the first step is to choose the gate location. The gate location directly affects the quality of the product and the smooth progress of the injection process. The gate location should follow these principles:

① Gates should be located on the parting surface for easy cleaning of the mold during machining and use.

② The distance between the gate position and various parts of the cavity should be as consistent as possible, and the flow path should be the shortest.

③ The gate position should ensure that when plastic enters the cavity, it flows smoothly into wide and thick-walled parts of the cavity to facilitate smooth flow.

④ The gate position should be set at the thickest section of the plastic part.

⑤ Don’t let plastic hit the walls, cores, or inserts directly when it flows. Let it flow into all parts of the cavity as fast as possible and don’t let the cores or inserts get bent.

⑥ Make the weld lines as small as possible or put them in places that don’t matter.

⑦ Make the gate and the way the plastic flows into the cavity so that the plastic flows the same way all over the cavity and so that the air can get out of the cavity.

6. Design of Venting System

The venting system is very important to ensure the quality of the molded products:

① Use vent grooves, usually at the end of the cavity to be filled. The depth of the vent groove varies depending on the plastic, usually determined by the maximum allowable gap for plastic without flash, such as POM below 0.02.

② Use the clearance between the core insert push rod or vent insert needle for venting.

③ To prevent vacuum deformation of the product during ejection, air vents need to be set up.

④ To prevent the product from being vacuum adsorbed to the cavity, air cushions need to be designed.

7. Design of Cooling System

Designing the cooling system is a complex task. It involves considering how well the cooling system cools and how evenly it cools. It also involves considering how the cooling system affects the overall structure of the mold:

① How the cooling system is laid out and what shapes it has.

② Where the cooling system is located and how big it is.

③ How to cool important parts like moving molds or inserts; how to cool sliders and angled tops.

④ How to design cooling parts and how to choose standard cooling parts.

⑤ How well the cooling system is sealed overall.

Ⅴ. Mold Manufacturing Process

1. Mold Manufacturing Preparation

Before you start the injection mold processing, you need to do some preparatory work. First, you need to analyze the mold based on the product requirements and design drawings to determine the structure, size, material, etc. Then, according to the analysis results, select the appropriate processing equipment and tools, and prepare the required materials and auxiliary equipment.

2. Mold Manufacturing

① Making mold blanks: Use the right materials and methods to make mold blanks based on the mold design drawings.

② Making mold cavities: After rough machining the blanks, finish machining them to make mold cavities. The accuracy and finish of the cavities directly affect the quality of injection molded products.

③ Making other mold parts: Make other mold parts like gating systems, cooling systems, and ejection systems based on the design drawings.

3. Mold Assembly

Put the mold parts together to make a mold. When you put the parts together, make sure they fit together well and are in the right place. This will make the mold strong and work well.

4. Mold Trial and Adjustment

Once the mold assembly is done, you need to do a trial production. The purpose of the trial production is to check whether the mold design meets the production requirements, and to adjust and optimize the mold if any problems are found. The trial production process is a key step to ensure the quality and performance of the mold.

5. Trial Production and Inspection

During the trial production process, you need to inspect the produced injection molded products, including dimensions, appearance, and performance. According to the inspection results, you need to adjust and optimize the mold until production requirements are met.

6. Delivery and Use

Once the mold is qualified through trial production and inspection, it can be delivered to the customer for use. During use, the injection mold designer needs to provide necessary technical support and maintenance services to ensure the normal operation and production efficiency of the mold.

Ⅵ. Conclusion

Making injection molds is a testament to human ingenuity and precision engineering. From the initial design stage to the production of perfect molds, each step in the process requires professional knowledge and attention to detail. As we’ve discussed in this guide, injection mold manufacturing is not just a manufacturing process; it is the cornerstone of modern industry.

When you get really good at injection mold manufacturing, you open up a whole new world of possibilities. You can get your innovative products to market faster, make your production processes more efficient, and maintain the highest standards of quality and reliability. Injection mold manufacturing is everywhere, from the automotive industry to the medical industry. It shapes the products we use and the world we live in.

The future of injection mold manufacturing is changing fast. New technologies like 3D printing and automation are changing how molds are designed, made, and used. New materials are also being developed that have better properties and can do more.

As we embrace these advancements, it is important to remember the basic principles that make injection mold manufacturing great: precision, quality, and innovation. By sticking to these principles, businesses and individuals can confidently navigate the ever-changing landscape of manufacturing.

So, whether you’re a seasoned industry veteran or a newbie to manufacturing, take the time to explore the fascinating world of injection mold manufacturing. Learn from the lessons of the past, embrace the present, and look to the future—where injection mold manufacturing will continue to drive innovation, efficiency, and progress.