– Injection mould quality is the result of ten interdependent factors spanning material selection, mould design, machine parameters, and post-processing—no single factor dominates in isolation.

– In our factory, material quality and mould steel choice account for roughly 40% of first-shot rejection causes; they must be locked in before any other optimization is meaningful.

– Cooling system design is the single most impactful design decision for reducing warpage and cycle time—uniform cooling within ±2°C across the cavity surface is our standard target.

– Gate location and size affect not only cosmetic appearance but also internal stress distribution, weld line strength, and dimensional accuracy over the life of the tool.

– Preventive maintenance on a documented schedule—every 50,000–100,000 shots—is the most cost-effective way to protect cumulative mould quality investment.

Why Do These 10 Factors Determine Injection Mould Quality?

Injection mould quality is determined by the interaction of ten critical factors: raw material properties, mould steel selection, cooling system design, gate design, runner system, ejection system, parting surface quality, process parameter control, machine condition, and preventive maintenance. In our factory, we evaluate all ten systematically on every new tool before first production run. Addressing only one or two while ignoring the rest consistently results in quality problems that are difficult to diagnose because the root cause is obscured by the interaction of multiple variables.

The ten factors are not equally weighted in every project. For a medical device housing with tight dimensional tolerances, material quality and cooling uniformity dominate. For a high-gloss consumer product, parting surface quality and gate location are most critical. For a high-volume commodity part, machine condition and maintenance schedule drive long-term quality consistency. Understanding which factors matter most for a specific application is the first step in building a quality control plan.

How Does Raw Material Quality Affect Injection Mould Output?

Raw material quality is the foundational variable in injection moulding quality—every other factor operates on the material that enters the barrel. Poor material quality manifests as inconsistent viscosity, contamination-induced discoloration, moisture-related defects (splay, bubbles), and unpredictable shrinkage. We’ve traced over 25% of first-shot quality rejections in our facility to material lot variation or pre-drying failures.

| Material Issue | Defect Caused | Prevention Method |

|---|---|---|

| Insufficient drying (hygroscopic resins) | Splay, bubbles, degraded surface finish | Dry to spec: ABS 80°C/4h, PC 120°C/4h, Nylon 80°C/6h |

| MFI variation between lots | Dimensional shift, fill pressure change | Request MFI certification per lot, adjust process |

| Contamination (foreign material) | Black specks, gate blush, weak weld lines | Dedicated hoppers, purge before production |

| Excessive regrind percentage | Reduced impact strength, color inconsistency | Limit regrind to 15–20% maximum for structural parts |

| Wrong colorant concentration | Color variation, weld line visibility | Calibrate masterbatch ratio at production start |

“Regrind plastic can be used at any percentage without affecting mould quality.”False

Each time thermoplastic is processed through the barrel, polymer chains degrade from heat exposure, reducing molecular weight and mechanical properties. Above 20% regrind content, impact strength can drop 15–30% and color consistency deteriorates. Most quality standards limit regrind to 15–20% for structural applications.

“Drying hygroscopic resins like nylon and PC to manufacturer specifications before moulding is essential for preventing splay defects.”True

Hygroscopic resins absorb moisture from the air. When processed with residual moisture above 0.02% (PC) or 0.2% (nylon 6), the water flashes to steam in the barrel, creating splay marks on the part surface and hydrolytic degradation that reduces molecular weight and mechanical strength permanently.

