PBS (Polybutylene Succinate) injection molding offers a sustainable and versatile alternative for producing biodegradable plastics with high mechanical properties.

PBS injection molding involves using PBS resin to produce environmentally friendly parts with excellent strength and biodegradability. It is ideal for applications in packaging, automotive, and consumer goods. The process offers reduced environmental impact compared to traditional plastics.

While PBS injection molding provides key sustainability benefits, understanding material properties and processing conditions is crucial to achieving optimal performance. Dive deeper into the practical uses and advantages of PBS for your manufacturing needs.

PBS injection molding produces biodegradable plastic parts.True

PBS is a biodegradable polymer, making it a more sustainable choice for manufacturing eco-friendly products.

PBS injection molding is more expensive than traditional plastics.False

Although PBS materials may have a higher upfront cost, the long-term environmental benefits and increasing demand can offset the price difference.

What are the Basic Characteristics of PBS?

PBS (Polybutylene Succinate) is a biodegradable polymer known for its eco-friendly properties, high strength, and flexibility, making it a sustainable alternative in various industries.

PBS is a biodegradable polymer derived from renewable resources. It offers excellent mechanical properties, including high strength and flexibility, and is used in applications such as packaging, agriculture, and medical products. PBS breaks down naturally, reducing environmental impact.

Biodegradability

Poly Butylene Succinate-PBS is fully bio-degradable which implies that it can be degradable easily by micro-organisms in the environment transforming it by the natural processes into carbon-dioxide and water.

This characteristic of PBS proves the material friendly to the environmen, especially suitable for replacing traditional petroleum-based plastics to reduce environmental pollution.

In contrast, traditional petroleum-based plastics may take hundreds of years to degrade in the natural environment and can produce harmful substances during degradation. The degradation of PBS is not very complex and it hardly has any influence on the environment and the ecosystem.

Physical Properties and Mechanical Properties

PBS is an aliphatic polyester with a unique chemical structure that sets it apart from traditional plastics. PBS has good mechanical properties such as tensile strength and impact strength. The tensile strength and flexural strength of it are similar to the petrochemical plastics which includes polypropylene (PP)1and polyethylene (PE)2 and the impact strength.

Also, PBS offers a great resistance to heat and chemical thereby exhibiting optimal performance in the temperature range of (-40) degrees C to 100 degrees C. Due to its high crystallinity, PBS exhibits good dimensional stability at elevated temperatures, which is commonly required in various industries.

Processing Properties

PBS material has good thermoplasticity and thermal stability. PBS can be processed through injection molding quite easily. It has got a fairly broad melting temperature that ranges between 90 °C to 120 °C and is compatible with most injection molding equipment and molds. PBS has good flowability to fill up complex molds and the produced parts has high precision.

Additionally, the processing window for PBS is broad, making it resistant to thermal degradation and suitable for large-scale industrial production.

Environmental Friendliness

PBS is biodegradable and environmentally friendly not only in the process of creation. The raw materials for PBS production can come from renewable resources such as corn and sugarcane.

These biomass materials are then are converted into PBS monomers through the processes of fermentation and others. In terms of energy consumption and emission which conventional petroleum-based plastics manufacturing was known for, the manufacturing of PBS is environmentally friendly and less carbonized.

Biocompatibility

PBS has good biocompatibility, and, therefore, commonly used in medical and food packaging industries. PBS does not trigger any immune response in the body and can be naturally metabolized and absorbed. Therefore, PBS is employed in the preparation of biomedical entities as those of surgical sutures and drug carrying systems.

PBS is biodegradable and environmentally friendly.True

PBS decomposes naturally, offering a sustainable alternative to conventional plastics and reducing environmental impact.

PBS is stronger than conventional plastics.False

PBS offers a balance of strength and flexibility, but it is not always stronger than other conventional plastics such as PET or PP.

