– MUD (Master Unit Die) systems typically reduce initial tooling capital expenditure (CapEx) by 40–60% compared to standard mold bases.

– TCO calculations must account for operational savings, specifically the reduction of changeover times from hours to minutes (SMED).

– Procurement strategies should prioritize MUD systems for low-to-medium volume product families to maximize ROI.

– Hidden costs like storage footprint and purging waste are significantly lower with MUD inserts.

What is a Master Unit Die (MUD) System and How Does it Impact Cost?

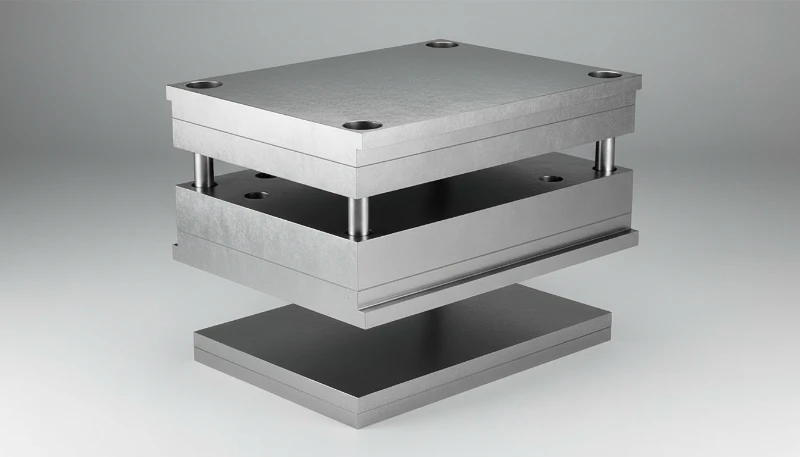

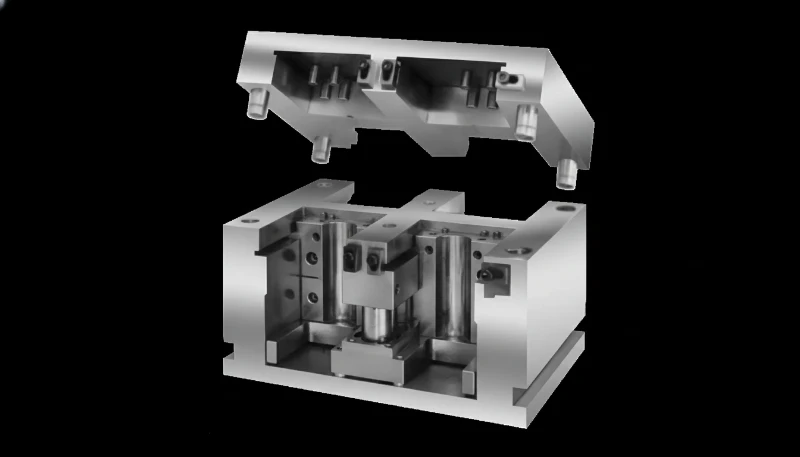

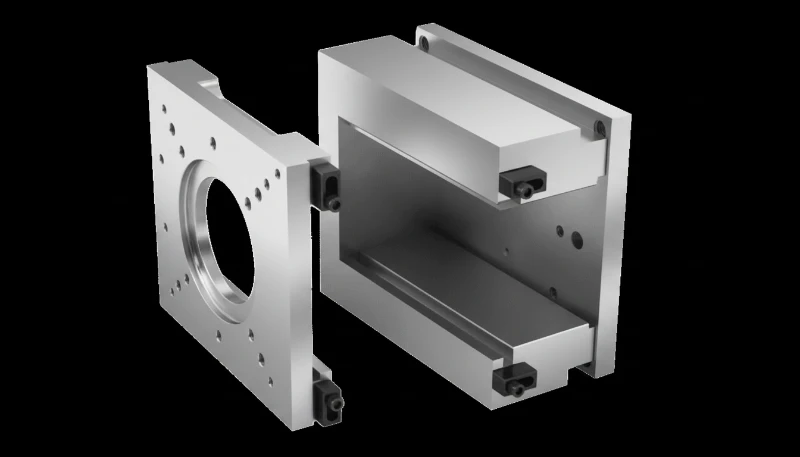

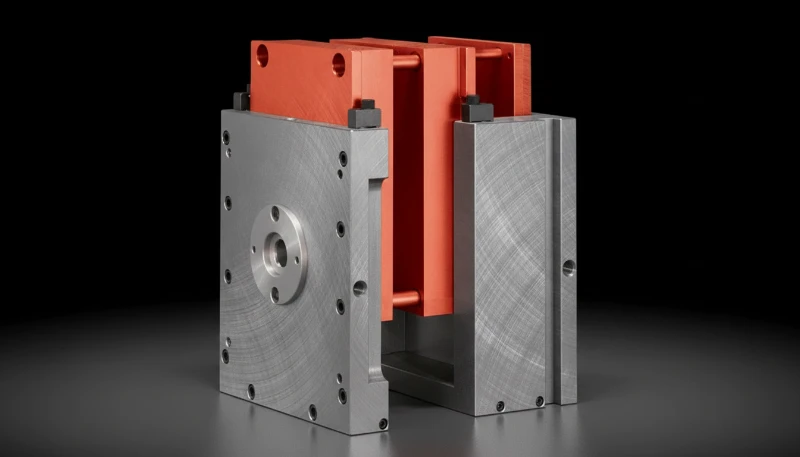

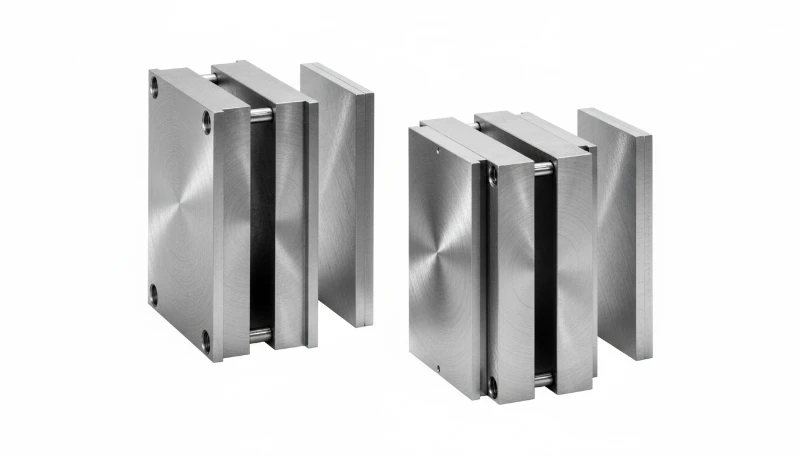

A Master Unit Die (MUD) system—often referred to as a "quick-change" frame—is a tooling strategy used in injection molding where a standard, universal mold base1 (the frame) remains bolted to the machine platens. Only the core and cavity inserts (the specific shape of the part) are removed and replaced during a product changeover.

From a financial perspective, the MUD system shifts the cost structure of injection molding TCO (Total Cost of Ownership). Unlike standard tooling, where the purchaser pays for a full mold base, ejection system, and cooling architecture for every single SKU (Stock Keeping Unit), the MUD approach amortizes the cost of the mold base across dozens or hundreds of inserts.

For CFOs and procurement strategy, this represents a shift from high upfront asset capitalization to a model focused on agility and reduced inventory holding costs.

What Parameters Define the TCO of MUD Versus Standard Tooling?

To accurately model mold ownership costs, one must compare technical and financial parameters between a standard stand-alone mold and a MUD insert.

