– High-gloss finishes (A-1 to A-3) increase tooling costs and require hardened steel molds.

– Textured finishes (D-1 to D-3) hide surface defects like sink but require significantly larger draft angles.

– Material selection limits finish quality; glass-filled polymers cannot achieve true mirror finishes.

What Is the SPI Surface Finish Standard?

The SPI Surface Finish Standard1 is a classification system originally established by the Society of the Plastics Industry2 (SPI)—now referred to as the Plastics Industry Association (PLASTICS). It defines the cosmetic quality of the surface of an injection molded part and the corresponding texturing or polishing method required for the mold cavity.

These standards provide a common language between industrial designers, engineers, and mold makers. The system helps predict the aesthetic outcome of a part, the cost of tooling, and the functional performance (e.g., friction, paint adhesion, or optical clarity).

The standards are categorized into four primary grades:

- Grade A (Gloss/Diamond Polish): Mirror-like finish.

- Grade B (Semi-Gloss/Paper): Smooth finish without high reflection.

- Grade C (Matte/Stone): Non-reflective, standard industrial finish.

- Grade D (Textured/Blast): Rough finish created via dry blasting or Electrical Discharge Machining (EDM).

What Are the Technical Parameters of SPI Finishes?

To ensure manufacturability, engineers must adhere to specific roughness averages (Ra) and draft angle requirements. The following table details the twelve primary SPI designations.

| SPI Grade | Finish Description | Method of Application | Typical Ra (µm) | Typical Ra (µin) | Min. Draft Angle | Primary Use Case |

|---|---|---|---|---|---|---|

| A-1 | Super High Gloss | Grade #3 Diamond Buff | 0.012 – 0.025 | 0 – 1 | 1° | Lenses, mirrors, visors |

| A-2 | High Gloss | Grade #6 Diamond Buff | 0.025 – 0.05 | 1 – 2 | 1° | Cosmetic cases, electronics |

| A-3 | Normal Gloss | Grade #15 Diamond Buff | 0.05 – 0.10 | 2 – 4 | 2° | Household goods, opaque parts |

| B-1 | Smooth / Semi-Gloss | 600 Grit Paper | 0.05 – 0.10 | 2 – 3 | 1° | Medium polish parts |

| B-2 | Smooth / Medium | 400 Grit Paper | 0.10 – 0.15 | 4 – 5 | 1° | General molding, paintable parts |

| B-3 | Smooth / Low Gloss | 320 Grit Paper | 0.28 – 0.32 | 9 – 10 | 2° | Economy molding |

| C-1 | Matte / Fine | 600 Grit Stone | 0.35 – 0.40 | 10 – 12 | 1.5° | Die cast look, internal parts |

| C-2 | Matte / Medium | 400 Grit Stone | 0.80 – 0.95 | 25 – 28 | 1.5° | Structural parts, easy release |

| C-3 | Matte / Rough | 320 Grit Stone | 0.95 – 1.10 | 38 – 42 | 2° | Heavy utility parts |

| D-1 | Textured / Satin | Dry Blast (Glass Bead) | Varies | Varies | 2.5°+ | Satin finish handles |

| D-2 | Textured / Dull | Dry Blast (Alum. Oxide) | Varies | Varies | 3°+ | Industrial housing, grip |

| D-3 | Textured / Rough | Dry Blast (#24 Oxide) | Varies | Varies | 3°+ | Heavy texture, defect hiding |

Note: Ra (Roughness Average) values are approximate and depend on the steel type and measuring equipment.

How Is the Polishing Process Executed Step-by-Step?

Achieving a specific SPI finish is a subtractive manufacturing process applied to the mold cavity steel.

- Rough Machining: The mold core and cavity are CNC machined to the approximate shape. The surface is rough, often showing tool marks.

- Stoning (Leveling): Toolmakers use abrasive stones to remove CNC tool marks and level the surface. This is the baseline for C-Grades.

- Paper Polishing: If a smoother finish is required, the surface is sanded with progressively finer grit sandpaper (from 320 to 600 grit). This achieves B-Grades.

- Diamond Buffing (Optional): For A-Grades, a diamond paste is applied to a rotary buffing tool. The steel is polished until it reaches optical reflectivity.

- Blasting (Optional): For D-Grades, the specific areas are masked, and media (glass beads or aluminum oxide) is blasted onto the surface under high pressure to create random texture depth.

What Are the Pros and Cons of Each Grade Category?

| SPI Category | Advantages | Disadvantages |

|---|---|---|

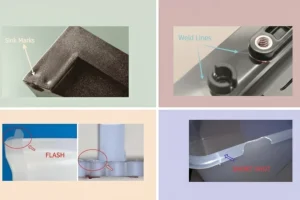

| Grade A (Gloss) | Highest aesthetic appeal; optical clarity for transparent parts; perceived high value. | Highest tooling cost; prone to "vacuum seal" sticking; highlights surface defects (scratches, fingerprints, sink marks. |

| Grade B (Semi-Gloss) | Good balance of cost and aesthetics; suitable for painting or plating; removes machining marks. | Can still show some molding defects; requires manual polishing labor. |

| Grade C (Matte) | Low tooling cost (fastest to machine); excellent for part release; hides minor tool marks. | Can look "unfinished" or industrial; not suitable for high-end consumer facing surfaces. |

| Grade D (Textured) | Excellent for hiding sink marks and flow lines; improves grip; durable surface appearance. | Hardest to clean (fingerprint traps); requires significant draft angles; difficult to repair if the mold is damaged. |

Textured finishes (SPI D-series) generally require larger draft angles than polished finishes to prevent part sticking.True

Textures create undercuts at a microscopic level; a general rule is 1.5 degrees of draft for every 0.001 inch of texture depth to prevent drag marks.

