– MUD (Master Unit Die) systems reduce initial tooling costs by up to 66% by utilizing a shared mold base frame.

– Standard mold bases offer superior cooling flexibility and structural integrity for high-volume, complex, or large-part production.

– MUD inserts significantly reduce changeover times (often <15 minutes), increasing machine uptime for low-volume, high-mix manufacturing.

– Standard tooling is preferred when strict ownership transfer or specific export standards (e.g., SPI Class 101) are required.

What Are the Fundamental Differences Between MUD Systems and Standard Mold Bases?

To select the correct tooling strategy, one must understand the structural and functional differences between a Master Unit Die (MUD) system and a standard stand-alone mold base.

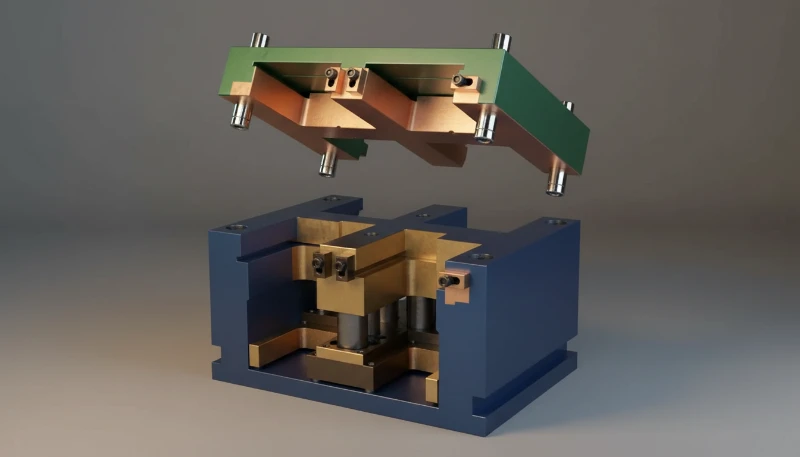

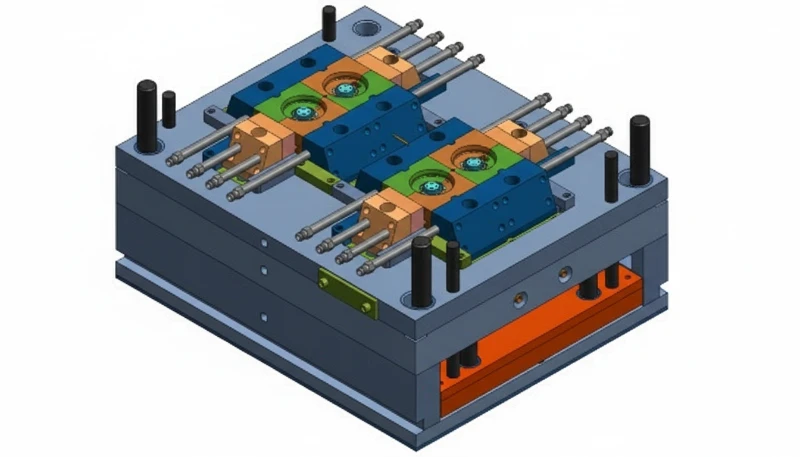

Master Unit Die (MUD) System:

A MUD system utilizes a standardized, reusable frame1 (the H-frame or U-frame) capable of accepting interchangeable mold inserts2. The molder owns the frame, which stays in the injection molding machine, while the customer typically pays only for the "insert" (the cavity and core plates).

- Context: Originally developed by DME (Detroit Mold Engineering), MUD has become a genericized term for quick-change insert systems.

- Mechanism: The ejection mechanism and guidance system are often shared.