Table 1: Comparative Cost Drivers for MUD vs. Standard Tooling

| 매개변수 | Standard Stand-Alone Mold | MUD System (Insert Only) | Financial Impact |

|---|---|---|---|

| Initial Tooling Cost | 100% (Base + Insert + Ejection) | 30% – 50% (Insert only) | Immediate CapEx reduction. |

| Changeover Time | 1 – 4 Hours | 10 – 20 Minutes | Reduced machine downtime; lower labor cost. |

| Tool Weight | Heavy (requires crane) | Light (often hand-loaded) | Reduced safety liability; faster handling. |

| Cooling Connections | Connect/Disconnect every run | Often remains connected to Frame | Eliminates water leaks; reduces setup complexity. |

| Storage Footprint | High (Full bases) | Low (Shelved inserts) | Reduces warehousing/real estate overhead. |

| 리드 타임 | 6 – 12 Weeks | 2 – 5 Weeks | Faster Time-to-Revenue. |

How Do You Calculate ROI in Injection Molding Using MUD?

Calculating ROI molding investments requires analyzing the break-even point where the savings in the mold base justify the limitations of the frame size.

The ROI Formula

ROI = {[(Savings in Tooling + Operational Savings) – Cost of MUD Frame)]/Cost of MUD Frame} × 100

Practical Financial Example

Scenario: A compay needs to launch 5 similar plastic housings made of Acrylonitrile Butadiene Styrene (ABS).

- Standard Approach:

- 5 Separate Standard Molds @ $12,000 each.

- Total CapEx: $60,000.

- MUD Approach:

- 1 Shared MUD Frame @ $2,500.

- 5 MUD Inserts @ $5,500 each.

- Total CapEx: $2,500 + $27,500 = $30,000.

- Direct Savings: $30,000 (50% Reduction).

Operational Savings (Annual):

If each mold is swapped once per week (52 changes/year) at $100/hr machine rate:

- Standard: 2 hours setup x 52 weeks = 104 hours = $10,400.

- MUD: 0.25 hours setup x 52 weeks = 13 hours = $1,300.

- OpEx Savings: $9,100 per year per machine.

MUD systems are the most cost-effective solution for every injection molding scenario, regardless of volume.False

This is False. MUD systems are ideal for short runs and frequent changeovers. For high-volume mass production (millions of cycles), dedicated multi-cavity standard molds often provide better cooling efficiency and cycle times.

Implementing MUD systems significantly reduces machine downtime associated with changeovers (SMED).True

This is True. Because the mold base remains in the machine and cooling lines often stay connected, swapping only the insert takes minutes rather than hours, increasing machine uptime.

What Are the Hidden Costs of Tooling and MUD Advantages?

When evaluating hidden costs of tooling, procurement managers often overlook the lifecycle expenses. MUD systems2 mitigate several non-obvious costs.

Table 2: Hidden Cost Analysis

| Hidden Cost | 설명 | MUD Advantage |

|---|---|---|

| Purging Waste | Material wasted while stabilizing the process after a changeover. | Faster thermal stabilization of small inserts reduces resin waste by ~30%. |

| Crane Maintenance | Cost of maintaining overhead cranes for heavy molds. | Inserts are often light enough for manual lifting or small carts. |

| Tool Maintenance | Greasing, cleaning, and repairing ejector pins. | Maintenance is simplified; inserts can be cleaned on a bench without disassembling a massive base. |

| Inventory Carrying | Cost of holding spare parts for 5 different mold bases. | Common spares (ejector pins, return pins) are standardized in the master frame. |

What Procurement Strategies Maximize Value with MUD Systems?

To optimize the TCO, the procurement strategy must align with engineering realities.

- Standardize Frames: Adopt a standard frame system (e.g., DME, PCS, or HASCO compatible) across the facility. Avoid mixing proprietary systems that lock you into a single vendor.

- Batch Processing: Schedule production of parts that share the same MUD frame sequentially. This eliminates the need to remove the frame from the platen, realizing the true "10-minute changeover."

- Negotiate Insert Pricing: Since the mold maker does not need to source and machine a base, ensure the quote reflects only cavity/core machining.

