Multiple cavity injection molds allow the production of multiple parts simultaneously in one mold, increasing efficiency and part consistency. This method is widely used in industries requiring high-volume production.

Multiple cavity injection molds enable the creation of multiple identical parts per cycle, reducing cycle time and production costs. It improves consistency and is ideal for high-volume manufacturing, particularly in automotive, consumer goods, and packaging industries.

Understanding the design and function of multiple cavity molds is key to optimizing production. Explore how they can enhance your manufacturing process and reduce operational costs.

Multiple cavity molds improve production efficiency by reducing cycle times.True

By producing multiple parts in one cycle, multiple cavity molds significantly reduce the overall cycle time and increase output.

Multiple cavity molds are only suitable for large-scale production.False

Multiple cavity molds can be used in both large and small-scale production, although they are especially cost-effective for high-volume runs.

What is the Definition of a Multi-Cavity Injection Mold?

A multi-cavity injection mold allows the production of multiple parts simultaneously, increasing efficiency and reducing manufacturing costs. It’s commonly used in high-volume production.

A multi-cavity injection mold produces several parts in a single injection cycle, improving efficiency. It’s ideal for mass production, especially in industries like automotive and consumer goods. This method reduces cycle time and operational costs.

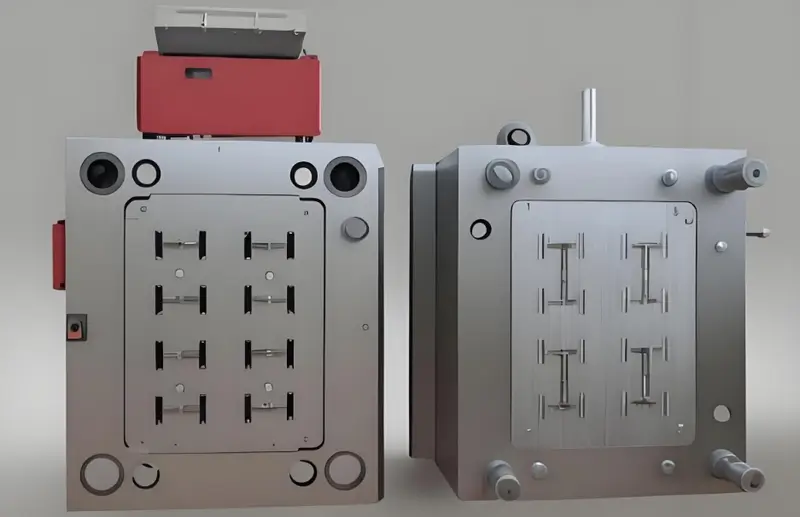

What are Multi-Cavity Molds?

When planning to produce several products at the same time, there is a type of mold referred to as the multi-cavity mold that can be used to mold multiple parts at the same time.

Compard to the single cavity molding, multi cavity molding1 is more efficient as they are able to create many products per injection cycle. Multi-cavity molds are applied in industries that require large scale production for instance the car industry, the electronic industry, and the medical industry.

Family molds, are a specific type of multi-cavity mold designed to produce different parts in the same mold. Family mold is particularly useful when the parts are assembled together later, ensuring that they fit perfectly.

Multiple cavity molds need to have unique features in their design and construction so that each cavity of the mold is the right shape, size and placed in the correct location.

Further, accurate design and manufacturing of the mold are needed to provide equal product quality across several cavities of a single core. This involves determining the type of material appropriate for molds, designing the melt flow path or runner system, and designing the temperature control system.

Differences Between Multi-Cavity and Single-Cavity Molds

A mold with only one cavity is a single-cavity mold and delivers only one product per plastic injection molding cycle.

On the other hand, the multi-cavity mold has more than one cavity and can produce multiple products per injection cycle. The overall concept and the creation of multi-cavity molds are slightly more complicated, however, the advantages and the possibilities for increasing productivity and thus decreasing the cost per product are more tangible.

There are also differences in the use of multi-cavity and single-cavity molds.

First, multi-cavity molds need more injection pressure and the occupying space of the material should be large enough to ensure the material to be filled in each cavity in equal ratio.

Second, temperature control for multi-cavity molds is a bit difficult in the terms of achieving same temperature for all the cavities.