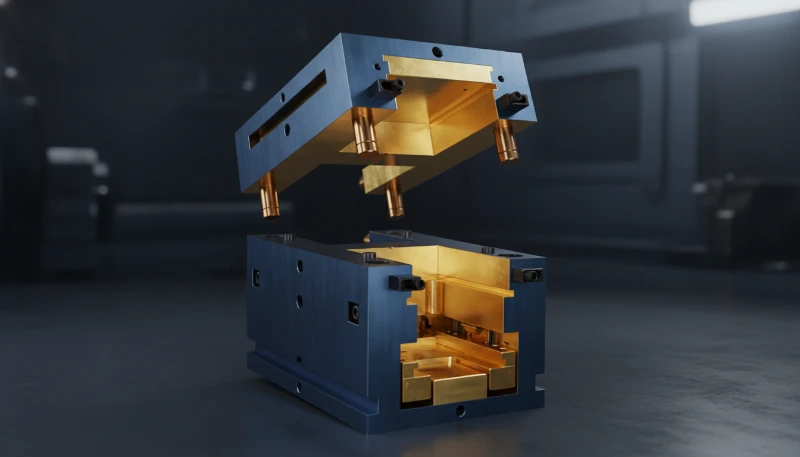

Standard Mold Base (Stand-alone Tooling):

A Standard Mold Base is a complete, self-contained tooling unit where the cavity, core, ejection system, and cooling channels are integrated into a dedicated frame (plates A, B, support pillars, clamp plates, etc.).

- Context: Often built to specific standards like LKM (Lung Kee Metal), HASCO, or FUTABA.

- Mechanism: Every aspect of the tool is customized for that specific part, including independent cooling and ejection systems.

How Do Key Parameters Compare?

The following table contrasts the technical specifications and operational parameters of MUD inserts versus standard bases.

| Parametro | MUD (Master Unit Die) System | Standard Mold Base |

|---|---|---|

| Initial Capital Cost | Low (can be 30–50% less than standard) | High (includes cost of entire steel base) |

| Tempi di consegna | Short (1–3 weeks typical) | Medium to Long (4–10 weeks typical) |

| Changeover Time | Fast (5–20 minutes) | Slow (1–4 hours) |

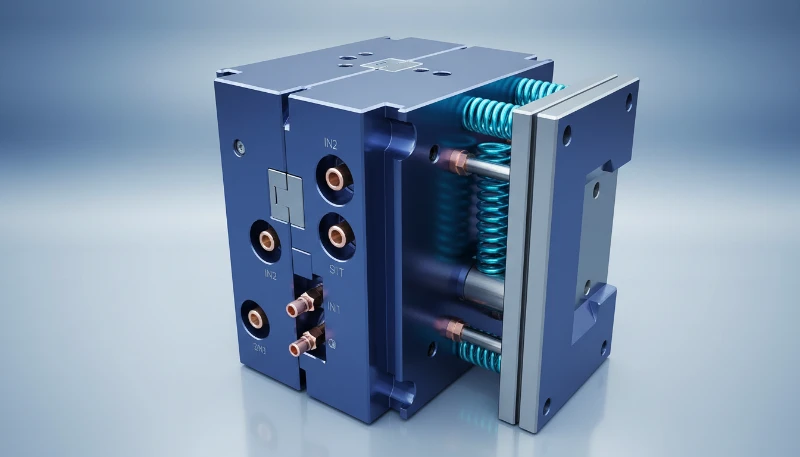

| Cooling Efficiency | Limited (constrained by frame geometry) | High (fully customizable conformal cooling) |

| Part Size Limit | Restricted (typically small to medium parts) | Flexible (limited only by machine tonnage) |

| Volume di produzione | Prototyping to Medium Volume (1k–100k) | High Volume / Mass Production (100k–1M+) |

| Tolerance Precision | Moderate (cumulative tolerance of frame + insert) | High (tight control over all plates) |

| Steel Types | Aluminum (Alum), P20, NAK80 | P20, H13, S7, 420SS (Stainless Steel) |

MUD inserts are significantly cheaper and faster to produce because they do not require the fabrication of a dedicated mold base.Vero

Since the frame is reused, the customer only pays for the cavity and core machining, reducing steel consumption and labor hours.

MUD molds cannot be used for production runs and are strictly for prototyping.Falso

MUD inserts are frequently used for low-to-mid volume production (bridge tooling) and can last for tens of thousands of cycles if made from durable steel like P20.

What Are the Cost and Operational Implications?

Understanding the costi di attrezzaggio per lo stampaggio a iniezione requires analyzing both the upfront investment and the long-term operational expenses (OpEx).

1. Upfront Investment (Capex)

- MUD: The elimination of the mold base reduces steel costs and machining time. For a family of parts (e.g., 5 variations of a housing), using one MUD frame with 5 inserts is drastically cheaper than building 5 standalone tools.

