PP is a translucent, semi-crystalline thermoplastic with high strength, good insulation, low water absorption, high heat deflection temperature, low density and high crystallinity.

Modified fillers usually include glass fiber, mineral filler, thermoplastic rubber, etc.

PP material types

Polypropylene PP materials, divided into two categories: homopolymer PP materials and copolymer PP materials.

Homopolymer PP materials

PP homopolymer, or PPH for short, is a polymer of a single propylene monomer. Polypropylene contains asymmetric carbon atoms on the main chain of the resulting polymer due to the different catalysts and polymerization processes used, resulting in different spatial arrangements of methyl and hydrogen atoms on its losing carbon, and the existence of three different three-dimensional structures of polypropylene.

Homopolymerized PPH can be divided into the following three categories.

a. Isotactic PP: The methyl group is arranged on the same side of the main chain of the molecule, called isotactic polypropylene, with high cleanliness, accounting for about 95% of PP production.

b. Intercalated PP: The methyl groups are alternately arranged on both sides of the main chain of the molecule, called intercalated PP, which has low crystallinity. The current production is small. Highly elastic thermoplastic or elastomer.

c. Irregular PP: The methyl groups are arranged on both sides of the main chain of the molecule in a disorderly manner, called irrational polypropylene, which is not crystalline and viscous and cannot be used as a plastic. APP is a by-product of isotactic polypropylene, its strength is very low, and its use alone is of little value, but it works well as a carrier for filler masterbatch, and can also be used as a toughening modifier for polypropylene, etc.

Copolymer PP materials

PP copolymer, abbreviated as PPC, is obtained by polymerization of propylene monomer with a small amount of other monomers (ethene, butene), and the main chain is distributed with links formed by the reaction of other monomers in addition to propylene links. According to the way of distribution of ethene monomer in the molecular chain.

Copolymer PP can be divided into random copolymer and block copolymer.

a. Random copolymer: ethylene monomer content 1-7%.

Modification method: propylene and ethylene enter into copolymerization at the same time.

Performance: better optical transparency, flexibility, lower melt finger temperature, high impact resistance.

Uses: high transparent film, water and sewage pipes, heating pipes, injection molding products.

b. Block copolymer: 5-20% ethylene monomer content.

Modification method: propylene polymerization after the passage of ethylene block copolymerization.

Performance: better rigidity and low temperature toughness.

Processing performance of PP injection molding

PP processing characteristics

a. The water absorption of PP is low, soaking in water for a day, the water absorption is less than 0.01%, so it does not need to be dried before processing.

b. The melt of PP is close to non-Newtonian fluid, and the viscosity is less sensitive to temperature, but depends on the size of shear rate.

c. PP is a crystalline polymer, the injection molding shrinkage is large, generally up to 1.6%~2%, which has a greater impact on the accuracy of the product and should be noted in the specific design of the mold and determine the process conditions. PP is easy to produce orientation in processing, resulting in differences in performance in different directions, which should be noted in molding.

d. PP products are more sensitive to notches, and products should avoid sharp corners and notches to avoid stress concentration.

e. PP is especially sensitive to oxygen at high temperature, in order to prevent thermal degradation during processing, antioxidant is generally added during resin synthesis. contact between PP melt and copper will lead to degradation, contact with copper should be avoided or anti-copper agent should be added.

f. After annealing treatment, PP products can eliminate residual internal stress and improve impact strength.

PP processing methods

a. Injection molding, extrusion and blow molding are used for molding PP materials.

Injection molding The choice of general injection molding machine, the gate increases with the weight of the product, the raw material melt index is medium (MI is 1 ~ 4.5 )

The specific molding process conditions are: barrel temperature after 160~180℃, in 180~200℃, before 200~220℃, nozzle 200~280℃, mold temperature 60~80℃, injection pressure 40~70Mpa, injection time 20~60s, cooling time 20~60s.

b. Extrusion It can produce film, sheet, pipe and silk products.

The length of the feeding section of the extruder screw should be longer than that of PE to overcome the disadvantage of low thermal conductivity.

The specific molding conditions are: 180℃ for the charging section, 250℃ for the others and 300℃ at the highest. The cooling conditions have great influence on the transparency and impact performance of the products.

PP extruded products can be stretched, i.e. one-way stretching or two-way stretching, the stretching multiplier can be more than 3 times; the strength, impact, transparency, heat resistance, surface gloss and barrier properties of PP products after stretching are significantly improved.

Injection molding conditions of PP

Handling of plastics

Pure PP is translucent ivory white and can be dyed in a variety of colors.PP dyeing is only possible with masterbatches on general injection molding machines. In some machines with separate plasticizing elements that enhance the mixing effect, color powder dyeing is also possible. For products used outdoors, UV stabilizer and carbon black filling are generally used.

The proportion of recycled material used should not exceed 15%, otherwise it will cause strength loss and decomposition discoloration. PP injection molding process generally does not need special drying treatment before.

Injection molding machine selection

There is no special requirement for the selection of injection molding machine. Due to the high crystallinity of PP. It is necessary to use the computerized injection molding machine with high injection pressure and multi-stage control. The clamping force is generally determined by 3800t/m2, and the injection volume is 20%-85%.