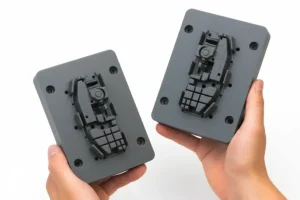

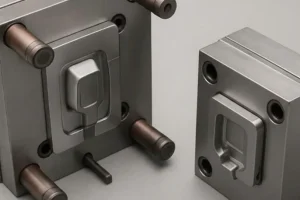

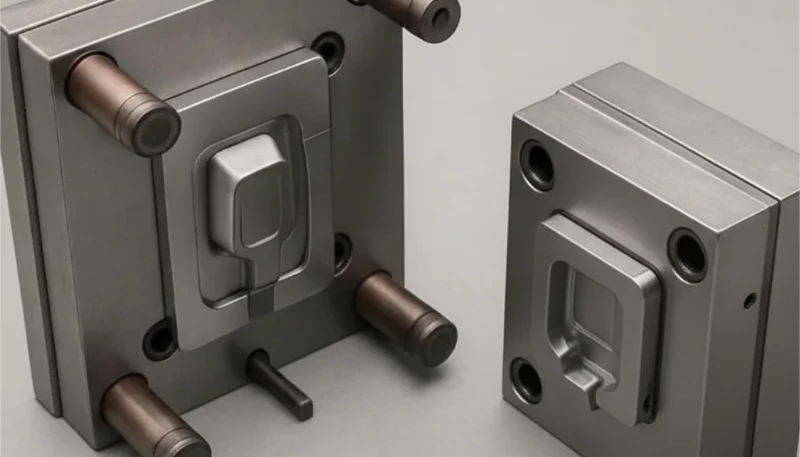

How Do Mould Steel and Cavity Surface Quality Influence the Final Part?

Mould steel choice and cavity surface condition directly determine part surface finish, dimensional stability, and how long the tool maintains quality over its production lifetime. We select steel grades based on the application requirements: P20 for general production, H13 for high-temperature resins and abrasive filled materials, and S136 (420 stainless) for corrosive resins and optical surfaces requiring mirror finishes.

Cavity surface finish is specified on the SPI scale (A1 through D3). An A1 finish (diamond-polished to Ra ≤ 0.012 µm) is required for optical lenses; a B2 finish (Ra 0.4–0.8 µm) is standard for general consumer housings. Mould steel must be polishable to the required SPI grade—not all steels achieve A-grade finishes regardless of polishing time. We’ve found that specifying the steel and surface finish requirement together at the design stage prevents expensive rework on tools built with the wrong steel for the intended cosmetic requirement.

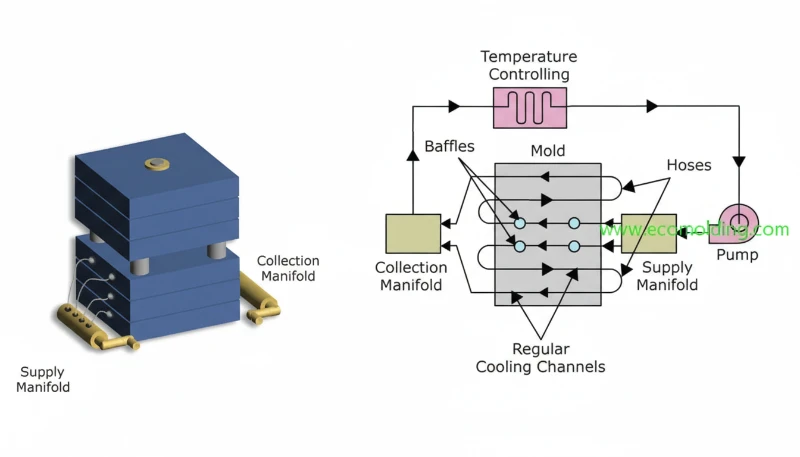

Why Is Cooling System Design the Most Critical Mould Design Decision?

The cooling system is responsible for extracting approximately 70% of the total heat input in every injection cycle. Its design determines cycle time, part dimensional accuracy, and warpage—three of the most economically significant quality parameters in production moulding. In our factory, we have never seen a cooling design that was over-engineered; we have frequently seen designs that were under-engineered and caused years of quality problems.

Our design rules for cooling channels: place channels within 10–15 mm of the cavity surface (closer is better, as long as structural integrity allows), space channels 25–35 mm apart for uniform heat extraction, maintain turbulent flow (Reynolds number >4,000) using 8–12 mm diameter channels with high flow rates, and always provide independent temperature control circuits for cavity and core sides. Differential temperature between cavity and core sides causes predictable bow or warp in the moulded part—something that can be corrected only by rebalancing the cooling, not by adjusting injection parameters.