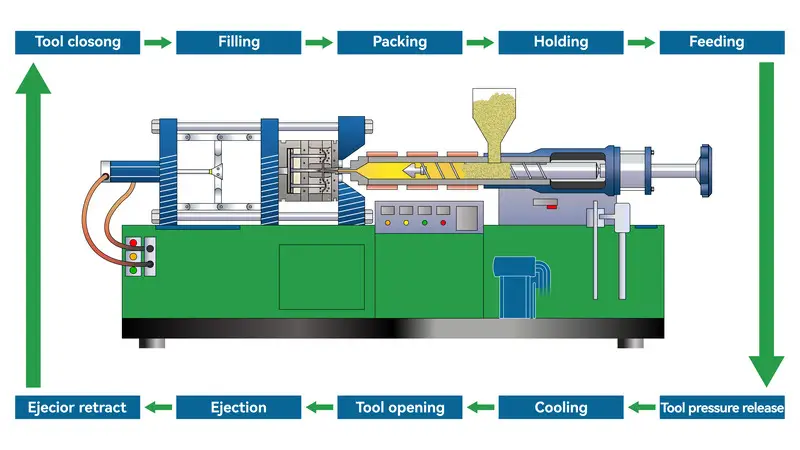

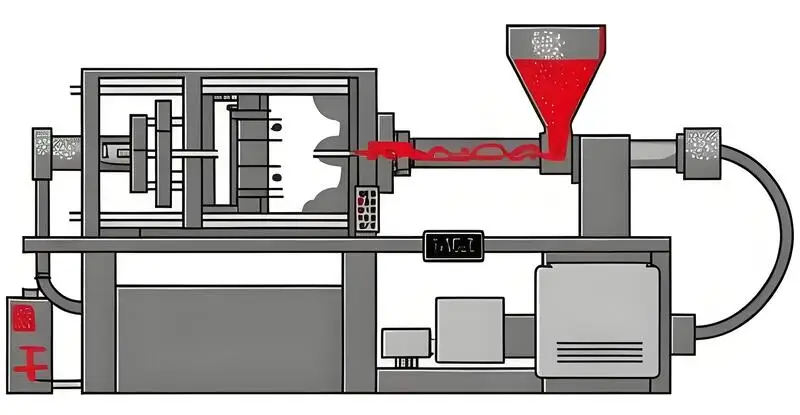

What is the Process Flow of PBS Injection Molding?

The PBS injection molding process involves heating PBS resin, injecting it into a mold, cooling the part, and ejecting it. This efficient process is widely used in producing high-quality plastic parts.

PBS injection molding starts with heating PBS resin, followed by injection into a mold. After cooling, the part is ejected. It ensures precision, low waste, and high-quality parts for industries like automotive and medical devices.

Material Preparation

Before injection molding3, PBS material needs to be dried to remove moisture. PBS has to be dried at the temperature of 80°C to 100°C during 4 to 6 hours to bring the moisture content of the material to the level below 0. 02%.

This brings in aspect of general moisture that if high can lead to formation of bubbles during the injection molding process which in turn compromises the look and durability of the final product.

Besides, drying can also avoid the situation that PBS will be hydrolyzed during melting, thus affecting the mechanical properties and appearance quality of the products.

Melting and Mixing

The dried PBS material, is combined with the hopper of an injection molding machine and heated through a heater. The screw of the injection molding machine rotates in order to evenly blend the molten PBS material equally to favorable viscosity and temperature.

Usually the melting temperature of PBS is set in the range 190°C-220°C. The action of the screw during melting also allows uniform plasticisation of the PBS that affects the mechanical properties and surface of a final product.

Injection Molding

PBS material melts and is forced through the nozzle and into the cavity of the mold under high pressure. The injection pressure4 is mainly between 60MPa and 100MPa depending on the type of product and its mold.

The injection time5is normally between 0. 5 seconds and 2 seconds to ensure that the mold cavity is completely filled. It is imperative to regulate the speed and pressure of the injection to achieve high dimensions and smooth surface on the products.

Cooling and Solidification

After injection, the mold is closed, and PBS material injected will cool down and set into the structure of the mold. Typically, the cooling time6 ranges from a minimum of 10 seconds up to a maximum of 60 seconds based on the size as well as the thickness of the product.

In the cooling stage, the cooling system of the mold regulates the mold temperature using water or oil to guarantee standard cooling of the product. Proper cooling rates can prevent internal stresses in the product, enhancing its mechanical properties and dimensional stability.

Demolding and Post-processing

After the product has cooled and has become solid, the mold is then opened and the product is taken out either by mechanical or altogether by hand.

After removal, there may be a need to make adjustments on the geometry of the removed product such as deburring, trimming among others to achieve the final quality standards. Post-processing can further improve the appearance quality and performance of the product, making it more suitable for customer needs.

PBS injection molding provides high-quality parts.True

PBS injection molding ensures high precision and excellent part quality due to its controlled heating and cooling process.

PBS injection molding is suitable for all plastic materials.False

PBS injection molding specifically uses PBS resin, and it may not be suitable for all plastic materials, which require different molding conditions.

What are the Advantages And Disadvantages of PBS Injection Molding?

PBS injection molding offers numerous benefits like biodegradable materials and excellent processing properties, making it ideal for eco-friendly applications. However, its limitations include higher costs and lower strength compared to conventional plastics.

PBS injection molding provides a sustainable solution by using biodegradable plastics, reducing environmental impact. It offers good processing capabilities but may result in higher material costs and lower mechanical strength compared to traditional plastics.

