La normalisation des moules d'injection est essentielle pour garantir la cohérence, l'efficacité et la rentabilité des processus de production dans diverses industries.

La fabrication de moules standardisés nécessite une ingénierie précise, une sélection de la qualité des matériaux, le respect des spécifications de conception des moules et la compatibilité avec les machines de moulage par injection. Les principaux avantages sont la réduction des délais de production et l'amélioration de l'uniformité des pièces.

Au fur et à mesure que vous approfondissez les spécificités de la fabrication de moules normalisés, la compréhension des facteurs clés qui influencent la performance et la longévité des moules sera essentielle pour optimiser vos résultats de fabrication.

Les moules standardisés réduisent les déchets et les délais de production.Vrai

Les moules normalisés sont conçus pour optimiser le flux de matériaux et réduire les erreurs de production, en améliorant l'efficacité et en minimisant les déchets.

Tous les procédés de moulage par injection utilisent des moules standardisés.Faux

Si de nombreux processus bénéficient de moules standardisés, des moules sur mesure sont souvent nécessaires pour des produits spécialisés ou des conceptions uniques.

Quelles sont les exigences en matière de conception des moules ?

La fabrication de moules d'injection standardisés nécessite des critères de conception précis pour garantir une qualité et une efficacité constantes dans la fabrication d'une large gamme de produits.

Les exigences essentielles en matière de conception des moules comprennent des tolérances précises, une sélection appropriée des matériaux, des systèmes de refroidissement efficaces et des composants normalisés pour faciliter une production sans heurts et maintenir une qualité de produit uniforme.

Analyse des produits

J'en sais beaucoup sur l'aspect et le fonctionnement des produits moulés par injection. Par exemple, si vous voulez qu'un produit soit vraiment beau, le moule doit être très lisse. Par exemple, si vous fabriquez une pièce pour l'intérieur d'une voiture, le moule doit être très lisse, entre 0,8 et 1,6 micromètre, pour que la pièce ait un bel aspect.

Analyser les méthode de démoulage1 du produit, en fonction de la forme du produit pour déterminer s'il convient d'utiliser le démoulage par broche d'éjection, le démoulage par plaque de poussée ou d'autres méthodes. Par exemple, pour les produits cylindriques, le démoulage par plaque de poussée peut être plus approprié car il permet de faire sortir le produit de manière uniforme et d'éviter sa déformation.

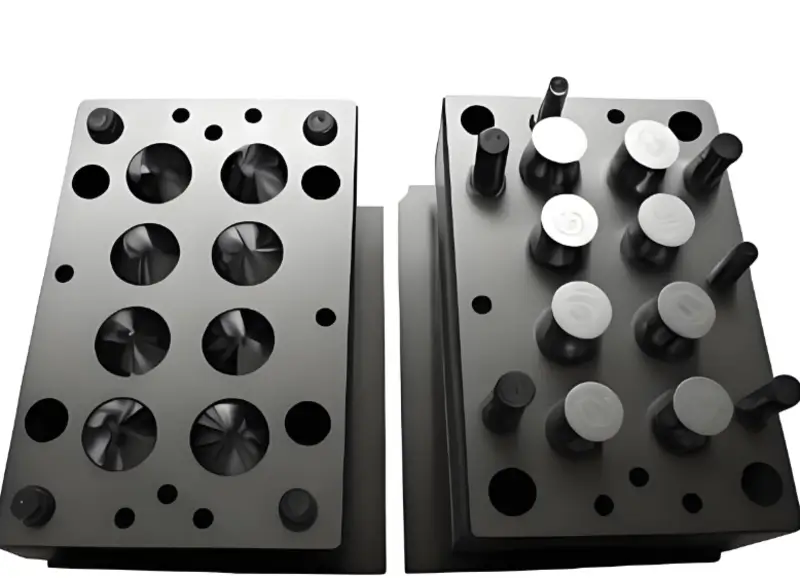

Conception de la structure du moule

Assurez-vous que le plan de joint du moule est raisonnable. Le plan de joint doit permettre d'éjecter facilement le produit et de minimiser les bavures. Par exemple, si le produit a une exigence de surface, le plan de joint doit être placé à un endroit où il n'affectera pas la surface.