- Audit Cooling Capabilities: Ensure the MUD frame selected has adequate cooling capacity for the material. For engineering resins like Polycarbonate (PC), ensure the frame supports high-temperature oil or water without leaking.

MUD inserts generally produce parts with lower dimensional accuracy compared to standard molds.False

This is False. The accuracy of the part depends on the machining tolerance of the cavity and core, not the mold base type. A precision-machined MUD insert produces parts identical in quality to a standard mold.

Using MUD systems reduces the storage space required for tooling inventory.True

This is True. Storing compact inserts requires significantly less warehouse shelving than storing full standard mold bases, reducing facility overhead.

Where are MUD Systems Most Financially Viable?

MUD systems are not a universal replacement for all tooling but are superior in specific application scenarios.

- Prototyping & Pilot Runs: When the design is not frozen, modifying a small insert is cheaper than modifying a full mold.

- Low-to-Medium Volume Production: Annual volumes between 1,000 and 50,000 parts where the cost of a full mold base cannot be amortized effectively.

- Family Parts: Products that are identical in function but vary slightly in size or feature (e.g., a series of plastic connectors).

- Just-in-Time (JIT) Manufacturing: Facilities requiring multiple changeovers per day to meet low-inventory goals.

What is the Step-by-Step Process for Conducting a TCO Analysis?

To perform a rigorous TCO calculation for a new project, follow this workflow:

- Volume Estimation: Determine the Estimated Annual Usage (EAU) and expected product lifespan.

- Family Grouping: Identify if the new part can share a MUD frame with existing active tools.

- CapEx Comparison:

- Get Quote A: Standard Mold Base.

- Get Quote B: MUD Insert (+ Frame cost if a new frame is needed).

- OpEx Calculation:

- Estimate Setup Time for A vs. B.

- Multiply by (Labor Rate + Machine Opportunity Cost).

- Multiply by number of changeovers per year.

- Break-Even Analysis: Plot the Total Cost (CapEx + accumulated OpEx) over 3 years. Identify where the lines cross.

- Decision Gate: If the MUD system saves >20% over 2 years and meets technical cooling requirements, approve MUD.

자주 묻는 질문(FAQ)

Q1: Can MUD systems handle high-temperature engineering materials?

Yes, but the frame must be designed for it. Standard mild steel frames may degrade under high heat. For materials like Polysulfone (PSU) or Polyphenylene Sulfide (PPS), use a stainless steel MUD frame with insulated plates.

Q2: Are MUD inserts compatible between different brands?

Generally, no. A DME MUD frame requires DME-compatible inserts. While some custom toolmakers can bridge compatibility, it is best to standardize on one ecosystem (e.g., "U" frame vs. "H" frame) to prevent operational errors.

Q3: How much cheaper is a MUD insert compared to a full mold?

The savings are typically on the tooling fabrication side. A MUD insert usually costs 35% to 60% less than a standalone Class 101 mold because the mold base, sprue bushing, and ejection housing are already paid for.

Q4: Do MUD systems affect cycle time?

It depends. For small parts, cycle times are comparable. However, because cooling lines sometimes run through the frame before the insert, thermal transfer can be slightly less efficient than a dedicated mold with conformal cooling. This may add a few seconds to the cycle, which must be weighed against the setup time savings.

Q5: What is the maximum size for a part in a MUD system?

MUD systems are size-limited. They are generally best for parts under 8 inches x 8 inches (200mm x 200mm). Large automotive bumpers or instrument panels exceed the structural capacity of quick-change frames.

결론

For CFOs and Procurement Managers, calculating ROI molding investments involves looking beyond the invoice price of the tool. The Total Cost of Ownership for MUD systems offers a compelling financial case for low-to-mid volume high-mix manufacturing. By reducing mold ownership costs3 through shared assets and slashing the hidden costs of tooling related to downtime and storage, MUD systems provide a lean, agile alternative to traditional tooling strategies. A robust TCO model that accounts for changeover labor and machine uptime will typically reveal that MUD systems pay for themselves within the first year of operation for appropriate product families.