Further, the multi-cavity mold design is relatively tougher in terms of the maintains and upkeep because the regular inspection and need to adjust is more frequent to ensure the proper functioning.

Multi-cavity molds increase production efficiency.True

By producing multiple parts per cycle, multi-cavity molds significantly reduce cycle times and increase output.

Multi-cavity molds are always cheaper than single-cavity molds.False

Although multi-cavity molds can lower per-part costs in high-volume production, their initial investment and setup can be higher compared to single-cavity molds.

What are the Advantages of Multi-Cavity Injection Molds?

Multi-cavity injection molds allow manufacturers to produce multiple parts in a single cycle, improving efficiency, reducing costs, and enhancing productivity across various industries.

Multi-cavity injection molds increase production efficiency by creating multiple parts per cycle. They reduce tooling costs, improve cycle times, and enhance overall part consistency, making them ideal for high-volume manufacturing.

Improved Production Efficiency

The biggest advantage of multi-cavity injection mold is that a lot of products can be made at one time through one injection process, which really improves efficiency.

For instance, where a mold has four cavities, it means that in every cycle of injection molding process2, four products are manufactured, this is four times as better as in a single cavity molds produce.

Also, the application of multi-cavity molds helps in cutting the time of the injection machines and optimizing the flow of production line.

In this way, the potential of multi-cavity molds can be fully utilized based on a rational plan of production so that prevent waste occurrence in the course of productions and augment the rate of production.

Reduced Production Costs

If the efficiency of production is increased substantially, multi cavity molds can substantially reduce cost per product.

Since multi-cavity molds involve a greater cost at the time of manufacturing, in large volume production these molds are of great value.

First, molds such as multi-cavity molds help minimize material waste. Since multiple products can be produced at the same time in one injection, waste is reduced.

Second, another advantage of multi-cavity molds is that they can reduce energy consumption. Since more products can be produced per injection, the energy consumption per unit time is relatively low, thereby reducing production costs.

Ensured Product Consistency

It is very important to produce products that meet precise dimensions in production. Multi-cavity molds can ensure that the products produced from multiple cavities have the same dimensions as planned.

For example, automotive parts and medical devices have high requirements for consistency, and multi cavity molding can provide this consistency.

Strong Adaptability

Multi-cavity molds are widely used in the manufacture of products of various shapes and are highly adaptable to the materials.

With the help of production lines they can not only generate voluminous production of goods, but also to produce customized products, which is quite beneficial for establishments.

Furthermore, multi-cavity molds can greatly solve the problem of high percentage of defective products.

Since the design and manufacture of each cavity are accurate, product quality can be closely controlled, hence lowering the defect rate and enhancing productivity.

Multi-cavity molds improve manufacturing efficiency.True

By producing several parts in one cycle, multi-cavity molds increase output and reduce cycle time, making them highly efficient for large-scale production.

Multi-cavity molds are always the most cost-effective option.False

Although multi-cavity molds are cost-effective for high-volume runs, they require higher upfront investment and may not be suitable for low-volume production.

What are the Design Considerations for Multi-Cavity Injection Molds?

Designing multi-cavity injection molds requires careful planning to ensure uniformity, efficiency, and cost-effectiveness in production. Key factors include cavity placement, cooling, and material flow.

Multi-cavity injection molds allow for the simultaneous production of multiple parts in one cycle. Important design considerations include uniform cavity filling, balanced cooling systems, and proper venting to avoid defects. These factors enhance production speed and reduce costs.

Choosing the Number of Cavities

When planning for multi-cavity injection molds it is very important to determine the right number of cavities to have.

Several factors are used while choosing number of cavities they are production capacity, size of the mold and the capacity of the injection machine.

In a light vein, the greater the number of cavities, the higher the productivity, but the higher the difficulty of mold structure and manufacture.

When designing a mold, we must consider the production volume. If the output is large, choosing more cavities can reduce costs and improve efficiency. The size of the mold is also very important.

Choosing too many cavities may make the mold size too large and unable to operate normally, so we should choose the number of cavities according to the actual situation. The capacity utilization rate of the machine should not be ignored.

If the production capacity of the injection molding machine3 is insufficient, it may not meet the needs of multi-cavity molds, and we need to choose a suitable injection molding machine and mold.

First of all, the absolute level of production must be taken into account. Thus, when the production volume is high, additional cavities may help increase productivity and decrease costs.