Décider où et comment procéder au criblage. Le criblage à canaux chauds peut réduire les déchets et améliorer l'utilisation des matériaux, mais il est plus coûteux ; le criblage latéral est plus simple et fonctionne pour une large gamme de produits, mais il peut laisser des marques de criblage sur la surface du produit. Par exemple, pour les produits en plastique transparent, il est préférable de procéder à un criblage par point d'arrêt, car cela permet de réduire les lignes de soudure et les marques de criblage et d'améliorer la transparence du produit.

Concevoir le cadre du moule2 avec une résistance et une rigidité suffisantes. La taille du cadre du moule doit être choisie en fonction de la taille du moule et de la pression d'injection. Par exemple, les grands moules d'injection nécessitent des cadres de moules plus épais et plus robustes pour résister à une pression d'injection plus élevée et empêcher la déformation du moule.

Dimension Standard

Lors du marquage des dimensions des pièces de moule, il est nécessaire de les marquer conformément aux normes nationales ou industrielles. Par exemple, lors du marquage de la taille de la cavité du moule, celle-ci doit être marquée en fonction de la précision du traitement et des exigences d'assemblage, et le choix des tolérances dimensionnelles doit être raisonnable. En général, les tolérances de niveau IT6-IT9 sont utilisées pour garantir l'interchangeabilité des pièces et la précision de l'assemblage.

L'utilisation de trous, d'arbres et d'autres dimensions structurelles standard facilite l'utilisation d'outils et de calibres standard pour le traitement et les essais. Par exemple, le pilier de guidage dans le moule doit avoir une taille standard, de sorte que le diamètre du trou de la douille de guidage et le diamètre extérieur doivent également être de taille standard. Il est ainsi plus facile de les acheter et de les remplacer.

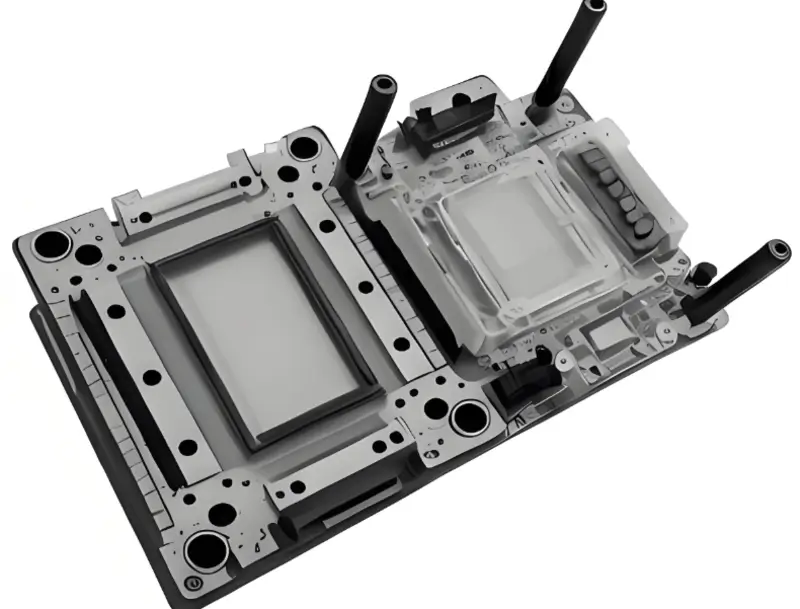

Conception du système de refroidissement

Le système de refroidissement3 doit pouvoir contrôler efficacement la température du moule, de sorte que la température de la surface de la cavité soit uniforme. Le diamètre du tuyau de refroidissement, l'espacement et la distance par rapport à la surface de la cavité doivent répondre à certaines exigences. En général, le diamètre du tuyau de refroidissement est compris entre 8 et 12 mm, l'espacement est de 3 à 5 fois le diamètre du tuyau et la distance par rapport à la surface de la cavité est de 10 à 15 mm, ce qui permet d'assurer l'efficacité du refroidissement et de raccourcir le cycle d'injection.

Lorsque vous disposez les tuyaux de refroidissement, assurez-vous qu'ils ne gênent pas d'autres structures du moule (comme les broches d'éjection, les glissières, etc.). Par exemple, si vous concevez des tuyaux de refroidissement près d'un curseur, pensez à la distance à laquelle le curseur se déplace et assurez-vous que les tuyaux de refroidissement ne gênent pas le mouvement de va-et-vient du curseur.

