The weld marks are an important factor affecting the quality of plastic parts. The research found that: under the same process conditions, the strength of the weld line area is only 10-92% of the original material, which seriously affects the normal use of injection molded products.

Avoiding these and other injection molding defects is all about using the right mold manufacturer and having a part manufacturer that has the right quality assurance to catch these defects and troubleshoot them.

For example, in the automotive industry, unqualified plastic parts directly lead to the decline of the quality of the car, and even endanger the safety of human life.

Therefore, it is of great practical significance to study the formation process of weld lines, and the influencing factors and find ways to eliminate the weld lines.

The formation mechanism of weld lines

Plastic products in the injection molding process, found in the plastic melt filling the cavity, such as two or more strands of melt in the first part of the meeting have been cooled so that they can not be completely integrated, it will be at the intersection of the groove, the formation of melt marks.

The “weld lines” of plastic products refer to the three-dimensional area where the morphological structure and mechanical properties of the two strands of molten material come into contact with each other, which is completely different from the other parts.

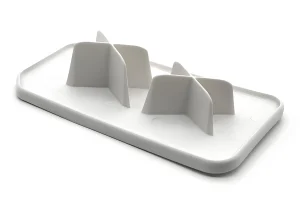

The most common weld lines in injection molded parts are of two basic types:

One is the melt joint marks formed at the meeting of the melt fronts entering the cavity from different gates, called cold melt joint marks, when two or more gates are used to reduce the melt flow and mold filling time due to the structural characteristics or large size of the injection molded parts.

Another is when the cavity is equipped with cores and inserts, the low-temperature melt is divided into two strands when bypassing this obstacle, and the two melt strands reunite after bypassing the obstacle to forming the weld marks, called hot weld marks.

Causes of weld marks on plastic products

1. The plastic melt passing through the gate at high speed enters the cavity directly, then touches the surface of the cavity and cures, then is pushed by the subsequent plastic melt, thus leaving snaking marks.

2. When the injection mold design adopts a multi-gate feeding scheme, the plastic melt flow fronts converge with each other; in the area of holes and obstacles, the melt flow fronts will also be divided into two; uneven uniform wall thickness will also lead to weld marks.

3. When a side gate is used and there is no stagnant material area or insufficient stagnant material area after the plastic passes through the gate, it will easily produce spray marks.

Solutions for weld marks on plastic products

1. Reduce the number of gates.

2. Adjust the gate position.

3. Add material overflow wells near the fusion part, move the weld line to the overflow wells, and then remove it.

4. Increase the exhaust in the weld line area to quickly evacuate the air and volatiles in this part. Raise the material temperature and mold temperature to enhance the flowability of plastic and increase the material temperature when fusing.

5. Change the location and number of gates to move the location of the weld line to another location.

6. Increase the injection speed.

7. Increase the injection pressure and increase the size of the pouring system.

8. Reduce the use of mold release agents.

9. Shorten the distance between the gate and the weld area.

10. Adjust the gate position so that the molten plastic hits the pin or wall after passing through the gate.

11. Change the gate form to an overlapping gate or lug gate with sufficient stagnation area in the gate area.

12. Slow down the initial injection speed of the plastic melt.

13. Increase the gate thickness/cross-sectional area so that the material flow front is formed immediately.

14. Raise the mold temperature to prevent rapid material curing.

Influence factors of melt marks and measures to improve their elimination

Since melt marks have an important influence on the quality of plastic parts, a lot of research has been done on their formation mechanism and performance evaluation, and various solutions have been proposed.

a. Influence of temperature

Increasing the temperature can accelerate the relaxation process of polymer and reduce the time of molecular chain entanglement, which is more conducive to the full fusion, diffusion, and entanglement of molecules at the front end of the material, thus improving the strength of the weld joint scar area.

It is proved that increasing the melt temperature is beneficial to reduce the depth of V-notch on the surface of plastic parts, and the depth of V-notch decreases from 7μm to 3μm when the melt temperature is increased from 220℃ to 250℃.

The effect of temperature on the tensile capacity of melt marks of PA66 injection molded products containing 33% glass fiber reinforcement was studied and found that: the tensile strength of specimens with and without melt marks increased with the increase of melt temperature.

The effect of temperature change on the tensile strength of weld splice marks is not linear, and the tensile strength of weld splice marks changes significantly with the increase of temperature when the temperature is relatively low (such as 70℃);

However, this change is relatively flat when the temperature rises to a certain degree.

Similar conclusions were obtained for experiments with PA66 (35% glass fiber reinforced), using ABS.

Using simulations it was found that mold temperature and melt temperature of the injection molding machine did not have the same effect on the strength of weld marks formed by different materials.

Using a combination of experiments and simulations, it was found that among the injection molding process parameters, the melt temperature had the greatest effect on the strength of weld splice marks of ABS plastic parts.

b. Influence of injection pressure and holding pressure

Injection pressure is an important factor in the filling and molding of plastic melt. Its role is to overcome the resistance of plastic melt when it flows in the barrel, nozzle, pouring system, and cavity, to give the plastic melt sufficient filling speed, and to be able to compact the melt to ensure the quality of injection molded products.

Increasing the injection pressure helps to overcome the flow channel resistance and transfer the pressure to the melt front, so that the melt can be fused at the weld mark with high pressure and increase the density at the weld mark, thus the strength of the weld mark can be improved.

Increasing the holding pressure not only provides more kinetic energy to the movement of the melt molecular chain but also promotes the mutual bonding of the two melt strands, thus increasing the density of the weld mark area and the strength of the weld mark.

c. Influence of injection speed and injection time

Increasing the injection speed and shortening the injection time will reduce the flow time before the melt fronts converge, reduce the heat loss and enhance the shear heat generation, so that the melt viscosity decreases and the flowability increases, thus improving the strength of the weld marks.

The strength of the weld splice marks is very sensitive to the injection time and will be enhanced as the injection time is reduced.

However, the injection speed is too large, and it is easy to produce turbulence (melt rupture), which seriously affects the performance of the plastic parts.

In general, weld line injection molding should be done at low pressure and slow speed, and then the plastic injection molding speed should be adjusted according to the shape of the molded part.

In practice, to shorten the production cycle and avoid turbulence, a medium to high injection speed is more often used.

The injection speed affects the flow behavior of the melt in the cavity, as well as the pressure and melt temperature in the cavity and the performance of the product.

Injection speed is large, the melt through the mold casting system and cavity flow rate is also large, the stronger the material is sheared, the greater the frictional heat, the temperature rises, viscosity decreases, the material process is also extended, the cavity pressure is also increased, the strength of the product weld marks are also increased.

In addition, when the uniform wall thickness of the parts is too different, the fluid flow through the injection mold cavity when the resistance is different, the resistance at the wall thickness is small, the flow rate is fast, and the resistance at the thin wall is large, the flow rate is slow.

Due to this difference in flow rate, so that the melt from different wall thicknesses, with different flow rates of convergence, and finally at the convergence of the formation of weld marks.