- Standard: You pay for the entire assembly (Top Clamp Plate, A-Plate, B-Plate, Support Plate, Ejector Housing). This is capital intensive but provides a tangible asset that is easily transferred between molders.

2. Operational Efficiency (OpEx)

- Changeovers: MUD frames allow inserts to be swapped without removing the frame from the platen. This "warm swap" capability minimizes downtime, making MUD ideal for "High-Mix, Low-Volume" manufacturing.

- Cycle Time: Standard mold bases allow for optimized cooling channel placement (water lines). In high-volume production, shaving 2 seconds off a cycle using a standard base often outweighs the initial savings of a MUD insert over the tool’s life.

3. Maintenance and Wear

- MUD: The interface between the insert and the frame can wear over time, potentially causing flash or alignment issues if the frame is not maintained by the molder.

- Standard: The guided ejection and leader pins are dedicated to the tool, ensuring consistent alignment over millions of cycles.

What Are the Advantages and Disadvantages of Each Approach?

MUD Systems (Quick-Change Inserts)

| Pros | Cons |

|---|---|

| Lower Tooling Cost: Only pay for the cavity/core. | Limitazioni di dimensione: Cannot accommodate large automotive panels or deep-draw parts. |

| Faster Time-to-Market: Less steel to machine means faster delivery. | Cooling Constraints: Water lines must route through the frame or strictly within the insert limits. |

| Reduced Inventory: Molds take up less physical shelf space. | Ownership Complexity: If you move suppliers, you cannot take the MUD frame; you only own the insert. |

| Agility: Ideal for design iterations and A/B testing. | Ejection Limitations: Often restricted to standard pin layouts provided by the master frame. |

Standard Mold Bases

| Pros | Cons |

|---|---|

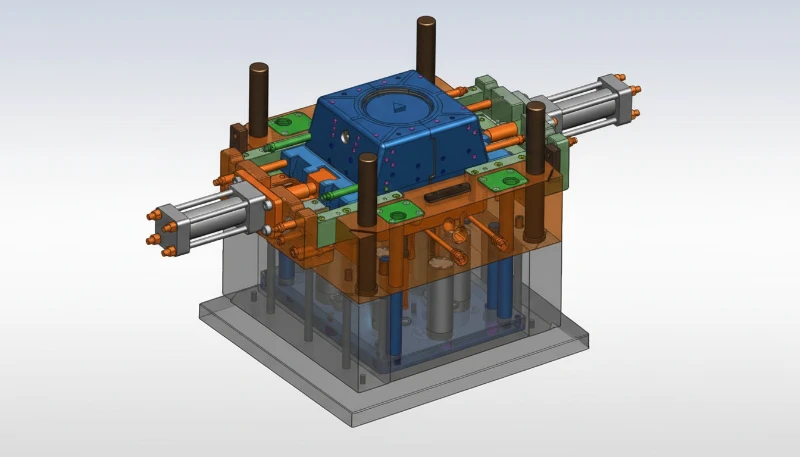

| Unlimited Customization: Slides, lifters, and unscrewing mechanisms are easier to integrate. | Costo iniziale elevato: Paying for hundreds of pounds of structural steel. |

| Optimized Cycle Times: Dedicated cooling = faster heat dissipation. | Heavy Logistics: Transporting and storing full bases is expensive and space-consuming. |

| Portability: The tool is a self-contained unit; easy to move to a new molder. | Slow Switchovers: Requires crane lifts, full cool-down, and setup for every run. |

| Durability: Built for SPI Class 101/102 standards (1M+ cycles). | Longer Lead Time: Sourcing and machining the base adds weeks to the schedule. |

Standard mold bases allow for superior cooling optimization, leading to shorter cycle times in mass production.Vero

Dedicated bases allow water lines to be placed precisely where needed without the geometric restrictions of a pre-existing master frame.

You can easily move a MUD insert to any injection molding factory without compatibility issues.Falso

MUD frames are not universal; an insert designed for a DME frame may not fit a HASCO frame or a custom house frame without modification.

When Should You Choose MUD Molds over Standard Bases?

Selecting the right strategy depends on the search intent of your project—specifically regarding volume and geometric complexity.