Conception du système d'éjection

La force d'éjection du système d'éjection4 doivent être réparties uniformément pour éviter de déformer ou d'endommager le produit. Le nombre, la position et le diamètre des aiguilles d'éjection doivent être déterminés en fonction de la forme, de la taille et du matériau du produit. Par exemple, pour les produits plats de grande taille, un plus grand nombre d'aiguilles d'éjection est nécessaire et la position des aiguilles d'éjection doit être uniformément répartie au bas du produit pour garantir que le produit peut être éjecté en douceur.

La course de l'éjecteur doit être suffisamment longue pour s'assurer que la pièce est complètement sortie du moule. En général, la course de l'éjecteur doit être supérieure à 1/3 de la hauteur de la pièce. Vous devez également tenir compte des actions d'ouverture et de fermeture du moule afin que le système d'éjection ne heurte pas d'autres parties du moule.

Couvercle coulissant et basculant

La structure de la glissière et du plateau basculant doit être compacte, flexible et fiable. La précision de guidage de la glissière doit être élevée, en utilisant généralement des rainures en T ou des rainures en queue d'aronde.

L'angle du plateau basculant doit être raisonnablement conçu en fonction des exigences de démoulage du produit, généralement pas plus de 15°, afin d'éviter un frottement excessif généré par le mouvement du plateau basculant, entraînant un phénomène de blocage.

Choisissez correctement le matériau de la glissière et du plateau basculant, avec une bonne résistance à l'usure et une bonne solidité. Par exemple, pour les moules à forte production, le coulisseau et le plateau basculant peuvent être fabriqués en acier trempé, tel que Cr12MoV, avec une dureté de trempe de HRC58-62, afin d'améliorer leur durée de vie.

Conception du système d'échappement

Le moule doit être conçu avec des canaux d'évacuation raisonnables pour éliminer l'air dans la cavité et le gaz produit par la fusion du plastique. La méthode d'évacuation peut être l'évacuation par écart, l'évacuation par fente ou l'utilisation d'acier respirant. Par exemple, une fente d'échappement de 0,02 à 0,05 mm peut être définie au niveau de la surface de séparation du moule, ou une fente d'échappement d'une profondeur de 0,03 à 0,08 mm peut être ouverte à un endroit approprié.

Sélection du matériau du moule

Lorsque vous choisissez le matériau de votre moule, vous devez tenir compte des conditions de travail et des exigences du moule. Pour les parties du moule soumises à des pressions élevées et à une forte usure (comme les cavités et les noyaux), vous pouvez utiliser de l'acier de moulage de haute qualité, comme le P20, le H13, etc.

Acier P205 L'acier H13 a une grande ténacité et des propriétés de fatigue thermique, il convient aux moules d'injection à haute température et à haute pression.

Pour le cadre du moule et les autres pièces de support, vous pouvez utiliser de l'acier de construction ordinaire, comme de l'acier 45, puis le traiter thermiquement pour l'améliorer.

Les moules standardisés garantissent une qualité constante des produits.Vrai

L'utilisation de composants et de critères de conception normalisés garantit que les produits sont fabriqués avec des spécifications et une qualité constantes.

Chaque moule d'injection a les mêmes exigences en matière de conception.Faux

Les exigences en matière de conception varient en fonction des spécifications du produit, des matériaux utilisés et des processus de production, ce qui nécessite des solutions sur mesure pour différentes applications.

Quelles sont les exigences en matière de fabrication de moules ?

La normalisation de la fabrication des moules d'injection est essentielle pour améliorer l'efficacité, réduire les coûts et garantir une qualité constante dans divers secteurs.

La fabrication normalisée de moules d'injection exige des tolérances précises, de l'acier de haute qualité, des systèmes de refroidissement cohérents et des principes de conception robustes. Cela permet d'améliorer l'efficacité, d'assurer la répétabilité et de garantir une qualité supérieure des pièces. Les industries telles que l'automobile, les biens de consommation et l'électronique bénéficient de ces processus rationalisés.