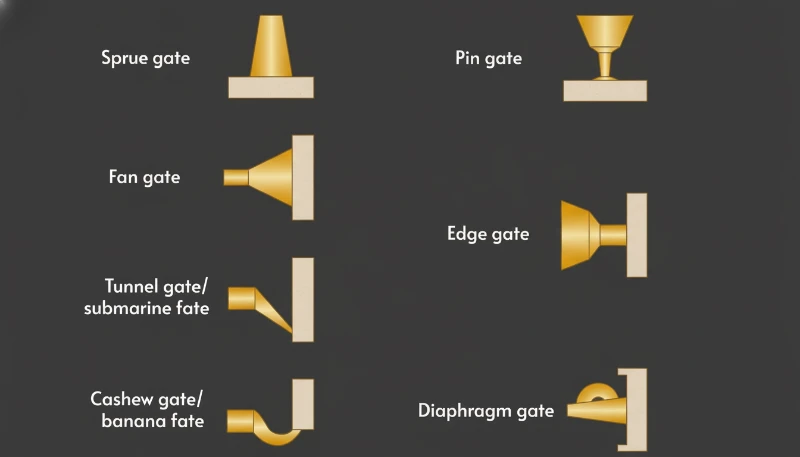

How Does Gate Design Affect Injection Mould Quality?

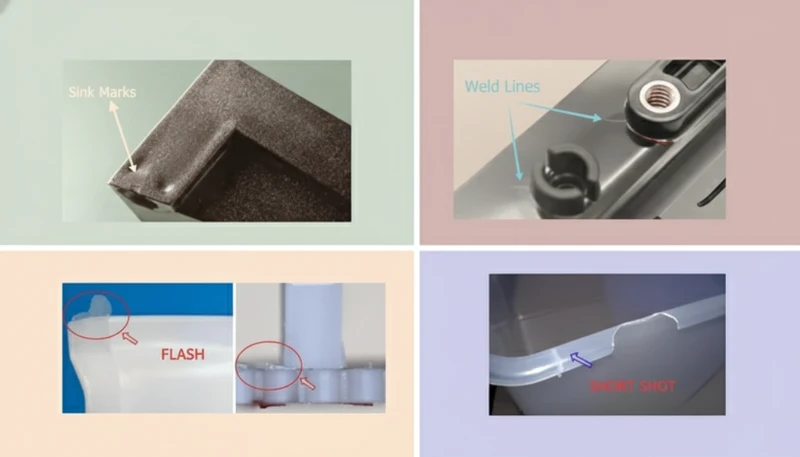

Gate design1 encompasses gate type, gate location, and gate dimensions—three variables that together determine how molten plastic enters the cavity and therefore govern fill pattern, pressure distribution, weld line2 location, residual stress state, and the cosmetic appearance of the gate area. Getting gate design wrong is one of the most expensive tooling errors because fixing it almost always requires modifying or replacing steel.

We follow these gate sizing guidelines: for amorphous resins (ABS, PC, PS), the gate depth should be 50–75% of wall thickness; for semi-crystalline resins (PP, nylon, POM), 60–80% of wall thickness. Undersized gates freeze before adequate pack pressure is applied, causing sink marks, voids, and undersized walls. We always position gates at the thickest wall section to prevent premature freeze-off and to direct flow toward thin sections with maximum pressure.