Second, space utilization is an essential parameter in the design process, namely the size of the mold. If the size of Mold is too large, the efficiency of injection machine will be influenced, so many cavities should be decided according to specific conditions.

Further, this involves the power of the injection machine that must be determined in amperes and the frequency. If the injection machine’s capacity is inadequate, it does not accommodate multi cavity molds, selection of appropriate injection machines and molds need to be made.

Runner System Design

The runner system is another important systems in the transfer of the molton plastic material from the injection machine towards every cavity. When properly developed, the runner system will enhance the material distribution to every cavity so that you get a proper quality product.

As far as the runner system4is concerned, there are numerous design aspects that must be taken into consideration including length and diameter of the runner, and even the shape.

First, it requires that the length of the runners should be suitable. If the runners are too long, the cooling is uneven which has repercussions on the quality of the final product.

Second, runners’ diameter should be suitable. If the diameter is too small, it may cause material flow obstruction, affecting product filling.

Also, much attention should be paid to the shape of runners as well as to various slight elements.

As a rule, round runners are more effective in terms of the flow, however, sometimes, it is necessary to use other forms of runners depending on production conditions.

Temperature Control System

Effective temperature control is critical for multi-cavity injection molds. Consistent product quality across all cavities depends on this, and these molds need to have their temperature precisely controlled to produce the same reliable standard of components every time, usually achieved by installing heating and cooling systems.

Several factors must be considered when designing a temperature control system. These factors include the layout of the heating and cooling systems and the placement of temperature sensors. All heating and cooling devices should be laid out reasonably so that the heat is evenly distributed everywhere.

Second, a sufficient number of temperature sensors should be installed, and they should be installed in each cavity so that their temperatures can be continuously checked, thereby accurately monitoring and controlling the temperature. In addition, the temperature control system needs to be regularly checked and maintained to ensure its normal operation.

Multi-cavity molds improve production efficiency.True

Multi-cavity molds enable the production of several parts at once, reducing cycle time and increasing overall output.

Multi-cavity molds are always cheaper than single-cavity molds.False

Although multi-cavity molds may reduce production costs over time, their initial design and tooling costs are typically higher due to increased complexity.

What is the Manufacturing Process of Multi-Cavity Injection Mold?

Multi-cavity injection molds enable mass production by creating multiple parts in a single mold cycle, increasing efficiency and reducing costs.

Multi-cavity injection molding involves creating multiple identical parts in one mold by using several cavities. It enhances production efficiency, reduces costs, and is commonly used for high-volume manufacturing, such as in automotive and consumer goods sectors.

Material Selection

Some aspects such as strength, wear resistance and thermal conductivity of the material to be used in the multi-cavity injection molds should be taken into consideration.

Such mold materials most often used are tool steels5and hard alloys which are capable to satisfy high strength and design accuracy in multi-cavity molds.

Selecting the right material for the mold is important when it comes to the performance as well as durability of multi-cavity injection mold.

First, the mold material has to be strong enough to be able withstand the level of stress it will be subjected to when undergoing injection at high pressure.

Second, the material of the mold should be hard wearing to increase the life time of the mold.

Also, the mold material should have good thermal conductivity to maintain even temperature of the mold hence enhancing the quality of the products.

Processing Technology

The types of processing technologies that can work with multi cavity injection molding include, CNC machining6, EDM, grinding7, and so much more. These advanced processing technologies increase the accuracy of the molds while at the same time achieving high quality.

Common of using methods in the manufacturing of molds in the modern world is through the use of the CNC machining technology which facilitates the high accuracy work. Applying the modern technology, such as computer numerical control allow the molds to be machined accurately so that each cavity is of the same size and shape.

EDM technology is mainly applied for working on complicated shapes of the material and high-hardness mold material. Through electrical discharge, precise machining of molds can be achieved. Machining by means of grinding is in most cases applied for fine tuning of mold surfaces. By grinding, it is possible to gain a better surface finish of the molds, and thus, the resultant products are improved.

Inspection and Testing

During the manufacturing process, especially in multi-cavity injection molds, it is very important to conduct inspection and testing.

Therefore, from the perspective of dimensional and quality control, the accuracy of the entire mold can be ensured by careful inspection and testing during and after the manufacturing process, which will continue to ensure product quality.