Planification des processus d'usinage

Planifier un processus d'usinage6 Il s'agit de l'ébauche, de la finition, de l'électroérosion et d'autres étapes. Par exemple, pour l'usinage des cavités des moules, il faut d'abord dégrossir la plus grande partie du matériau, puis effectuer une semi-finition et enfin une finition pour s'assurer que la cavité est de la bonne taille et présente une bonne surface.

Déterminez la quantité de matière supplémentaire à laisser sur la pièce pour chaque opération d'usinage. Vous devez décider de la quantité de matière supplémentaire à laisser sur la pièce en fonction de sa taille, de sa forme et de sa précision. En général, il faut laisser 1 à 3 mm de matière supplémentaire pour l'ébauche et 0,1 à 0,5 mm pour la finition.

Exigences en matière de coupe

Le choix des outils de coupe7 doit être approprié, en fonction du matériau de la pièce, de la précision de l'usinage et du processus d'usinage pour sélectionner le type d'outil, le matériau et les paramètres géométriques.

Par exemple, pour le traitement de l'acier trempé, vous pouvez choisir des outils en carbure, qui ont une dureté élevée et une bonne résistance à l'usure ; pour le traitement de l'alliage d'aluminium, vous pouvez choisir des outils en acier rapide, qui ont des arêtes de coupe vives et permettent d'obtenir une meilleure qualité de surface.

Les paramètres de coupe (tels que la vitesse de coupe, l'avance, la profondeur de coupe) doivent être fixés de manière raisonnable. La vitesse de coupe doit être déterminée en fonction des caractéristiques de l'outil et du matériau, l'avance et la profondeur de coupe doivent tenir compte de la précision de l'usinage et de la capacité de charge de l'outil. Par exemple, pour l'usinage de l'acier de moulage, la vitesse de coupe est généralement comprise entre 50 et 100 m/min, l'avance entre 0,1 et 0,3 mm/r et la profondeur de coupe entre 0,5 et 2 mm.

Exigences en matière d'EDM

La conception des électrodes d'électroérosion doit être précise et la taille de l'électrode doit tenir compte de l'espace de décharge. L'écart de décharge est généralement compris entre 0,05 et 0,2 mm, et la taille de l'électrode doit être conçue pour compenser la taille de la cavité et l'écart de décharge.

Paramètres EDM8 (tels que le courant de décharge, le temps de décharge, la largeur d'impulsion, etc.) doivent être ajustés raisonnablement pour obtenir une bonne qualité de surface et une bonne précision d'usinage. Par exemple, le courant de décharge est généralement de 10-50A, la largeur d'impulsion est de 10-100μs, et il doit être ajusté de manière appropriée en fonction des différentes exigences de traitement.

Traitement de surface des moules

Lorsqu'il s'agit de contrôler la précision des pièces moulées, la précision dimensionnelle9 des pièces du moule doit être strictement contrôlée, en utilisant des jauges appropriées pour les essais. L'utilisation de pieds à coulisse, de micromètres, de machines à mesurer les coordonnées et d'autres outils permet de mesurer les dimensions. Pour les dimensions clés, la tolérance doit être de ±0,01 mm.

La précision de la forme des pièces (rectitude, planéité, rondeur, etc.) doit également répondre aux exigences. Par exemple, la planéité du plan de joint du moule est généralement inférieure à 0,03 mm afin de garantir une fermeture précise du moule.

Exigences en matière d'assemblage des moules

Avant d'assembler le moule, vous devez nettoyer les pièces pour les débarrasser d'éléments tels que l'huile, la limaille de fer, etc. Après les avoir nettoyées, vous devez les traiter avec de l'antirouille. Après les avoir nettoyées, vous devez les traiter avec de l'antirouille afin qu'elles ne rouillent pas.

Sur la base des plans d'assemblage et du processus d'assemblage, vous devez vous assurer que chaque pièce est assemblée au bon endroit. Par exemple, lorsque vous assemblez l'axe de guidage et la douille de guidage, vous devez vous assurer qu'ils sont concentriques. Normalement, la concentricité requise est de ± 0,03 mm. Cela permet de s'assurer que le moule peut s'ouvrir et se fermer avec précision.

Lors de l'assemblage du moule, vous devez procéder à certains ajustements, tels que le réglage de la hauteur de la broche d'éjection, la position du curseur, etc. La hauteur de la broche d'éjection doit être ajustée pour que le produit puisse être éjecté en douceur, et la surface supérieure de l'éjecteur doit être au même niveau que la surface inférieure de la cavité ou légèrement plus élevée de 0,05 à 0,1 mm.