Advantages

-

Environmental Friendliness: PBS is an environ- mentally friendly material, thus by using PBS products there will be a reduction in pollution from plastics. The most exciting thing is that PBS can be naturally biodegraded by microorganisms in the environment without the formation of toxic substances, which meets the principles of sustainable development.

-

Excellent Mechanical Properties: PBS has good strength and toughness, making it satisfy a number of usage expectations. The mechanical properties of PBS material are in the similar level as the regular petroleum-based plastic and sometimes better in terms of toughness.

-

Good Processing Performance:PBS has the moderate melting temperature, and sufficient flow-ability for injection moulding process. The processing window of PBS is quite wide and thus, the product does not undergo thermal degradation easily which is beneficial in large scale production in industries.

-

Biocompatibility: The biocompatibility of PBS is quite satisfactory to allow its use as material of medical facility and food packaging. PBS is not regarded as an antigen in the human body which enables it to be naturally metabolized and absorbed.

-

Renewable Raw Materials: PBS raw materials can be derived from renewable sources ranging from corn and sugarcane among others. All this makes PBS to have a lower carbon foot print throughout its products life cycle, helping to reduce dependence on petrochemical resources.

Disadvantages

-

High Cost: Despite the advantages associated with PBS, its production cost is still high because of the nature of the raw materials and the process,. At the moment, PBS price is still relatively high as compared to most traditional petroleum-based plastics, thus exerting a certain influence on its market adaptability.

-

Limited Heat Resistance: PBS can withstand a certain amount of heat, but it is not as good as some petroleum-based plastics in high temperature applications, which limits its application in high temperature environments. Another disadvantage of PBS is that its glass transition temperature (Tg) is relatively low, and it may deform or lose mechanical properties in high temperature environments.

-

Sensitivity to Hydrolysis: PBS has poor hydrolytic stability and the extent of hydrolysis increases in areas with high humidity which in turn causes degradation of the mechanical properties and thermal properties of the material and thus need protection during usage. Due to its high hydrolytic sensitivity, PBS cannot be used in some of the areas with high humidity; thus, requiring appropriate protection.

PBS injection molding offers biodegradable solutions.True

PBS plastics are biodegradable, making them an eco-friendly option for applications requiring sustainable materials.

PBS injection molding is always more expensive than other plastics.False

While PBS may have higher initial material costs, its environmental benefits and specific applications can justify the price, especially for eco-conscious brands.

What are the Application Fields of PBS Injection Molding?

PBS injection molding is used in a variety of industries, from packaging to automotive, due to its biodegradability and durability. It offers a sustainable alternative for many applications.

PBS injection molding is commonly applied in packaging, automotive parts, medical devices, and disposable cutlery. Its biodegradability makes it ideal for eco-friendly products, offering a sustainable solution without sacrificing strength or performance.

Food Packaging

PBS exhibits reasonable biocompatibility and biodegradability, which makes it relatively excellent for the food packaging industries. PBS\’s water resistance, gas barrier properties, and antibacterial capabilities aid in prolonging the freshness of food.

For instance, PBS can be made into a food bag, cling films, disposable tableware, and so on; these PBS products become biodegradable after use and will not endanger the ecological environment of the world.

Thus, it can be stated that the safety and environmental friendly nature of PBS gives the product vast market applicability in food packaging industry.

Medical Devices

Due to its biocompatibility, PBS can be used to manufacture medical devices. For example, PBS can be used to manufacture surgical sutures, drug delivery systems, etc.

These medical devices can be absorbed by the human body or naturally degraded after use, thereby reducing secondary damage to the human body. The use of PBS not only helps to improve the safety of medical devices, but also helps to facilitate postoperative treatment plans.

Agricultural Tools

PBS’s biodegradability as well as excellent mechanical features are preferred for use in the agricultural industry. For instance, PBS can be produced in to mulch films, seedling trays, and the likes.

These PBS products can naturally biodegrade after its use and thus minimizing on the effects of the agricultural wastes on the environment. PBS agricultural films could effectively cover crops and depolymerize to decrease the environmental load after the growing season.

Daily Necessities

PBS can also be used to manufacture different composite items that are a necessity in everyday life like pen holder, toothbrush handle, toys and the like.

These daily necessities can naturally degrade after use, reducing household waste\’s impact on the environment. Because of its environmental friendliness, PBS is regarded as the material of choice for creating green daily essentials to meet the needs of conscious customers.

Electronics and Electrical Appliances

PBS also has promises in electronics and electrical appliances industries. For instance, PBS may be employed as the cases for electronic products, cable sheaths, and more. These PBS products have suitable mechanical properties and they possess the ability to biodegrade when they are disposed of thus mitigating the effects endured by electronic waste.

