In the high-stakes world of healthcare manufacturing, there is no margin for error. For procurement teams and engineers, partnering with an ISO 13485 certified molder1 is not just a badge of quality—it is a mandatory prerequisite for regulatory acceptance. This standard defines the Quality Management System (QMS) specifically for the medical industry, emphasizing risk management, traceability, and process validation over the continuous improvement focus of general manufacturing.

This white paper provides a technical deep dive into the regulatory landscape, cleanroom requirements, and validation protocols necessary for producing FDA compliant plastic parts2.

– ISO 13485 prioritizes patient safety and risk management (ISO 14971) over the customer satisfaction focus of ISO 9001.

– Medical injection molding often requires controlled environments, such as ISO Class 7 or Class 8 cleanrooms, to minimize particulate burden.

– Process Validation (IQ, OQ, PQ) is critical for establishing a “worst-case” proven window of operation, ensuring every part meets specification without 100% inspection.

– Full lot traceability—from raw resin pellet to finished device—is non-negotiable for FDA compliance.

What is ISO 13485 and How Does It Differ from ISO 9001?

ISO 13485:2016 is the international standard for QMS in the medical device industry. While it shares a structure with ISO 9001, their objectives diverge significantly.

- ISO 9001 focuses on Miglioramento continuo and Customer Satisfaction.

- ISO 13485 focuses on Patient Safety, Risk Management, and Maintaining the Effectiveness of the QMS.

For a supplier to deliver medical injection molding standards3, they must demonstrate that their processes are not just efficient, but consistently capable of producing safe, effective devices.

Comparison Matrix: ISO 9001 vs. ISO 13485

| Caratteristica | ISO 9001 (General Industry) | ISO 13485 (Medical Devices) |

|---|---|---|

| Obiettivo primario | Miglioramento continuo | Safety & Efficacy |

| Risk Management | Implicit / Business Risk | Explicit (Must comply with ISO 14971) |

| Documentation | Flexible | Rigorous/Prescriptive (Device Master Record) |

| Work Environment | General Cleanliness | Controlled Environment (Cleanroom/Bioburden control) |

| Traceability | Forward (Recall) | Bidirectional (Raw Material to Patient & Patient to Material) |

ISO 13485 certification automatically grants FDA approval for a medical device.Falso

ISO 13485 is a QMS standard for the manufacturer. FDA approval (510(k) or PMA) is a separate regulatory clearance for the device itself.

ISO 13485 requires adherence to ISO 14971 for risk management throughout the product lifecycle.Vero

The standard explicitly integrates risk analysis to identify and mitigate potential hazards associated with the medical device.

What Defines a Valid Cleanroom Molding Class 7 Environment?

To prevent contamination from airborne particulates, cleanroom molding class 74 is frequently specified for invasive or high-risk components. Cleanrooms are classified by ISO 14644-1 based on the number of particles per cubic meter of air.

ISO 14644-1 Cleanroom Standards for Molding

| ISO Class | US FED STD 209E Equiv. | Max Particles (≥0.5µm) / m³ | Air Changes Per Hour (ACH) | Applicazione tipica |

|---|---|---|---|---|

| ISO 7 | Class 10,000 | 352,000 | 60 – 90 | Surgical instruments, catheters, implants. |

| ISO 8 | Class 100,000 | 3,520,000 | 5 – 48 | Housing enclosures, caps, non-invasive tubing. |

| ISO 9 | Room Air | N/A | N/A | General packaging, secondary assembly. |

Practical Insight: In a molding context, the machine itself may be enclosed in a cleanroom, or the mold clamp area may be shrouded with HEPA-filtered laminar flow hoods to create a localized ISO 7 environment within an ISO 8 room (a "clean booth" approach).

How is Process Validation (IQ, OQ, PQ) Executed?

Validation is the evidence that a process consistently yields a product meeting predetermined specifications. In medical device manufacturing5, you cannot inspect quality into a product; the process itself must be proven robust. This is achieved through the "Holy Trinity" of validation:

- Qualificazione dell'installazione (IQ):

- Question: Is the equipment installed correctly?

- Action: Verify wiring, software versions, safety features, and auxiliary equipment (chillers, dryers) match manufacturer specs.

- Qualificazione operativa (OQ):

- Question: Does the process work at the limits?

- Action: Establish the processing window. Mold parts at High/Low settings for melt temperature, injection pressure, and cooling time. Parts must pass QA at these "worst-case" extremes.

- Qualificazione delle prestazioni (PQ):

- Question: Can the process run consistently over time?

- Action: Run the machine at nominal settings for a standard production run (e.g., 24 hours or 3 shifts). Verify Cpk/Ppk (Process Capability) values are >1.33.

Process validation (IQ/OQ/PQ) is mandatory for any process where the output cannot be fully verified by subsequent inspection.Vero

If you cannot destructively test every part, you must validate the process to ensure every unit is compliant.

Once a mold is validated (PQ), you can move it to a different machine without re-validation.Falso

Validation is machine-specific. Moving a mold requires at least a partial re-validation (often IQ and limited OQ) to ensure the new machine matches the process parameters.

What is the Role of Traceability and Documentation?