Exigences en matière de débogage des moules

Une fois l'assemblage du moule terminé, il faut procéder au débogage. Avant le débogage, nous devons vérifier si l'ouverture et la fermeture du moule sont souples, si le système d'éjection fonctionne correctement et si le système de refroidissement et le système d'échappement sont fluides. Par exemple, l'action d'ouverture et de fermeture du moule doit être souple, la vitesse d'ouverture et de fermeture du moule doit être raisonnable ; en général, la vitesse d'ouverture du moule est comprise entre 30 et 50 mm/s et la vitesse de fermeture du moule entre 20 et 40 mm/s.

Lors du débogage du processus de moulage par injection, il convient d'observer la situation du remplissage de la matière plastique fondue, la qualité du moulage du produit, etc. En fonction de la situation de débogage, il convient d'ajuster le moule, par exemple la taille de la porte, le temps de refroidissement, etc. jusqu'à ce que la qualité du produit réponde aux exigences.

Les moules standardisés réduisent les coûts de production.Vrai

En utilisant des processus et des matériaux standardisés, les fabricants peuvent réduire les coûts grâce à des économies d'échelle et à la réduction des déchets.

Les moules standardisés sont des solutions uniques.Faux

Bien qu'ils favorisent la cohérence, les moules standardisés nécessitent une personnalisation précise pour répondre aux exigences spécifiques du produit et aux normes de qualité.

Quelles sont les exigences en matière de documentation et de gestion des moules ?

Une documentation et une gestion adéquates sont essentielles à la fabrication de moules d'injection normalisés, car elles garantissent la qualité, la cohérence et l'efficacité de l'ensemble de la production.

La documentation sur les moules comprend les spécifications de conception, les registres de maintenance et les dossiers d'inspection. Les exigences clés en matière de gestion garantissent la conformité aux normes industrielles, l'efficacité du flux de travail et une qualité constante des produits.

Spécification du dessin du moule

Les dessins de moules doivent respecter les normes nationales de dessin, notamment en ce qui concerne le format du dessin, l'échelle, la sélection des vues, l'étiquetage des dimensions, etc. Par exemple, le format de dessin est généralement le format standard A0 - A4. Les proportions doivent être choisies raisonnablement en fonction de la taille et de la complexité du moule. La vue doit montrer pleinement la structure du moule et la forme des pièces.

Indiquez sur les dessins le matériau, le traitement thermique, le traitement de surface et d'autres paramètres techniques. Par exemple, si le matériau des pièces de la cavité du moule est l'acier P20, que le traitement thermique requis est la trempe + le revenu, et que la dureté doit être HRC30 - 35, alors la surface doit être nitrurée avec une épaisseur de couche de nitruration de 0,05 - 0,1 mm.

Préparation des documents techniques du moule

Préparer la spécification de conception du moule, en expliquant en détail l'idée de conception du moule, les caractéristiques structurelles, la détermination des principales dimensions, etc. Par exemple, dans le cahier des charges, expliquer l'emplacement de la porte et le type de base de sélection, ainsi que le système de refroidissement et le principe de conception du système d'éjection.

Préparation des documents relatifs à la technologie de traitement des moules, y compris l'itinéraire du processus d'usinage de chaque pièce, les surépaisseurs d'usinage, les paramètres de coupe, etc. Les documents relatifs à la technologie de traitement doivent pouvoir guider la production de traitement des moules, afin de garantir la qualité et l'efficacité du traitement. Préparation des exigences des moules en matière de traitement de surface, comme le traitement de nitruration, le traitement de chromage dur.

Le traitement de nitruration peut améliorer la dureté, la résistance à l'usure et la résistance à la corrosion de la surface du moule. Par exemple, après le traitement de nitruration, la dureté de la surface de la cavité du moule peut atteindre HV900 - HV1200, ce qui peut améliorer efficacement la durée de vie du moule.

La qualité du traitement de surface doit répondre aux exigences, l'épaisseur de la couche de traitement de surface, la dureté et d'autres indicateurs devant répondre aux normes requises. L'épaisseur de la couche de chromage dur est généralement de 0,02 à 0,05 mm et la dureté atteint HV800 à HV1000.