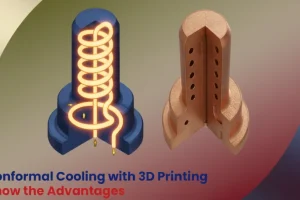

Mold and gate design

Mould temperature 50-90℃, for high size requirement use high mould temperature. Core temperature is more than 5℃ lower than cavity temperature, runner diameter is 4-7mm, pin gate length is 1-1.5mm, diameter can be as small as 0.7mm.

The shorter the length of the edge-shaped gate, the better, about 0.7mm, the depth is half of the wall thickness, the width is twice the wall thickness, and the length of the melt flow in the cavity increases ken by ken.

The mold must have good exhaust, the exhaust hole is 0.025mm-0.038mm deep and 1.5mm thick, to avoid shrinkage marks, we should use large and round injection port and round runner, the thickness of reinforcement should be small (for example, 50-60% of the wall thickness).

For products made of homopolymer PP, the thickness cannot exceed 3mm, otherwise there will be bubbles (thick-walled products can only use copolymer PP).

Melting temperature

The melting point of PP is 160-175℃, and the decomposition temperature is 350℃, but the temperature setting should not exceed 275℃ during injection processing, and the melting section temperature should preferably be 240℃.

Injection speed

To reduce internal stress and deformation, high speed injection should be chosen, but some grades of PP and molds are not applicable (bubbles and air patterns appear). If light and dark streaks appear on the engraved patterned surface spread by the gate, low speed injection and higher mold temperature should be used.

Molten back pressure

Available 5bar melt back pressure, the back pressure of color powder material can be adjusted higher.

Injection and pressure holding

Use a higher injection pressure (1500-1800 bar) and holding pressure (about 80% of the injection pressure). Turn the holding pressure at roughly 95% of the full stroke and use a longer holding time.

Post-processing of finished products

To prevent shrinkage and deformation from post-crystallization, the products are generally treated with hot water soaking.

Advantages and disadvantages of PP material

Odorless and non-toxic. The melting point can be as high as 167℃ because of the regular structure and high crystallization. Heat and corrosion resistance, and steam sterilization of products are its outstanding advantages. Small density, is the lightest general-purpose plastic. The disadvantages are poor low temperature impact resistance and easy aging, but can be overcome by modification respectively.

Copolymer type PP material has lower heat deflection temperature (100℃), low transparency, low gloss, low rigidity, but has stronger impact strength, and the impact strength of PP increases with the increase of ethylene content.

The Vicat softening temperature of PP is 150℃. Due to the high crystallinity, this material has good surface stiffness and scratch resistance,PP does not have the problem of environmental stress cracking.

Advantages of PP material

- small relative density, only 0.89-0.91, is one of the lightest varieties of plastics.

- good mechanical properties, in addition to impact resistance, other mechanical properties are better than polyethylene, molding and processing performance.

- with high heat resistance, continuous use temperature up to 110-120 ℃. 4.

- good chemical properties, almost no water absorption, and most chemicals do not react. 5.

- Pure texture, non-toxic. 6.

- good electrical insulation.

- Transparency of polypropylene products is better than that of HDPE products.

Disadvantages of PP material

- The products have poor cold resistance and low impact strength at low temperature.

- The products are susceptible to aging by light, heat and oxygen in use.

- bad colorability.

- easy to burn. 5.

- poor toughness, high static electricity, poor dyeing, printing and adhesion.

Application areas of PP materials

Polypropylene (PP) is one of the top five general-purpose plastics and is used in a wide range of applications in daily life.

As a food-grade plastic, it is widely used in food packaging, such as foam boxes, PP plastic cups and so on.

Polypropylene can be divided into five categories according to its main applications: PP injection molding, PP drawing, PP fiber, PP film, and PP pipe.

- Woven products: PP consumed by woven products is mainly used for packaging of grain, fertilizer and cement, etc.

- Injection molded products: Injection molded products are mainly used in small home appliances, daily necessities, toys, washing machines, automobiles and crates.

- film products: polypropylene film mainly includes BOPP, CPP, general packaging film and microporous film, etc. BOPP has many excellent characteristics such as light weight, high mechanical strength, non-toxic, transparent, moisture-proof, etc. It is widely used in packaging, electrical, electronic and electrical appliances, tape, label film, film, lamination and many other fields, of which the packaging industry uses the largest amount.

- Fiber products: polypropylene fiber is a fiber product made from polypropylene by melt spinning. Because polypropylene fiber has many excellent properties, and therefore in the decoration, industry, clothing in three major areas of increasingly widespread application, has become the second largest variety of synthetic fibers.

Summary

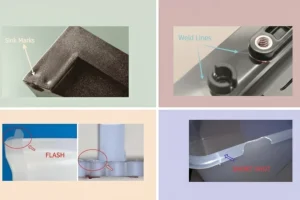

This blog introduces the types, properties and injection molding process of engineering plastics PP, the selection of equipment, product modeling and mold design considerations in actual production, and the solutions to common defects.

In the actual PP material selection and injection molding product production, it is recommended to choose an experienced injection mold and injection molding product supplier to recommend a suitable PP material in terms of product usage and functional requirements, appearance, etc. to ensure the smooth implementation of the project.