Choose MUD Molds When:

- Prototipazione: You need 50–500 parts for functional testing and might change the design soon.

- Bridge Tooling: You need parts immediately while waiting for a high-cavitation production mold to be built.

- Low Volume Production: Annual demand is under 20,000 units. The ROI on a standard base would take too long to realize.

- Family Parts: You are molding several small components that use the same material.

- Vincoli di bilancio: The project has a strict CapEx limit.

Choose Standard Mold Bases When:

- Produzione ad alto volume: Demand exceeds 100,000 units annually. The unit price savings from faster cycle times will pay for the base.

- Geometria complessa: The part requires complex side-actions, multiple hydraulic slides, or 3-plate mold designs that MUD frames struggle to accommodate.

- Alta precisione: The part requires extremely tight tolerances (e.g., +/- 0.01mm) where the added stack-up tolerance of a MUD insert is unacceptable.

- Asset Portability: You require the freedom to move the tool to a different supplier globally without compatibility risks.

- High Temperature Materials: Processing engineering resins like Polyphenylene Sulfide (PPS) or Polyetheretherketone (PEEK) requires high mold temperatures that might damage standard MUD frames or seals.

How Should You Calculate ROI for Your Project?

To determine the best tooling ROI3, follow this stepwise calculation process:

- Ottenere citazioni: Get a quote for both a MUD insert and a standalone Class 102 mold.

- Esempio: MUD Insert: $4,000 | Standard Mold: $9,000.

- Estimate Cycle Time: Ask the molder for estimated cycle times for both.

- Esempio: MUD: 35 seconds | Standard (optimized cooling): 28 seconds.

- Calculate Part Price Delta: Determine the machine hourly rate (e.g., $60/hr).

- MUD Cost/Part (Machine time): $(60 / 3600) * 35 = $0.583

- Standard Cost/Part (Machine time): $(60 / 3600) * 28 = $0.466

- Savings per part with Standard: $0.117

- Determine Break-even Point:

- Cost Difference: $9,000 – $4,000 = $5,000.

- Break-even Quantity: $5,000 / $0.117 = 42,735 parts.

- Decision: If your lifetime volume is <42k, choose MUD. If >42k, choose Standard.

Frequently Asked Questions About MUD vs. Standard Tooling

Q1: Can I convert a MUD insert into a standard mold later?

Generally, no. While you can physically remove the insert, it is machined to fit a specific frame. Converting it to a standalone mold would require manufacturing a custom frame to fit that specific insert, which often costs as much as building a new mold base from scratch.

Q2: Does using a MUD mold affect part quality?

For most standard plastic parts, no. However, for optical-grade parts or parts requiring extremely tight concentricity, the slight "float" or tolerance stack-up in a MUD system (between the frame and insert) can introduce minor variations compared to a rigid standard base.

Q3: Who owns the MUD frame?

Typically, the injection molding factory owns the frame (Master Unit). The customer owns the insert. This creates a "lock-in" effect; if you want to move your production, you only take the inserts, and the new supplier must have a compatible frame.

Q4: Are MUD molds limited to soft steel or aluminum?

No. While often associated with aluminum (Alum) for prototypes, MUD inserts can be machined from hardened steels like H13 or S7 for production runs. The limitation is the frame’s capacity, not the insert material.

Q5: What is the maximum size for a MUD insert?

Common standard MUD frames (like the DME 84/90 series) usually handle insert areas up to approximately 12" x 15" (300mm x 380mm). Larger sizes exist but become less standard and lose the cost/speed advantage.

Sintesi

La decisione tra MUD vs standard mold tooling ultimately rests on a balance between upfront capital preservation and long-term unit cost efficiency. Master Unit Die systems are the superior choice for prototyping, market testing, and low-volume runs, offering speed and low entry costs. Conversely, Standard Mold Bases are the requisite investment for high-volume, high-precision manufacturing where cycle time reduction and asset portability are paramount. By analyzing the break-even point based on cycle time savings, procurement teams can make data-driven decisions that optimize tooling ROI.

-

Find out how reusable frames can lower costs and speed up production for multiple part variations. ↩

-

Learn how interchangeable inserts enable flexibility and cost savings for prototyping and low-volume runs. ↩

-

Get a step-by-step guide to evaluating the return on investment for different mold tooling strategies. ↩