Marquage des pièces de moule

Les pièces de moule doivent être clairement marquées, avec le nom de la pièce, le numéro, le matériau et d'autres informations. La méthode de marquage peut être l'estampage, la gravure ou l'utilisation d'étiquettes, etc. Par exemple, utilisez des tampons en acier sur les pièces de la cavité du moule avec le nom de la pièce "Cavité", le numéro "CX - 01" et le matériau "P20" pour faciliter la gestion et l'assemblage des pièces.

Gestion des archives de moules

Établir le dossier du moule, y compris les dessins de conception du moule, les documents techniques, les dossiers de traitement, les dossiers de débogage et d'autres informations.

Les dossiers de moules doivent être classés et organisés pour faciliter la recherche et la gestion. Par exemple, en fonction du numéro du moule, il convient de créer un dossier, d'y classer les dessins, documents et autres informations pertinentes et de les numériser à l'aide du système de gestion électronique des documents afin d'améliorer l'efficacité de la gestion.

Entretien des moules et documents d'entretien

Préparation d'un manuel d'entretien et de maintenance du moule, décrivant la maintenance quotidienne du contenu du moule, le cycle de maintenance, le remplacement des pièces d'usure, etc.

Par exemple, le manuel stipule que le moule doit être nettoyé après chaque injection, que le système de refroidissement doit être inspecté et entretenu régulièrement (par exemple, chaque semaine ou chaque mois) et que l'usure des pièces d'usure (par exemple, les broches d'éjection, les glissières, etc.) doit être inspectée régulièrement et remplacée en temps utile lorsque l'usure dépasse une certaine limite.

Une documentation adéquate sur les moules améliore la qualité et l'efficacité de la production.Vrai

Des registres détaillés et des pratiques de gestion normalisées permettent de rationaliser le processus de fabrication et d'améliorer la cohérence et la qualité des produits.

Tous les moules d'injection nécessitent une documentation identique.Faux

Les besoins en documentation varient en fonction de la conception du moule, de sa complexité et des normes industrielles, ce qui nécessite des pratiques de documentation personnalisées pour différents projets.

Quelles sont les exigences en matière de qualité et de performance des moules ?

Il est essentiel de comprendre les exigences de qualité et de performance pour la fabrication de moules d'injection normalisés afin de garantir la cohérence des produits et l'efficacité de la production.

La fabrication normalisée de moules d'injection nécessite des matériaux de haute qualité, un usinage précis et le respect des spécifications de conception afin de garantir des performances optimales des moules, leur durabilité et une production régulière.

Exigences en matière de durée de vie des moules

Les moules doivent avoir une durée de vie suffisante, en fonction du type de moule et des conditions d'utilisation pour déterminer les indicateurs de durée de vie du moule. Par exemple, les exigences générales en matière de durée de vie des moules d'injection sont de 300 000 à 1 million de fois, tandis que pour les moules de haute précision et à exigences élevées, tels que les moules pour lentilles optiques, les exigences en matière de durée de vie peuvent aller jusqu'à des millions de fois.

Grâce à une conception raisonnable, à des matériaux de haute qualité et à des méthodes de traitement et de fabrication correctes, il est possible d'améliorer la durée de vie du moule. Par exemple, l'utilisation d'un acier de moulage approprié, l'optimisation de la structure du moule, la réduction de la concentration des contraintes, le traitement de surface approprié du moule.

Qualité des produits Cohérence

La qualité des produits fabriqués par le moule doit être constante, et la précision dimensionnelle, la qualité de l'apparence, les propriétés physiques et d'autres indicateurs des produits doivent se situer dans les tolérances spécifiées.

Par exemple, les tolérances dimensionnelles clés des produits doivent être contrôlées à ±0,1 mm, et la surface d'aspect doit être exempte de défauts évidents tels que les bords arrondis, les bulles et les marques de rétrécissement.

Inspection et entretien réguliers du moule pour garantir la stabilité de la qualité du produit. Il s'agit notamment de vérifier l'usure du moule, l'effet de refroidissement du système de refroidissement, etc., afin de détecter les problèmes et de les traiter à temps.