FDA 21 CFR Part 820 (Quality System Regulation) and ISO 13485 mandate rigorous traceability. A medical molder must be able to trace a defective part back to:

- The specific molding machine and operator.

- The exact time and date of production.

- The processing parameters used during that shot.

- The raw material lot number (Resin) and masterbatch.

Device Master Record (DMR): The "recipe" for the device, containing drawings, material specs, and work instructions.

Device History Record (DHR): The "diary" of the production run, proving the DMR was followed.

What Are the Pros and Cons of Strict ISO 13485 Compliance?

| Aspetto | Vantaggi | Svantaggi |

|---|---|---|

| Garanzia di qualità | Drastic reduction in defect rates; high reliability. | Significant upfront time and cost for validation (IQ/OQ/PQ). |

| Market Access | Essential for selling in EU (CE Mark), Canada (MDSAP), and US markets. | Requires continuous auditing and expensive maintenance of the QMS. |

| Risk Mitigation | Clear documentation protects against liability in case of recalls. | Administrative burden; "paperwork" can slow down rapid prototyping phases. |

| Stabilità del processo | Scientific molding ensures repeatable cycles. | Less flexibility to "tweak" parameters on the fly without change controls. |

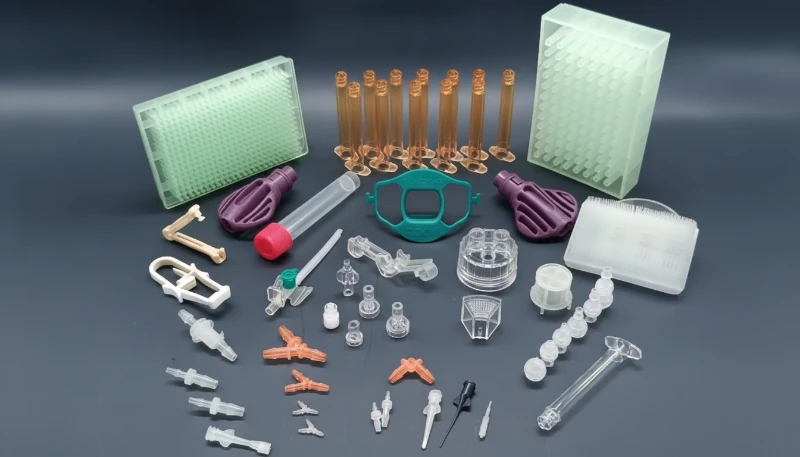

What Are Typical Application Scenarios?

- Surgical Consumables: Trocar housings and scalpel handles molded in ISO 7 cleanrooms using Polycarbonate (PC) or PEEK.

- Drug Delivery: Insulin pen components and inhaler actuators requiring tight tolerance gears and distinct tactile clicks (POM/ABS).

- Diagnostics: Microfluidic chips and petri dishes molded from Polystyrene (PS) or PMMA with high optical clarity and low autofluorescence.

- Implants: Bioresorbable screws or PEEK spinal cages requiring implant-grade certification and strict bioburden controls.

FAQ: Medical Injection Molding Compliance

1. Is ISO 13485 mandatory for all injection molders?

No. It is only mandatory if the molder produces finished medical devices or components intended for medical use where the customer requires it for their own regulatory filings.

2. What is the difference between Medical Grade and Standard Grade resin?

Medical grade resins undergo biocompatibility testing (USP Class VI or ISO 10993) and have "lock-down" formulations. Suppliers guarantee that they will not change the chemical formula without significant prior notice (often 2 years), ensuring regulatory stability.

3. Does FDA regulate the injection molder directly?

The FDA regulates the "Specification Developer" (the brand owner). However, contract molders are subject to FDA audits as critical suppliers. The molder must adhere to 21 CFR Part 820 quality standards.

4. What is a "Bioburden" test?

Bioburden testing measures the number of viable bacteria living on a surface before sterilization. Molders must control the manufacturing environment to keep bioburden low so that the final sterilization method (Gamma, EtO) is effective.

5. Why is Scientific Molding important for medical parts?

Scientific molding relies on data (rheology, viscosity curves) rather than operator intuition. This data-driven approach is the only way to validate a process (OQ/PQ) and prove to auditors that the process is under control.

Sintesi

Achieving ISO 13485 compliance in injection molding is a comprehensive commitment to patient safety. It transforms the manufacturing floor from a production site into a controlled scientific environment. For OEMs, selecting an ISO 13485 certified molder with verified cleanroom capabilities and robust process validation protocols is the only way to mitigate risk and ensure the seamless regulatory approval of FDA compliant plastic parts.

-

An ISO 13485 certified molder has a quality system audited specifically for the risks and traceability required in medical device production. ↩

-

FDA compliant plastic parts must be manufactured under a quality system (21 CFR Part 820) that aligns closely with ISO 13485 standards. ↩

-

Medical injection molding standards encompass strict controls on bioburden, particulate matter, and material biocompatibility (ISO 10993). ↩

-

Cleanroom molding class 7 ensures that the air quality meets strict particulate limits, vital for preventing contamination in invasive devices. ↩

-

Medical device manufacturing demands a transition from simple part checking to full process validation to guarantee statistical reliability. ↩