PBS is ideal for biodegradable packaging.True

PBS is biodegradable, making it an excellent choice for packaging that reduces environmental impact.

PBS is the best choice for heavy-duty automotive parts.False

PBS is more suitable for lightweight and eco-friendly applications, but it may not provide the strength needed for heavy-duty automotive parts.

What is the Future Development Trend of PBS Injection Molding?

The future of PBS (Polybutylene Succinate) injection molding looks promising, with increasing applications in sustainable manufacturing and biodegradable plastics for various industries.

PBS injection molding is advancing toward eco-friendly solutions, offering biodegradable plastic products. It enhances sustainability in industries like packaging, agriculture, and consumer goods by reducing environmental impact and relying on renewable resources.

Improving Production Efficiency

To reduce the production cost of PBS, researchers and enterprises have endeavored to enhance the efficiency of PBS manufacture so as to lower its related production cost.

For instance, timely enhancement of production techniques and research on better catalyst can enhance the overall production of PBS, hence lowering the manufacturing cost.

Organizational cost cutting does not only lead to less cost but also implies more energy efficiency and less emission of wastes making production more environmental friendly.

Developing New PBS Alloys

To enhance the capabilities of PBS, scientists work to create new PBS alloys For instance, with another biodegradable polymer, the preparation of PBS alloys with improved thermal and mechanical properties and heat resistant can increase the application of PBS.

The development of PBS alloys could not only enhance the materials’ performance, but also expand its application areas, including the use in higher temperatures and more severe conditions.

Promoting PBS Applications

The cost of PBS has been decreasing, and the performance has been bettering that it will open up new application fields. For example, in the automobile, electrical and electronics and appliance industries, PBS is expected to substitute some conventional plastics and become the new material.

The use of PBS in these areas will not only decrease reliance on petroleum-based plastics but also increase the eco-friendliness and sustainability of various goods.

Environmental Policy Promotion

There are increasing policy responses on the management of the plastic pollution and formulation of a number of environment policies by governments of the world. Such polices will encourage the research and utilisation of eco-friendly products like PBS.

For instance, the restriction of single-use plastics products in the European countries will create massive market for the PBS products. The implementation of environmental policies will further accelerate the market promotion and application of PBS.

Introduction of New Technologies

With the advancement in technology, the introduction of new technologies will also enhance the expansion of PBS injection molding.

For instance, the cases where the application of 3D printing technology may help in increasing flexibility and efficiency of PBS in the production of its products. Moreover, 3D printing of PBS materials shall create new markets and satisfy more individual and tailored requirements.

Development of the Circular Economy

With the spread of the circular economy concept, the recycling and reuse of PBS after disposal will become an important direction.

Substances of PBS products can be recycled as the new raw material after use through the biodegradation, thus achieving resource recycling. The recycling of PBS can not only reduce environmental pollution but also improve resource utilization efficiency, achieving sustainable development.

PBS injection molding helps reduce environmental impact.True

PBS is biodegradable and derived from renewable resources, making it a sustainable choice in injection molding.

PBS injection molding will replace all traditional plastics.False

While PBS offers eco-friendly benefits, it isn't a one-size-fits-all solution and is best used for specific applications that align with sustainability goals.

Conclusion

Overall, PBS injection molding is one of the best green and efficient technologies of processing plastics that opens a wide range of development opportunities.

Based on the continuous enhancement of the production process and expanding the application range of PBS materials, it is believed that in the future, PBS will become one of the most effective biodegradable polymers and make positive contributions to the environmental friendly development of the plastics industry.

Through the above detailed introduction, I believe that everyone has a deeper understanding of PBS injection molding. Whether from the perspective of environmental protection, economy or technology, PBS injection molding is a processing technology with great potential, which is worthy of further research and promotion.

Moreover, the application impact of PBS is not only to alleviate the problem of plastic pollution, improve the sustainable use of resources, and promote the development of green economy.

For the future development of PBS injection molding, with the increase of new technologies and the expansion of the market, PBS injection molding will provide better convenience and green solutions for our lives.

-

Learn about Polypropylene: Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. ↩

-

Learn about Polyethylene: Polyethylene is a polymer, primarily used for packaging (plastic bags, plastic films, geomembranes and containers including bottles, cups, jars, etc.). ↩

-

Learn about Injection Molding: A Comprehensive Guide: Injection molding is a manufacturing process where molten plastic is injected into a mold to create parts with high accuracy and repeatability. ↩

-

Learn about How do you calculate injection pressure?Injection pressure is the pressure at which the mold is filled. ↩

-

Learn about Injection Time: Injection time is the time it takes the screw to move from the injection start position to the transfer position. ↩

-

Learn about Cooling time : Cooling time is the time after the end of packing until ejection ↩