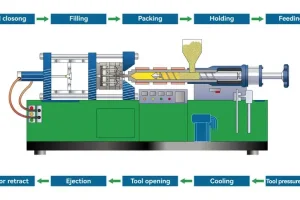

Exigences du cycle de moulage par injection

Les moules doivent pouvoir répondre à certaines exigences en matière de cycle de moulage par injection, raccourcir le cycle de moulage par injection10 peut améliorer l'efficacité de la production. Par exemple, l'exigence générale du cycle de moulage par injection se situe entre 10 et 60 secondes. L'optimisation du système de refroidissement du moule, la conception raisonnable de la porte et de la glissière, etc. permettent de raccourcir le cycle de moulage.

Interchangeabilité du moule

Les pièces du moule doivent être bien interchangeables pour faciliter l'entretien et le remplacement du moule. Par exemple, le même type de goupilles d'éjection, de piliers de guidage, de douilles de guidage et d'autres pièces peuvent être remplacés les uns par les autres, la tolérance dimensionnelle et la précision d'ajustement des pièces doivent répondre aux exigences d'interchangeabilité, et utilisent généralement le système de trou de base ou le système d'arbre de base de l'ajustement.

Sécurité du moule

Le moule doit tenir compte de la sécurité des opérations et mettre en place les dispositifs de protection nécessaires. Par exemple, dans les zones d'ouverture et de fermeture du moule, des garde-corps sont installés pour empêcher les mains ou d'autres parties du corps de l'opérateur de pénétrer dans la zone de travail du moule afin d'éviter les blessures accidentelles.

La conception structurelle du moule doit éviter les arêtes et les coins tranchants ainsi que les structures susceptibles de provoquer l'éjection des pièces, afin d'éviter que celles-ci ne s'envolent et ne blessent des personnes.

Les moules standardisés garantissent la cohérence de la production dans le domaine du moulage par injection.Vrai

L'utilisation de moules standardisés permet d'assurer l'uniformité de plusieurs séries de production, ce qui se traduit par une qualité constante des produits.

Les moules d'injection standardisés sont toujours moins coûteux que les moules sur mesure.Faux

Si les moules standardisés peuvent être plus rentables au départ, des moules sur mesure peuvent être nécessaires pour des conceptions de produits spécifiques, ce qui risque d'augmenter les coûts.

Quelles sont les exigences en matière d'acceptation des moules ?

Il est essentiel de comprendre les exigences d'acceptation des moules pour obtenir des moules d'injection normalisés de haute qualité, garantissant la précision du produit et l'efficacité de la fabrication.

Les exigences en matière d'acceptation des moules comprennent des tolérances strictes, des normes de finition de surface et des contrôles de fonctionnalité appropriés. Elles garantissent que les moules d'injection produisent des pièces avec précision et cohérence, réduisant ainsi les défauts et améliorant l'efficacité des processus de fabrication.

Inspection de l'apparence

Vérifiez l'aspect du moule, notamment la rugosité de la surface, la couleur, le marquage, etc. La surface du moule doit être lisse et exempte de rayures évidentes, de rouille et d'autres défauts. Le marquage doit être clair, précis et conforme aux exigences de la conception.

Vérifier l'assemblage des pièces du moule, l'assemblage doit être serré, il ne doit pas y avoir de phénomène de desserrement. Par exemple, vérifiez si les vis sont serrées et si l'écart d'ajustement entre les pièces est conforme aux exigences.

Contrôle de la précision dimensionnelle

Adoptez des jauges appropriées pour vérifier les dimensions clés du moule, telles que les dimensions de la cavité, les dimensions du noyau, les dimensions du guide, etc. La tolérance dimensionnelle doit être conforme aux exigences des dessins de conception, et les dimensions excédentaires doivent être analysées et traitées.

Vérifier la précision de la forme du moule, comme la planéité, la rectitude, la rondeur, etc. Par exemple, vérifiez la planéité du plan de joint du moule à l'aide d'un indicateur de niveau et la rectitude du pilier de guidage à l'aide d'un indicateur de pourcentage.

Contrôle de la fonction

Vérifier la fonction d'ouverture et de fermeture du moule, l'action d'ouverture et de fermeture doit être souple, régulière et sans stagnation. Vérifier le fonctionnement du système d'éjection, l'action de l'éjecteur doit être normale, la force d'éjection doit répondre aux exigences.