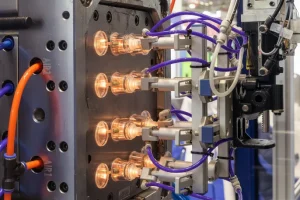

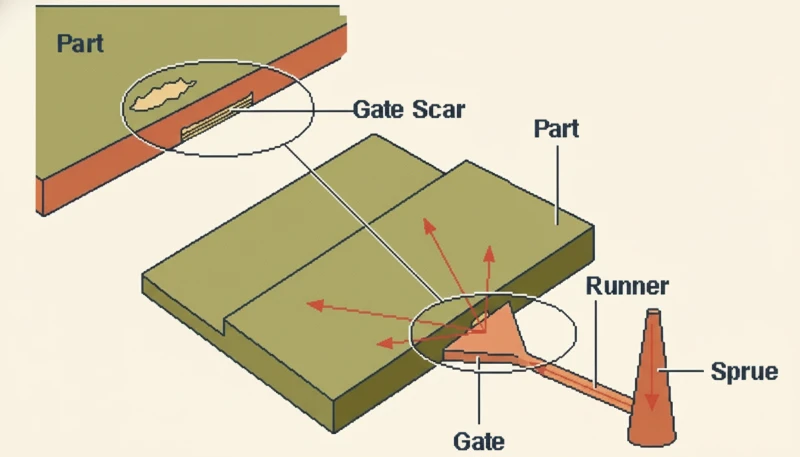

How Do Runner System and Ejection System Design Impact Part Quality?

The runner system delivers material from the sprue to the gate. A poorly designed runner wastes material, generates excessive pressure drop, and causes fill imbalances in multi-cavity tools. We prefer full-round runners (minimum pressure drop, maximum thermal efficiency) over trapezoidal or half-round profiles on cold runner systems. For high-volume programmes, hot runner systems3 eliminate runner scrap entirely and allow sequential valve-gate control for complex fill management.

The ejection system is responsible for removing the part from the mould without marking, distorting, or cracking it. Ejector pin placement must distribute ejection force across the strongest areas of the part (thick sections, bosses, ribs) and avoid applying concentrated force to thin cosmetic surfaces. We calculate the required ejection area to keep contact stress below 10 MPa for most resins and below 5 MPa for brittle materials like unfilled POM or glass-filled nylons at high ejection speeds.

“Flash at the parting line is primarily caused by excessive injection pressure.”False

While excessive injection pressure can cause flash, the most common cause is an insufficient clamping force relative to the cavity projected area, or worn/damaged parting surfaces that allow plastic to escape. A properly calculated clamping force (typically 2–5 tons per square inch of projected area) prevents flash regardless of injection pressure, as long as parting surfaces are in good condition.

“Process parameter stability across shifts and operators is as important as mould quality for long-term production quality.”True

A well-built mould produces consistent quality only when process parameters—melt temperature, injection speed, holding pressure, cooling time—remain stable. Shift-to-shift variation without documented process sheets and automated parameter monitoring routinely introduces 5–15% quality variation independent of mould condition.

How Do Machine Condition and Preventive Maintenance Protect Long-Term Mould Quality?

Machine condition and mould maintenance are the two most overlooked quality factors in production moulding operations. In our experience, a well-designed, well-built mould running on a worn machine consistently underperforms a moderate mould running on a well-maintained machine. Machine-side quality factors include: barrel and screw wear (causes inconsistent shot volume and melt temperature), clamp tonnage accuracy (insufficient tonnage allows parting line opening during injection), and tie-bar parallelism (uneven clamping force causes differential cavity pressure).

Our preventive maintenance schedule for precision moulds: every 50,000 shots—clean cooling channels, inspect ejector pin clearances, check parting surface flatness, apply rust inhibitor to all unpainted surfaces; every 250,000 shots—CMM spot-check of critical cavity dimensions, replace worn ejector pins, polish any cavity surface degradation, re-certify cooling channel flow rates. We track all maintenance in a log attached to each mould. Moulds without maintenance logs are treated as unknown-condition tools and require full dimensional certification before production approval.

Frequently Asked Questions

What is the most common cause of sink marks in injection moulded parts?

Sink marks most commonly result from inadequate holding pressure or premature gate freeze that prevents material from compensating for volumetric shrinkage during cooling. Secondary causes include wall thickness transitions that are too abrupt (creating differential shrinkage), and cooling channels that are too far from the cavity surface to extract heat efficiently. We resolve most sink mark problems by increasing hold time, adjusting gate size, or redesigning thick-to-thin transitions.