There are many elements involved in the inspection and testing of molds.

Initially, it is essential to take precise measurements of mold dimensions so that each cavity is the same size and shape.

Secondly, materials need testing for strength, wear resistance, thermal conductivity, and other properties meet the requirements.

Further checks are needed to determine whether the temperature control and flow system are functioning properly.

Multi-cavity molds increase production efficiency.True

By producing multiple parts in one cycle, multi-cavity molds minimize cycle times and improve throughput.

Multi-cavity molds are always more cost-effective.False

While multi-cavity molds can reduce per-part costs, their initial investment and complexity can make them less economical for low-volume production runs.

What are the Application Cases of Multi-Cavity Injection Molds?

Multi-cavity injection molds enable the production of multiple parts in one cycle, improving efficiency and reducing costs across various industries.

Multi-cavity injection molds are used to produce multiple identical parts in a single mold cycle, improving production efficiency and reducing costs. They are widely applied in automotive, consumer products, medical devices, and packaging.

Automotive Parts

In the manufacturing of cars, multi-cavity injection molds are used or producing an assortment of common plastics such as dashboard, door panels, bumpers etc.

These parts need high strength as well as high accuracy and the multi-cavity injection molds have the ability to satisfy these conditions along with the increase in productivity.

Efficient processes and high-quality products are required in the production of automotive parts.

Therefore, by applying multi-cavity injection molds, it is possible to increase productivity while maintaining production quality in line with the requirements of automotive manufacturing.

In addition, multi-cavity injection molds can reduce material waste and energy consumption, thereby reducing production costs.

Medical Devices

The medical devices are needed to have high consistency and accuracy, and the multi-cavity injection molds can guarantee the production consistency in the mass production, which is widely used in the production of such products as syringes, test tubes and other medical instrumentality.

The production of medical devices requires strict quality control and efficient production processes. Through the application of multi-cavity injection molds, the increase in productivity and the product quality and comprehensiveness of medical device production can be met.

In addition, multi-cavity injection molds can reduce pollution and waste in the production process, making medical devices and equipment safe and environmentally friendly.

Consumer Electronics

Multi-cavity injection molds are also used for Products that are associated with electronics goods such as phone cases, keyboards, and mice. The use of multi- cavity mold can greatly enhance the productivity to meet the expansive market demand for the electronics products.

The production of consumer electronic products, needs an efficient production line and good quality products. Through multi-cavity injection molds, efficiency in production can be achieved simultaneously to the quality of the products as per the consumer electronics products manufacturing demands.

Further, it is acknowledged that multi-cavity injection molds can help to minimize the usage of material and energy, hence decrease production costs.

Multi-cavity injection molds reduce production costs.True

By producing multiple parts in one cycle, multi-cavity molds significantly reduce cycle times, leading to lower production costs per unit.

Multi-cavity molds are suitable for all product types.False

While multi-cavity molds are ideal for high-volume, identical parts, they may not be suitable for complex or large parts that require precise customization.

Conclusion

As an important part of injection mold technology, multi-cavity injection molds have indisputable advantages. It can improve productivity, reduce production costs, and ensure product consistency.

Therefore, with the continuous advancement of technology and the continuous growth of market demand, multi-cavity injection molds will play a greater role in different fields.

This study focuses on the reasonable design and manufacture of multi-cavity injection molds, which can improve production efficiency, reduce production costs, and meet the market demand for high-quality plastic products. I hope this article can provide readers with relevant information and references on multi-cavity injection molds.

-

Learn about Single-Cavity vs. Multi-Cavity Injection Molding : Injection molding may be facilitated by means of a single- or multi-cavity mold. ↩

-

Learn about What are the Steps of the Injection Molding Process?Injection molding is a process used to make a lot of plastic parts . ↩

-

Learn about Injection molding machine : An injection molding machine is a machine for manufacturing plastic products by the injection molding process. ↩

-

Learn about Everything You Need to Know about Cold Runner System in Injection Molding : Cold runner systems operate by allowing the plastic to cool in the runner channels . ↩

-

Learn about Tool steel : Tool steel include cutting tools, dies, hand tools, knives, and others. ↩

-

Learn about What is CNC Machining: Definition, Process, Purpose & More : SCNC machining is a type of automated machining process . ↩

-

Learn about Grinding (abrasive cutting) : Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool. ↩