Vérifier le fonctionnement du système de refroidissement et du système d'échappement, le tuyau de refroidissement doit être lisse, l'effet de refroidissement doit être bon ; le canal d'échappement doit être capable d'évacuer efficacement. Par exemple, le système de refroidissement doit être vérifié par un test à l'eau et le système d'échappement doit être vérifié par un test au moule d'injection.

Contrôle de la qualité des produits

Effectuer un essai de moulage avec le moule pour vérifier la qualité de moulage du produit. La précision des dimensions, la qualité de l'apparence et les propriétés physiques du produit doivent répondre aux exigences de la conception du produit. Par exemple, vérifiez si l'épaisseur de la paroi du produit est uniforme et s'il y a des défauts tels que des marques de fusion et des marques de rétraction à la surface.

Ajuster le moule en fonction de la situation du moule d'essai jusqu'à ce que la qualité du produit soit satisfaisante. Les ajustements portent sur la taille de la porte, le temps de refroidissement, la position d'éjection, etc.

Acceptation des documents

Vérifiez si les dessins de conception, les documents techniques, les registres de traitement et les registres de débogage du moule sont complets. Le contenu des documents doit être complet, précis et conforme aux normes et exigences applicables.

Par exemple, vérifiez si les dessins de conception sont signés par les concepteurs et si les documents techniques contiennent les exigences en matière de matériaux et de traitement thermique du moule.

Les critères d'acceptation des moules garantissent une fonctionnalité et une précision optimales des produits finis.Vrai

Le respect des normes d'acceptation permet de réduire les défauts et d'améliorer l'efficacité globale de la fabrication, tout en renforçant la qualité des produits.

Tous les moules qui répondent à ces exigences garantissent automatiquement le succès du produit.Faux

Il est essentiel de répondre aux exigences d'acceptation des moules, mais d'autres facteurs tels que la qualité des matériaux et le contrôle des processus sont également vitaux pour la réussite du produit.

Conclusion

Les exigences de normalisation des moules d'injection comprennent l'analyse du produit, la conception de la structure du moule, les normes dimensionnelles, la conception du système de refroidissement et d'éjection. La conception du moule doit tenir compte de la fonction du produit, de la méthode de démoulage, de la surface de séparation, de la position de la porte, de l'effet de refroidissement, etc. pour garantir la qualité du produit.

La fabrication des moules nécessite un usinage précis, la sélection de matériaux et de traitements de surface appropriés, le contrôle de la précision des pièces et de l'assemblage. Les exigences de qualité couvrent la durée de vie du moule, l'uniformité du produit, le cycle de moulage et la sécurité. L'acceptation du moule implique des inspections visuelles, dimensionnelles et fonctionnelles, ainsi que l'acceptation de la qualité du produit et de la documentation pour s'assurer que le moule répond aux normes de conception et de production.

-

La compréhension des différentes méthodes de démoulage peut améliorer la conception de vos produits et l'efficacité de la fabrication. ↩

-

Un cadre de moule bien conçu est essentiel pour la durabilité et la performance des processus de moulage par injection. ↩

-

Un système de refroidissement efficace est essentiel pour maintenir la température du moule et améliorer les temps de cycle en production. ↩

-

La compréhension du système d'éjection est essentielle pour optimiser la conception du moule et garantir la qualité du produit. ↩

-

L'étude des propriétés de l'acier P20 peut vous aider à choisir le bon matériau pour vos moules d'injection, en améliorant la durabilité et les performances. ↩

-

L'apprentissage des processus d'usinage peut améliorer l'efficacité de votre production de moules et garantir des résultats de haute qualité. ↩

-

Explorez ce lien pour comprendre les différents outils de coupe disponibles et leurs applications spécifiques pour différents matériaux. ↩

-

Cette ressource fournira des indications sur la manière d'ajuster efficacement les paramètres d'électroérosion pour améliorer la qualité et la précision de la surface. ↩

-

Découvrez les meilleures pratiques et les outils permettant de maintenir la précision dimensionnelle des pièces moulées, essentielle pour une fabrication de haute qualité. ↩

-

Découvrez comment réduire la durée du cycle de moulage par injection : Le cycle de moulage par injection n'est pas une mince affaire. Il influe sur la quantité de travail que vous réalisez et sur vos bénéfices. ↩