How does vent design affect injection mould quality?

Inadequate venting traps air at the last-fill locations, causing burn marks (diesel effect), short shots, and high local pressure that can crack fragile part geometry. We vent cavities to 0.01–0.02 mm depth at all natural trap locations and add parting-line vents every 25–50 mm on complex parts. Clean, properly sized vents are the lowest-cost quality improvement available—a 2-hour vent cleaning at preventive maintenance intervals prevents defects that would cost hours of troubleshooting.

How does draft angle affect ejection quality?

Insufficient draft angle causes excessive ejection force that creates ejector pin marks, part distortion, or part cracking during ejection. Our standard minimum draft angles: 0.5–1° for textured surfaces per 0.025 mm of texture depth, 1–2° for polished surfaces, and 3–5° for rough or matte surfaces. For glass-filled resins that have higher friction, we add 0.5–1° beyond the standard minimum.

What is the SPI mould classification system and how does it relate to quality?

The SPI (Society of the Plastics Industry, now Plastics Industry Association) mould class system rates injection moulds from Class 101 (highest quality, 1M+ shots, hardened steel) to Class 105 (low quality, <500 shots, prototype tooling). The class designation specifies steel hardness, cooling channel requirements, and inspection standards. A Class 102 mould is certified for 500,000–1 million shots with H13 or 420SS steel; a Class 104 mould uses aluminum or P20 and is rated for <100,000 shots. Matching the mould class to production requirements is essential for achieving consistent part quality at the lowest long-term cost.

How does injection speed affect surface quality in injection moulding?

Injection speed controls the shear rate in the runner and gate, which affects surface gloss, weld line visibility, and flow mark formation. Too-slow injection allows the material to cool and solidify before filling is complete (resulting in flow marks and weld lines). Too-fast injection creates excessive shear heat and can cause burning, gate blush, or jetting. We optimize injection speed by performing a fill-only study (short shots at 95% fill) to identify the optimal speed range where the part fills uniformly without visible flow defects.

Can injection mould quality be recovered after cavity wear?

Yes, in most cases. Minor cavity wear (dimensional loss of 0.02–0.1 mm) can be corrected by welding and re-machining the affected area using TIG welding with matching steel rod, followed by hardening and re-polishing. Severe wear requires EDM plunge to remove the worn surface, welding to restore material, and full re-machining. We assess repair feasibility based on remaining steel wall thickness; cavities with less than 8–10 mm wall thickness at the repair location are typically replaced rather than repaired.

Summary

The ten factors affecting injection mould quality—raw material, steel selection, cooling design, gate design, runner system, ejection system, parting surface quality, process parameters, machine condition, and maintenance schedule—form an interconnected system. In our factory, we treat quality problems as systems problems: we don’t assume a single factor is responsible until we’ve audited all ten and identified the primary and contributing causes systematically.

For teams looking to improve injection mould quality, we recommend starting with the three factors most likely to have the largest impact: raw material incoming quality control, cooling system thermal uniformity audit, and process parameter documentation and monitoring. These three factors collectively account for 55–65% of production quality variation in our experience. Fix these, then work through the remaining factors in order of their relevance to your specific quality problem.

-

Gate design refers to the configuration, location, and dimensions of the entry point through which molten plastic flows from the runner system into the mould cavity. Gate type selection (edge, pin, tunnel, hot-tip, valve) significantly affects part cosmetics, dimensional accuracy, and ease of gate removal. ↩

-

A weld line (also called a knit line) forms where two separate flow fronts of molten plastic meet and fuse during cavity filling. Weld lines are structurally weaker than the surrounding material (typically 10–30% lower tensile strength) and can appear as visible lines on the part surface, especially with pigmented or glass-filled resins. ↩

-

A hot runner system is a heated manifold and nozzle assembly installed in the mould that keeps the plastic in the runner channels molten throughout the production cycle, eliminating the solid runner waste generated by conventional cold runner systems. Hot runner systems improve material efficiency and cycle time but require higher tooling investment and precise temperature control. ↩