A higher SPI finish grade (like A-1) always improves part ejection.False

Mirror finishes can actually create a vacuum seal effect between the part and the mold steel, causing parts to stick. This often requires air poppets or vacuum breakers to eject the part without deformation.

Practical Tips for Optimizing Surface Finish Selection

-

Material Compatibility:

- High Gloss (A-1): Best with amorphous resins like Polycarbonate (PC), Acrylic (PMMA), and ABS.

- Textured (D-1): Ideal for crystalline resins like Polypropylene (PP) and Polyethylene (PE) which naturally have a lower gloss.

- Reinforced Resins: If using 30% Glass-Filled Nylon (PA66 GF30), avoid A-grade finishes. The glass fibers will "read through" the surface, ruining the mirror effect. Stick to C or D grades.

-

The "Sink Mark" Strategy:

- If your design has thick ribs or bosses that might cause sink marks on the A-side (visible side), choose a Grade D (Textured) or heavy Grade C (Matte) finish. The texture breaks up light reflection, making sink marks nearly invisible to the naked eye.

-

Cost Management:

- Moving from a C-1 (Stone) to an A-1 (Diamond) finish can increase mold manufacturing time by 15-30% due to the manual labor required. Only specify A-1 where strictly necessary (e.g., a display window), not on the entire part.

What Are Common Application Scenarios?

- SPI A-1: Automotive headlight lenses, optical prisms, medical pipettes.

- SPI A-2: Smartphone screens, high-end cosmetic compacts.

- SPI B-1: Keyboard keys, housings intended for painting.

- SPI C-1: Internal automotive brackets, calculators, remote control battery covers.

- SPI D-2: Power tool handles, steering column covers, ruggedized laptop cases.

How to Choose the Right SPI Finish (Step-by-Step)

- Define Functionality: Does the part need to be transparent? (Choose A). Does it need grip? (Choose D). Does it need to release easily from the mold? (Choose C).

- Check the Polymer: Is the material unfilled or glass-filled? If glass-filled, cap your expectations at B-3 or C-1.

- Review Draft Angles: Check your CAD model. If you have 0° or 0.5° draft, you cannot use a texture (D-grade). You must add draft or switch to a polished finish.

- Determine Budget: If cost is the primary driver, specify SPI C-1. It is the standard "machined" finish that requires minimal post-processing.

- Consult the Molder: Before finalizing, ask the injection molder if the chosen finish requires specific mold steels (e.g., H13 vs P20) which could impact lead time.

Frequently Asked Questions (FAQ)

Q: What is the difference between SPI and VDI 3400 standards3?

A: SPI is the US industry standard, focusing on the polishing method (diamond, paper, stone). VDI 3400 (Verein Deutscher Ingenieure) is a European standard usually defined by texture depth (Roughness) generated by EDM. For example, VDI 12 is roughly equivalent to SPI A-3/B-1, while VDI 30 resembles SPI C-1.

Q: Can I change the surface finish after the mold is made?

A: It is easy to go from "smooth to rough" (e.g., adding texture to a polished mold). It is very difficult and expensive to go from "rough to smooth" (removing texture to polish it), as this requires removing metal, which may affect dimensional tolerances.

Q: Does surface finish affect cycle time?

A: Yes. Mirror finishes (A-1) may require longer cooling times or slower ejection to prevent vacuum sticking. Rough textures (D-3) may also slow ejection if the draft angle is insufficient, causing drag.

Q: Which finish is best for painting?

A: SPI B-1 or B-2 is generally preferred for parts that will be painted. The surface is smooth enough to prevent texture "print-through" but has enough micro-roughness to help the paint adhere better than a super-high gloss surface.

Q: Does the mold steel affect the finish quality?

A: Absolutely. You cannot achieve an A-1 finish on aluminum or soft P20 steel because the metal is too porous and soft to hold a true mirror shine. Hardened steels like H13, S7, or 420 Stainless Steel are required for A-1 and A-2 finishes.

Summary

Selecting the correct SPI Surface Finish is not just an aesthetic choice; it dictates the mold steel, the draft angles required in design, and the final cost of the tool. While SPI A-Grades offer premium, optical-quality looks, they come with higher maintenance and manufacturing costs. SPI C and D Grades offer practical, robust surfaces that hide molding defects and reduce tooling costs. Engineers must balance visual requirements with the physical realities of the chosen polymer and part geometry.

-

Understanding the SPI Surface Finish Standard is crucial for selecting the right finish for injection molded parts, impacting aesthetics and functionality. ↩

-

Learn about the organization that established the SPI standards, which are essential for communication between designers and mold makers. ↩

-

Understanding the differences between SPI and VDI 3400 standards helps in selecting the right finish for global applications. ↩